Multi-stage whirlwind separating device of vacuum cleaner

A technology of cyclone separation device and cyclone separator, which is used in suction filters and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

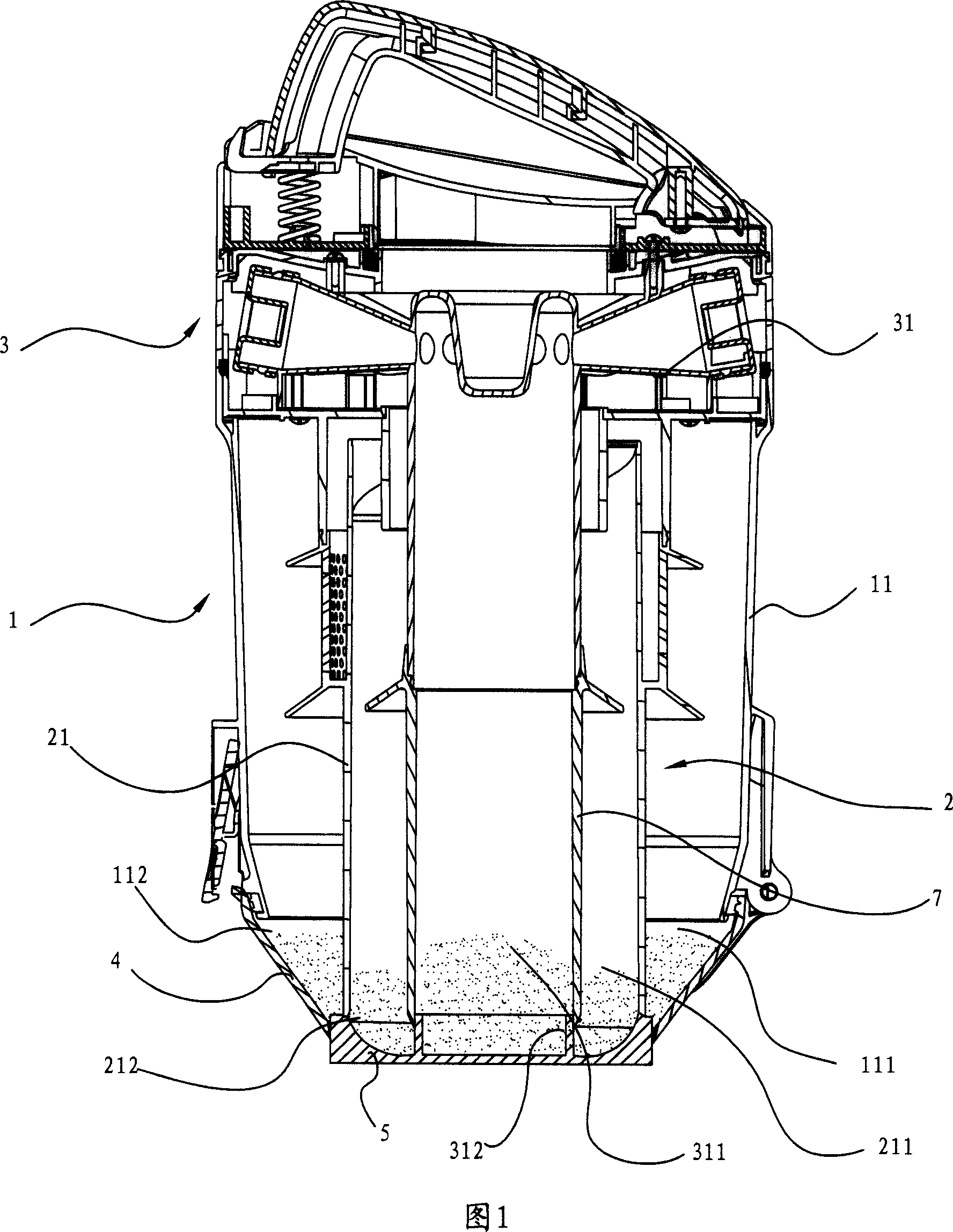

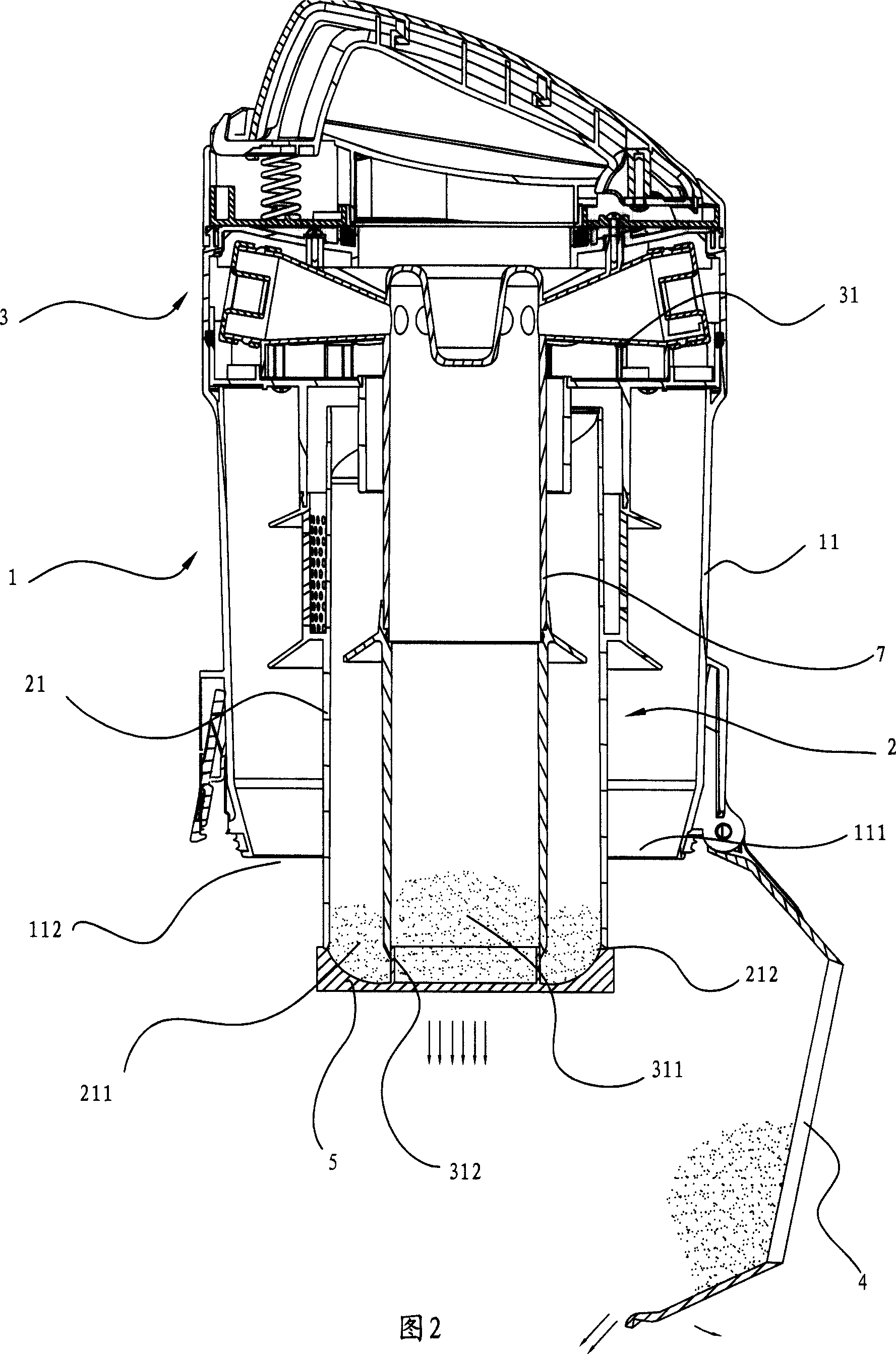

[0019] Referring to the multi-stage cyclone separation device of a vacuum cleaner shown in accompanying drawings 1-2, it is a three-stage cyclone separation device, which has a primary cyclone separator 1 located upstream and a secondary cyclone located downstream of the primary cyclone separator 1. Separator 2 and the three-stage cyclone separator 3 located downstream of the secondary cyclone separator 2, the air inlet 10 is arranged on the primary cyclone separator 1; wherein, the secondary cyclone separator 2 is located on the inside of the primary cyclone separator 1 The first-stage cyclone separator 1's diversion body is also the outer barrel of the second-stage cyclone separator 2; The lines lie on the same conical surface, and the conical point of the conical surface is roughly located on the axis of the secondary cyclone separator 2 .

[0020] The primary cyclone separator 1 comprises a primary separation barrel 11 whose lower part is a primary dust collection chamber ...

