Heat and corrosion resistant cast austenitic stainless steelalloy with improved high temperature strength

An austenitic stainless steel, corrosion-resistant technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problem of destroying the properties of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

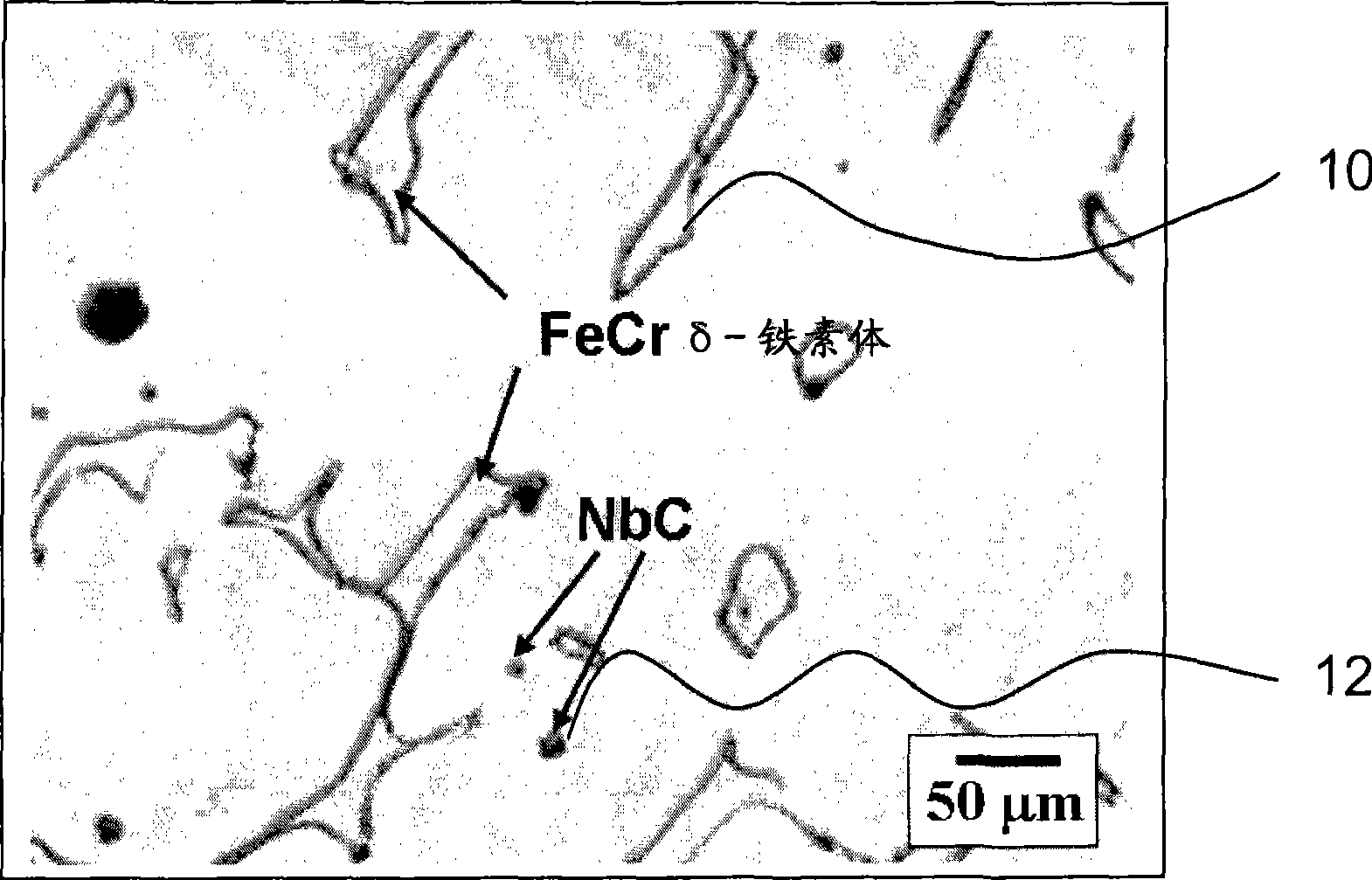

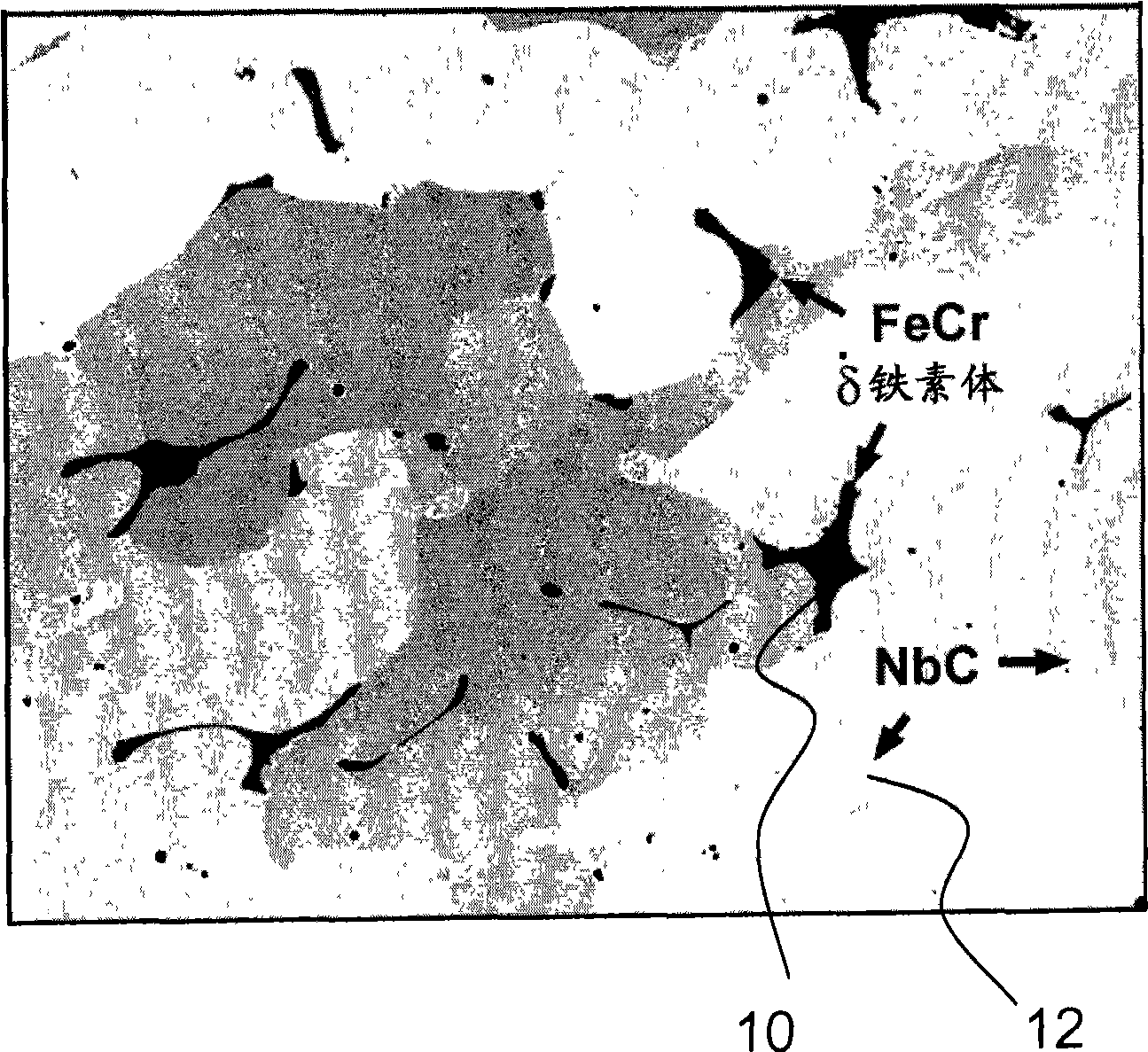

[0021] CF8C is the traditional casting equivalent of Type 347 stainless steel. The chemistry of CF8C-Plus is based on the composition of CF8C with precise additions of Nickel (Ni), Manganese (Mn) and Nitrogen (N), with reduced Silicon (Si) content and adjustments for other minor alloying elements. These modifications to the alloy were made to improve the high-temperature mechanical properties and casting characteristics of CF8C steels using inexpensive alloying elements without the need for post-casting heat treatment.

[0022] Table I

[0023]

[0024] Table I relates to maximum and minimum value ranges for the constituent elements of the alloys according to the invention. Table I also includes (in the column labeled "Alloy Examples") examples of embodiments of alloys made in accordance with the present invention. Embodiments covered by the present invention include alloys having any subgroup of compositional ranges falling between the minimum and maximum ranges shown in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com