Automobile air bag fixing and reinforcing structure

A technology of fixing reinforcement and airbags, applied in vehicle components, vehicle safety arrangements, pedestrian/occupant safety arrangements, etc., can solve the problems of inconvenient installation, high temperature performance not as good as metal, and high cost, and achieve convenient installation, stable high and low temperature performance, and structure. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, according to the accompanying drawings, preferred embodiments of the present invention are given and described in detail, so that the functions and features of the present invention can be better understood.

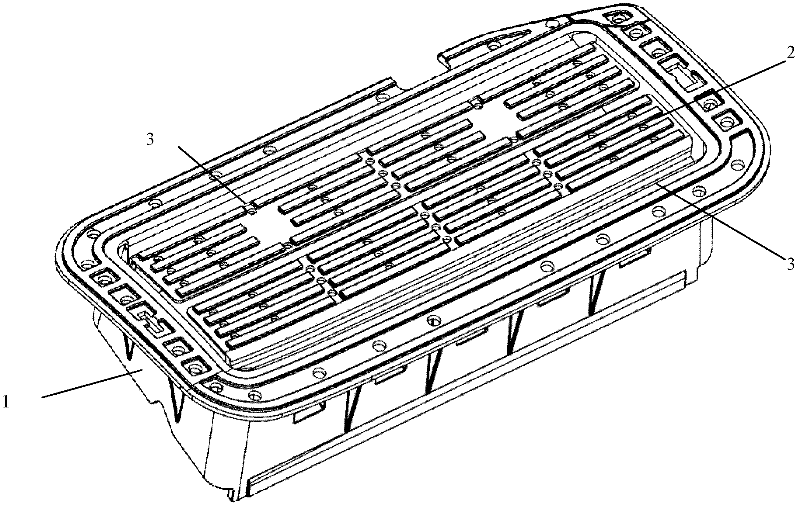

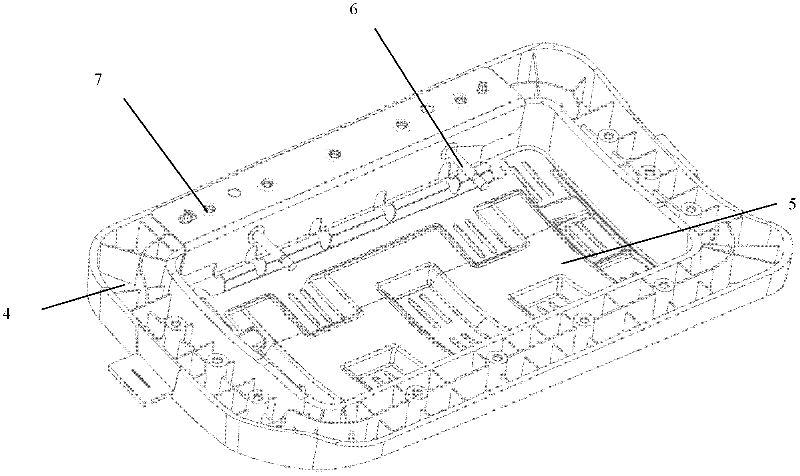

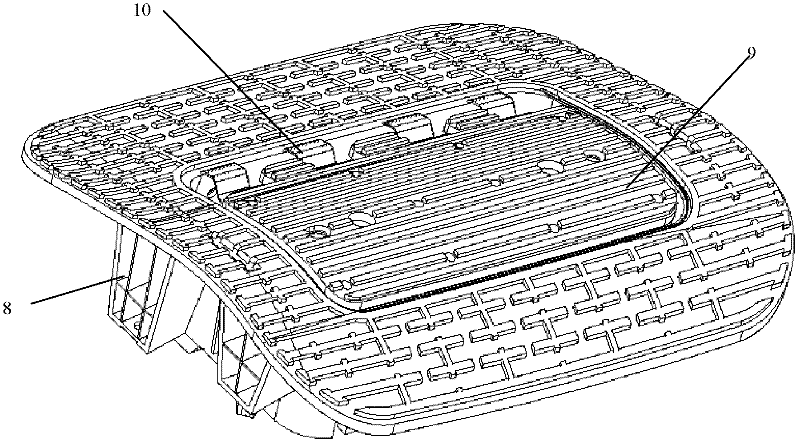

[0023] Figure 3-Figure 5 A fixing reinforcement structure of an automobile airbag constructed according to a preferred aspect of the present invention is shown. Such as image 3 As shown, the fixed reinforcement structure of the automobile airbag includes an airbag reinforcement frame 8, an airbag door 9 and an airbag hinge 10, and these three are integrally formed by insert injection molding, wherein the structures of the airbag reinforcement frame 8 and the airbag door 9 are the same as those of the existing Airbag reinforcement frame 1 and airbag door 2 in the technology (see attached figure 1 ) structure is substantially the same, the difference is that the airbag reinforcement frame 8 and the airbag door 9 are made of filled and toughened polypropyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com