Printer calibration method and device used for color management

A technology of color management and calibration methods, applied in printing devices, printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

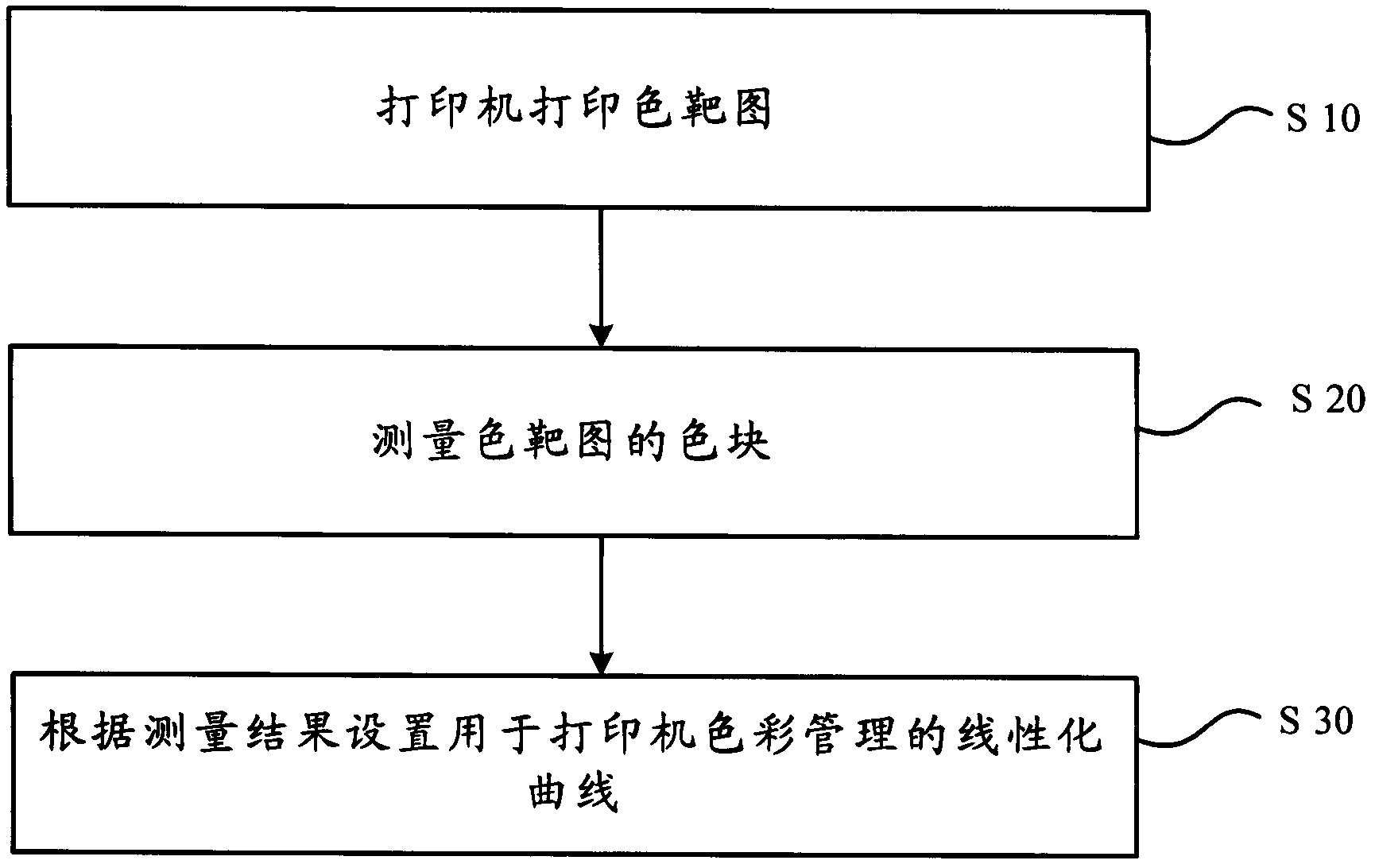

[0018] figure 1 A flowchart showing a printer calibration method for color management according to an embodiment of the present invention, including:

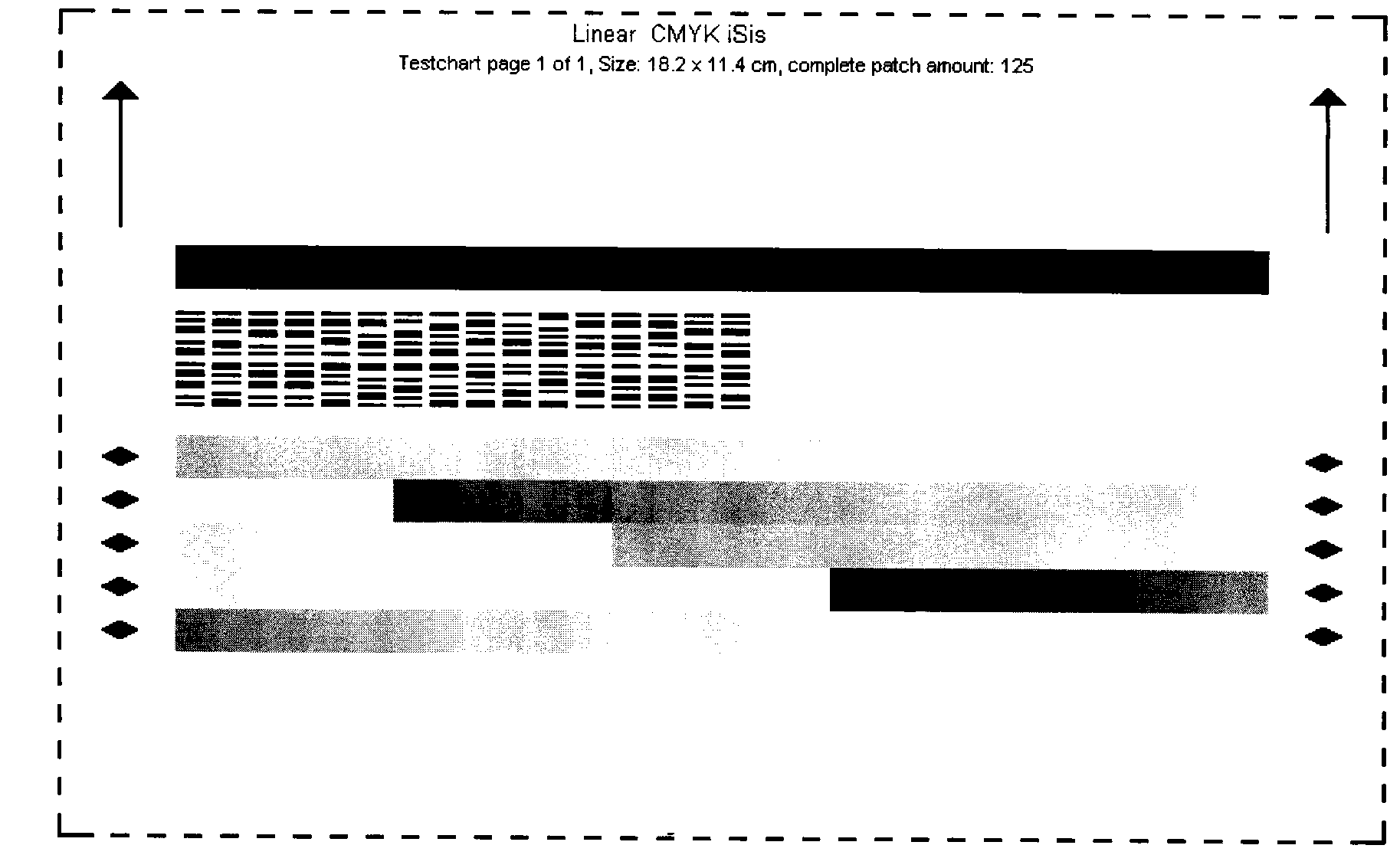

[0019] Step S10, the printer prints the color target map;

[0020] Step S20, measuring the color blocks of the color target diagram;

[0021] Step S30, setting a linearization curve for color management of the printer according to the measurement result.

[0022] This method is based on a one-dimensional method, and adjusts the curves of each color surface of the printer individually, that is, the linearization curve, which solves the problem of calibrating equipment levels and grading, and can ensure that the calibrated equipment meets the printing standards, so as to achieve the final equipment calibration. Purpose.

[0023] Preferably, the linearization curve of the set device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com