Portable self-supporting manual-lifting screen

A self-supporting, screen technology, applied in the direction of instruments, projection devices, optics, etc., can solve the problems of large tension of the folding support arm, falling of the upper support part, and inconvenient portability, etc., and achieves simple structure, good stability, good stretching, and durability. small force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with accompanying drawing.

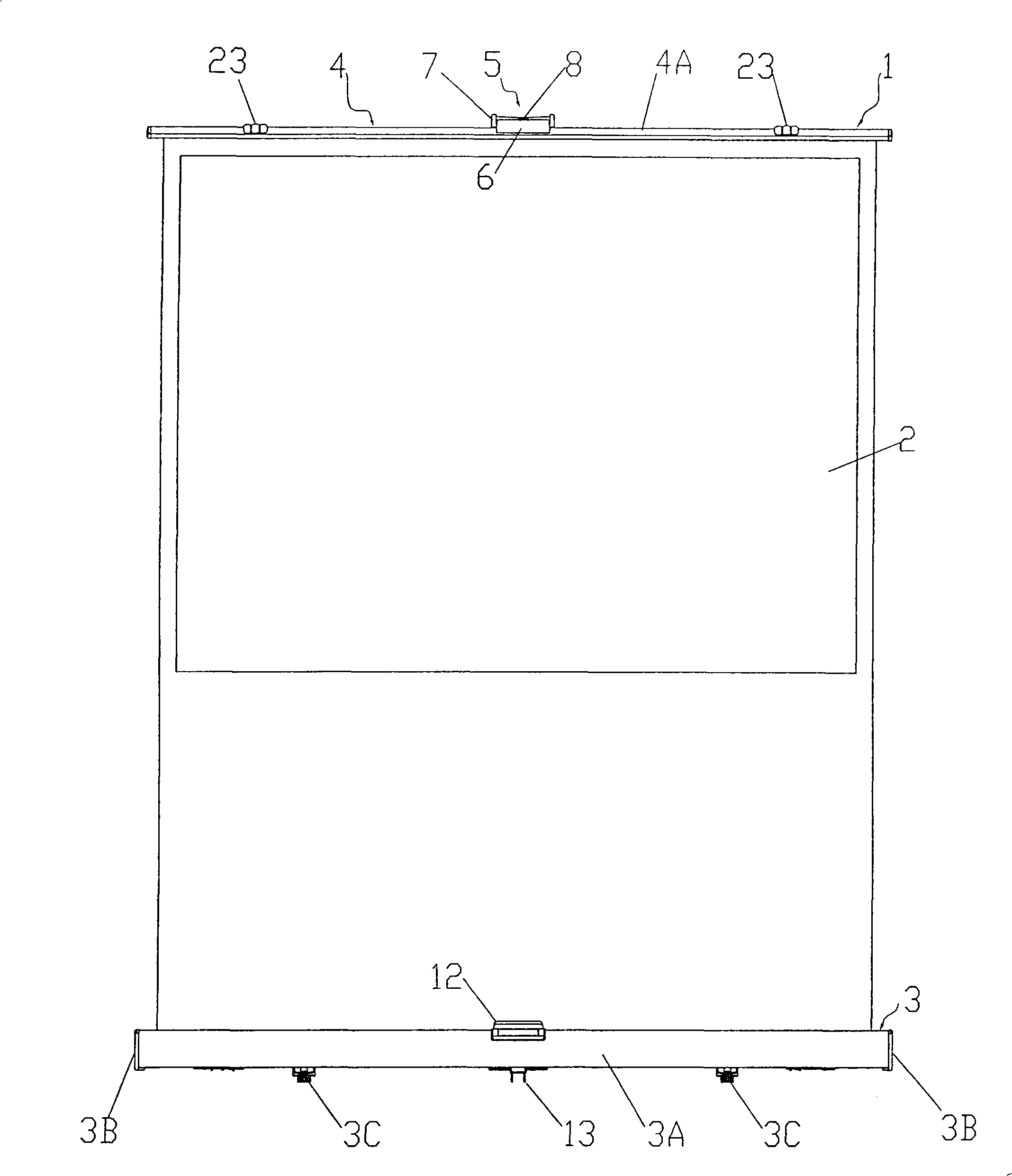

