Dispenser streamline production equipment

A technology of production equipment and assembly line, which is applied to the device and coating of surface coating liquid, which can solve the problems of deviation of station placement and inaccurate connection of process time and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

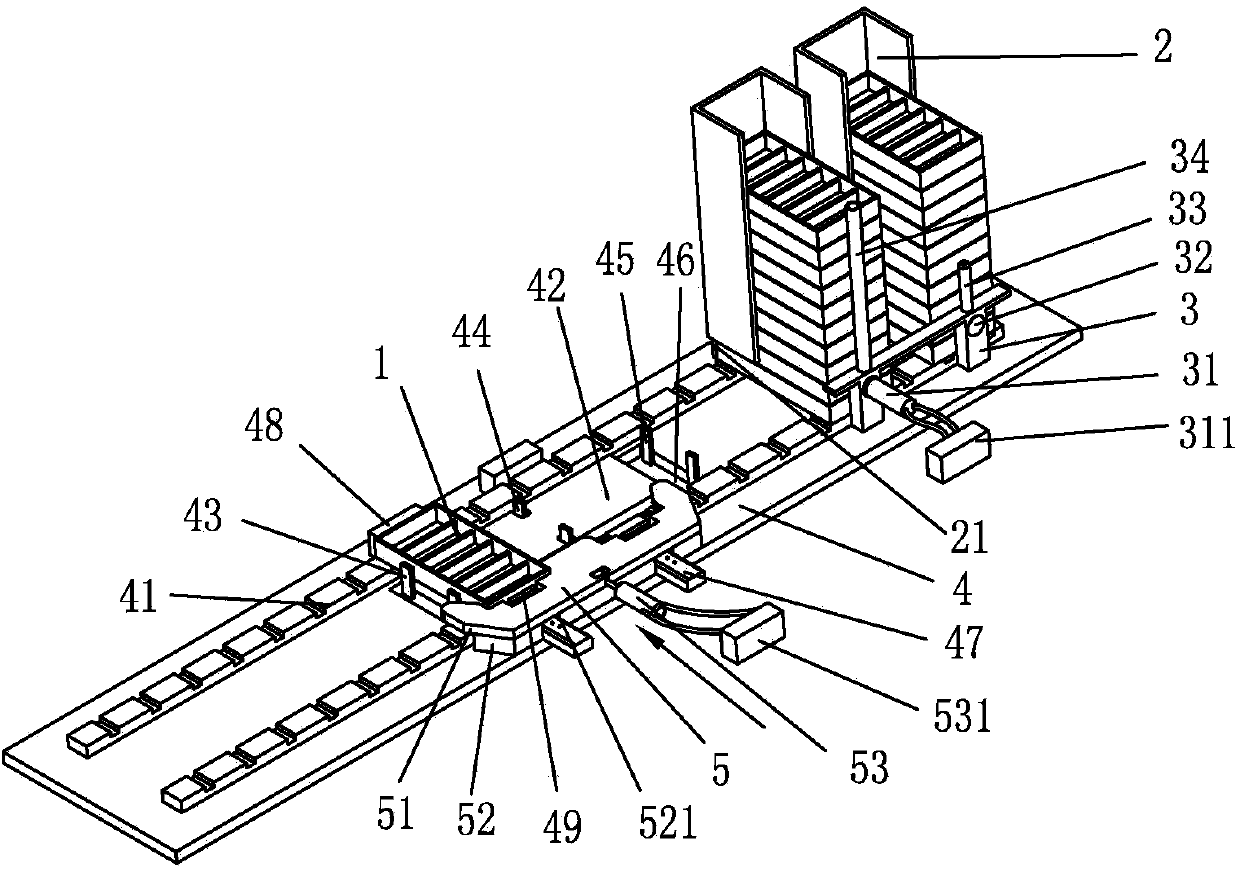

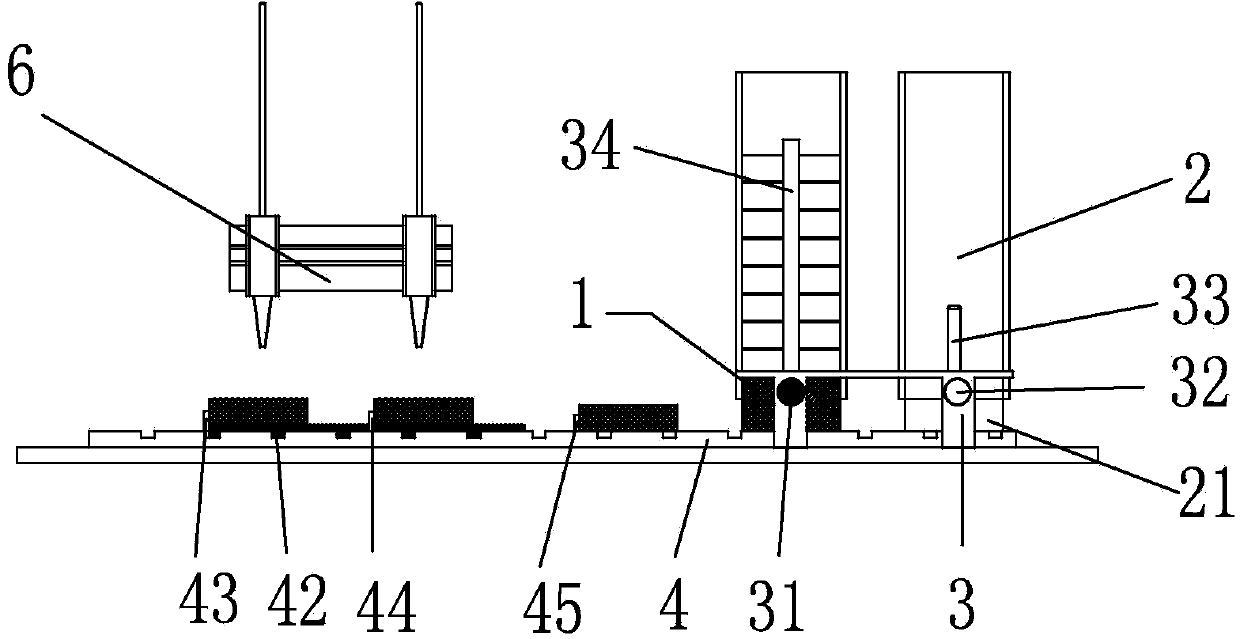

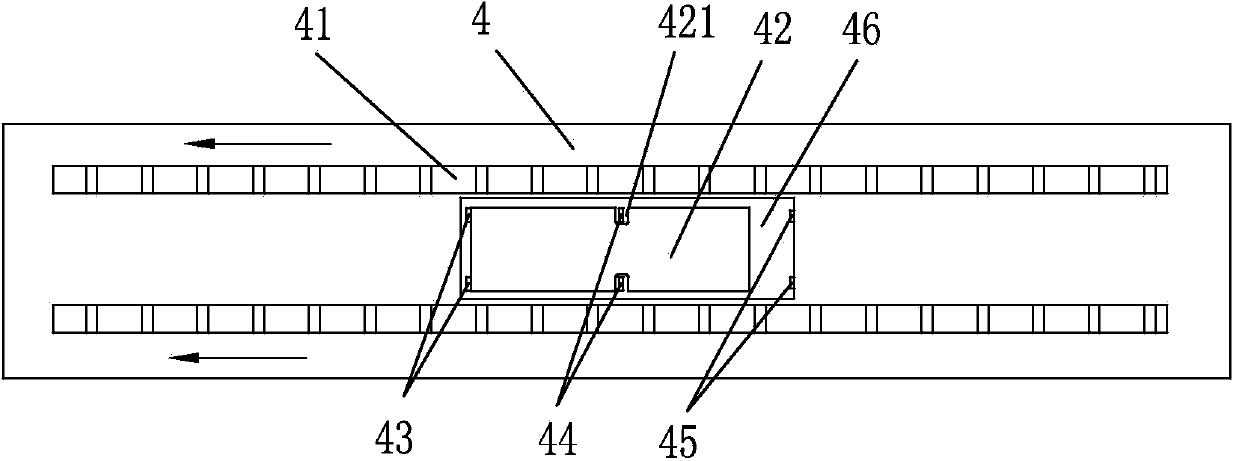

[0023] Such as figure 1 Shown is the overall three-dimensional diagram of this set of assembly line production equipment, figure 2 , image 3 , Figure 4 Corresponding to the feeding process, conveying process, and clamping process, the feeding point of this dispenser is located on the far right side of the dispenser. In order to improve work efficiency, the feeding point is equipped with 2 material storage boxes. The section of frame 2 is a half rectangle, which is semi-open. The inner wall of the rectangle just matches the outline of the battery cover 1. The battery cover 1 is stacked in the storage frame 2 from top to bottom. The bottom of the storage frame 2 is not sealed. Between the bottom of the material frame 2 and the transmission platform 4, a backstop material 21 is arranged. The backstop material 21 is a plate-shaped plane, and the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap