Trepanning sampling method of blind hole of ultralong deep hole

A blind hole and deep hole technology, applied in the sampling device and other directions, can solve problems such as small gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

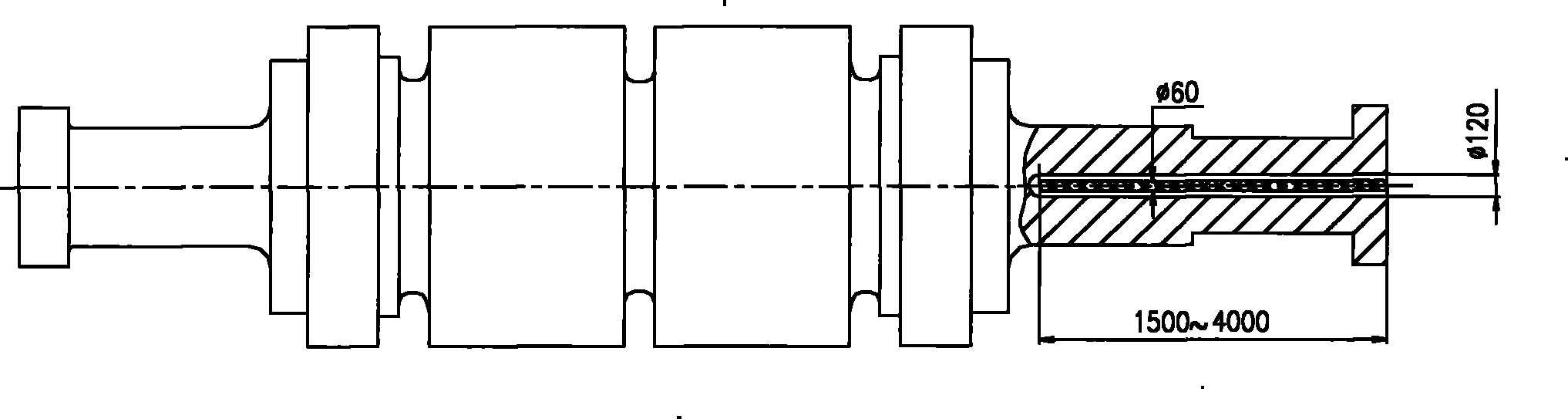

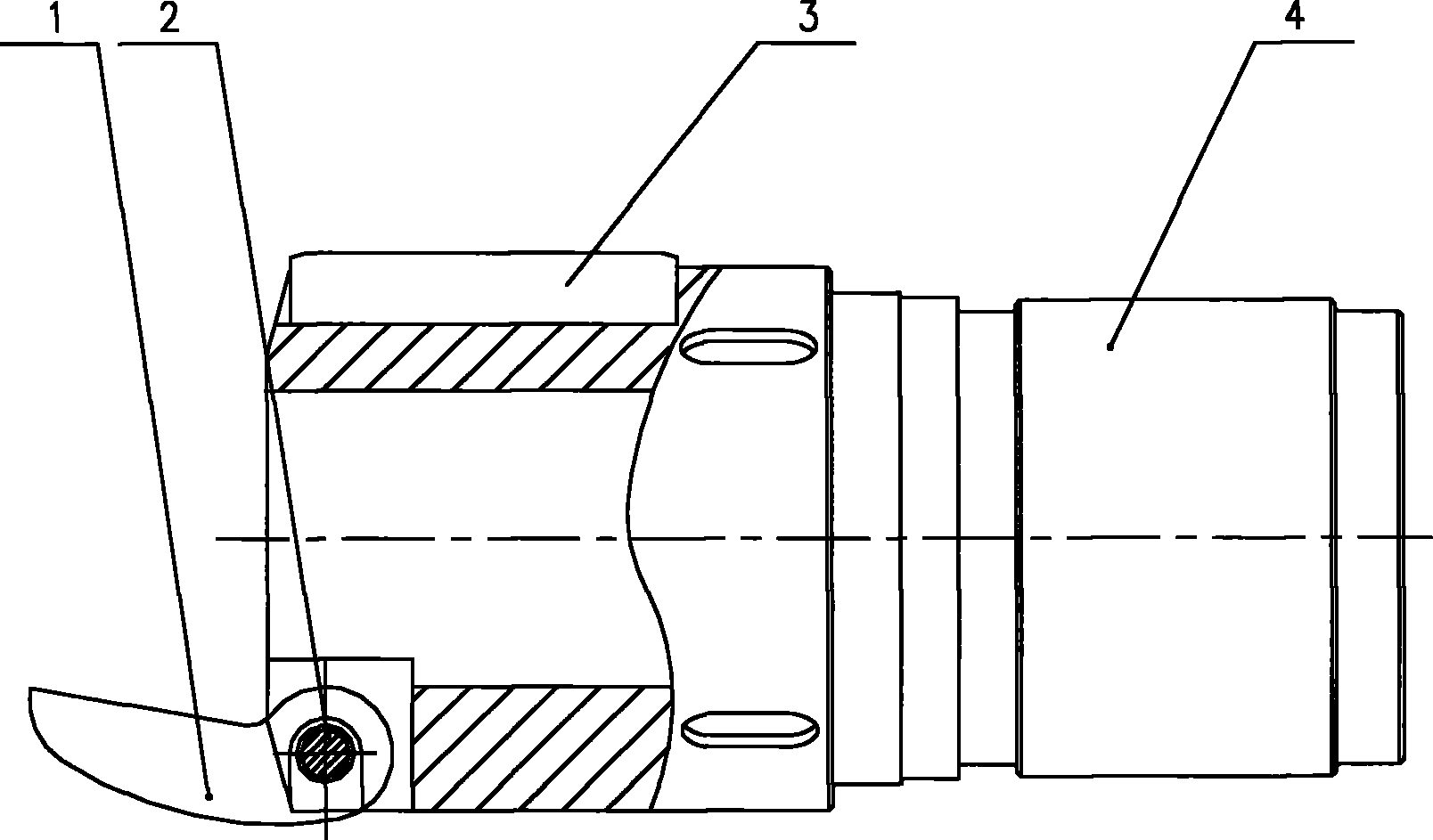

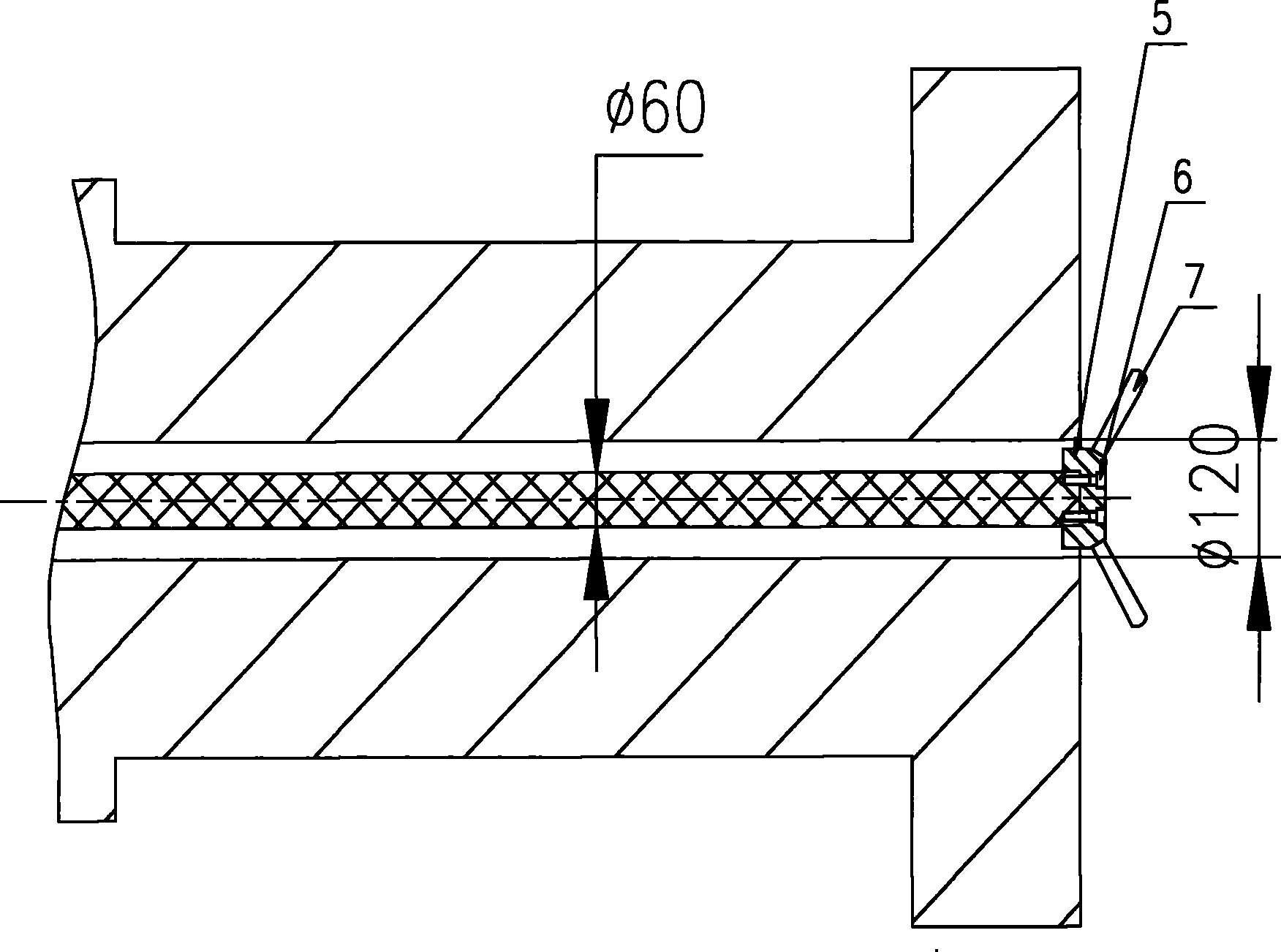

[0022] The nesting sampling method of the ultra-long, deep and blind holes of the present invention can be used in such as figure 1 Nesting sampling is carried out in the ultra-long and deep blind holes of the ultra-supercritical rotor workpiece shown, wherein the aperture of the blind hole is D=120mm, the diameter of the core rod is d≥60mm, and the length of the core rod is 1500-4000mm.

[0023] The present invention performs nesting sampling in the super long deep blind hole through the following steps:

[0024] 1. Turn the shape of the ultra-supercritical rotor of the workpiece on a heavy-duty horizontal lathe, and then use a turning tool on the sampling end of the workpiece to create a shallow circular line at a diameter of 40mm, which is used as the center of the two M12 screw holes line;

[0025] 2. On the boring machine, drill and tap 2-M12 screw holes on a shallow circular line with a diameter of 40mm;

[0026] 3. The deep hole drilling and boring machine of the above model TD...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com