Bicycle pneumatic tire tread pattern structure

A technology of pneumatic tires and tread patterns, applied in the direction of tire tread/tread pattern, tire parts, vehicle parts, etc., can solve the problem of durability and comfort performance degradation, inability to break through performance, lack of grip and impact resistance and other issues to achieve the effect of reducing the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

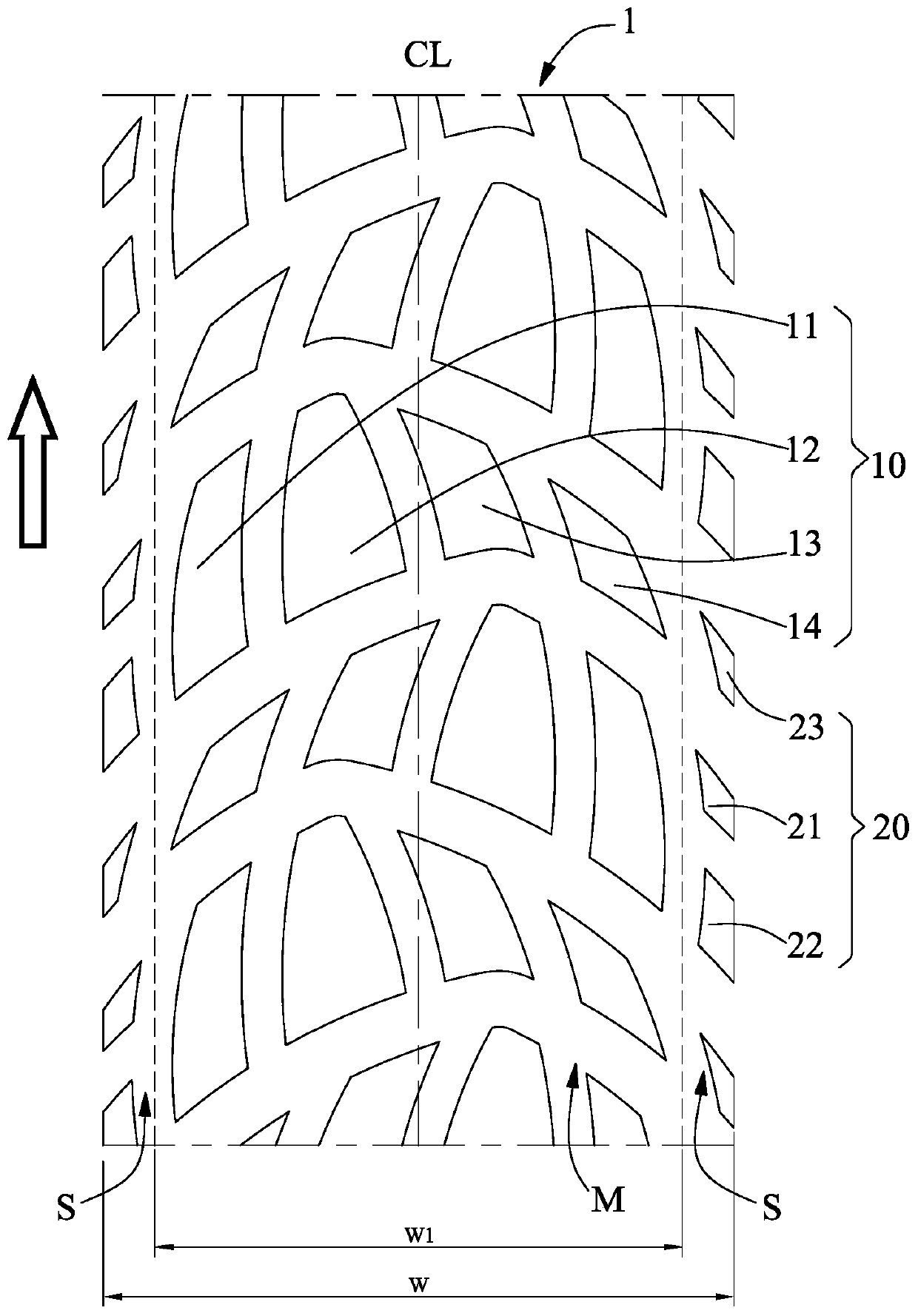

