Method for roller adjustment in a printing press and dampening unit of a printing press

An adjustment method and technology for printing presses, which are applied in the fields of roller adjustment in printing presses and wetting devices of printing presses, and can solve problems such as the influence of printing plate wetting uniformity and the lack of consideration of roller bending.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

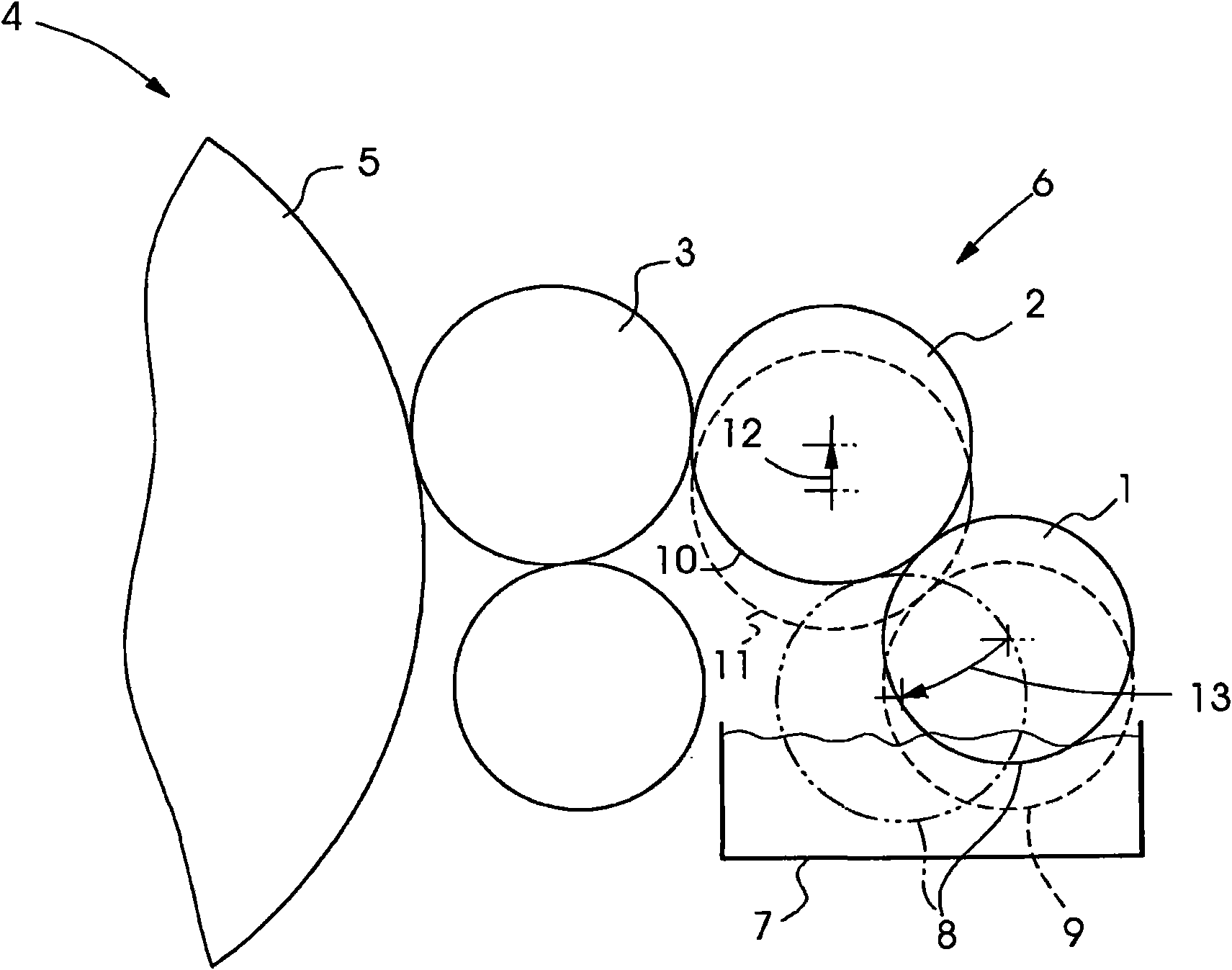

[0019] figure 1 A printing press 4 is shown in , which has a printing plate cylinder 5 and a dampening device 6 for moistening the printing plate cylinder 5 . The printing press 4 is an offset printing press for printing sheets. The dampening device 6 comprises an impregnation roll 1 as a first