Winding device for open-end spinning machine workstation

A technology of a winding device and a spinning machine, which is applied in the directions of transportation and packaging, thin material handling, and transportation of filamentous materials, etc., can solve problems such as laboriousness and stress damage to the outer winding layer of cross-winding bobbins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

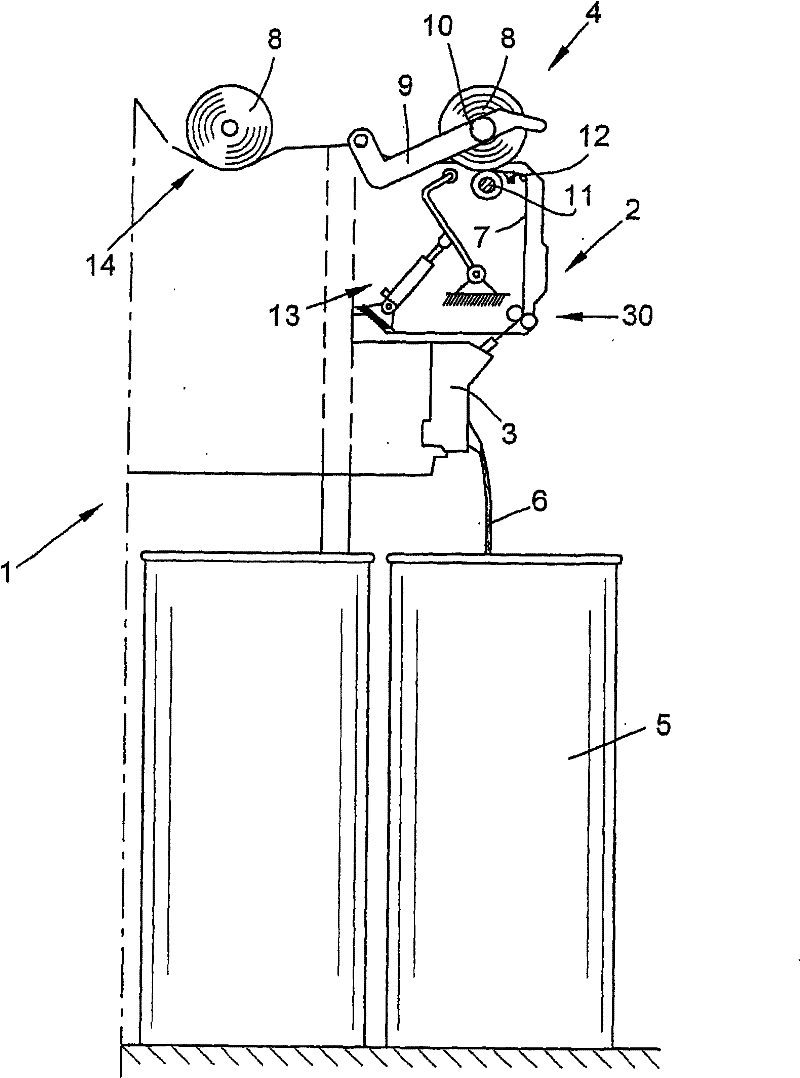

[0022] figure 1 One half of a semi-automatic open-end spinning machine known per se and designated with reference number 1 is shown schematically.

[0023] This open-end spinning machine, whose workstations are manually operated by the operator to start spinning, has a large number of similar workstations 2 between the end frames (not shown) in which the individual components of the textile machine are arranged. central drive. The workstations 2 are each equipped with an open-end spinning device, a so-called spinning pot 3 and a winding mechanism 4 .

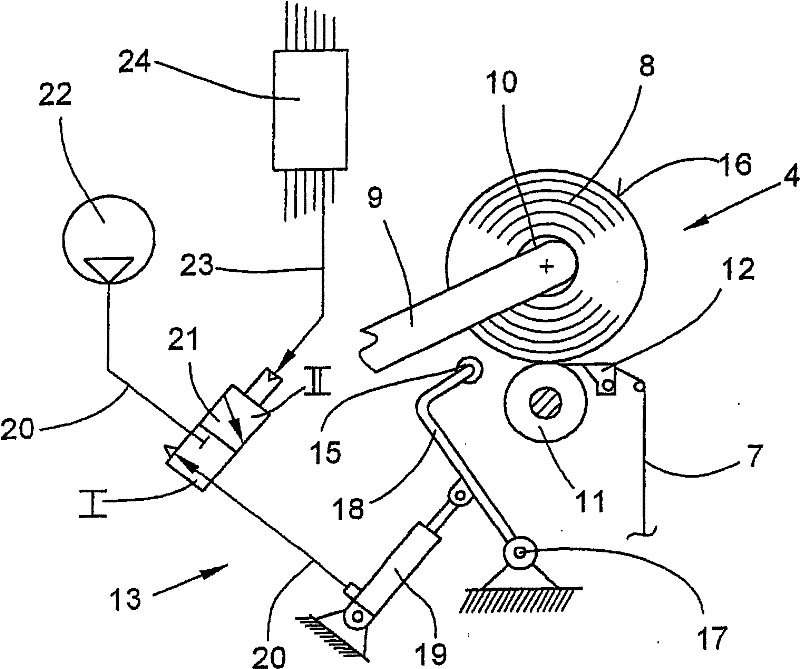

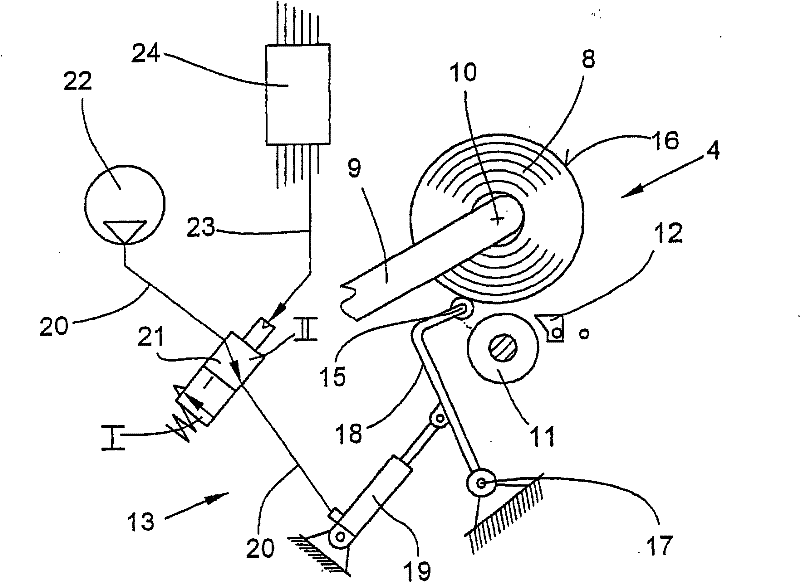

[0024] In the spinning pot 3 , the fiber strips 6 supplied in the spinning bobbins 5 are respectively spun into yarns 7 , which are then wound up on the winding mechanism 4 to form cross-wound bobbins 8 . as from figure 2 and 3 Specifically, it can be seen that the winding mechanism 4 has a creel 9 for rotatably holding the cross-winding bobbin tube 10 of the cross-winding bobbin 8, drives the winding drive roller 11 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com