Hot-air blower

A technology of hair dryer and hot air, which is applied in the direction of instant heating clips, clothing, hairdressing equipment, etc., and can solve the problems of reduced cooling efficiency of discharge electrodes, unstable generation of nano-sized mist, and heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

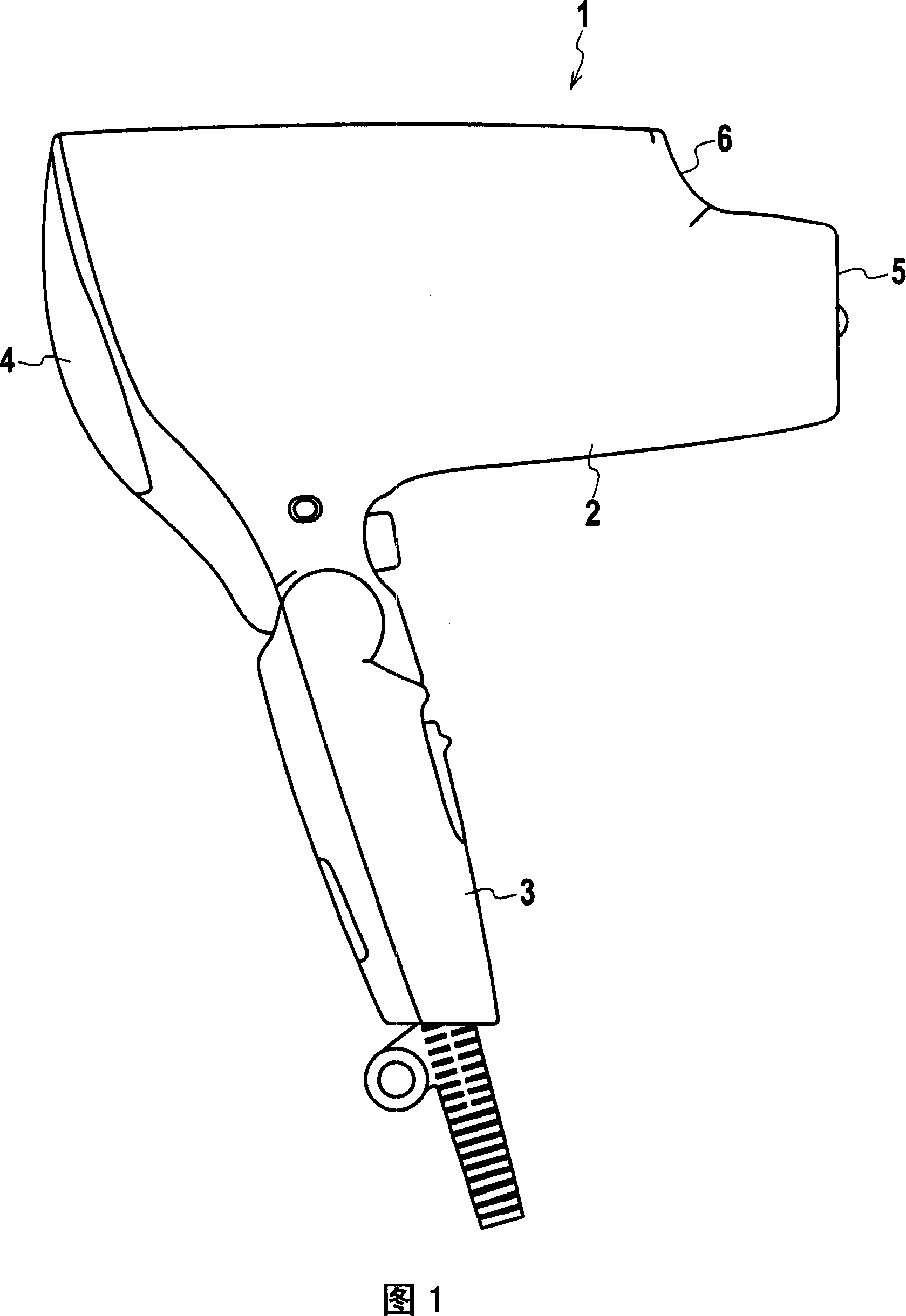

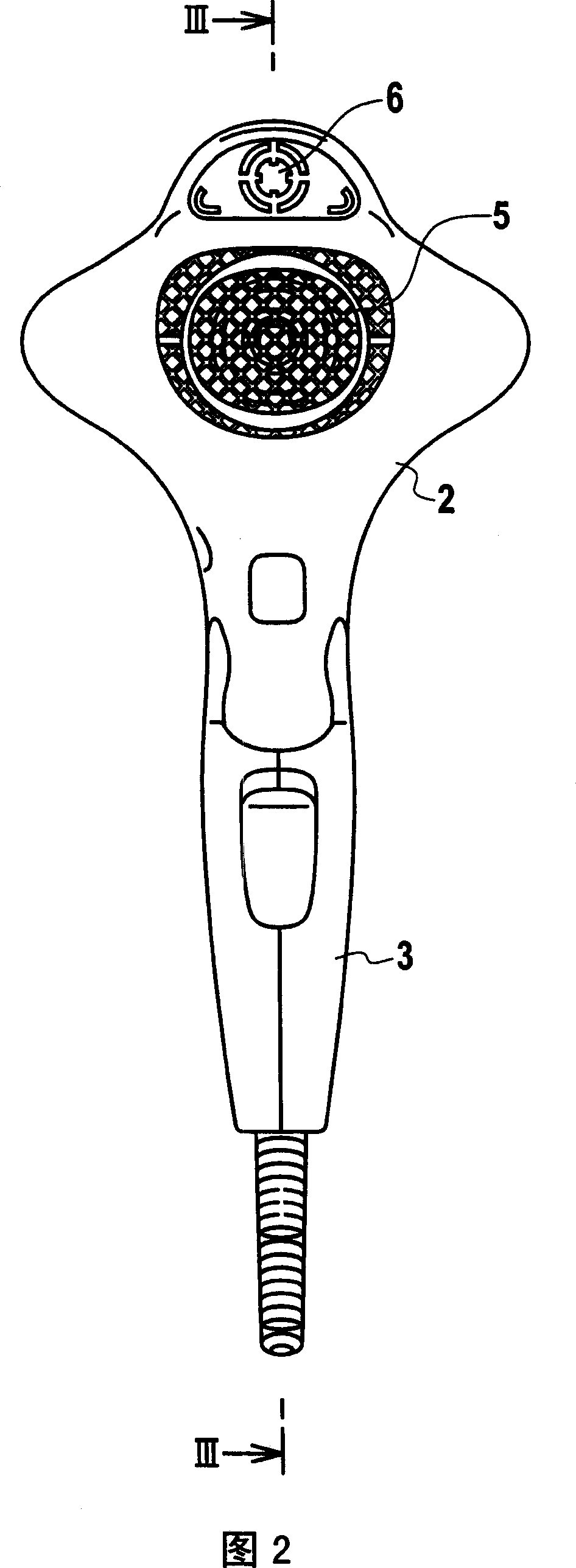

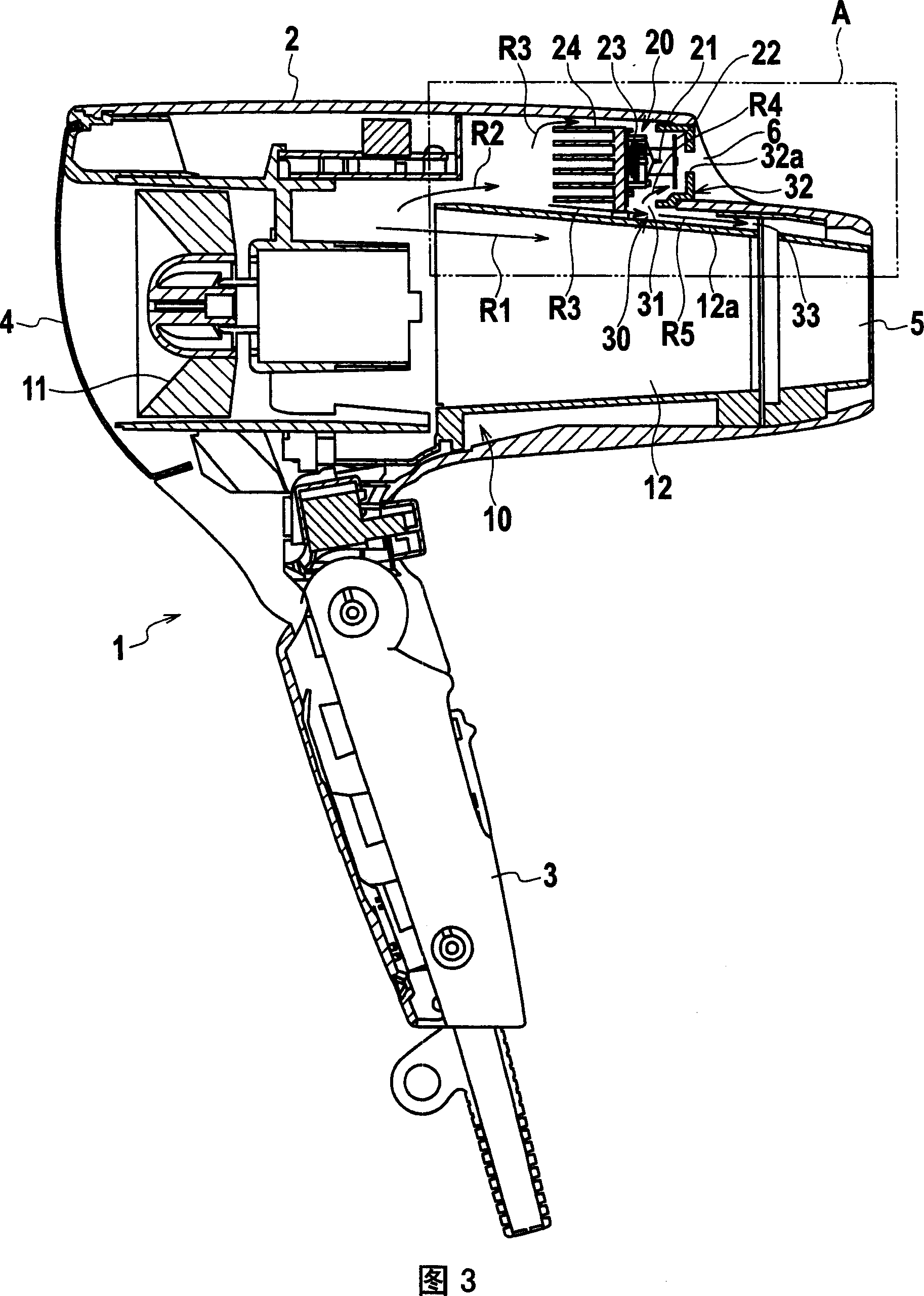

[0017] Fig. 1 is a side view of a dryer which is an example of a hot air blower, Fig. 2 is a front view of the dryer, Fig. 3 is an enlarged sectional view of the dryer taken along line III-III in Fig. 2 , and Fig. 4 is an enlarged sectional view of part A in FIG. 3 .

