Automated test tube cap removal apparatus

一种试管盖、盖帽的技术,应用在自动化试管盖帽移除装置领域,能够解决盖帽移除效率低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will now be described with reference to the accompanying drawings.

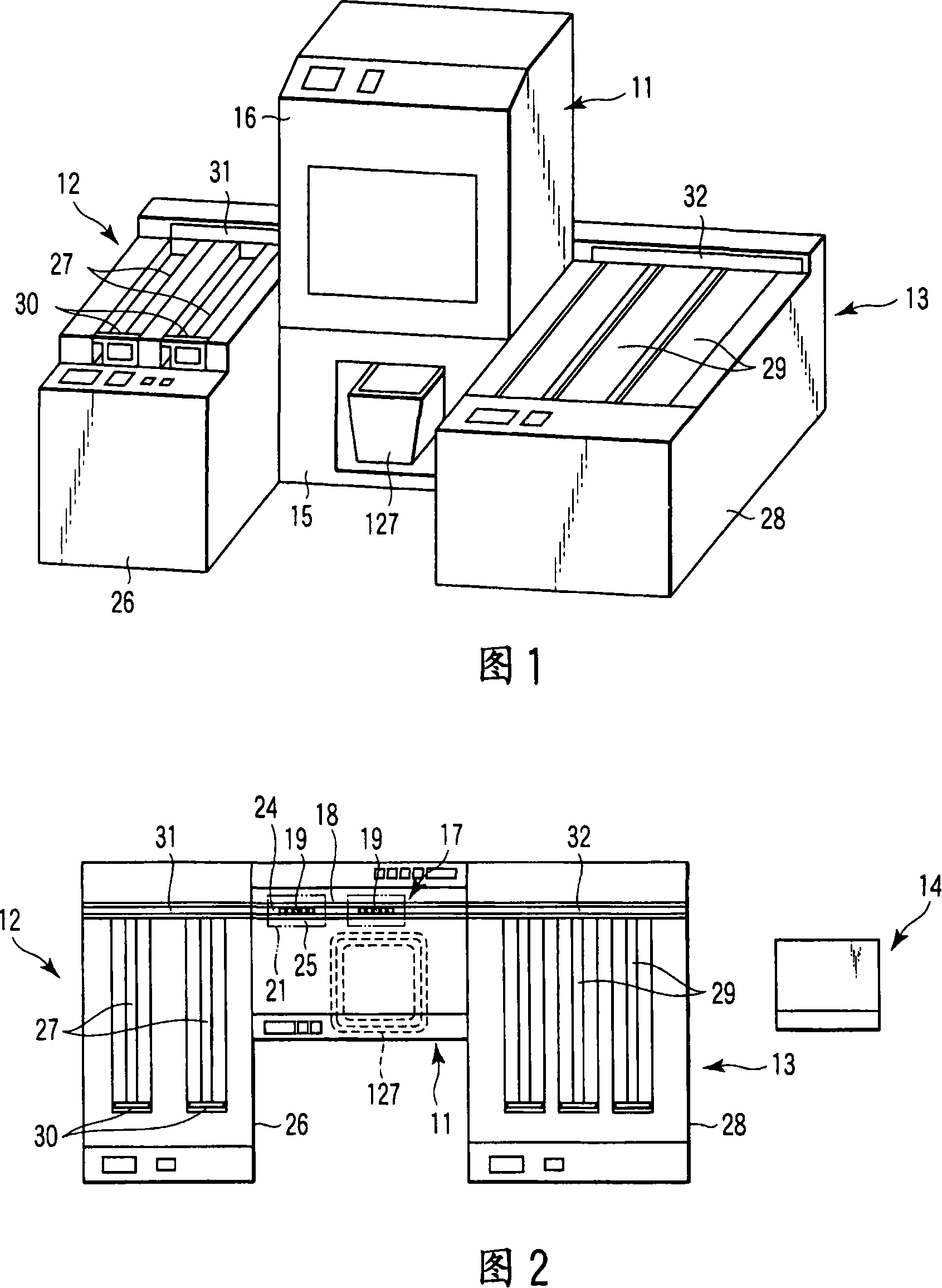

[0034] 1 and 2 are perspective and plan views, respectively, of an automated test tube cap removal apparatus. As shown in Figures 1 and 2, a cap remover 11 is provided in the central part of the device. An activation unit 12 serving as a test tube rack loading unit is provided on the left-hand side of the cap remover 11 , and a stacker unit 13 is on the right-hand side. Also, a control unit 14 having a CPU is provided near the starting unit 12 .

