Brake control valve for fast railway freight cars and method of operation thereof

A technology for brake control and railway wagons, which is applied in the direction of control valves and air release valves, brakes, brake components, etc., and can solve problems such as long boosting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is to provide a brake control valve for fast railway wagons that shortens the braking idling time to shorten the braking distance and the working method of the brake control valve. Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

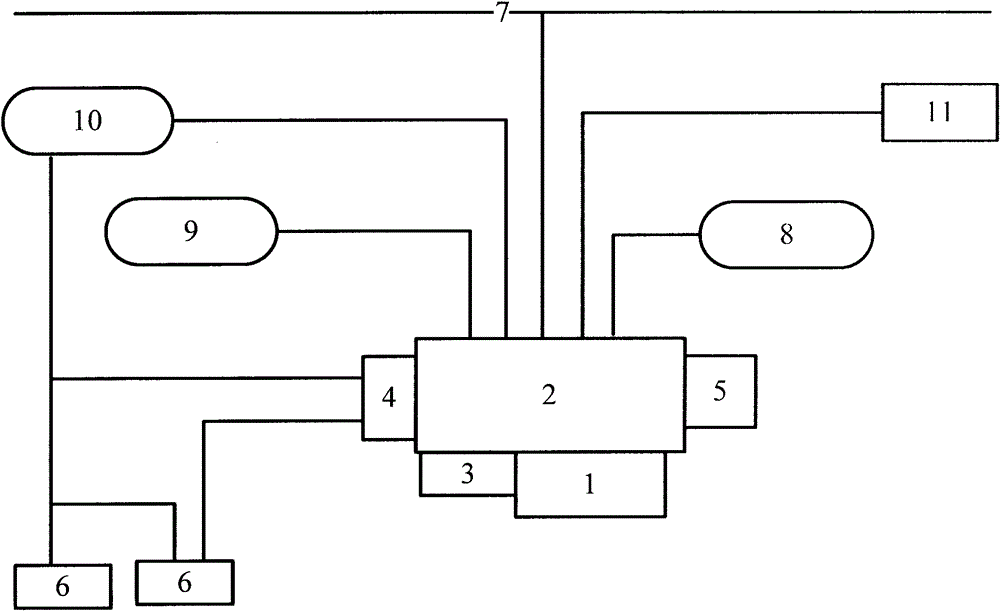

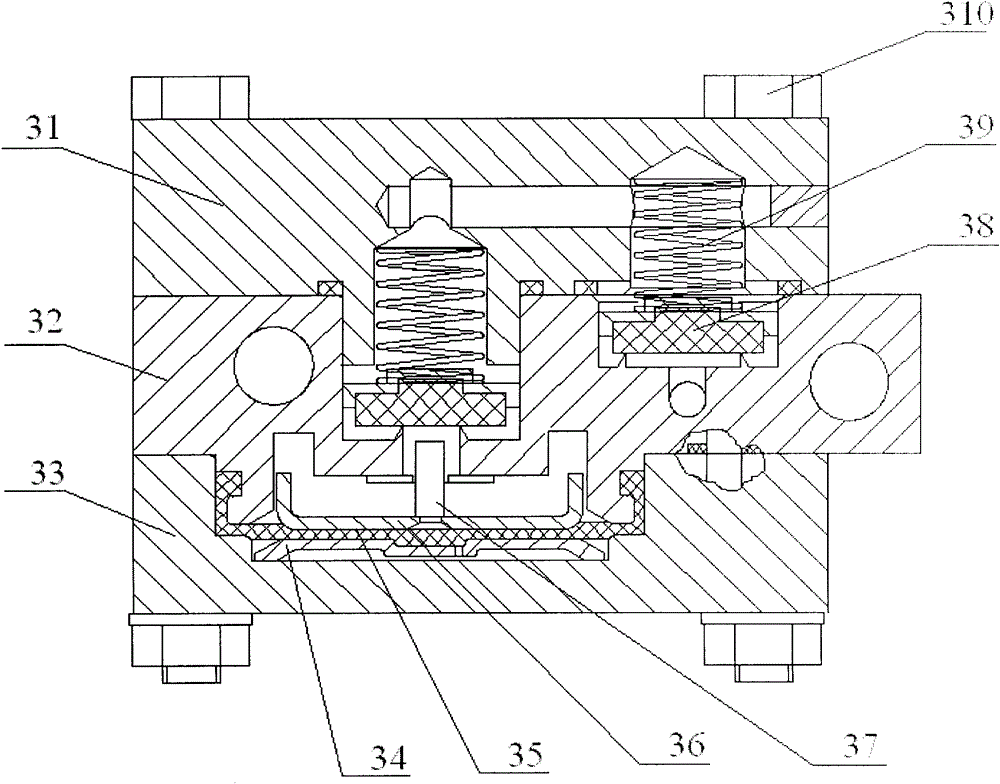

[0027] figure 1 Shown in is the schematic diagram of the connecting structure of the air brake of the express railway wagon of the present invention. The fast railway freight car brake shown in the figure includes a control valve main valve 1 , an intermediate body 2 connected with the main valve 1 , and an air charging valve 3 connected with the intermediate body 2 . The average valve 4 and the regulating valve 5 for adjusting the brake cylinder pressure are both communicated with the main valve 1 through the intermediate body 2, and the intermediate body 2 is also communicated with the air cylinder assembly and the train pipe 7, so The aver...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap