Elastic shape memory material with repeated self-repairing function and preparation method thereof

A memory material and self-healing technology, applied in the field of shape memory materials, can solve the problems that shape memory materials are difficult to achieve rapid self-healing, limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

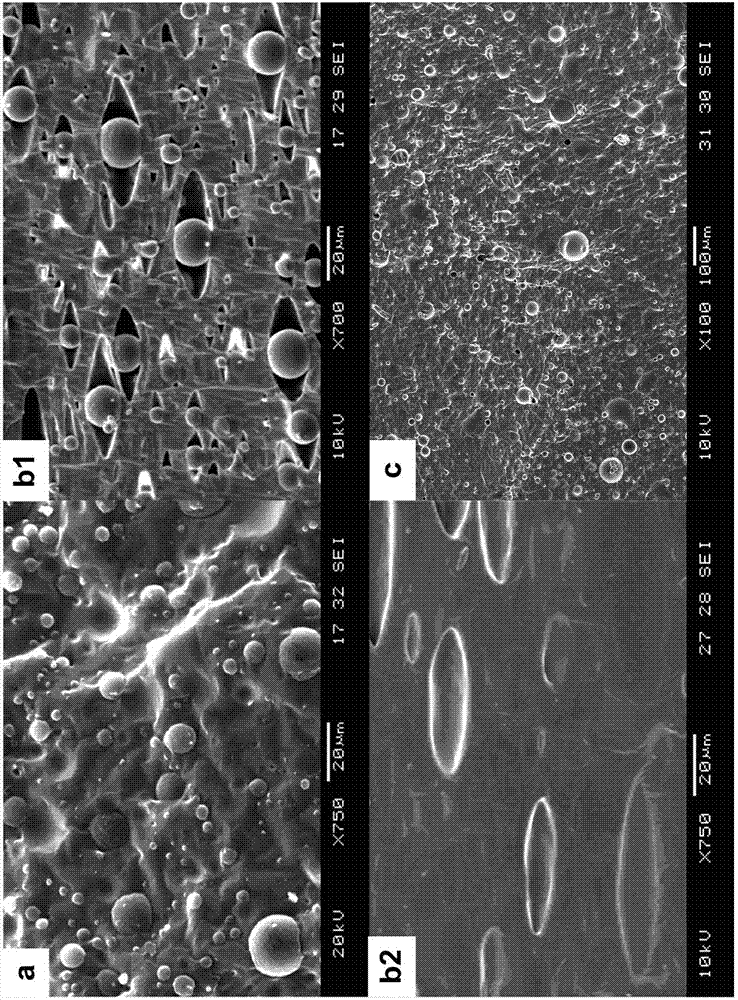

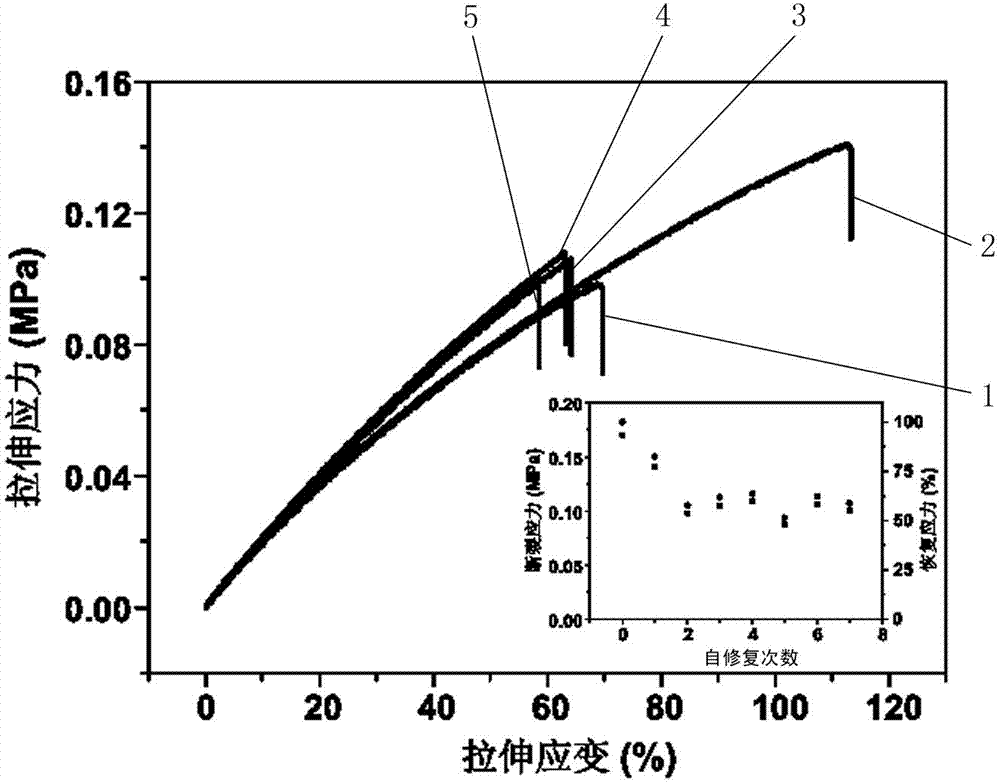

Embodiment 1

[0033] The elastic shape memory material with multiple fast self-repairing functions of the present invention selects 40 parts of hot melt adhesive based on ethylene-vinyl acetate according to the volume fraction, and silicone rubber composed of a two-component elastomer and a curing agent 60 parts, the method for preparing the present invention: (a), first cut the purchased hot-melt glue stick into small pieces, and mix the hot-melt glue piece with the purchased liquid silicone rubber elastomer in a container according to the proportion; (b) 1. Heat the above mixture to above the melting point of the hot melt adhesive (50°C) (70°C ~ 100°C), stir well until there are no particles visible to the naked eye in the mixture; (c), drop the mixture obtained in step (b) to room temperature for 20 After ℃ ~ 24 ℃, mix and cure according to the mass ratio of silicone rubber elastomer and curing agent of 10:1, and stir it evenly again; (d), pour the fully mixed mixture into the mold, and p...

Embodiment 2

[0035] Select 15 parts of hot melt adhesive based on ethylene-vinyl acetate by volume, 85 parts of silicone rubber composed of two-component elastomer and curing agent, and the mass ratio of silicone rubber elastomer to curing agent is 5. : 0.5 ratio of mixing and curing, at 100 ℃, after curing for 1 hour, the desired finished product can be obtained. Others are the same as in Embodiment 1, and will not be repeated.

Embodiment 3

[0037] Select 20 parts of hot melt adhesive based on ethylene-vinyl acetate by volume, 80 parts of silicone rubber composed of two-component elastomer and curing agent, and the mass ratio of silicone rubber elastomer to curing agent is 15. : The ratio of 1.5 is mixed and solidified, and the others are the same as in Example 1, and will not be repeated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com