Trepanning sampling method of blind hole of ultralong deep hole and cut-off tool

A technology for cutting tools and blind holes, which is applied to sampling devices and other directions, and can solve problems such as small gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

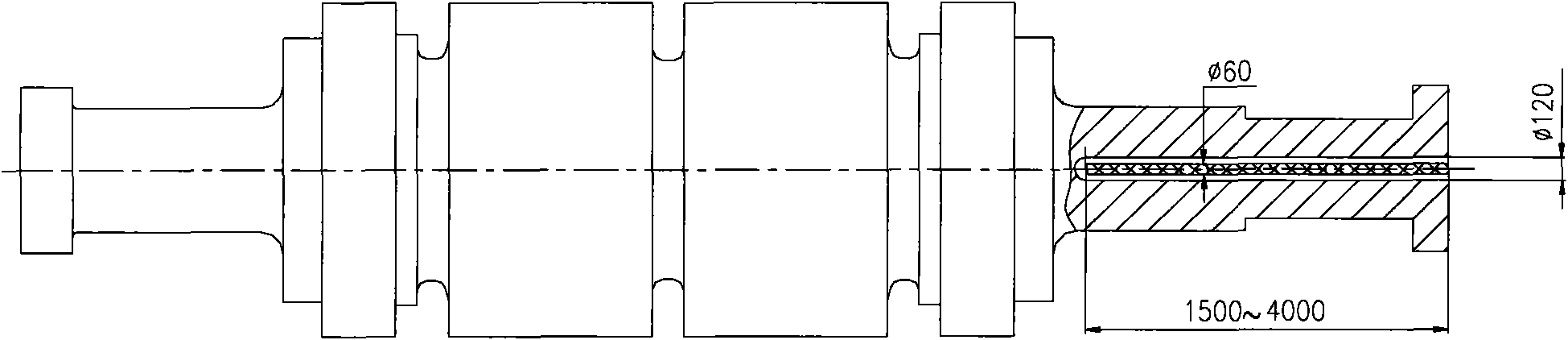

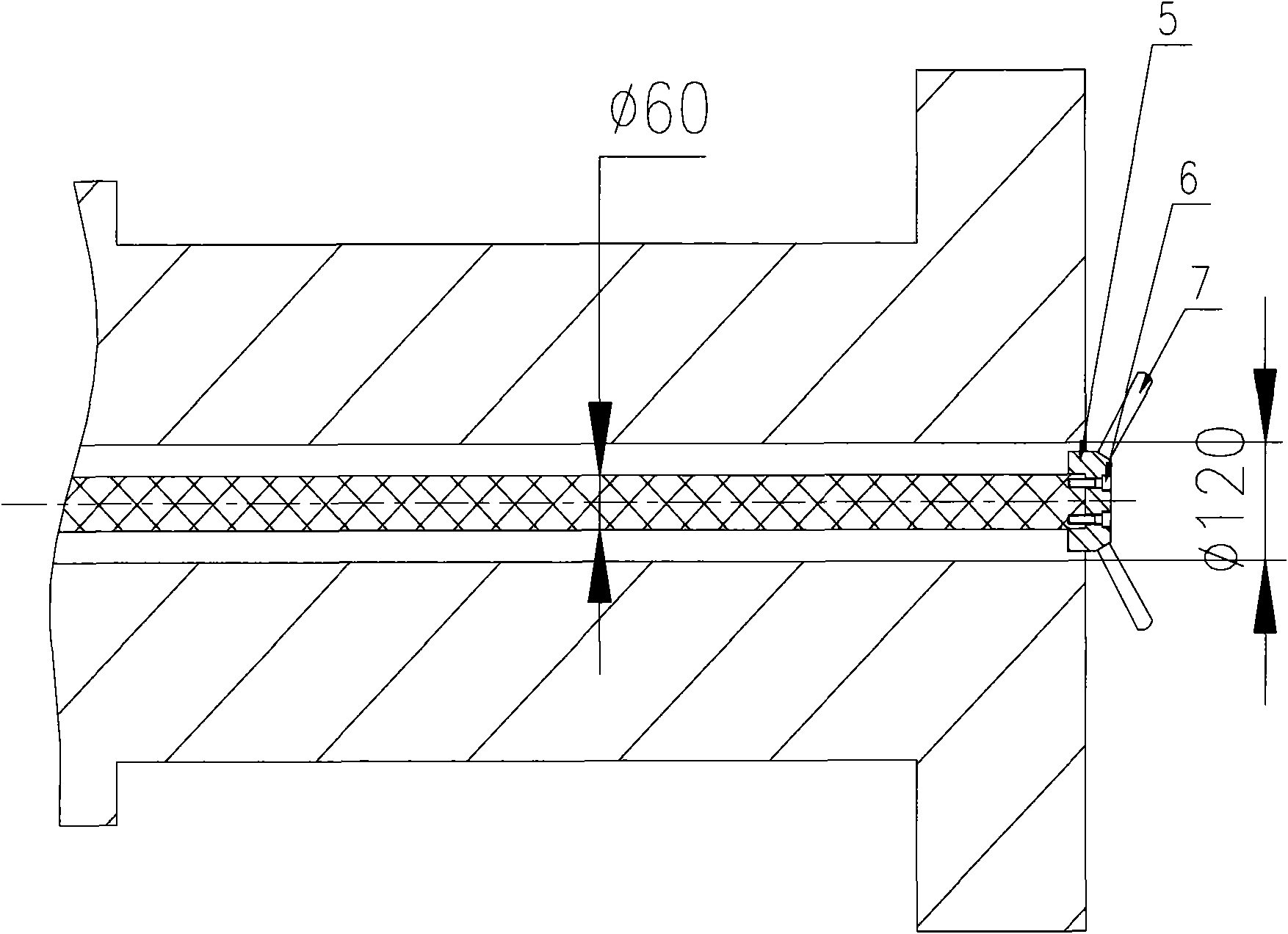

[0027] The nesting sampling method of super long deep hole blind hole of the present invention can be used in such as figure 1 The nesting sampling is carried out in the ultra-long deep hole blind hole of the ultra-supercritical rotor workpiece shown, wherein the blind hole diameter D=120mm, the mandrel diameter d≥60mm, and the mandrel length is 1500-4000mm.

