Dust collector

A technology for vacuum cleaners and barrels, which is applied in the directions of vacuum cleaners, suction filters, cleaning equipment, etc., can solve the problems of inconvenient operation of ash dumping, and achieve the effect of convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

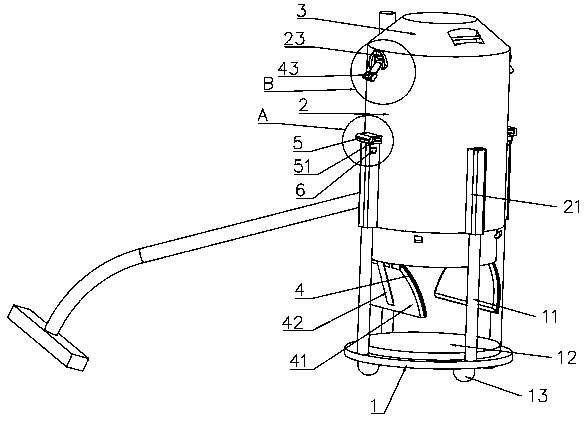

[0017] A vacuum cleaner, comprising a base 1 , a bucket body 2 , a dust suction assembly 3 , and a lower cover assembly 4 .

[0018] The base 1 is provided with 4 sliding rods 11 that are evenly distributed along the center circumference and vertically arranged, and a plurality of walking wheels 13 are provided at the bottom of the base 1 to facilitate the overall movement of the vacuum cleaner during cleaning and dust collection operations.

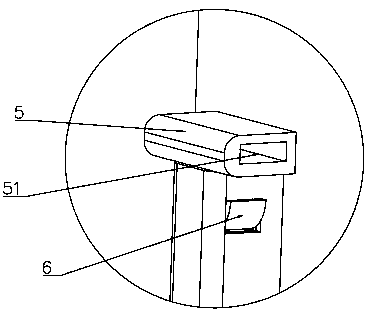

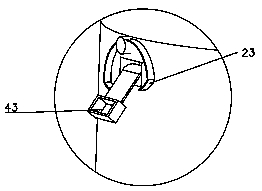

[0019] A dust storage chamber is formed inside the barrel body 2 for dust storage during the dust collection process. A suction port is provided on the side wall of the barrel body 2, and a suction pipe with a suction head is detachably connected to the suction port. Different suction pipes can be replaced in the working environment. The upper end opening of the barrel body 2 is set, and the dust suction assembly 3 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com