Optical fiber type mid-IR laser source generated by 3-5micrometre continuous wave differential frequency and its implementing method

An infrared laser and fiber-optic technology, applied in the optical field, can solve problems such as the difficulty in meeting the requirements of broadband tuning, the limitation of the spectral range of fiber amplifiers, and the wavelength tuning range of a single fiber laser is only tens of nanometers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

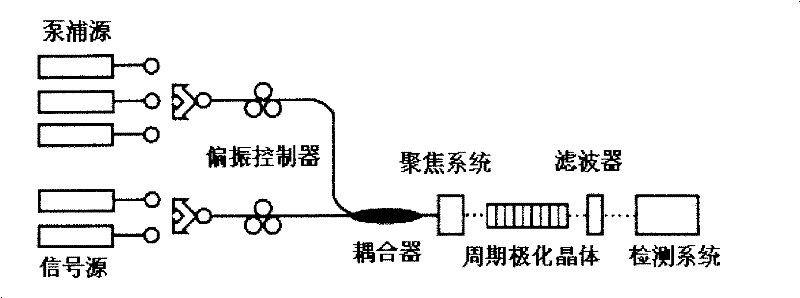

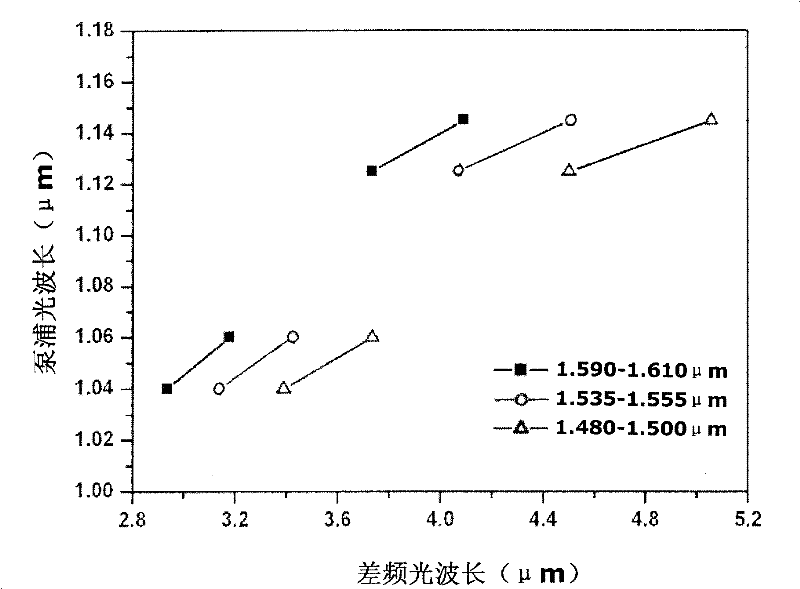

[0017] see figure 1 , the fiber-type 3-5 micron continuous wave difference frequency produces a mid-infrared laser source, the pump source and the signal source respectively adopt a wavelength segmentation combination scheme, which is characterized in that the signal source is composed of multiple bands of erbium-doped fiber lasers, and the bands are selected from S Waveband (1480-1530nm), C-band (1530-1560nm) and L-band (1565-1610nm); the pump source is also composed of multi-band ytterbium-doped fiber lasers, and the waveband is selected from 1000-1100nm and 1100-1200nm; The optical output ports of each of the erbium-doped fiber lasers are connected to the first output optical fiber, and the optical output ports of each erbium-doped fiber laser are connected to the second output optical fiber; the first and second output optical fibers are respectively connected with Polarization controller, the first and second output optical fibers are combined and coupled to a fiber coupl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com