Conveying device of dispensing machine

A technology of conveying device and dispensing machine, which is applied to the device and coating of surface coating liquid, which can solve the problems of working hours error, easy production of products, manual transportation of dispensing machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

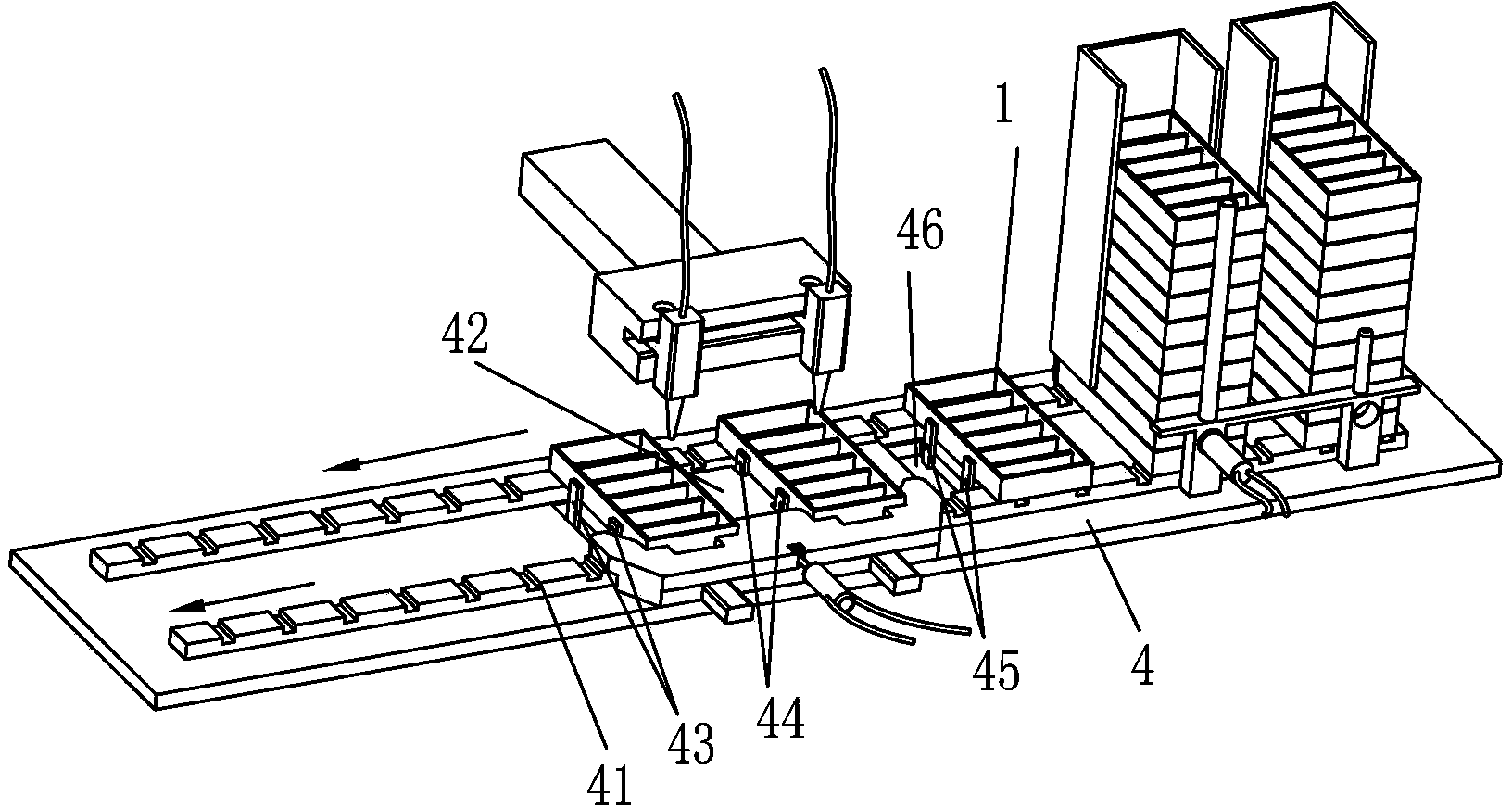

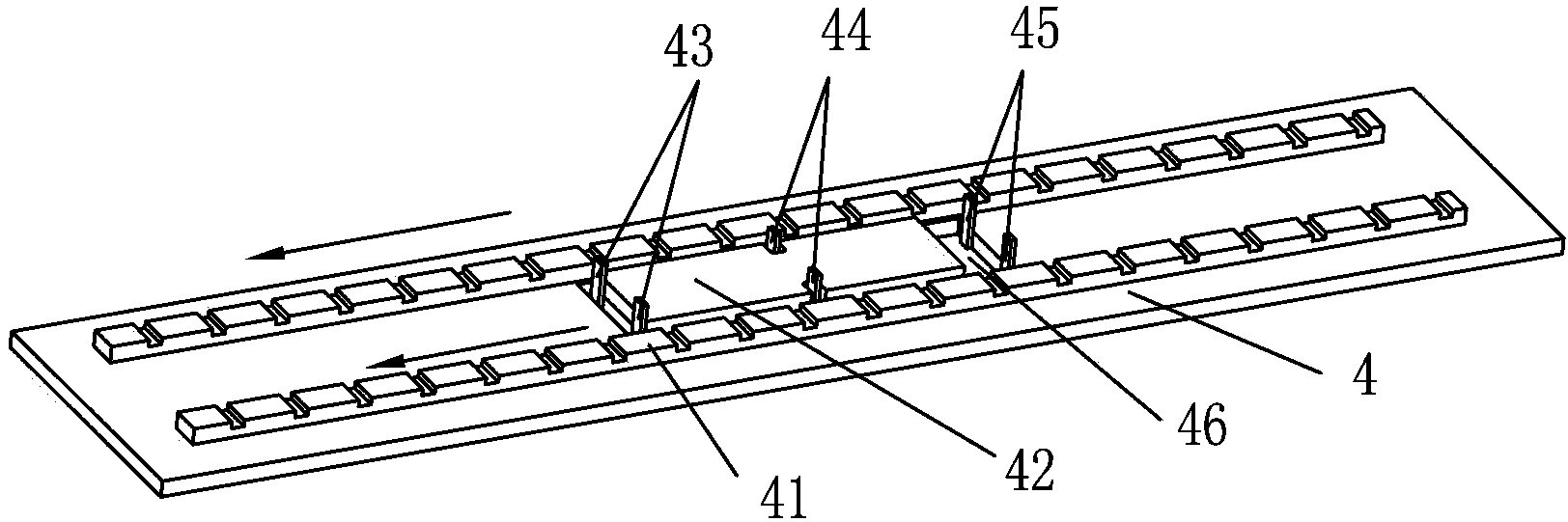

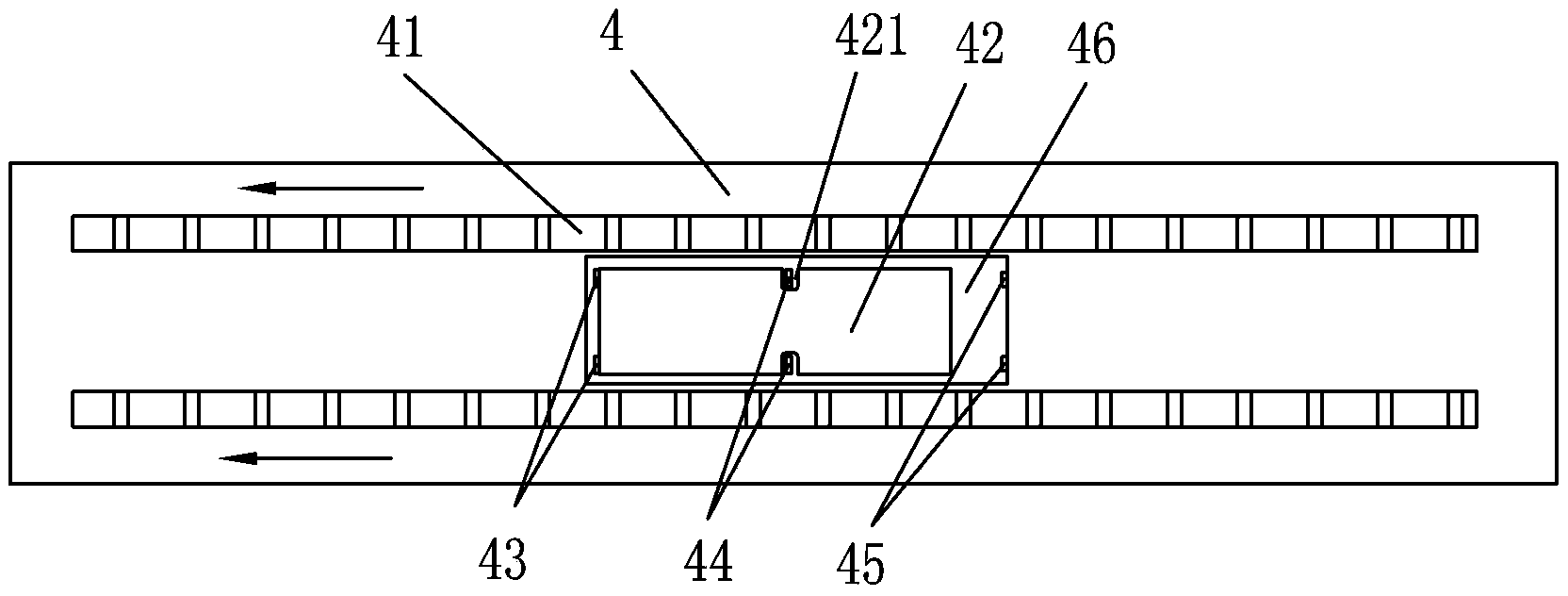

[0014] Such as Figure 1 to Figure 4 As shown, the feed device of the dispenser is located on the far right side of the dispenser. In order to improve work efficiency, the feed device is provided with two material storage boxes. The battery cover 1 falls onto the conveyor belt 41 through the feed device, and the transmission The belt 41 is two crawlers moving in parallel, and the direction of movement is from right to left, as shown by the arrow in the figure, the middle position of the transfer platform 4 is provided with a cavity 46 directly below the dispensing head of the glue dispenser. 46 is rectangular, and a top plate 42 is installed in the cavity 46. A cylinder B422 is connected to the bottom of the top plate 42. The cylinder B422 can push the top plate 42 to reciprocate up and down. The upper end surface, when the top plate is jacked up...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap