Method of measuring volumes of ink droplets and method of controlling nozzles of inkjet head using the method

一种喷墨头、喷墨打印头的技术,应用在仪器、印刷、光学等方向,能够解决差异等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

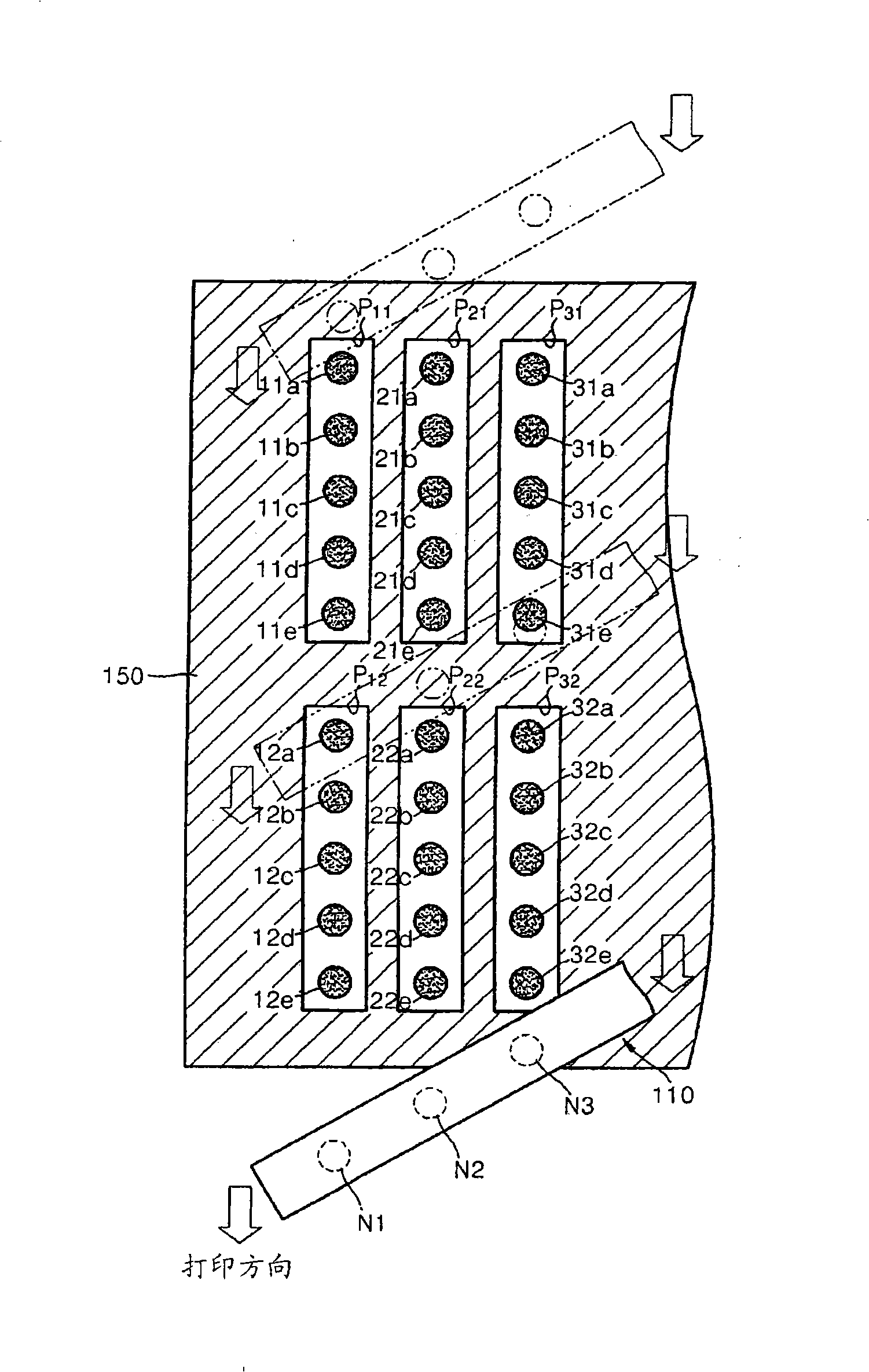

[0031] Reference will now be made in detail to embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like elements throughout. The embodiments are described below in order to explain the present invention by referring to the figures.