[0018] As shown in FIGS. 1 and 2, in the dryer 1 as the hot air blower according to the present embodiment, the handle 3 is foldably attached to the lower portion of the cover 2, and the inlet 4 is formed at the rear end of the cover 2. A discharge port 5 is formed at the distal end of the cover body 2 . An ion mist discharge port 6 is also formed at the upper end portion of the cover 2 so as to be in the same direction as the discharge port 5 .

[0019] As shown in Fig. 3, be provided with main unit block 10 in cover body 2, main unit block 10 comprises: the fan 11 that acts as blowing unit, fan 11 takes in outside air from inlet 4, to blow outside air from outlet. 5 discharge; and a heater 12 serving as a he...

no. 2 example

[0039] Fig. 5 is an enlarged sectional view of a relevant portion of a dryer according to a second embodiment, which is a view similar to Fig. 4 . The dryer according to this embodiment has the same constituent elements as the dryer according to the first embodiment. Therefore, these same constituent elements are denoted by like reference numerals, and redundant description thereof will be omitted.

[0040] As shown in FIG. 5, the configuration of the dryer 1A according to the present embodiment is basically the same as that of the dryer 1 of the first embodiment, and here, the electrostatically atomizing block 20 is arranged in the heat dissipation flow channel R2 branched from the main air flow channel R1 Inside, the part of the heat dissipation flow channel R2 located on the downstream side of the electrostatic atomization block 20 is branched into a first branch flow channel R4 and a second branch flow channel R5, and the air supply adjustment unit 30A is arranged in the f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap