Preparation method of spicy dried beef

A technology of beef jerky and spicy, applied in application, food preparation, food science, etc., can solve problems affecting product sales, unqualified colony count, and impact on meat quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The production process of spicy beef jerky includes the following processes: raw meat thawing process, raw meat dividing process, boiling or marinating process, frying process, seasoning process, vacuum packaging process, storage process,

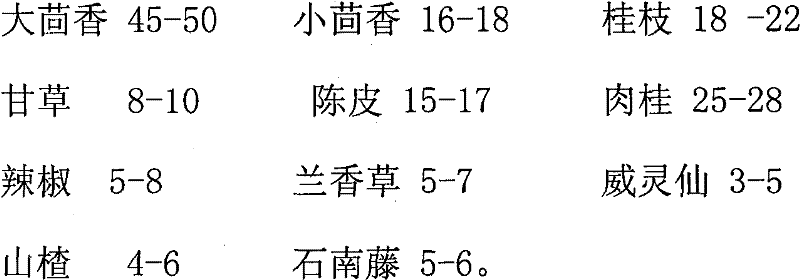

[0023] In the described mixing process, the spices added contain the following substances and parts by weight:

[0024] Anise 45 Cumin 16 Guizhi 18

[0025] Licorice 8 Tangerine Peel 15 Cinnamon 25

[0026] Pepper 5 Orchid Herb 5 Clematis 3

[0027] Hawthorn 4 Heather 5.

[0028] In the described packaging process, the packaging material used is aluminum foil.

[0029] The storage temperature in the storage procedure is 20-25°C.

[0030] Described beef is yellow beef.

Embodiment 2

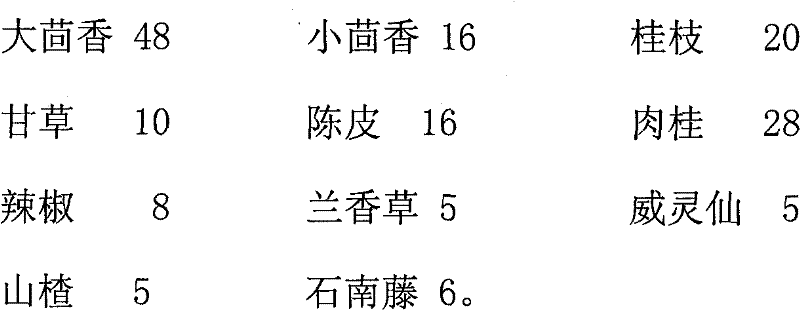

[0032] Except that the spices used in the mixing operation contains the following substances and parts by weight, all the other are the same as in Example 1.

[0033] Anise 48 Cumin 16 Guizhi 20

[0034] Licorice 10 Tangerine Peel 16 Cinnamon 28

[0035] Pepper 8 Orchid Herb 5 Clematis 5

[0036] Hawthorn 5 Heather 6.

Embodiment 3

[0038] Except that the spices used in the mixing operation contains the following substances and parts by weight, all the other are the same as in Example 1.

[0039] Anise 50 Cumin 18 Guizhi 22

[0040] Licorice 10 Tangerine Peel 17 Cinnamon 28

[0041] Pepper 8 Orchid Herb 7 Clematis 5

[0042] Hawthorn 5 Heather 6.

[0043] The spicy beef jerky made in Examples 1, 2, and 3 does not have flatulence during the shelf life of 1 year, the bacterial colony index is qualified, and the color of the meat remains unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com