Embodiment 2

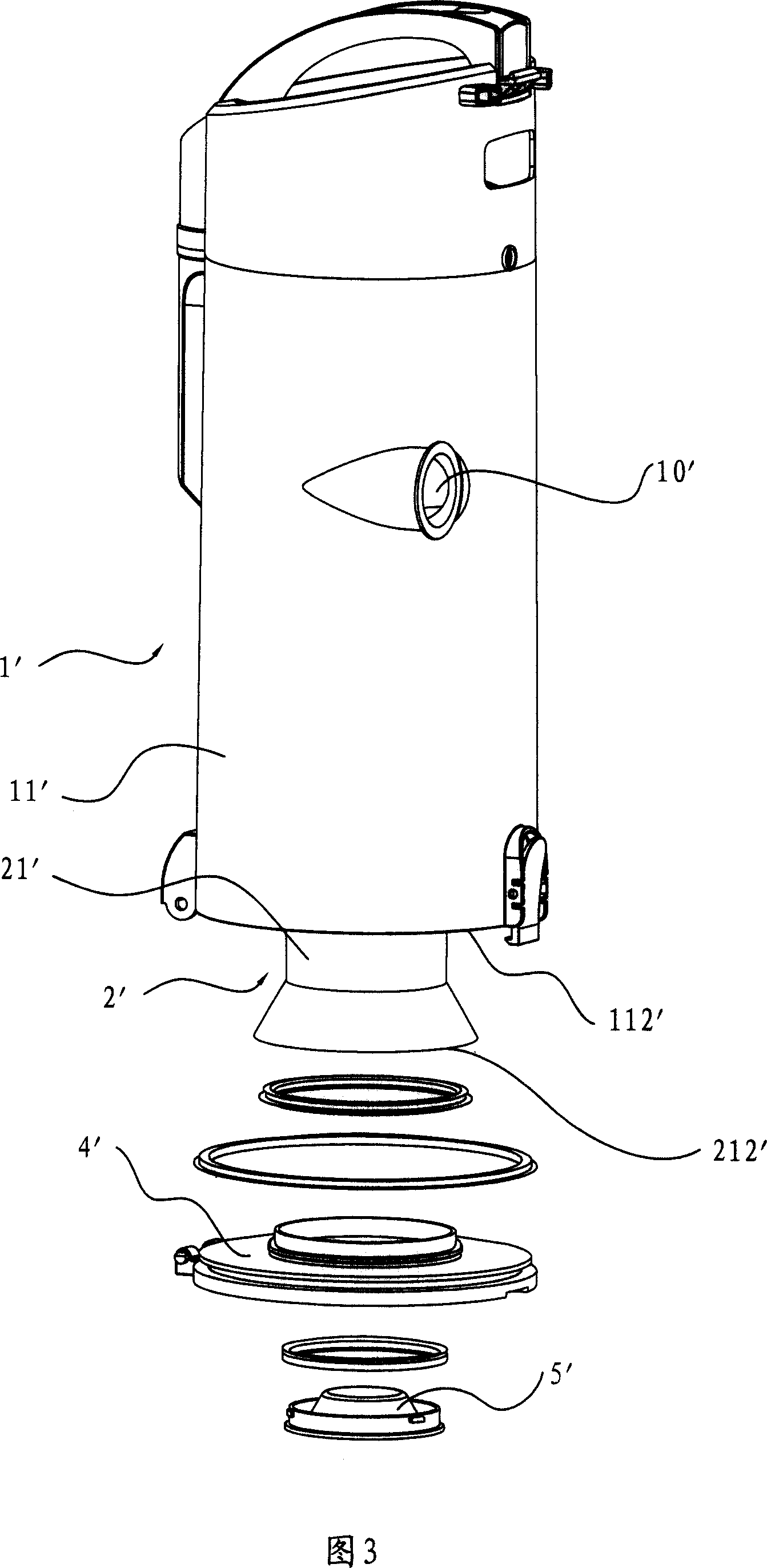

[0025] A multi-stage cyclone separation device of a vacuum cleaner as shown in Figure 3, this is a secondary cyclone separation device, with a primary cyclone separator 1 ' positioned upstream, a secondary cyclone separator positioned downstream of the primary cyclone separator 1 ' device 2' and the third-stage cyclone separator 3' downstream of the secondary cyclone separator 2', the air inlet 10' is arranged on the first-stage cyclone separator 1'; wherein, the second-stage cyclone separator 2' is located at the first-stage cyclone separator The inner part of the separator 1', the guide body of the primary cyclone separator 1' is also the outer barrel of the secondary cyclone separator 2';

[0026] The primary cyclone separator 1' includes a primary separation bucket 11' whose lower part is a primary dust collection chamber 111', and the secondary cyclone separator 2' includes a secondary separation bucket 21' whose lower part is a secondary dust collection chamber 211'. The...

Embodiment 3

[0030] The difference between the third embodiment and the second embodiment is only in the arrangement of the bottom covers of the dust buckets at all levels, as shown in Figure 4. Primary cyclone 1" pivot connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com