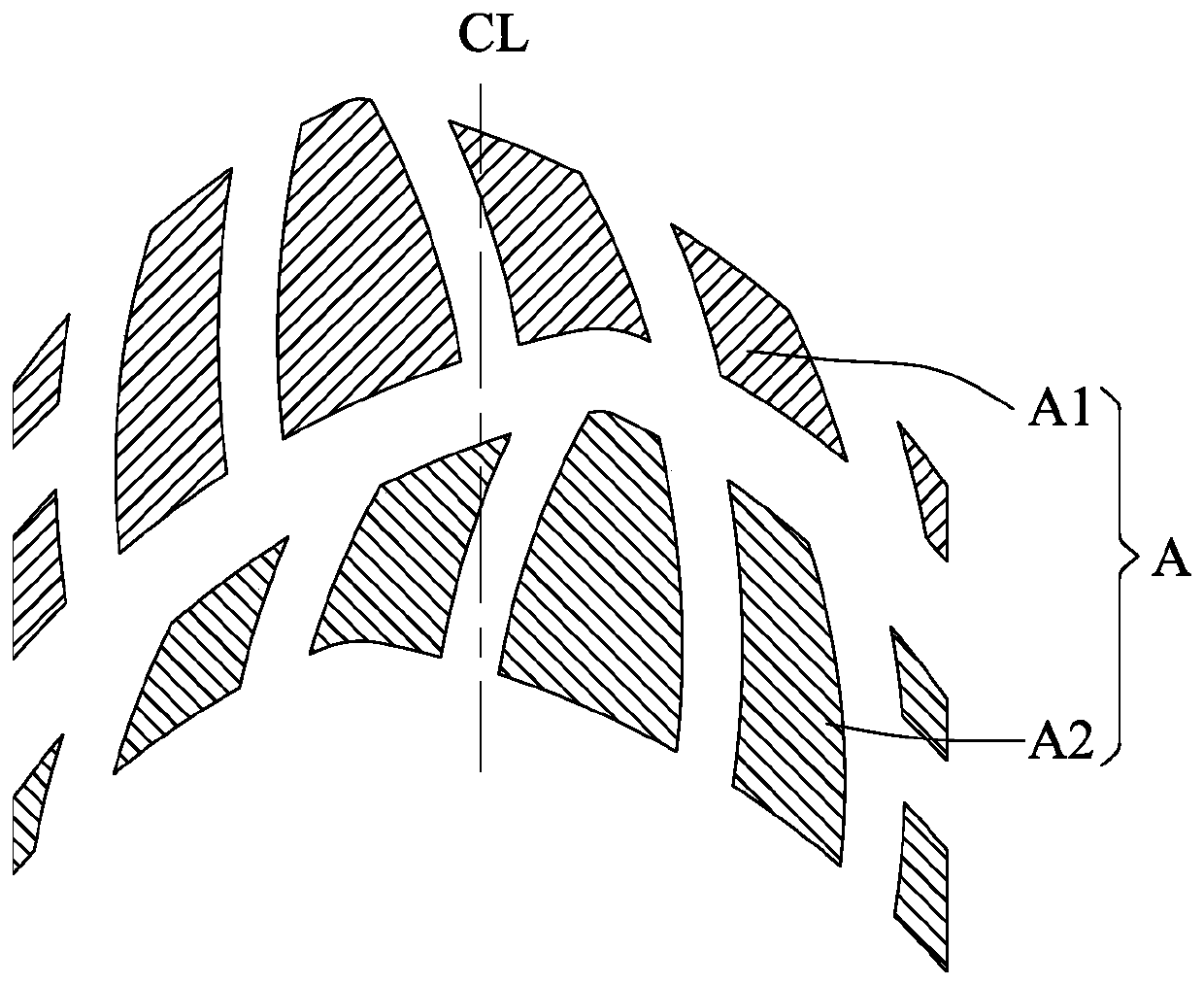

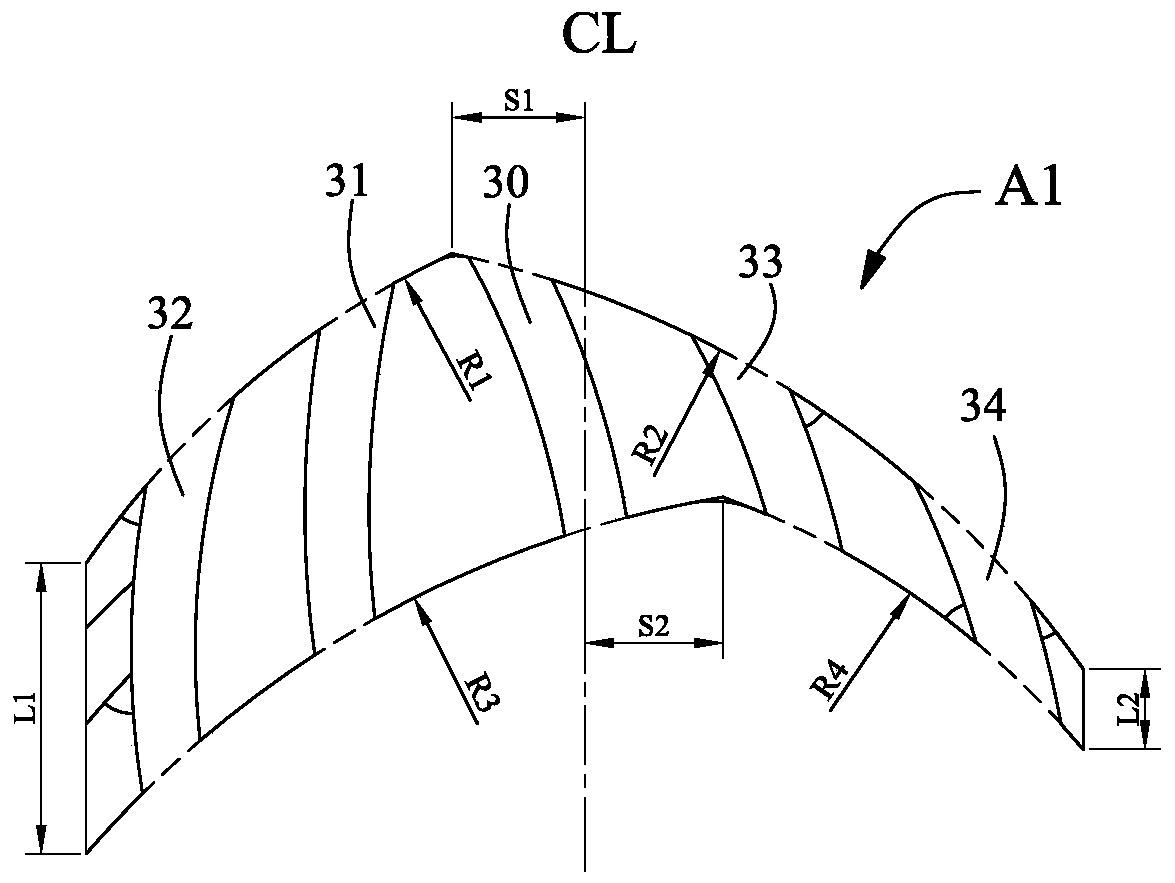

[0027] Such as Figure 1 to Figure 7 As shown, the present invention discloses a bicycle tire tread pattern structure. exist figure 1 The vertical direction is set as the tire circumferential direction, the lateral direction is set as the tire axial direction, CL represents the tread centerline, the end close to the tread centerline CL represents the inner end, and the end far away from the tread centerline CL represents the outer end , the direction of the arrow represents the driving direction of the tire, the end of the forward arrow represents the front end, and the end of the reverse arrow represents the rear end. exist Figure 6 The vertical direction in the middle is set as the radial direction of the tire, the end close to the tire axis represents the inner end, and the end far away from the tire axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com