elastic flat comb

A technology of elasticity and combing needles, which is applied in the field of hair combs, can solve problems such as the lack of elasticity of the combing needles of hair combs, and achieve the effects of saving raw materials, simplifying production and assembly steps, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

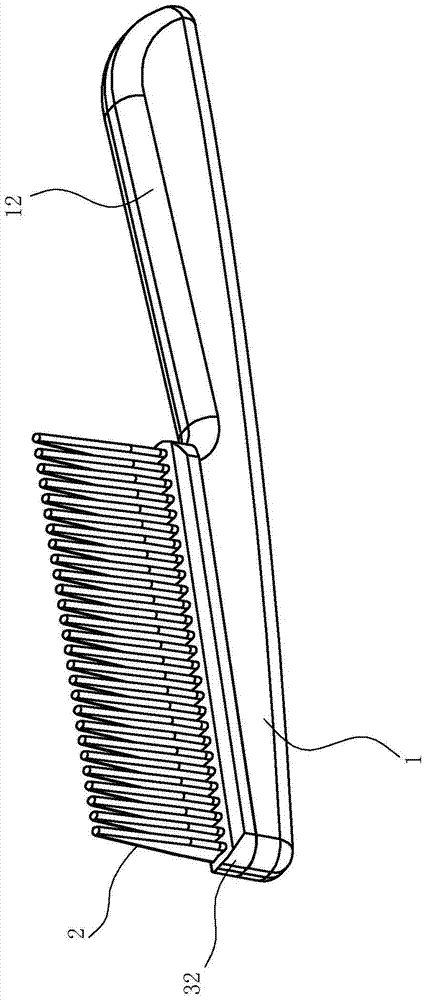

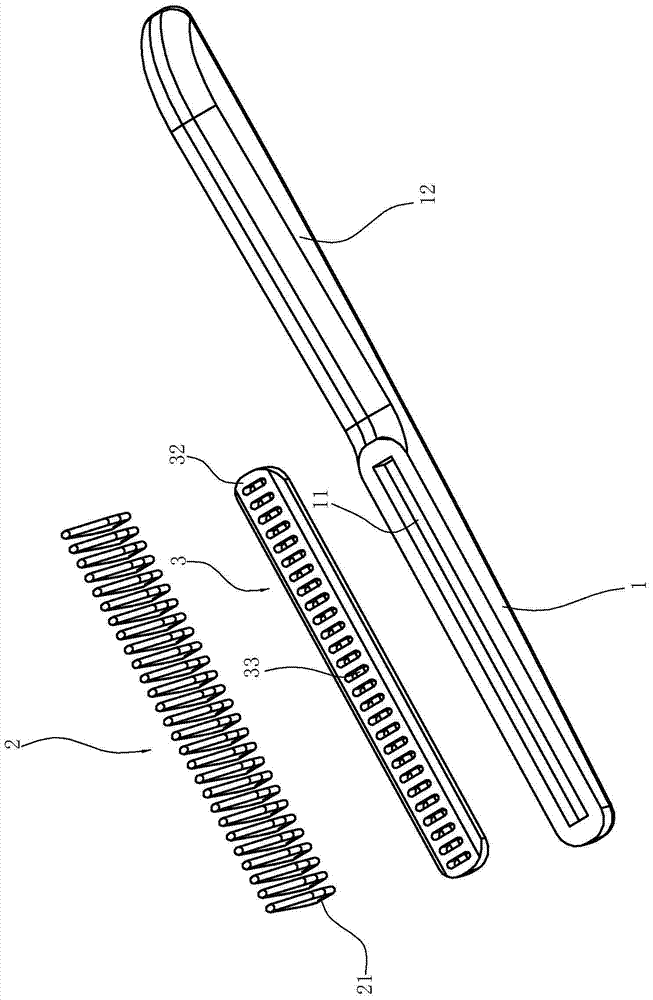

[0021] Such as Figure 1 to Figure 4 As shown, the elastic flat comb includes:

[0022] The base plate 1 is made of wood material or other materials, and the tail end of the base plate is extended to form a handle 12 for the operator to hold. A groove 11 is provided on the surface of the base plate 1 connected with the connecting base 3 . In this embodiment, the groove 11 is rectangular.

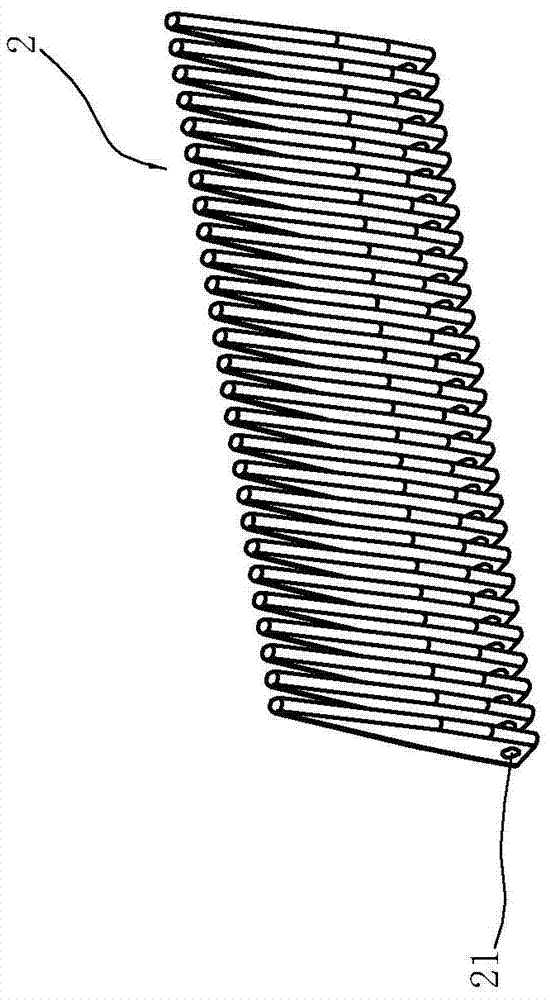

[0023] Combing needles 2, and each combing needle 2 is an independent single structure, and the root of each combing needle is provided with a through hole 21. In this embodiment, each combing needle 2 is a flat plate structure, and the root of each combing needle is roughly rectangular , the remaining part is roughly triangular, and the end of the comb needle is a smooth round head, and the width of the base of the comb needle is greater than the width of the comb needle exposed to the connecting seat.

[0024] The connection seat 3 is made of silica gel material, and includes a base 32 ...

Embodiment 2

[0031] Such as Figure 5 As shown, the elastic flat comb includes:

[0032] The base plate 4 is made of wood material or other materials, and the tail end of the base plate is extended to form a handle 42 for the operator to hold. A groove 41 is formed on the surface of the base plate 4 connected with the connecting base 6 . In this embodiment, the groove 41 is rectangular.

[0033] Combing needles 5, and each combing needle 5 is an independent single structure, and the root of each combing needle is provided with a through hole 51. In the present embodiment, each combing needle 5 is a flat plate structure, and the root of each combing needle is roughly rectangular , the remaining part is roughly triangular, and the end of the comb needle is a smooth round head, and the width of the base of the comb needle is greater than the width of the comb needle exposed to the connecting seat.

[0034] The connecting seat 6 is made of silica gel material, including a base 62 and an ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com