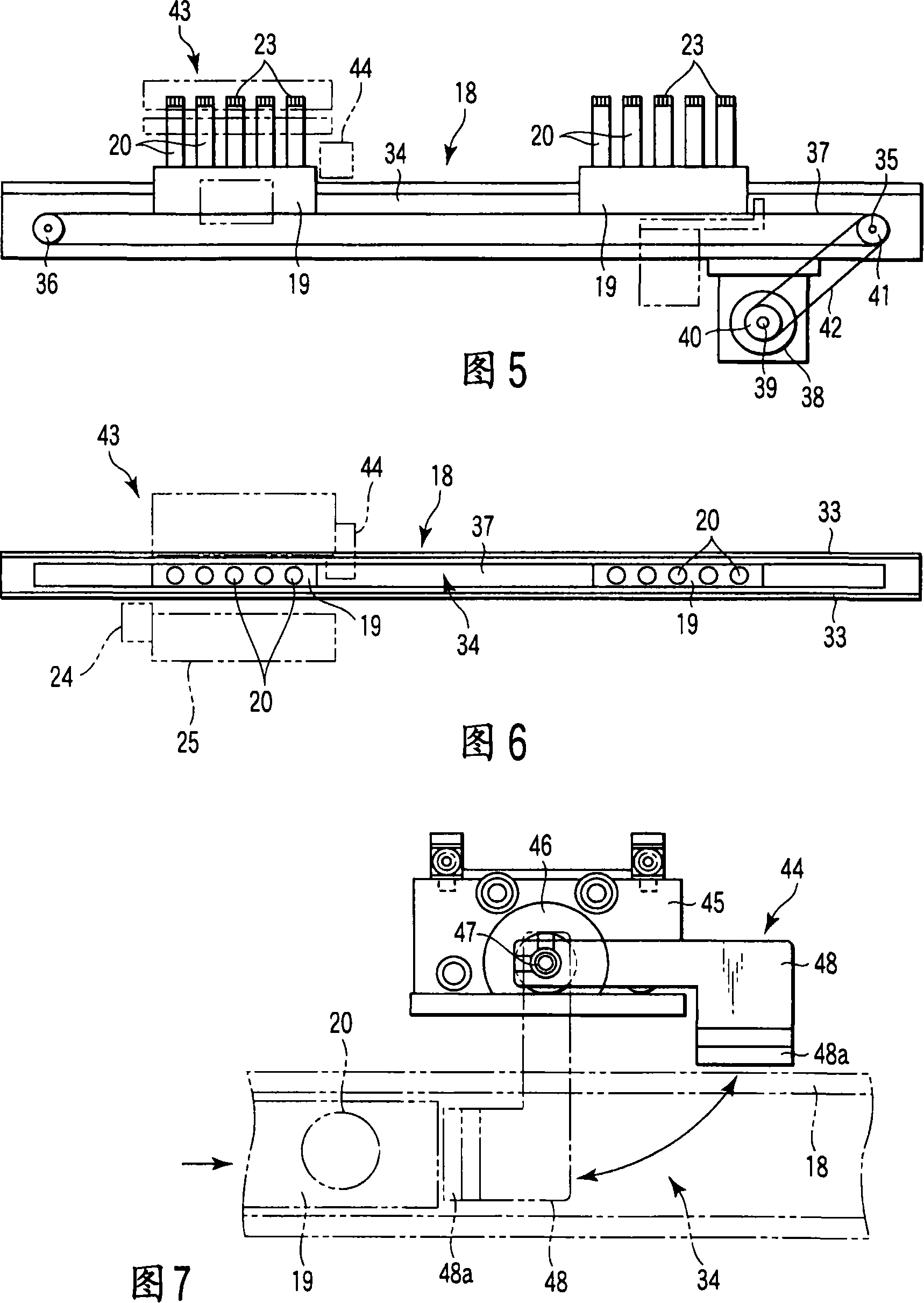

[0035] In the cap remover 11 , a storage box 16 is arranged on top of a base 15 , and a cap removing mechanism 17 (described later) is positioned in the box 16 . A rack transfer path 18 is provided at the rear of the box 16 . The transport path 18 transports a test tube rack 19 holding test tubes 20 .

