Sand-proof otter board, printed pile and sand-proof otter lattice

A technology of sand-blocking nets and grids, which is applied in construction, protective equipment, etc., and can solve problems such as the reduction in the number of straws, the short service life of straw circles, and the impact on personal safety and traffic safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] (1) Mold processing:

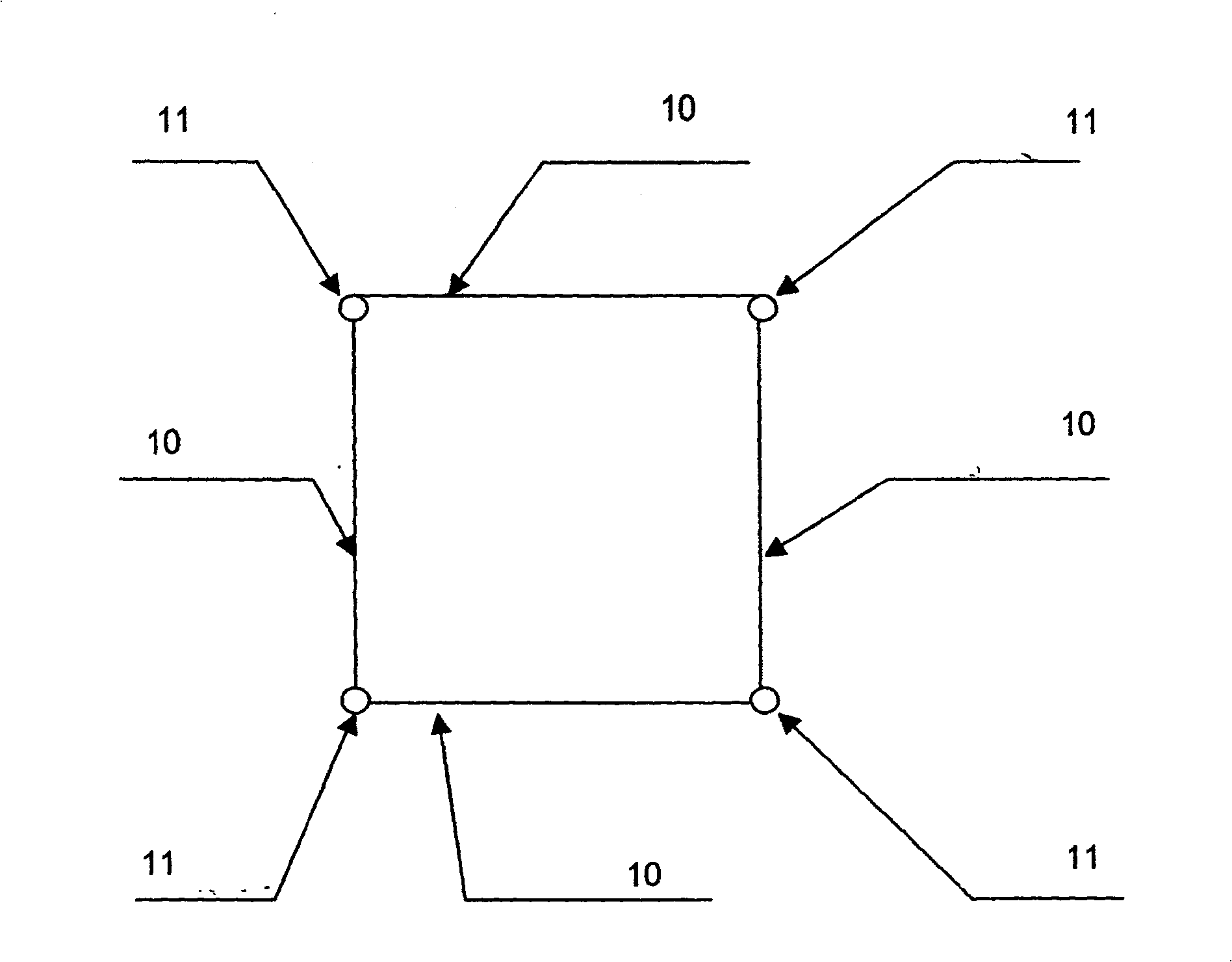

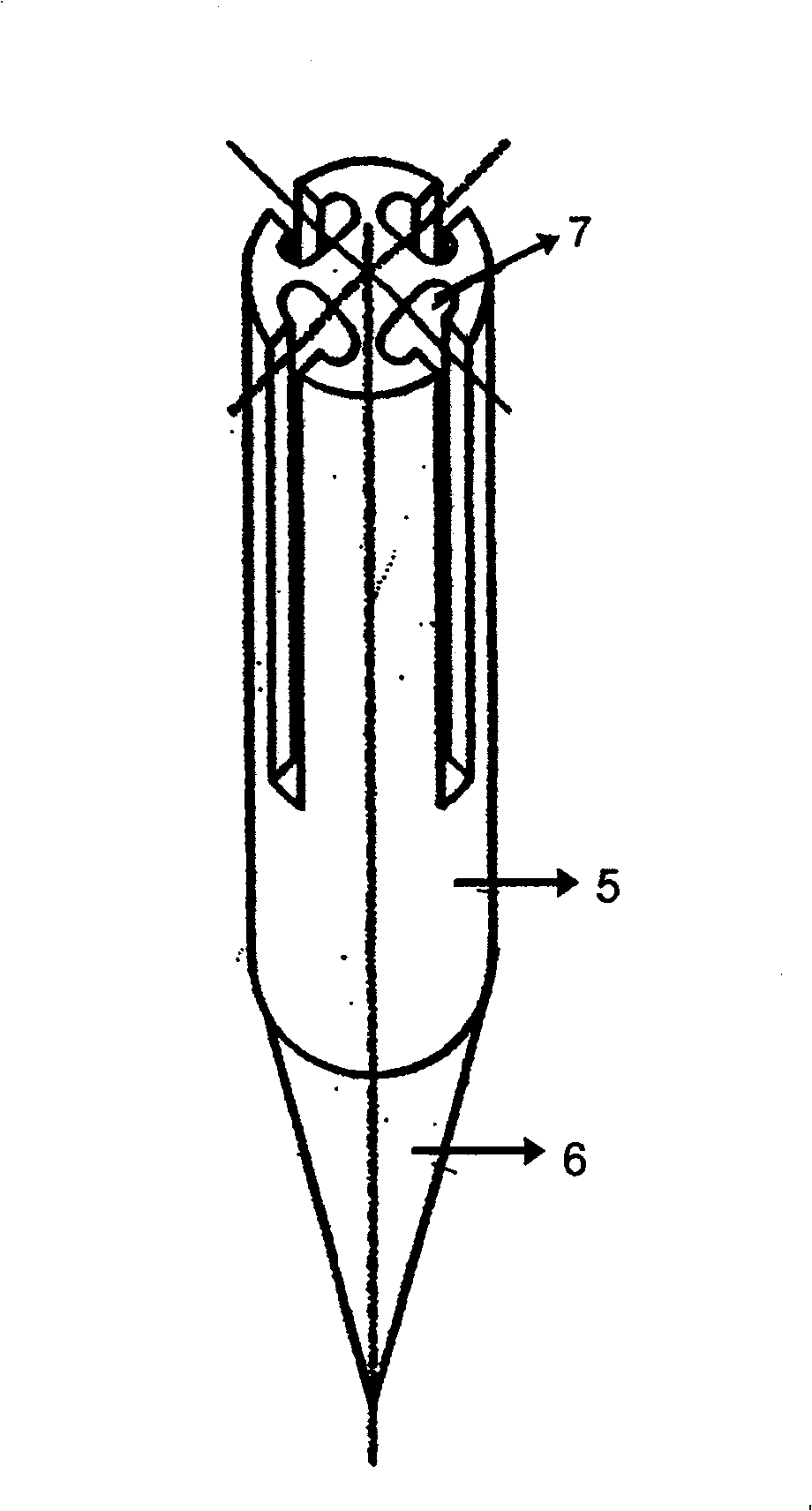

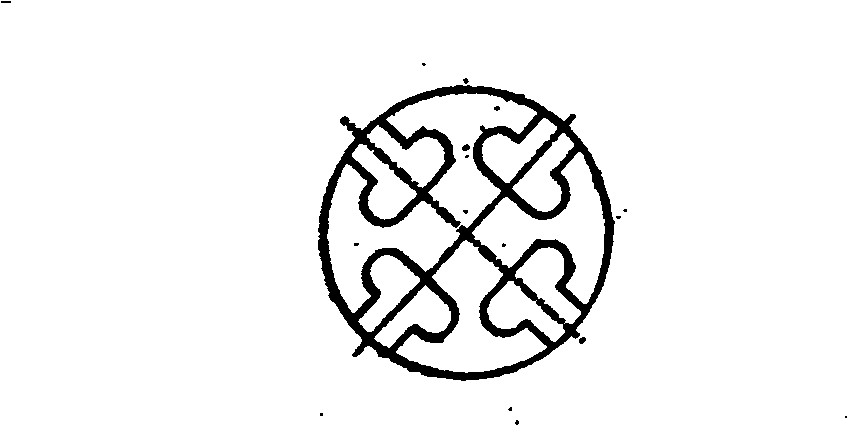

[0056] Using mold steel with the grade of P20, the mold of the sand-blocking mesh plate with 7 equally spaced ribs and the tips of 4 T-shaped chutes are processed on the CNC computer programming center, electric discharge machine, precision grinding machine, and milling machine equipment. pile of stencils. Figure 8-9 Respectively is the mold photograph of described sharp pile, sand-blocking net plate ( Figure 8 The "pillar" shown in is a common name for "sharp pile"). The various parts of the picket mold such as Figure 6 As shown, it consists of a front mold and a rear mold, the rear mold is composed of modules 1a-11a, and the front mold is composed of modules 12a-14a. The modules 1a-14a are respectively: fixed block, gear, rack, bottom plate, square iron, needle plate, bottom needle plate, B plate, cavity, slider, guide post, A plate, guide sleeve, and panel. The various parts of the mold of the sand blocking screen are as follows: Figur...

Embodiment 2

[0076] In the same manner as in Example 1, sand-blocking mesh panels and pickets were prepared and combined into a sand-blocking grid. The difference lies in that high-density polyethylene is used instead of polypropylene as the material for preparing the sand-blocking screen and picket, and the injection pressure during injection molding is increased to 80MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com