A c-band coupler with shielded wire

A shielded wire, C-band technology, used in waveguide-type devices, electrical components, connecting devices, etc., can solve the problems of unstable high and low temperature performance, narrow operating bandwidth, and poor consistency in mass production, and achieve stable high and low temperature performance. Working frequency bandwidth, the effect of solving large interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following describes the present invention in further detail with reference to the accompanying drawings and specific embodiments, without limiting the scope of implementation of the present invention.

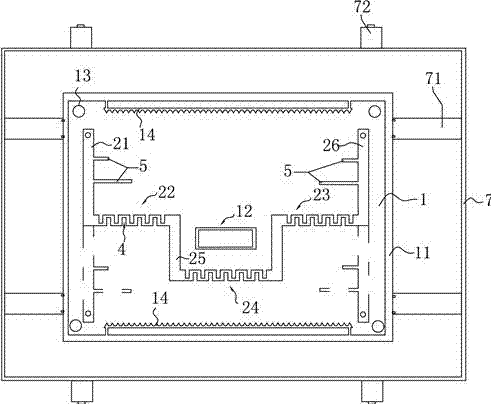

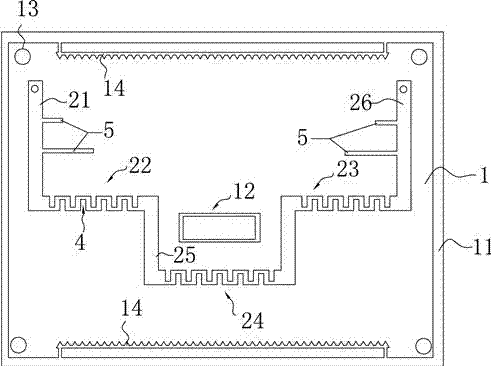

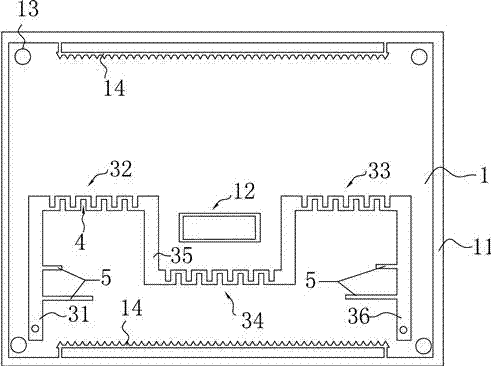

[0025] Such as Figure 1 to Figure 5 As shown, the C-band coupler with shielded wire described in this embodiment includes a metal shell 7, an insulating bridge 71 arranged in the metal shell 7, and a PCB board 1 arranged on the insulating bridge; The front side of the PCB board 1 is provided with a first input section 21 and a second input section 26. One end of the first input section 21 laterally extends to the side of the second input section 26 with a first coupling section 22, and the second input section A second coupling section 23 extends laterally from one end of the section 26 to the side of the first input section 21; the free ends of the first coupling section 22 and the second coupling section 23 respectively extend downwardly with a first connecting secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com