Weight-based feeding machine

A feeding machine and weighing type technology, which is applied in the field of weighing feeding machine, can solve the problems of feed waste, caking feed when the timer runs, unable to accurately control the feeding amount, etc., and achieve the effect of convenient installation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

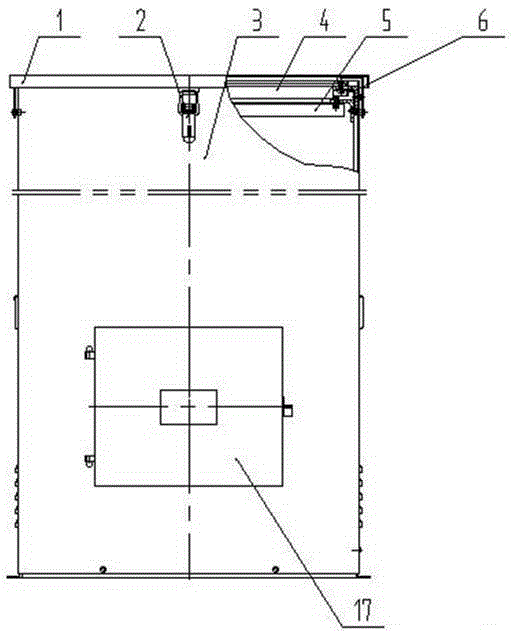

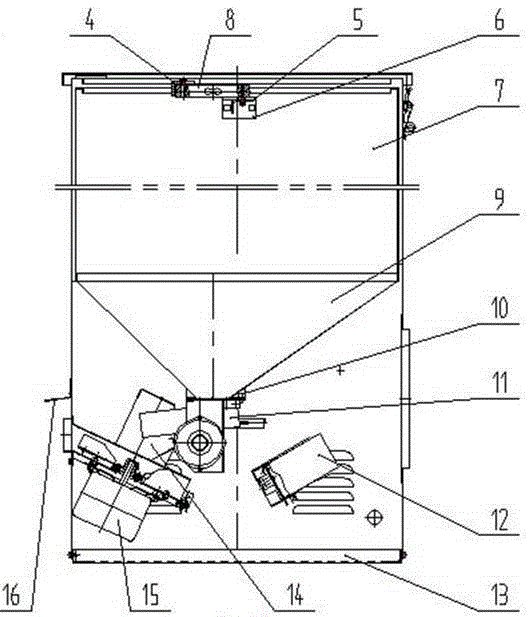

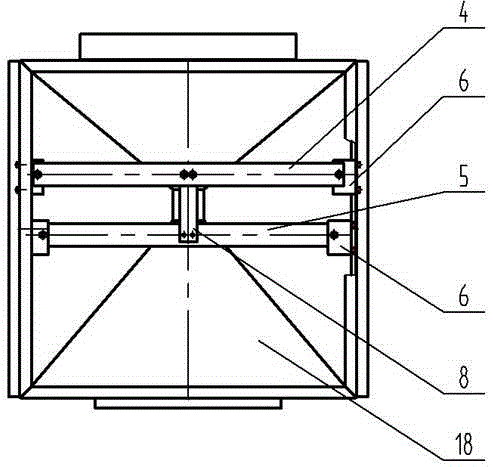

[0014] Such as Figure 1-3 As shown, the gravimetric feeder includes a case cover 1, a case body 3, a weighing hopper 18, a load cell 5, a feeding mechanism 11, and a material throwing mechanism 15, and the case body 3 is installed on the bottom frame 13, and the The box cover 1 is installed on the box body 3 of the door 17, and the locked hasp 2 is installed between the box cover 1 and the box body 3. The fixed beam 4 is fixed in the box body 3 by the supporting angle irons 6 at both ends, and the fixed beam 4 is fixed on the box body 3. Load cell 8 is installed, and the other end of load cell 8 is installed weighing hopper 18, and weighing hopper 18 is positioned at casing 3, and the following of weighing hopper 18 is installed blanking mechanism 11 by mounting plate 10, and the blanking mechanism 11 The hopper 14 is installed below, and the hopper 14 is installed on the throwing mechanism 15, and the throwing mechanism 15 is obliquely installed in the casing 3, and the disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com