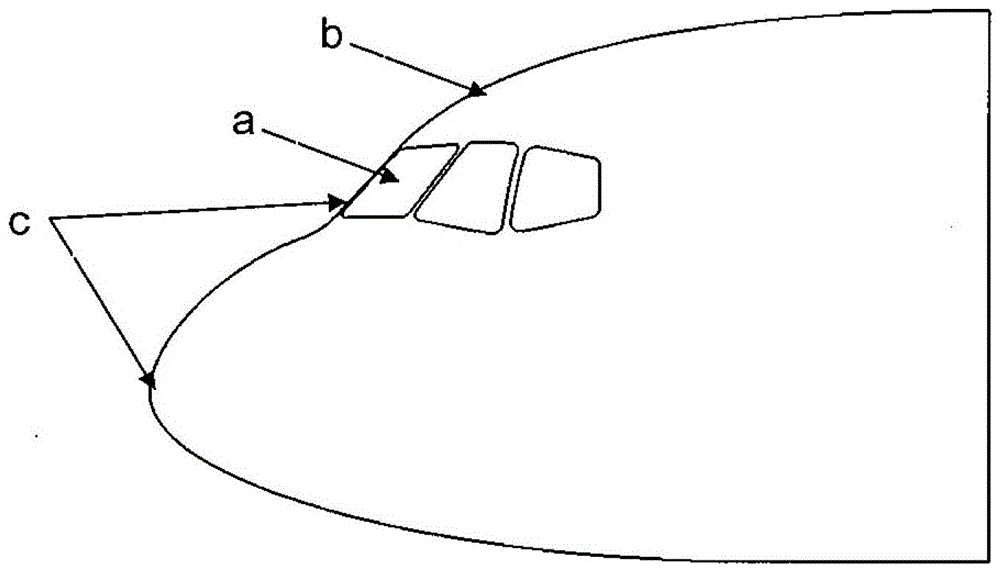

Integrated Design Method of Single Windshield Head

A design method and nose technology, applied in computing, fuselage, aircraft parts, etc., can solve problems such as large aerodynamic resistance, poor flow characteristics at the windshield, and poor transition surface quality, so as to reduce fuel consumption, improve aerodynamic characteristics and flow High-order continuous effect of quality and curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] As required, specific embodiments of the invention will be disclosed herein. However, it should be understood that the embodiments disclosed herein are merely typical examples of the invention, which can be embodied in various forms. Therefore, specific details disclosed herein are not to be considered limiting, but merely as a basis for the claims and as a representative basis for teaching one skilled in the art to variously employ the invention in any appropriate way in practice, This includes taking various features disclosed herein and combining features that may not be expressly disclosed herein.

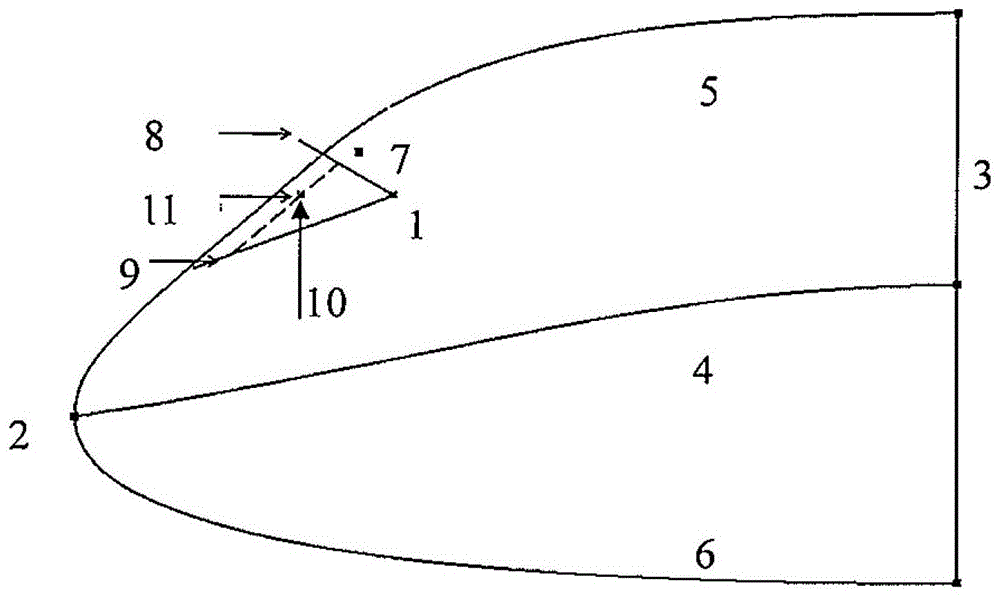

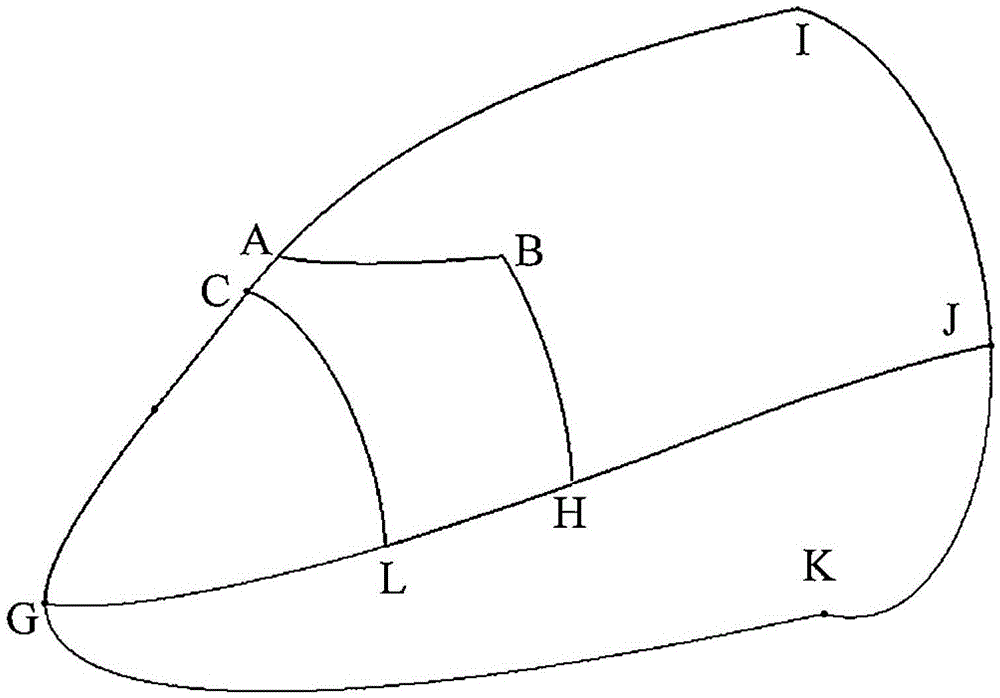

[0041] According to a preferred embodiment of the present invention, the single-curved windshield nose integrated design method includes the following steps:

[0042] 1.0. Extract Catia forming parameters according to the design constraints of the machine head;

[0043] 2.0. Establish a parametric surface model of the machine head, and the surface generation sequence is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com