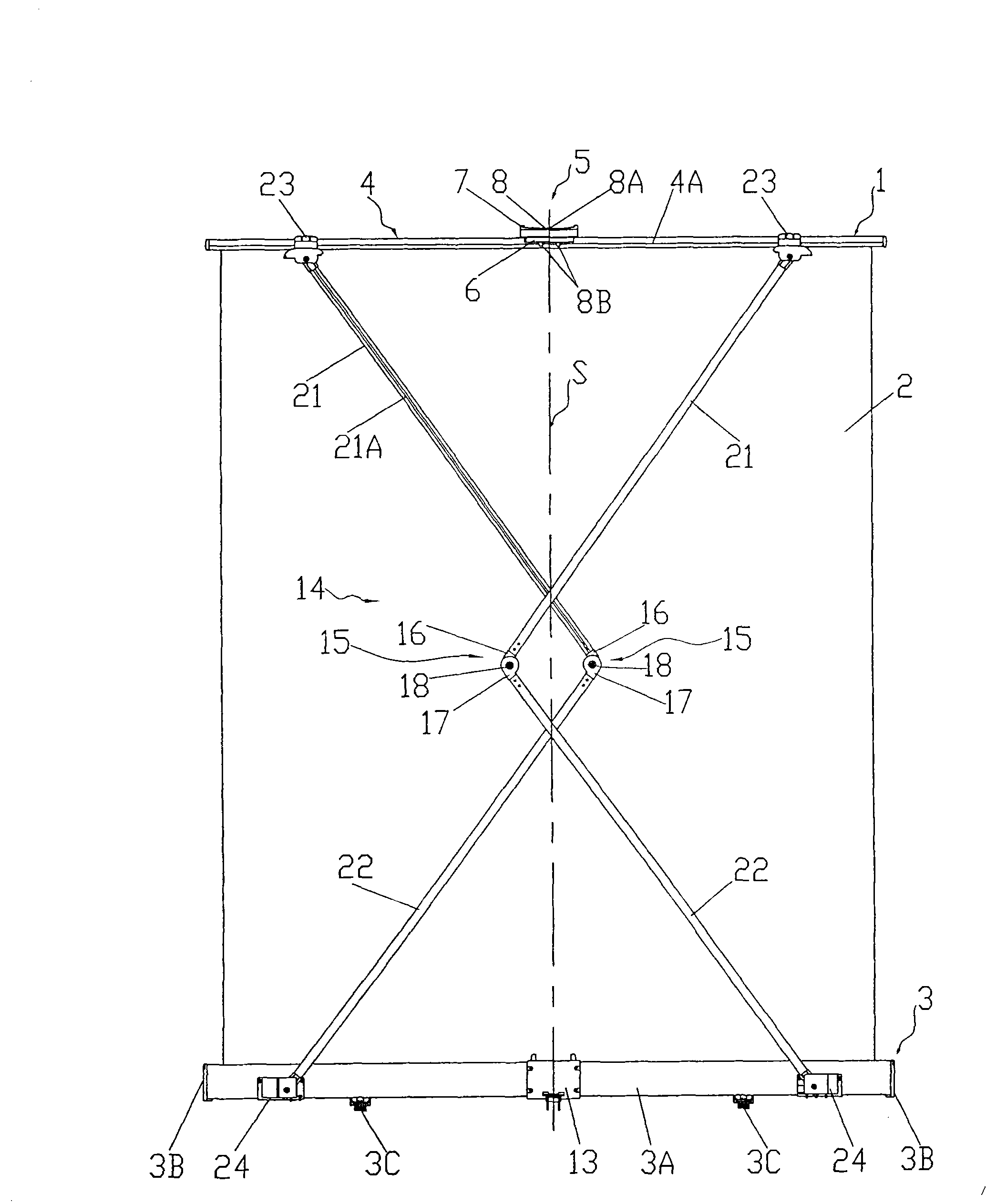

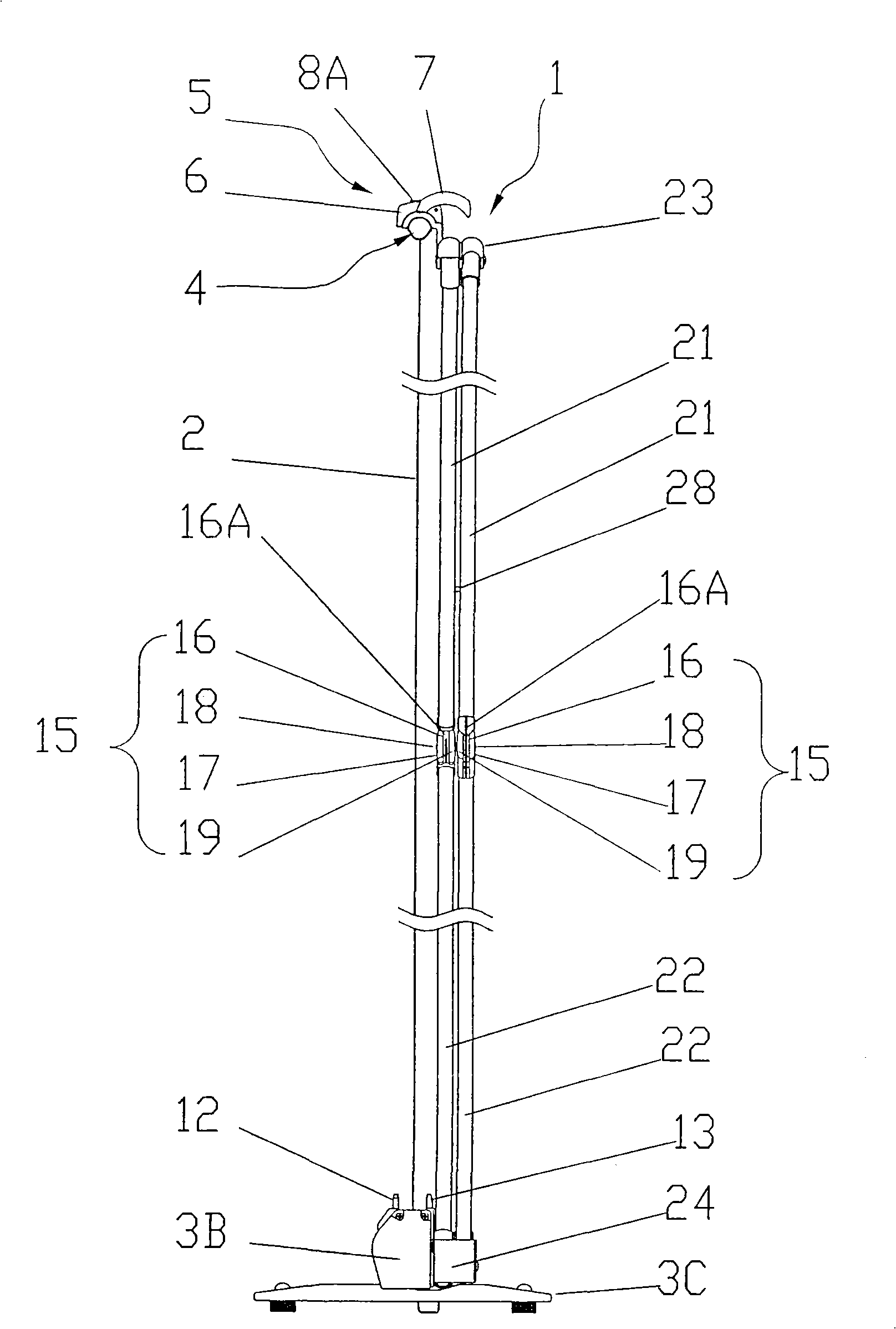

[0047] The serial numbers of the parts in the accompanying drawings are as follows:

[0048] Lifting screen 1: Screen 2: Housing 3: Housing body 3A: End cap 3B: Foot 3C: Opening 3K; Upper rod support part 4; Upper rod 4A: Handle part 5: Handle cover 6: Square through hole 6A; spring baffle 6B: threaded part 6C: handle part 7: unlocking device 8: unlocking push key part 8A: engaging part 8B; sliding guide groove 8C: fixed frame 9: sliding guide post 9A; screw 10 : Return spring 11: Front base 12: Engaged portion 12A: Rear base 13: Engaged portion 13A: Supporting portion 13B; L-shaped folding support arm 14: Hinged connection portion 15: Upper hinged part 16 : U-shaped cable guide groove 16A: Deployed position limiting protrusion 16B: Lower hinge member 17: Cable guide groove 17A: Deployed position limiting support part 17B: Screw rod 18: Nut 19: Fixing piece at the upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com