roll, a metering roll 2 as a second roll and a dampening roll 3 as a third roll. In addition to the metering roller 2 , the touch roller 3 abuts against a not shown oscillating roller, which oscillates in the axial direction. The impregnation roll 1 is arranged in a bucket 7 in order to draw dampening medium from the bucket. The metering roll 2 is arranged as an intermediate roll between the impregnation roll 1 and the dampening roll 3 and transfers dampening medium from the impregnation roll to the dampening roll.

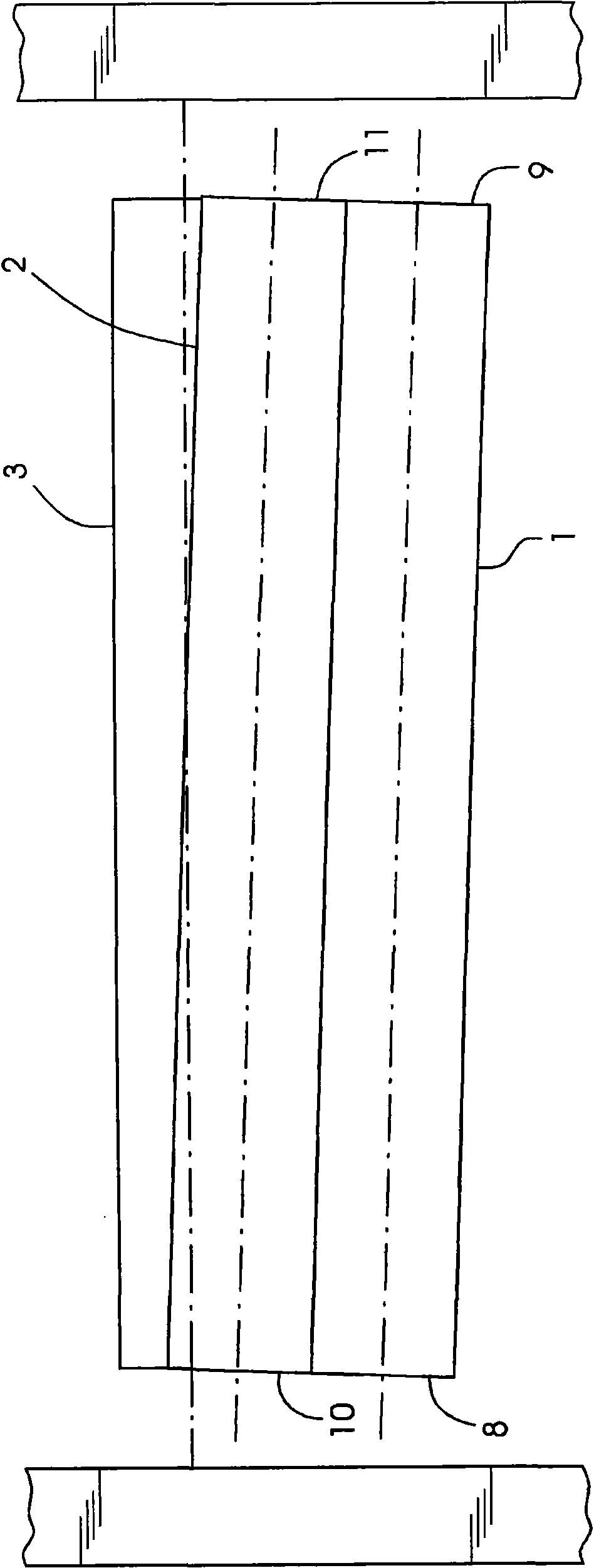

[0020] exist figure 2 In , the plate cylinder 5 is not shown for the sake of clarity. figure 2 It is shown that the rollers 1 , 2 and 3 are arranged on a frame wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com