Root canal instrument handle made of two co-axial portions joined in axial translation and in rotation

A root canal and instrument technology, applied in the direction of dental nerve/root treatment tools, medical science, dentistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

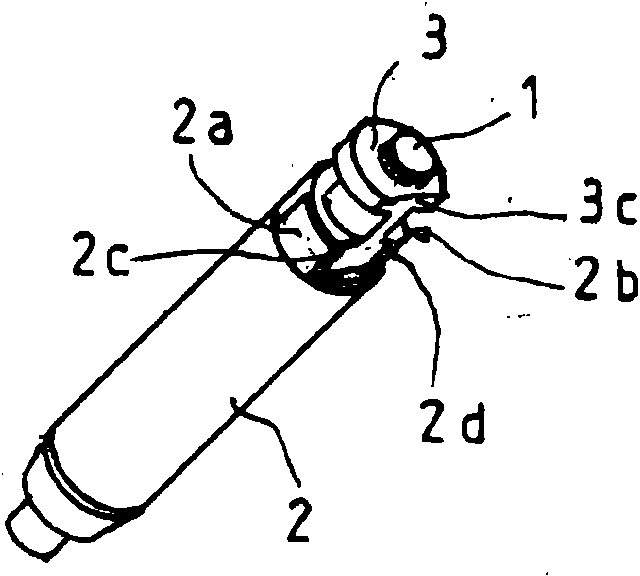

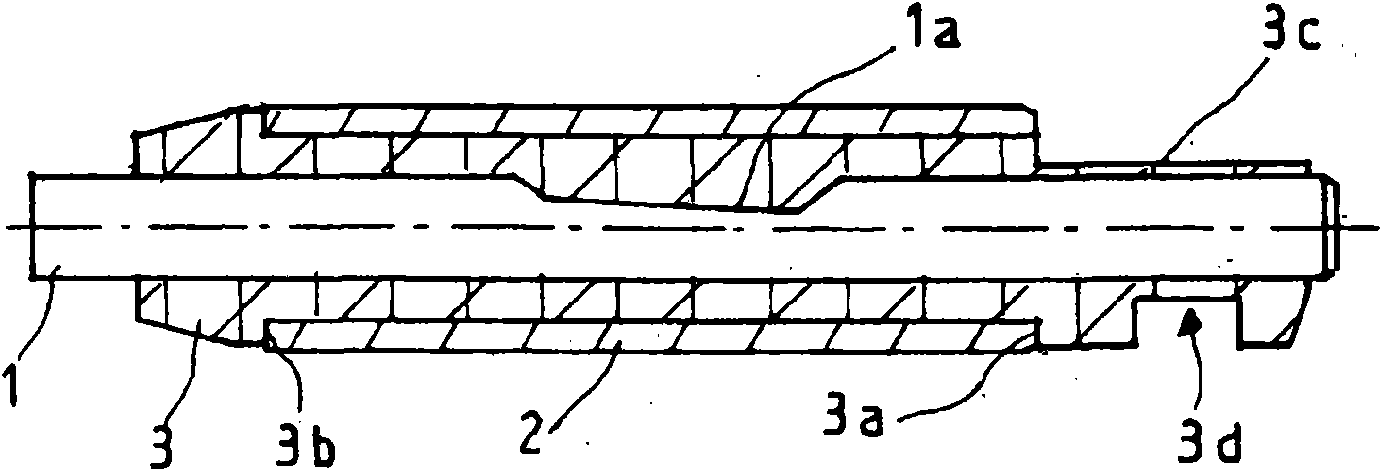

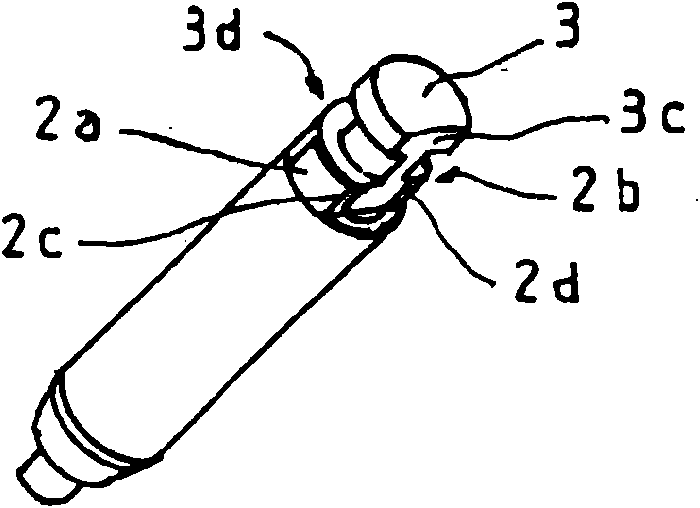

[0022] [22] The principle of the handle according to the invention is realized by two coaxial parts, for example cylindrical, said two coaxial parts being an inner part 3 and an outer sleeve 2, so Said outer sleeve 2 covers said inner part over at least a part of its length, and is provided with means for connecting said outer sleeve 2 to said inner part 3 both in axial translation and in rotation . Irrespective of manufacturing tolerances, the inner diameter of the outer sleeve is equal to the outer diameter of the inner part 3 over the covered length.

[0023] [23] Of course, the cross-section of the handle does not have to be cylindrical, for example, a polygonal cross-section can be considered, or as Figure 8 Exemplarily, the section of the interface between the sleeve 2 and the inner part 3 is polygonal.

[0024] [24] According to figure 1 or 2, the handle according to the invention is mounted on an instrument or blade 1 , which passes through the handle from one side...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap