Manufacturing method of longitudinal water blocking device for intermediate joint of medium voltage power cable

A technology for power cables and intermediate joints, applied in the direction of connecting/terminating cable equipment, etc., can solve the problem of not having longitudinal water blocking ability, etc., to improve the longitudinal waterproof ability, avoid water reverse osmosis, and improve the longitudinal waterproof ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

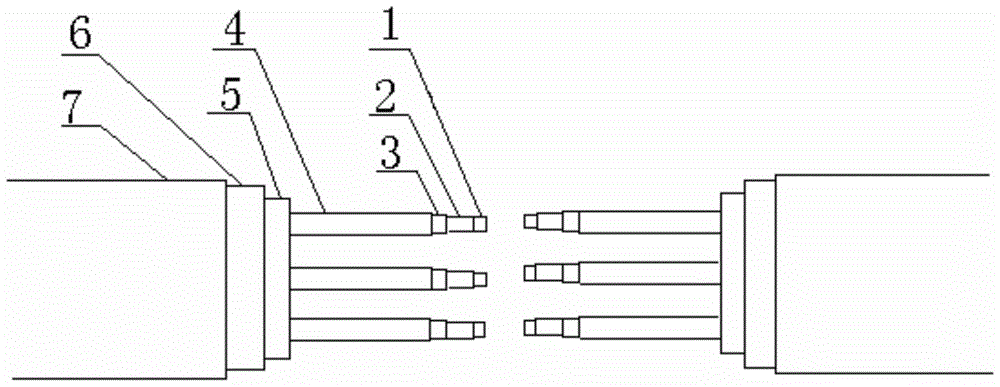

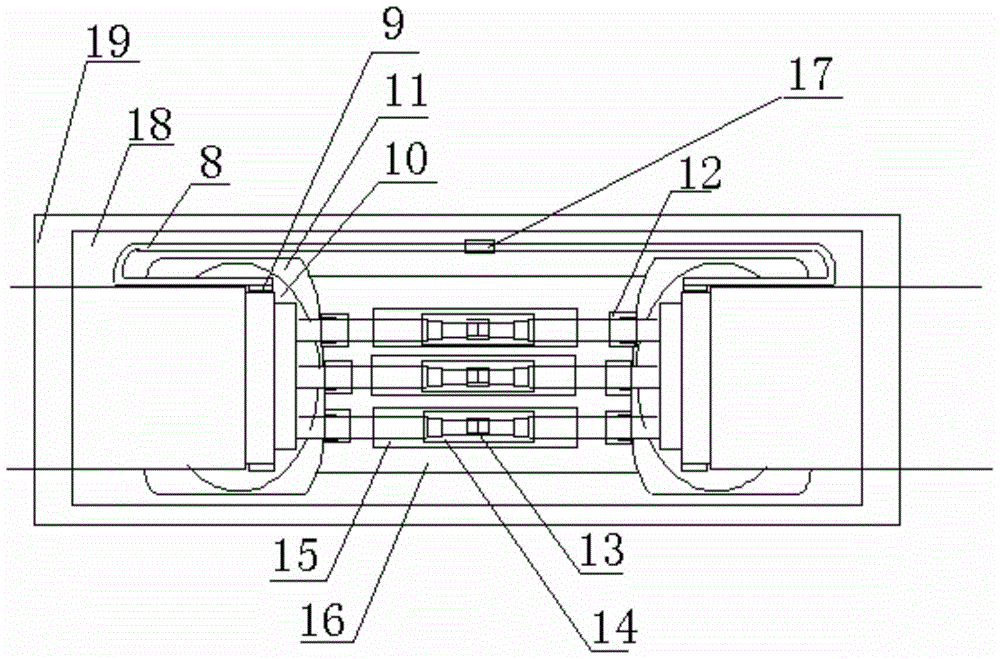

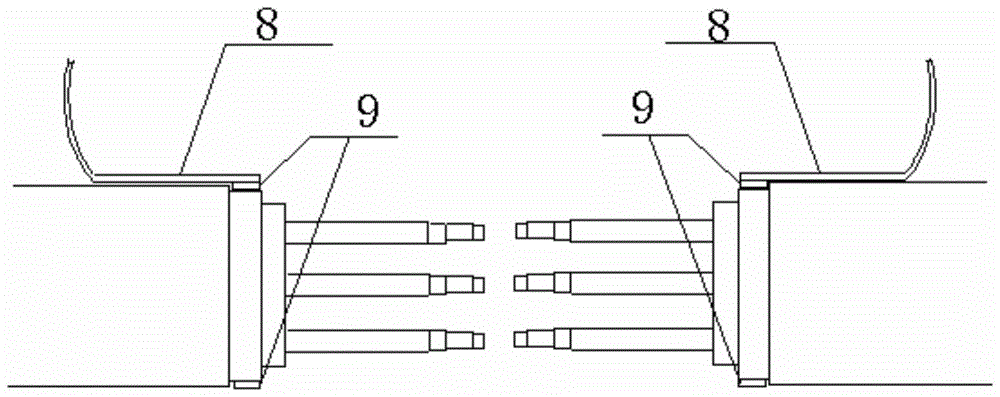

[0025] Specific implementation mode 1. Combination figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 Describe this embodiment, the manufacturing method of the medium-voltage power cable intermediate joint longitudinal water blocking device described in this embodiment, the specific steps of the method are:

[0026] Step 1. Cut the joints of the two cables layer by layer from outside to inside;

[0027] Step 2: Connect the two constant force springs 9 on the outer sides of the armor layers 6 of the two cables respectively, crimp one end of the two copper braids 8 into the two constant force springs 9 respectively, and the two copper braids The other end of band 8 is fixedly connected by crimping sleeve 17;

[0028] Step 3, sealing the inner sheath 5, the armor layer 6 and the constant force spring 9 of the two cables with the two first waterproof sleeves 10 respectively;

[0029] Step 4, put the two second waterproof cases 11 on the outer...

specific Embodiment approach 2

[0038] Specific embodiment 2. This embodiment is a further description of the manufacturing method of the medium-voltage power cable intermediate joint longitudinal water blocking device described in specific embodiment 1. The cable described in step 1 includes three-phase wire cores 1, three One main insulation layer 2, three semi-conductive layers 3, three copper shielding layers 4, inner sheath 5, armor layer 6 and outer sheath 7; three main insulation layers 2 are respectively coaxially coated on three-phase wires The outer side of the core 1; the three semiconductive layers 3 are coaxially coated on the outer sides of the three main insulating layers 2; the three copper shielding layers 4 are coaxially coated on the outer sides of the three semiconductive layers 3; the inner protection Layer 5 is wrapped on the outside of the three copper shielding layers 4 ; the armor layer 6 is wrapped on the outside of the inner sheath 5 .

specific Embodiment approach 3

[0039] Specific Embodiment 3. This embodiment is a further description of the manufacturing method of the medium-voltage power cable intermediate joint longitudinal water blocking device described in Embodiment 1. The first waterproof sleeve 10, the second waterproof sleeve 11 and the finger sleeve 12 Wrapped with waterproof tape to achieve.

[0040] Strip and cut the two ends of the cable to be made into the cable intermediate joint according to the required size ( figure 1 shown), tie the copper braid and the armor layer with a constant force spring or copper wire, and cross the outer sheath, armor layer, and inner sheath with waterproof tape around the breakpoint of the outer sheath and armor layer Repeatedly bypass the gaps between the three-phase cables to form the first waterproof jacket (the first longitudinal water-blocking layer), and then use the cold-shrinkable waterproof second waterproof jacket (the second longitudinal water-blocking layer) to pass through the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com