Golf head

A golf head and club head technology, which is applied to golf balls, golf clubs, rackets, etc., can solve the problems of short staying time, increased ball-biting performance of the hitting panel, and unsatisfactory ball-controlling effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The structure and effect of the present invention will be described in detail by citing the following embodiments in conjunction with the accompanying drawings.

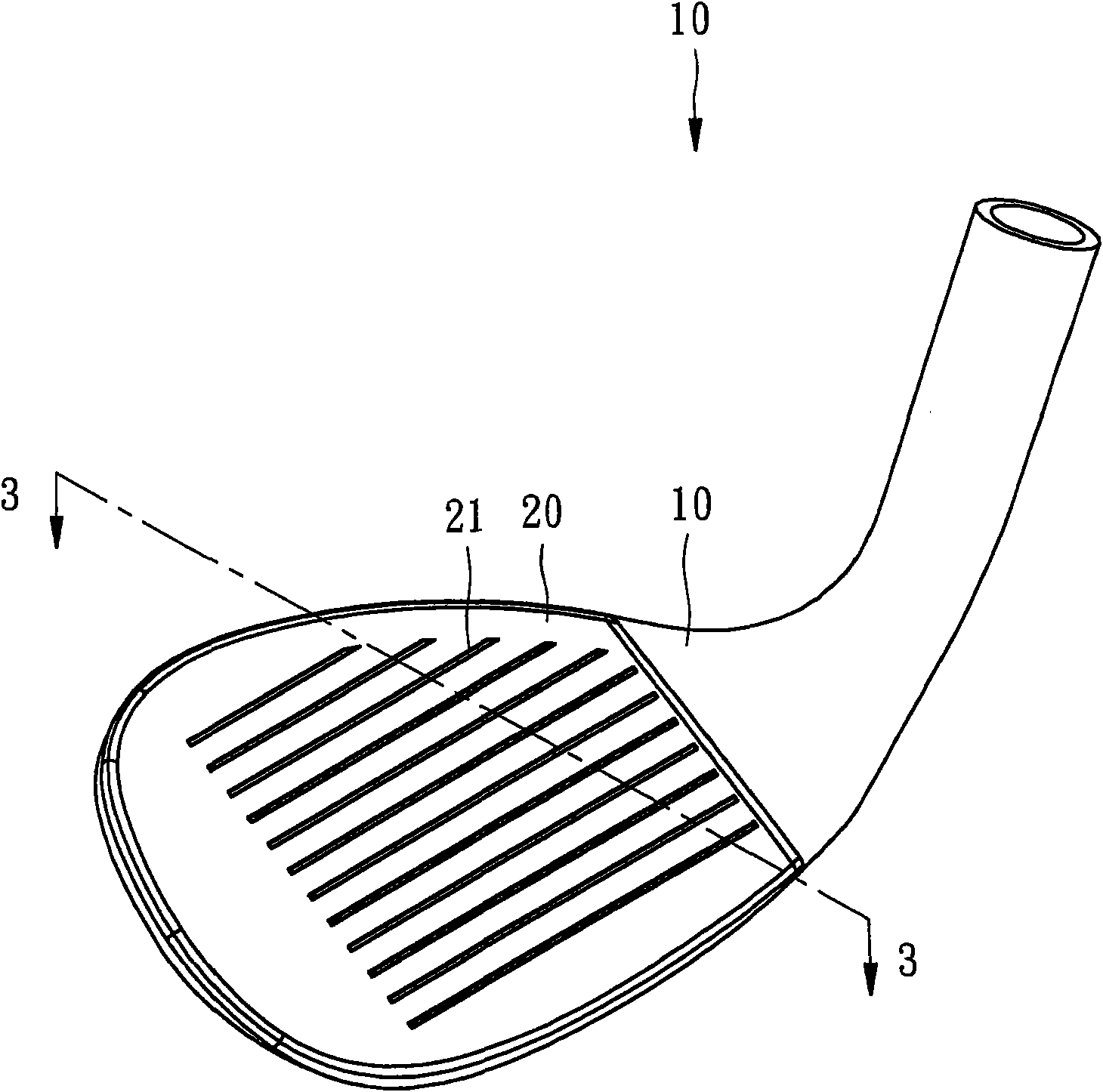

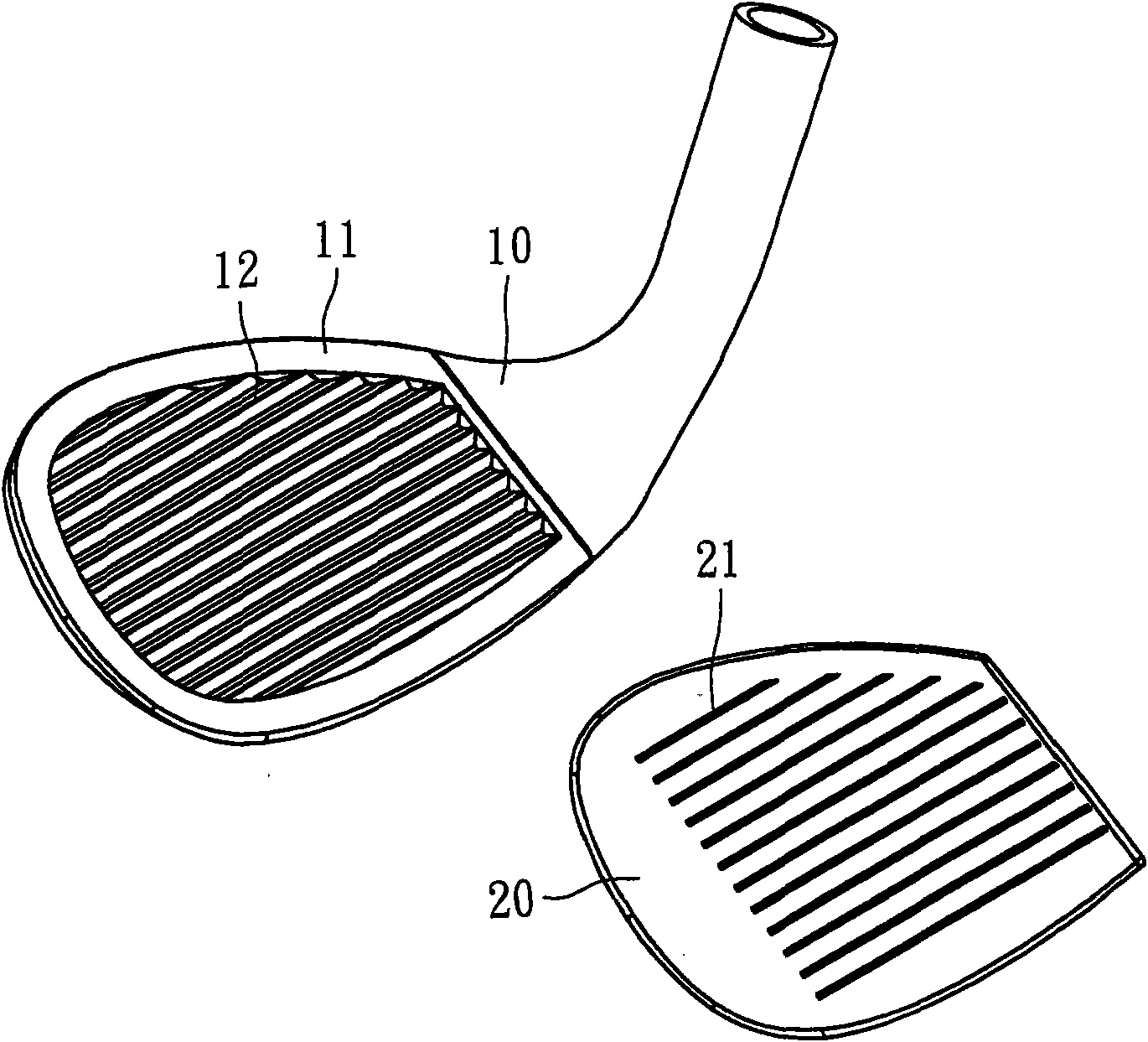

[0020] Such as figure 1 and Figure 5 As shown, the present invention is implemented in the state of the iron club head. Of course, the same structure can also be applied to the wood club head or other club heads. The golf head provided by the present invention includes:

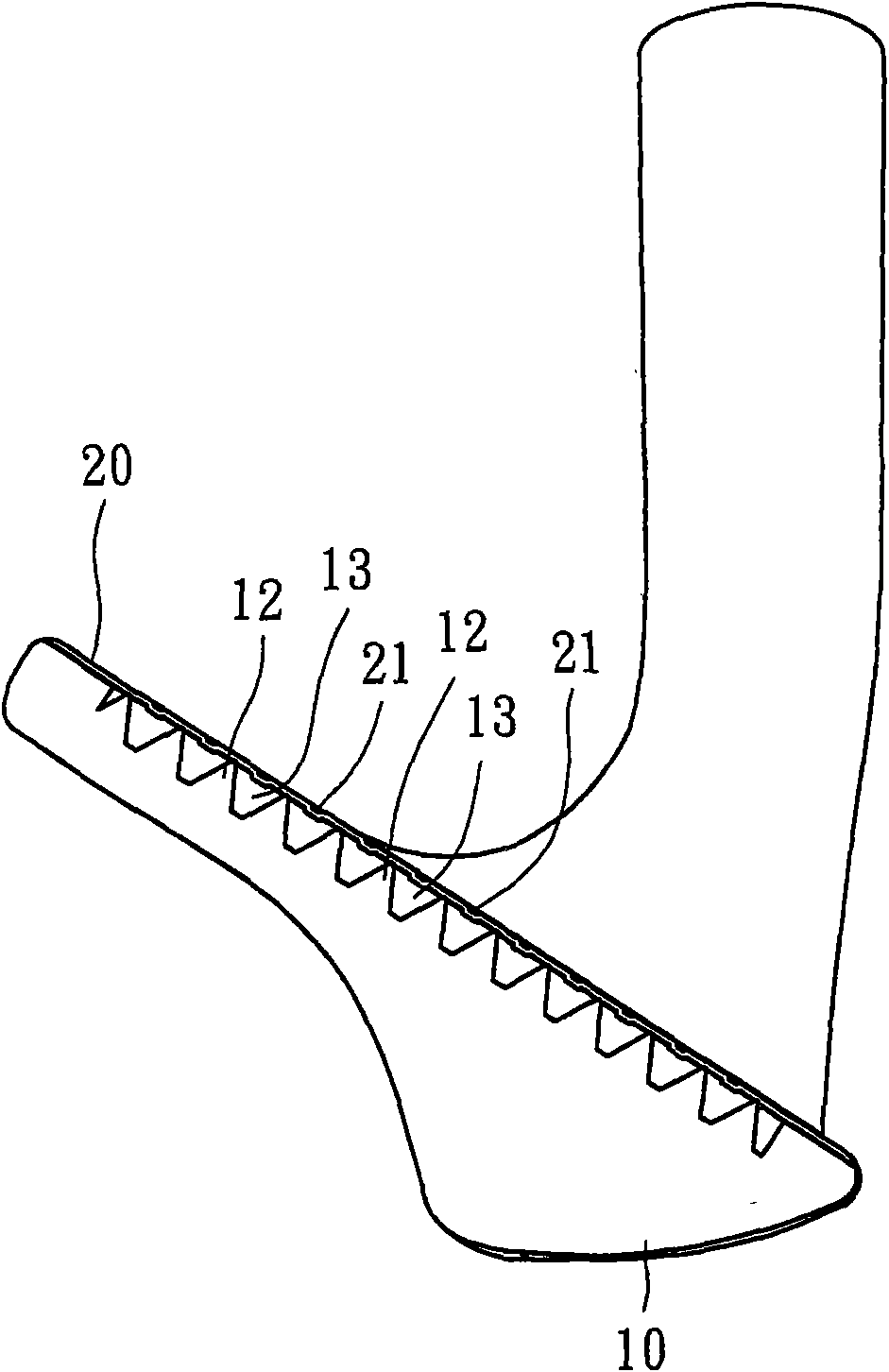

[0021] Such as Figure 1 to Figure 5 As shown, a club head body 10, the club head body 10 is provided with a groove 11 at the position of the ball striking surface, and a plurality of supporting parts 12 are protruded on the bottom wall of the groove 11 to form a plurality of inner line grooves 13 (such as image 3 shown), each support portion 12 can be arranged in a horizontal arrangement, and can also be arranged in a vertical or different angle arrangement (such as Figure 5 shown), and the distance between two adjacent supporting part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com