[0028] The present invention carries out nesting sampling in the ultra-long deep hole blind hole through the following steps:

[0029] 1. Turn the shape of the ultra-supercritical rotor of the workpiece on a heavy-duty horizontal lathe, and then use a turning tool to draw a shallow circular line with a diameter of 40mm on the sampling end of the workpiece. The shallow circular line is used as the center of the two M12 screw holes Wire;

[0030] 2. On the drilling and boring machine, drill and tap 2-M12 screw holes on a shallow circular line with a diameter of 40mm;

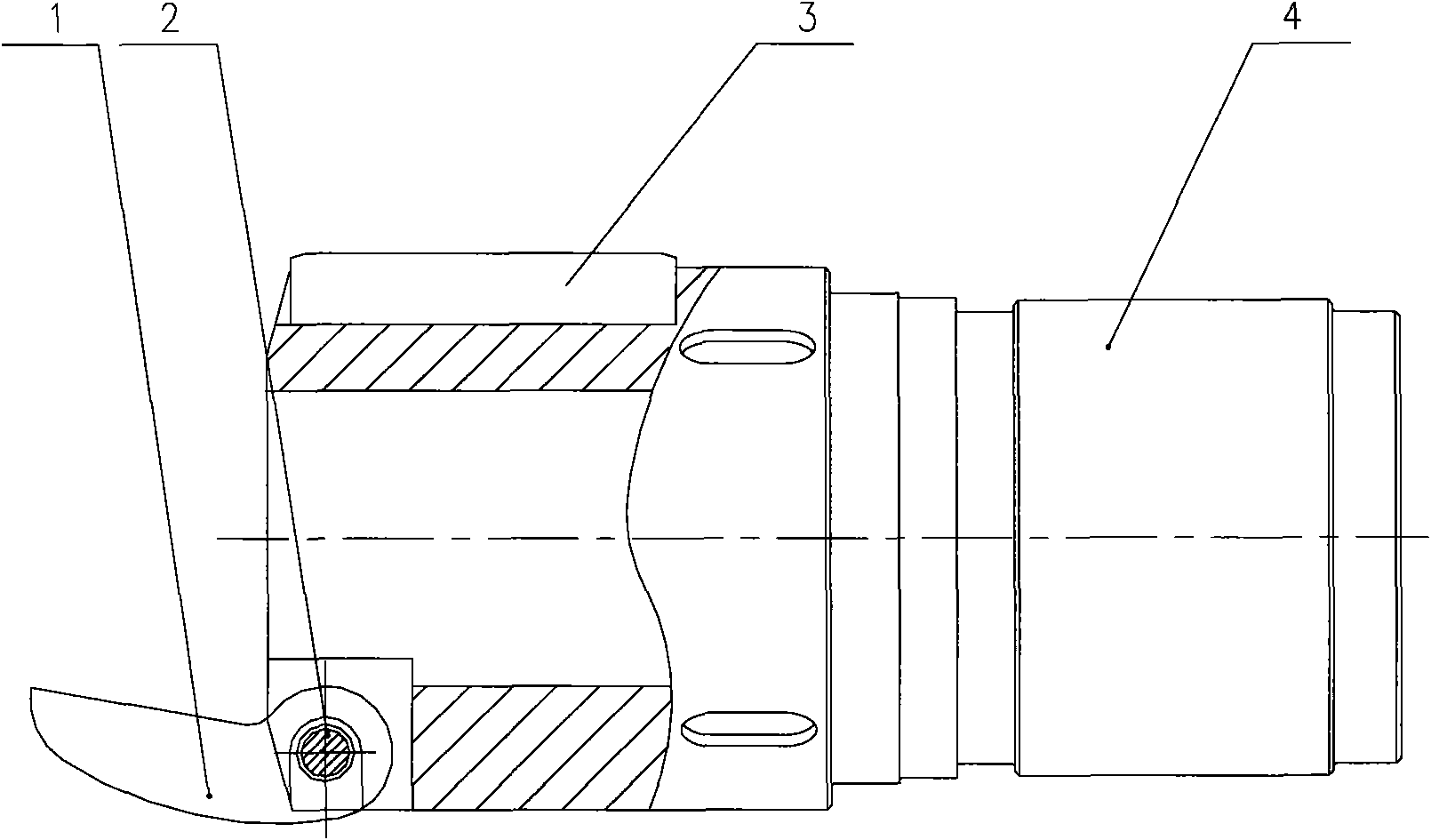

[0031] 3. For the deep hole drilling and boring mach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com