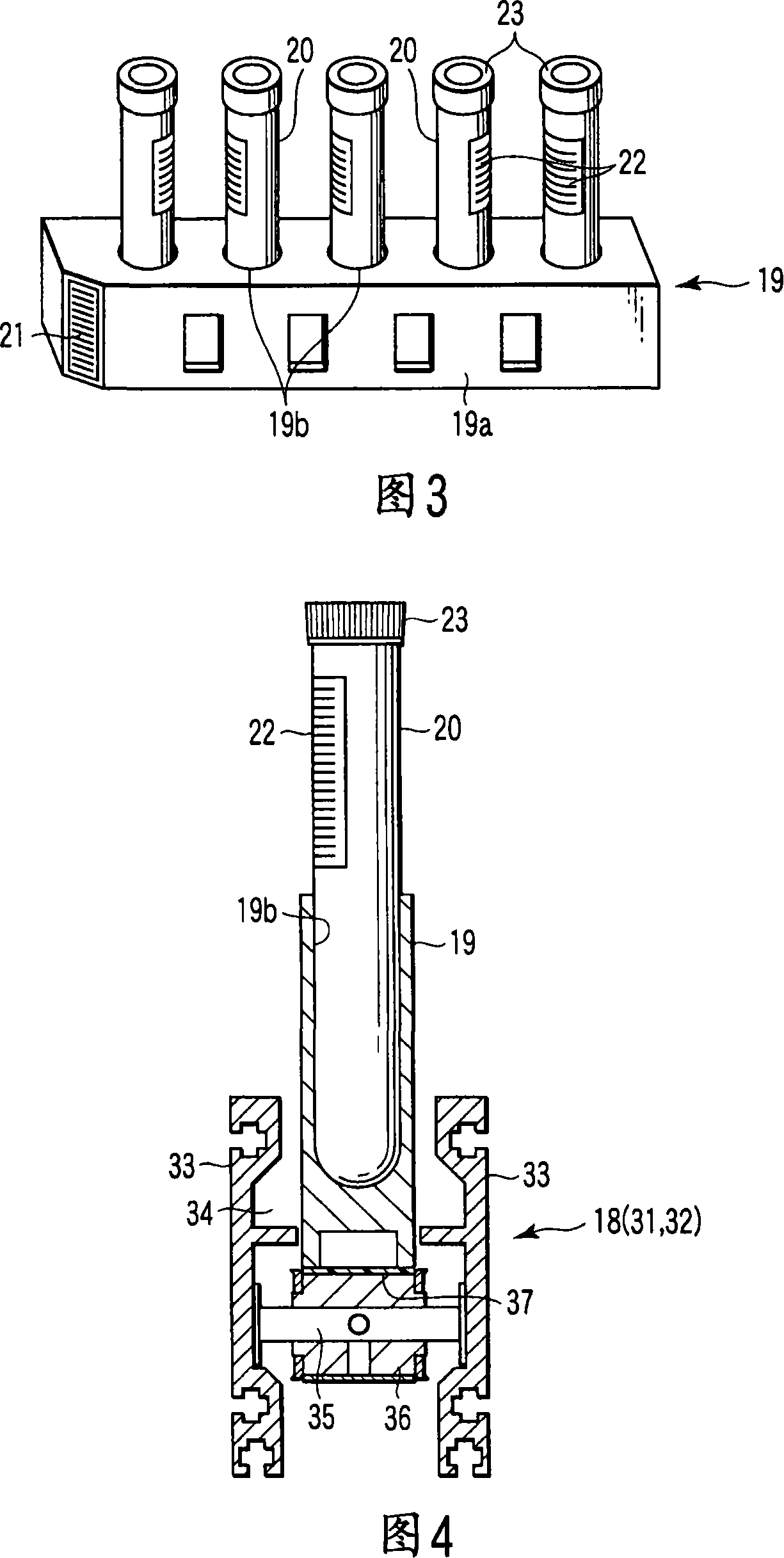

[0036] As shown in Figure 3, each test tube rack 19 can hold a plurality of test tubes 20, five test tubes in a row, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com