Dung leaking plate structure for sow obstetric table

A technology of leaking manure boards and breeding sows, applied in animal houses, applications, animal husbandry, etc., can solve the problems of inconvenient breastfeeding, waste, and inappropriateness of weak piglets, and achieve the effect of saving feed costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

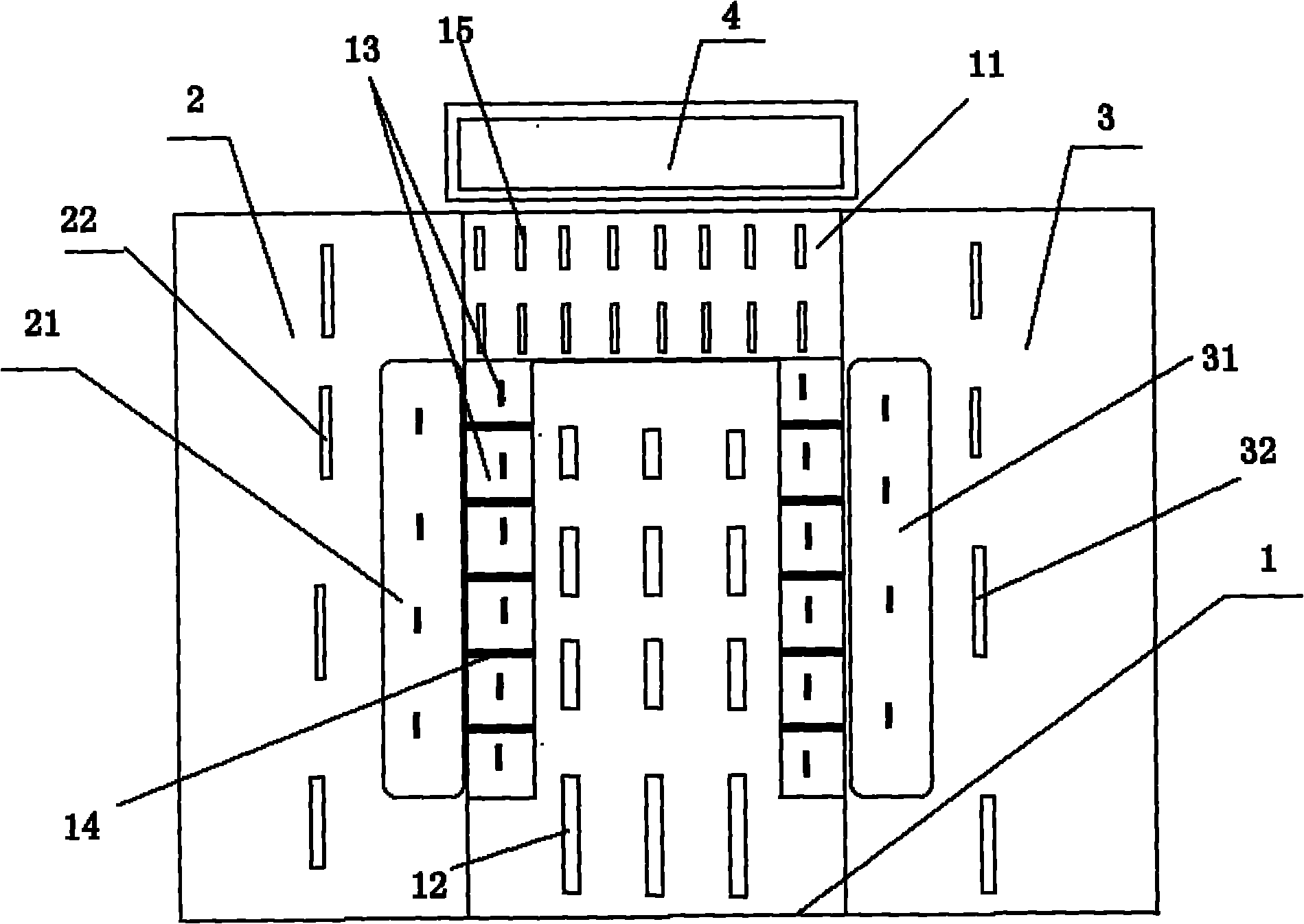

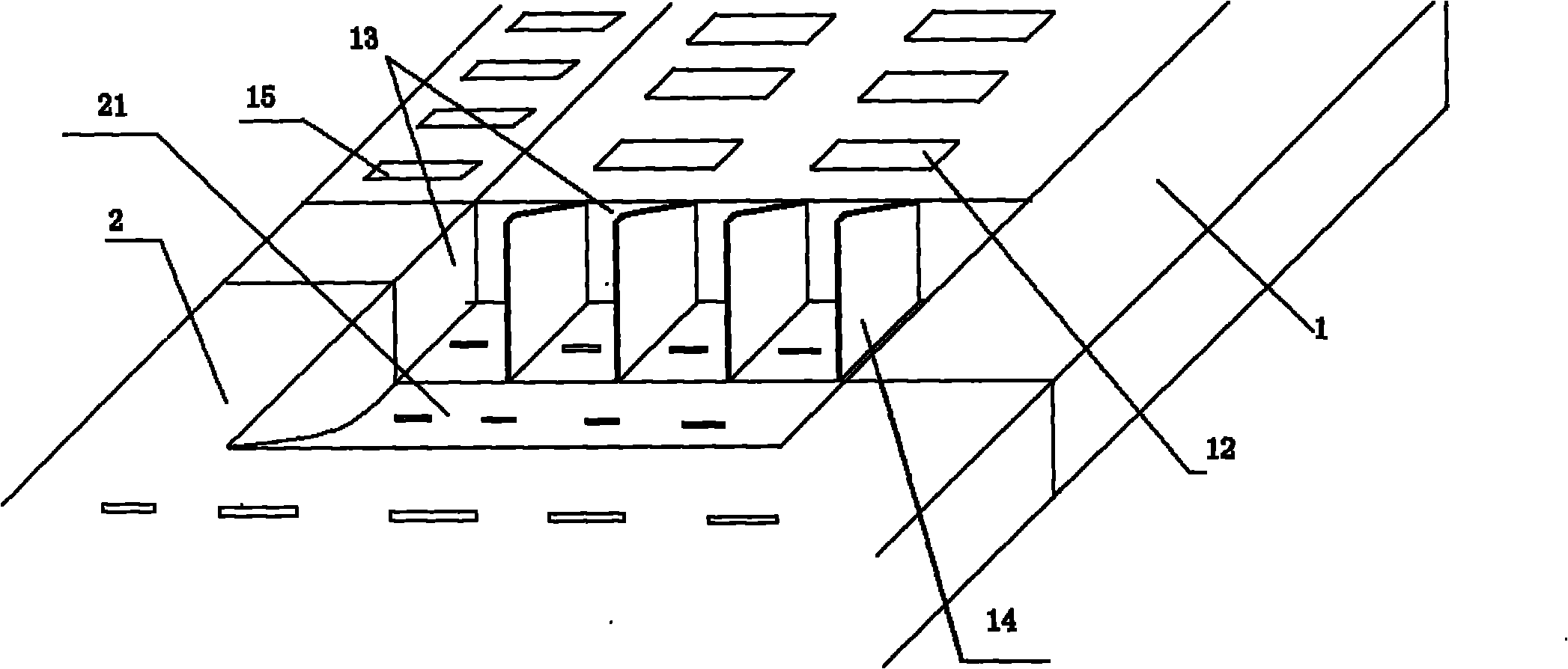

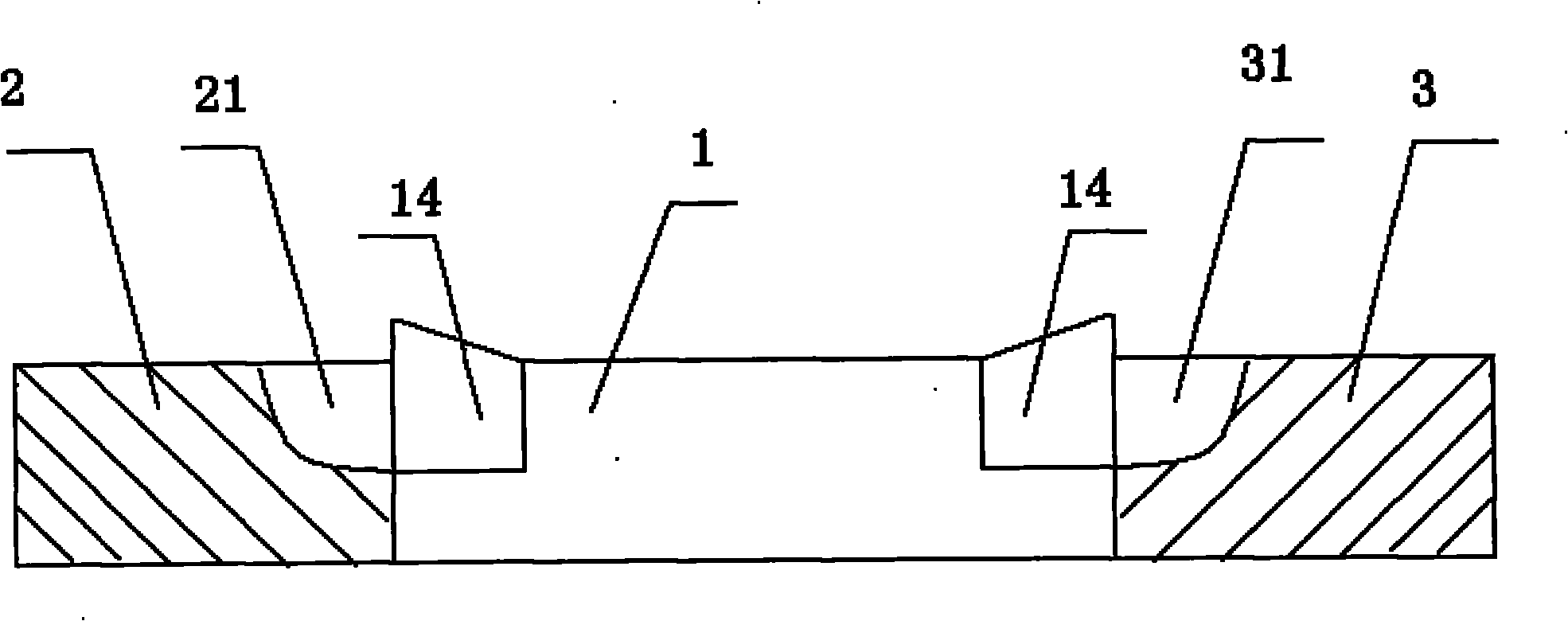

[0022] Combine below Figure 1 to Figure 4 , To further explain the present invention:

[0023] A dung leakage board structure for a sow farrowing bed includes a sow dung leakage board 1. On the left and right sides of the sow dung leakage board 1, a left piglet dung leakage board 2 and a right piglet dung leakage board 3 are arranged in sequence. The sow manure leakage plate 1, the left piglet manure leakage plate 2 and the right piglet manure leakage plate 3 are provided with manure leakage holes. There are recessed grooves 13 and recessed grooves 13 on both sides of the sow manure leakage plate 1. A plurality of partitions 14 are arranged in the middle, and the plurality of partitions 14 can separate each piglet to prevent the piglets from pushing each other when they eat. The space between any two partitions 14 is the area where the sow’s nipple is placed; arc-shaped recessed areas 21, 31 are provided on the left piglet manure leakage plate 2 and / or the right piglet manure l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com