Inner filling type corn seed-metering device

A kind of technology of inner filling and metering device, which is applied in the direction of seeder parts, etc., can solve the problems of double or multiple seeds, reduce the rate of voids, reduce the rate of double or multiple seeds, etc., and achieve the reduction of double or multiple seeds The effect of grain rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

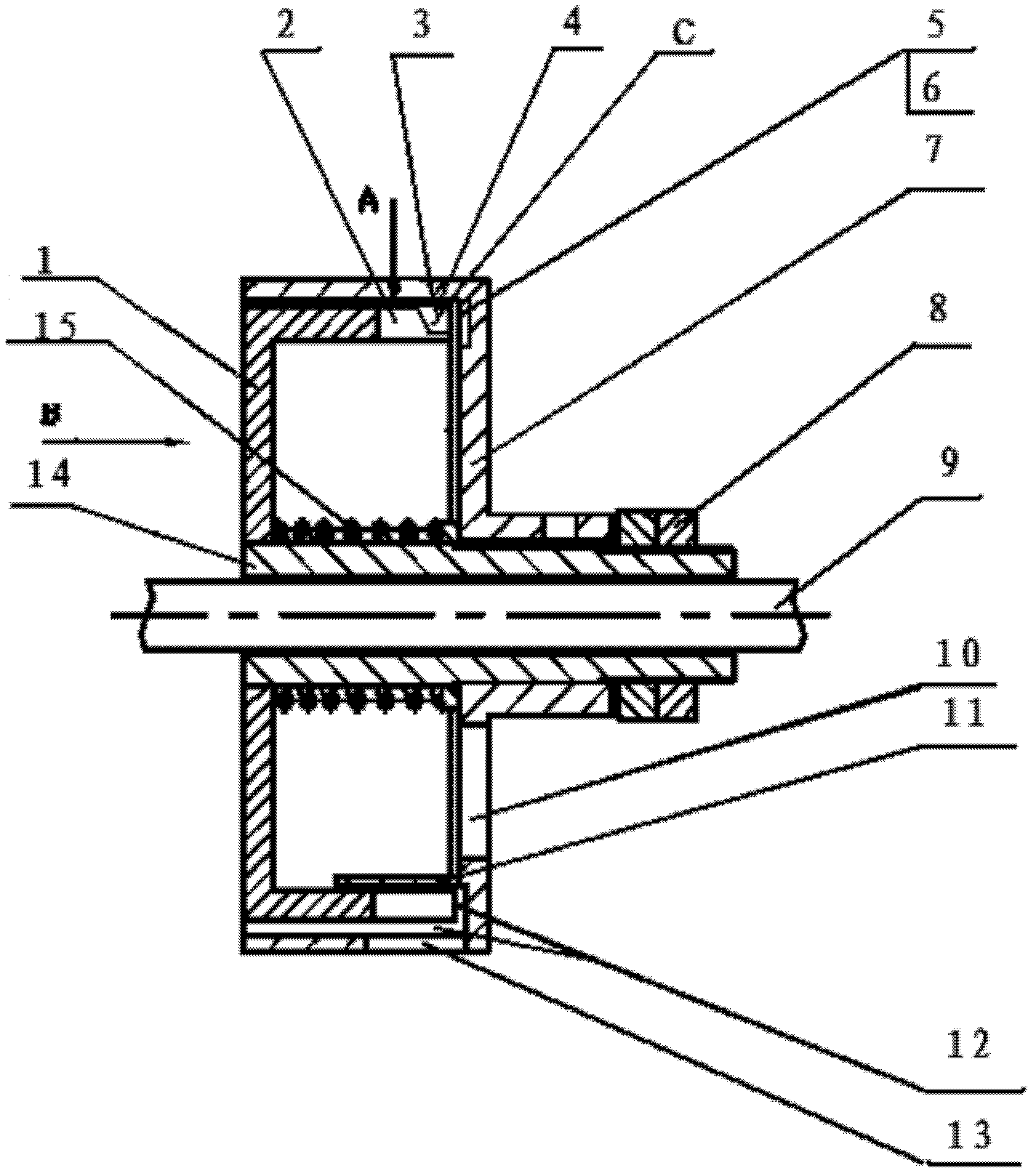

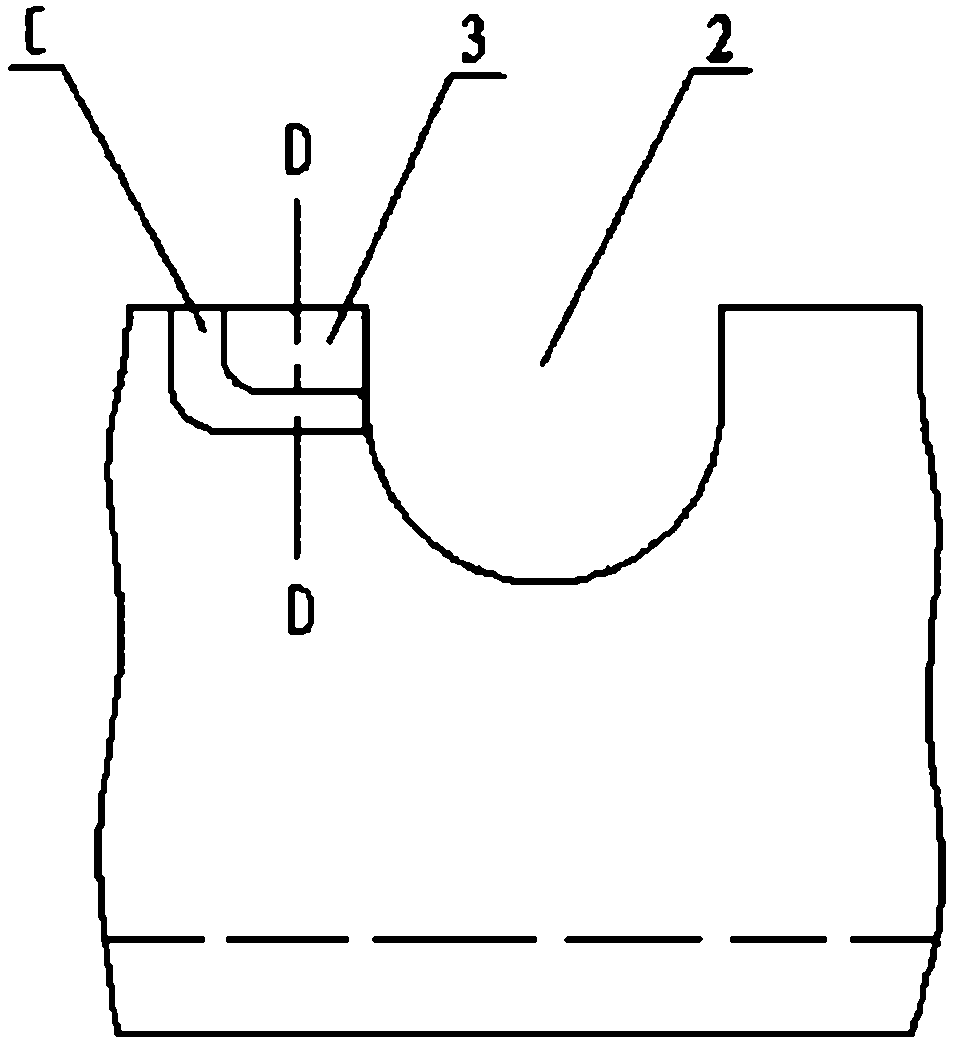

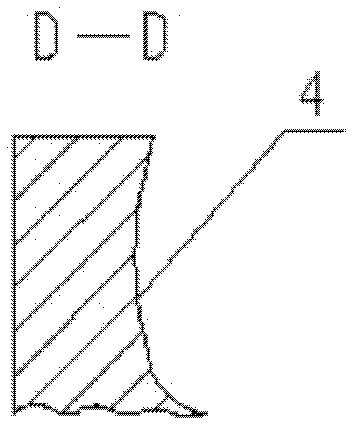

[0017] The inner-filled corn metering device is composed of a housing 7, a seeding wheel 1, a seeding wheel shaft 14, a seeding square shaft 9, an inner seed protection plate 11, a spring 15 and an adjustment nut 8, and the seeding wheel shaft 14 is set In the central hole of the housing 7, the seeding wheel shaft 14 is slidingly fitted with the central hole of the housing 7; the seeding square shaft 9 is installed in the square hole of the seeding wheel shaft 14, and the adjusting nut 8 and the spring 15 are fixed on the seeding On the wheel shaft rod 14; the inner seed protection plate is contained on the inner side wall of the housing 7, and the side wall of the housing 7 has a seed inlet 10 communicated with the seed box, and a seed injection port is also arranged on the cylindrical surface of the housing 13. There are lateral and radial seed unloading grooves 12 on the inner surface and the inner cylindrical surface of the seed injection port of the housing respectively, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com