Superconductive element and relative preparation process

A technology for superconducting and components, which is applied to superconducting components and related fields of preparation, and can solve problems such as inserts that cannot obtain superconducting materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

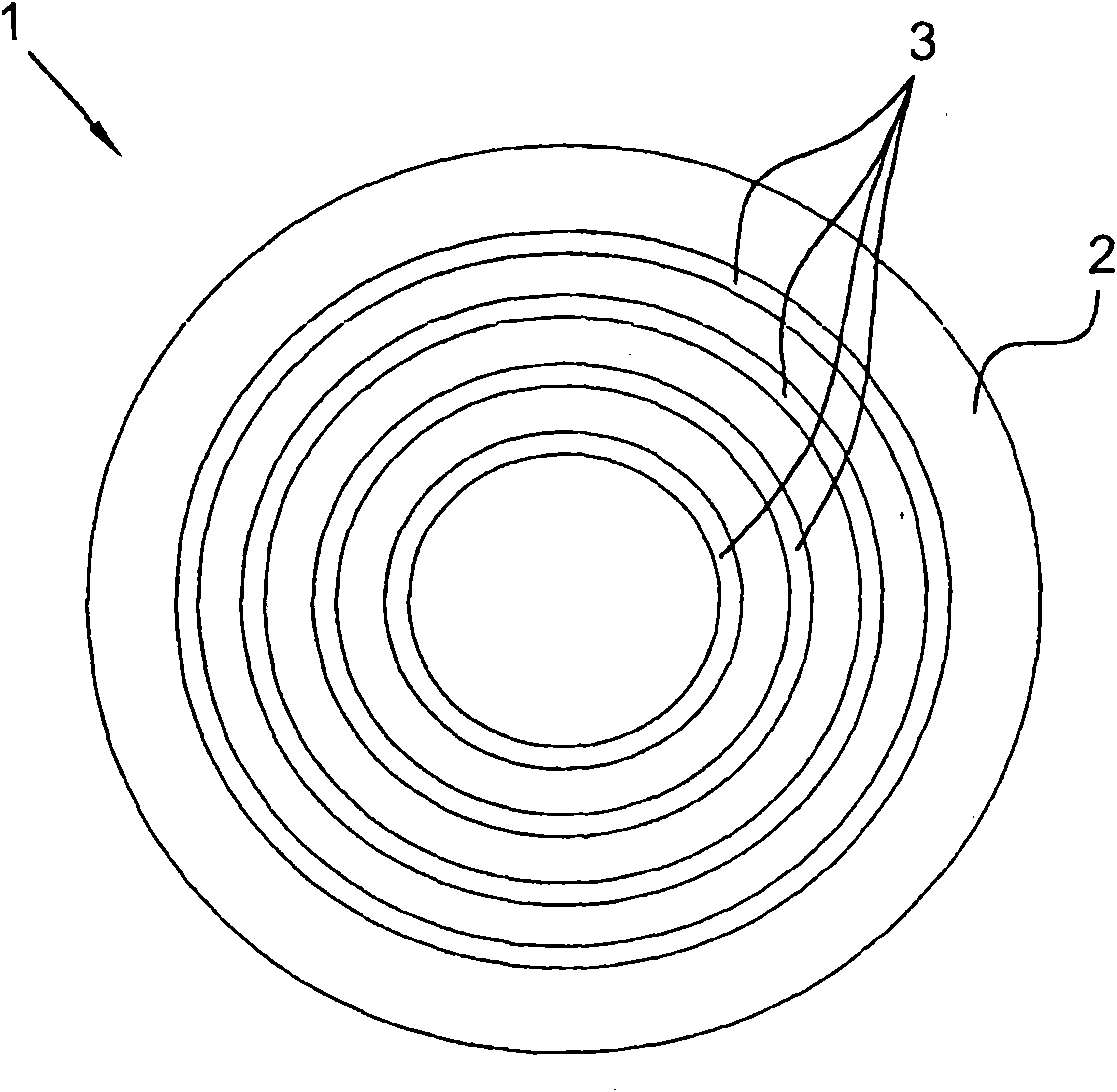

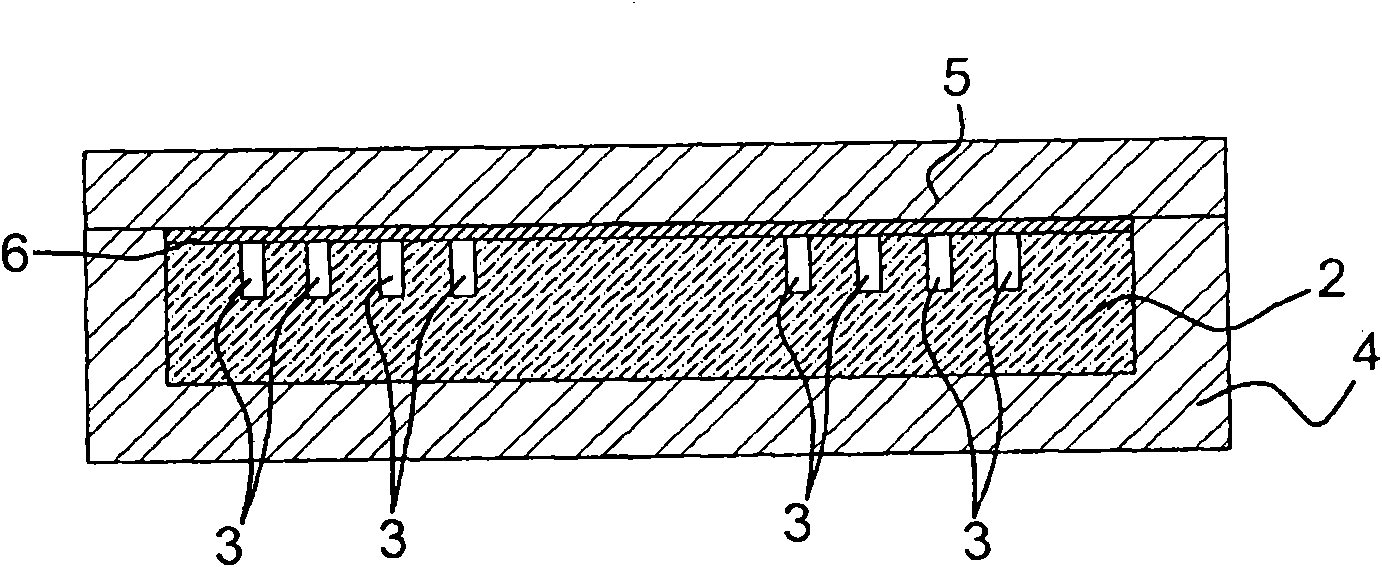

[0173] A superconducting element according to the present invention was produced in the following manner. A groove with a width of 0.5-1 mm and a depth of 4.5 mm is formed by electrocorrosion on the surface of a disc-shaped steel support with a diameter of 60 mm. The grooves were formed in such a way that an open track was created on the support in a helical manner starting at an inner diameter of 20 mm and unwinding into 7 helices until reaching an outer diameter of 54 mm. The grooves are filled with a precursor powder consisting of crystalline boron. The boron powder is mechanically activated by rolling with rotating cylinders in a mill. The powder thus milled was then filtered through a sieve having a mesh size of 40 microns. The average diameter of the powder is 25 microns. The powder in the grooves is manually compacted with the help of rollers until it reaches a density equal to 1.2 g / cm 3 up to the actual density. The support with grooves filled with compacted powd...

example 2

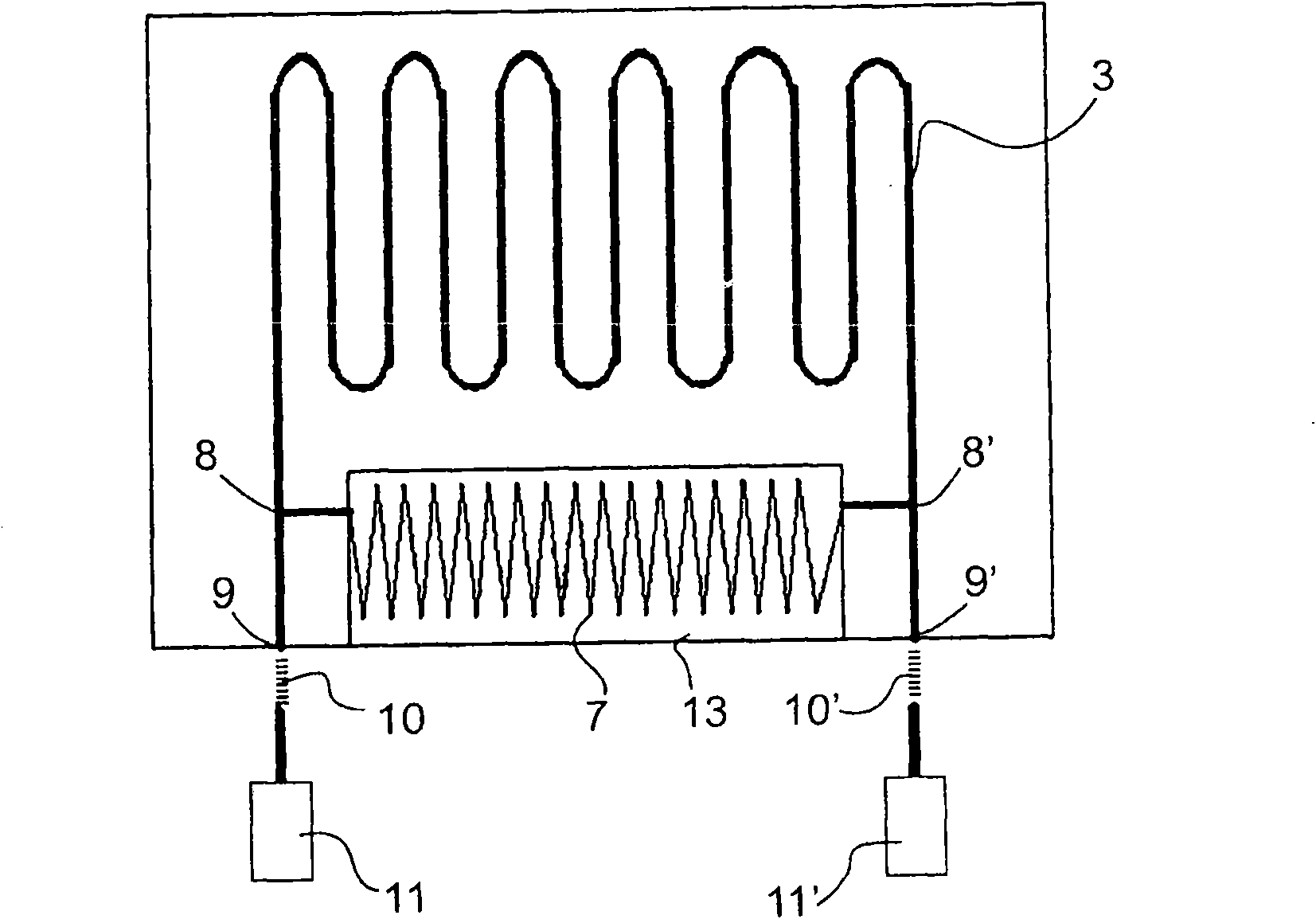

[0175] Use a disc-shaped steel support with a diameter of 70mm and a thickness of 8mm to prepare a superconducting permanent magnet as a superconducting element, and inlay two spiral grooves (size: 1.5mm wide, 2.5-3.0mm deep) on both sides of the steel support ), the helical groove develops in 16 helices from the center of the disc to the periphery according to an isotropic trend, that is, two helices wrap around the normal axis of the support in the same direction. The two grooves are connected by two holes of diameter 3 mm in the support so as to connect the two centers to each other and to connect the two ends of the helical groove.

[0176] Insert the same crystalline boron powder as in Example 1 into the grooves and holes of the support and manually compact until the actual density reaches 1.2g / cm 3 until. Two magnesium sheets of the same type as used in Example 1 were positioned on supports facing each other on both sides of the disc. Then, the support thus prepared wa...

example 3

[0179] The superconducting element consisting of a disc-shaped non-magnetic AISI 316 steel support 8 mm thick and 60 mm in diameter has 19 strips of MgB in the form of concentric circles embedded on both surfaces 2The superconducting closed track is 0.5mm thick, the diameter ranges from 52mm to 10mm, the depth is 3-4mm, and the central cylinder has a diameter of 5mm. The superconducting element was prepared as in Example 2, and its residual magnetic field flux density was measured at its center at a distance of 1 mm from the surface. It exhibits a continuous magnetic flux density of 1 Tesla at a temperature of 21K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap