Improved membrane type material tensioning structure

A tensioning mechanism and plate technology, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of difficulty in adjusting and controlling the tension force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

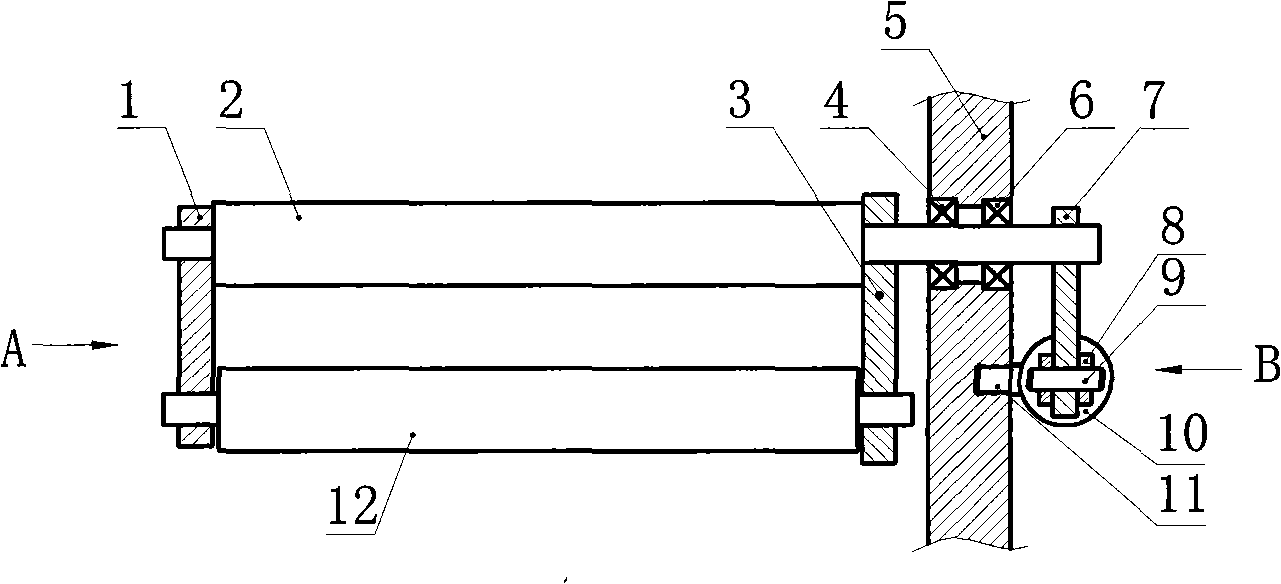

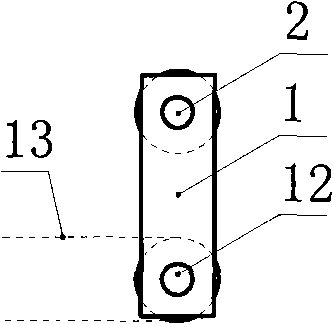

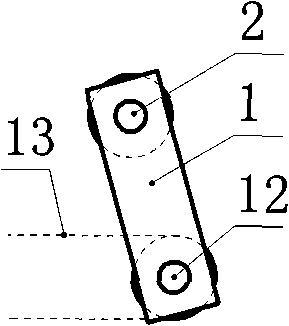

[0011] See figure 1 , the present invention comprises driving roller 2 and take-up roller 12, and driving roller 2 and take-up roller 12 are installed in parallel, and its two ends are respectively connected by front fixing plate 1 and rear fixing plate 3, and the rotating shaft of driving roller 2 passes bearing 4, 6 is installed on the plate parts 5, the rotating shaft is connected with the connecting rod 7, which also includes a cylinder 10, and the cylinder 10 is installed on the plate parts 5 by rotating the bolt 11; the guide rod of the cylinder 10 is connected with a U-shaped block 8; the U-shaped The block 8 is sleeved on the rotating shaft 9, and the rotating shaft 9 is installed on the connecting rod 7. Among the figure, 13 is membrane material.

[0012] When in use, the film material 13 is wound on the tensioning roller 12. When the cylinder 10 pulls the connecting rod 7, the connecting rod 7 drives the driving roller 2 to rotate, and the driving roller 2 is tighte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com