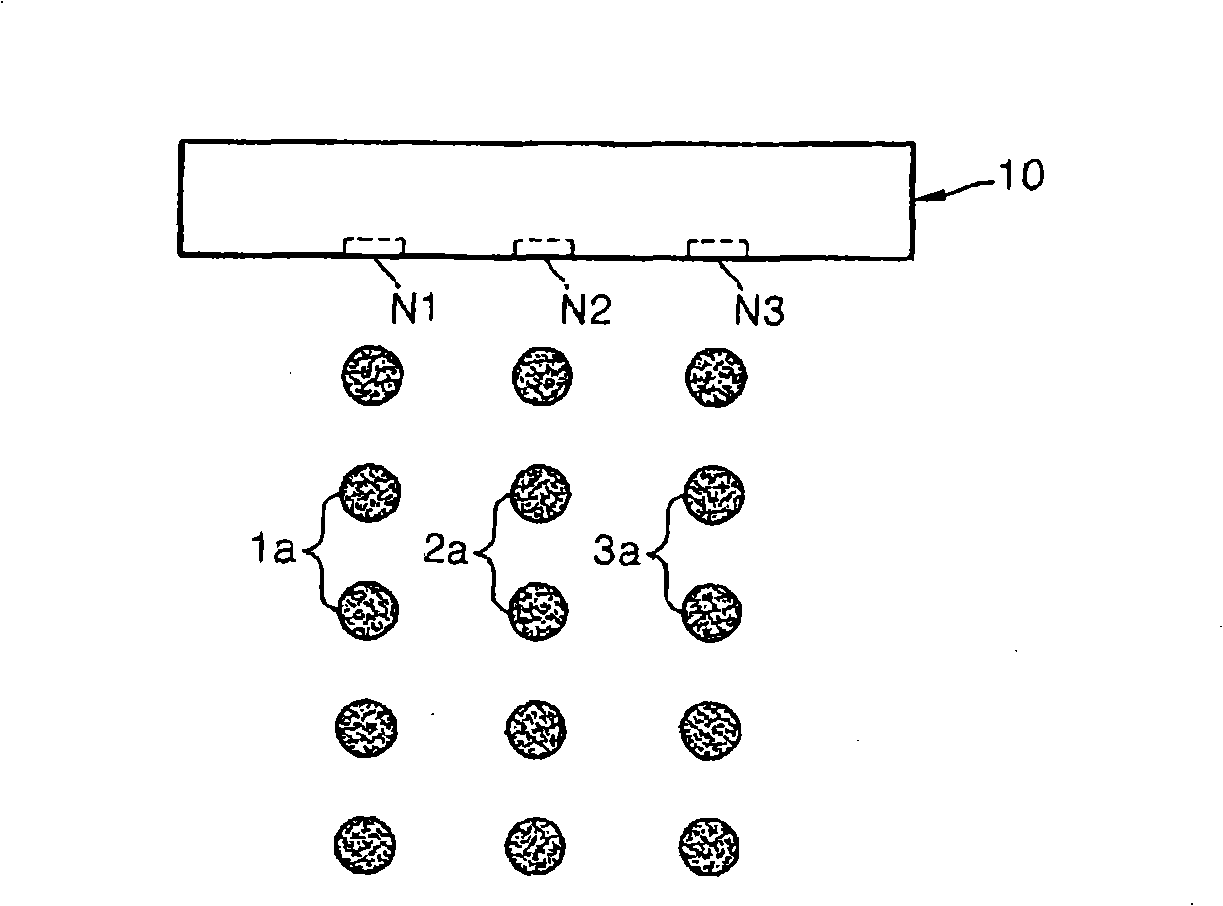

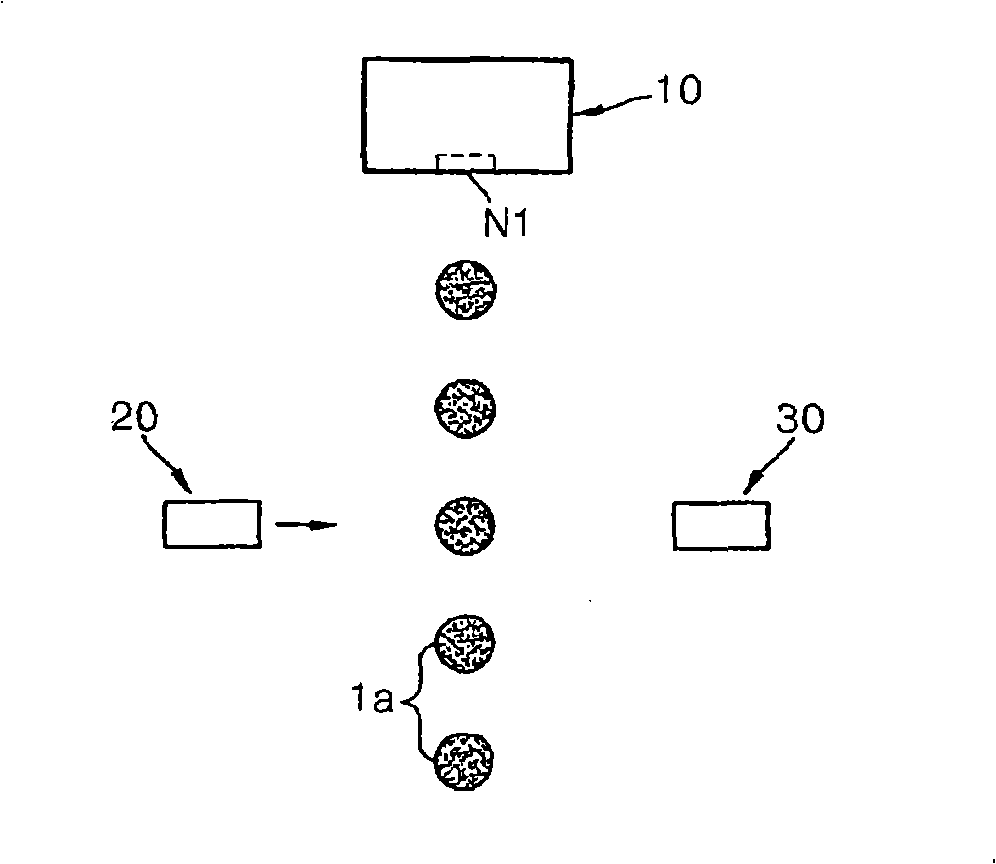

[0032] figure 2 The inkjet head 110 is shown for performing a printing process of printing in pixels to form color filters while moving in a printing direction and ejecting ink droplets.

[0033] refer to figure 2, a plurality of pixels P11, P12, P21, P22, P31, and P32 separated by the black matrix 150 are formed on a substrate (not shown) at predetermined intervals. Printing is performed by ejecting ink droplets from the nozzles N1 , N2 , and N3 of the inkjet head 110 into the pixels P11 , P12 , P21 , P22 , P31 , and P32 . exist figure 2 , since the pixel pitch (for example, the pitch between pixels P11 and P21 ) is narrower than the nozzle pitch (fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com