An underwater concrete pouring pile elevation control device and its application method

A technology for underwater concrete and control devices, which is applied in sheet pile walls, buildings, and foundation structure engineering, etc. It can solve problems such as inability to accurately determine the height of the concrete surface, difficulty in pouring, and short pipe removal, achieving good economic benefits and flexible assembly , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

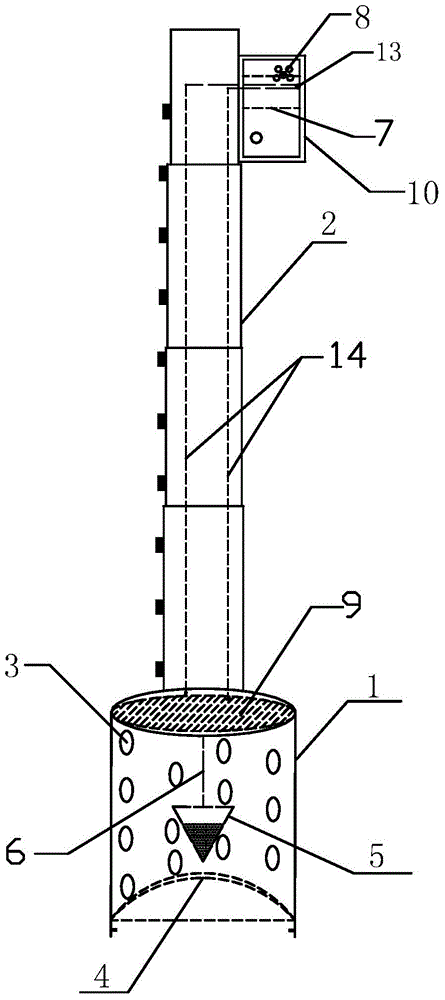

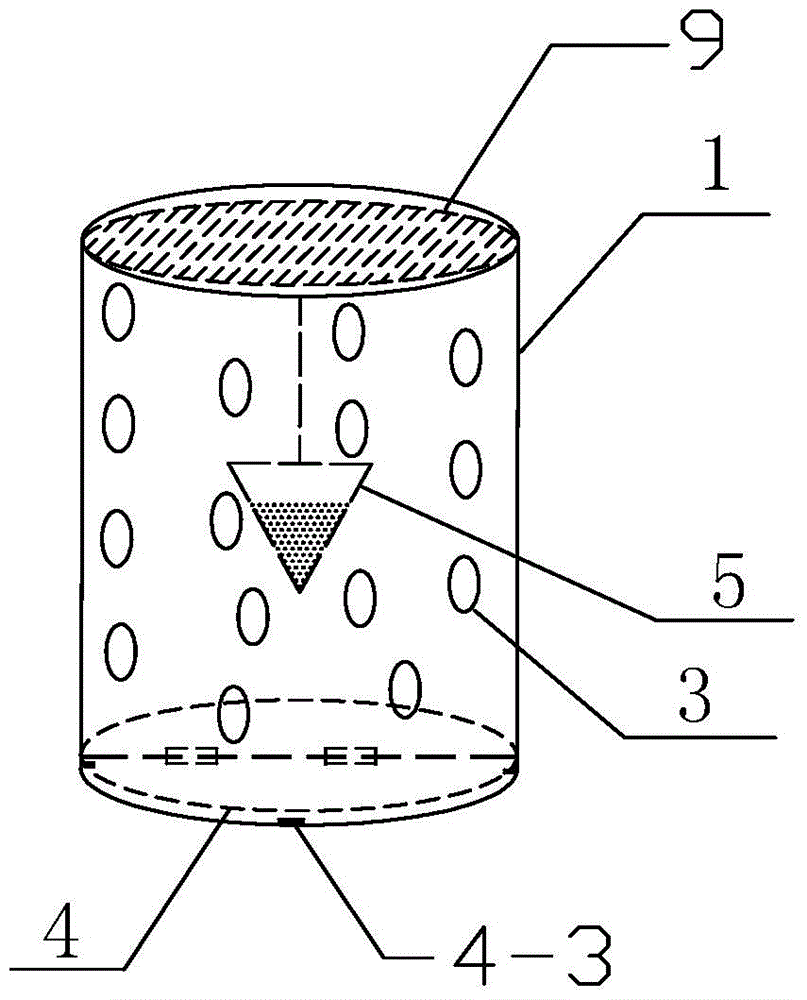

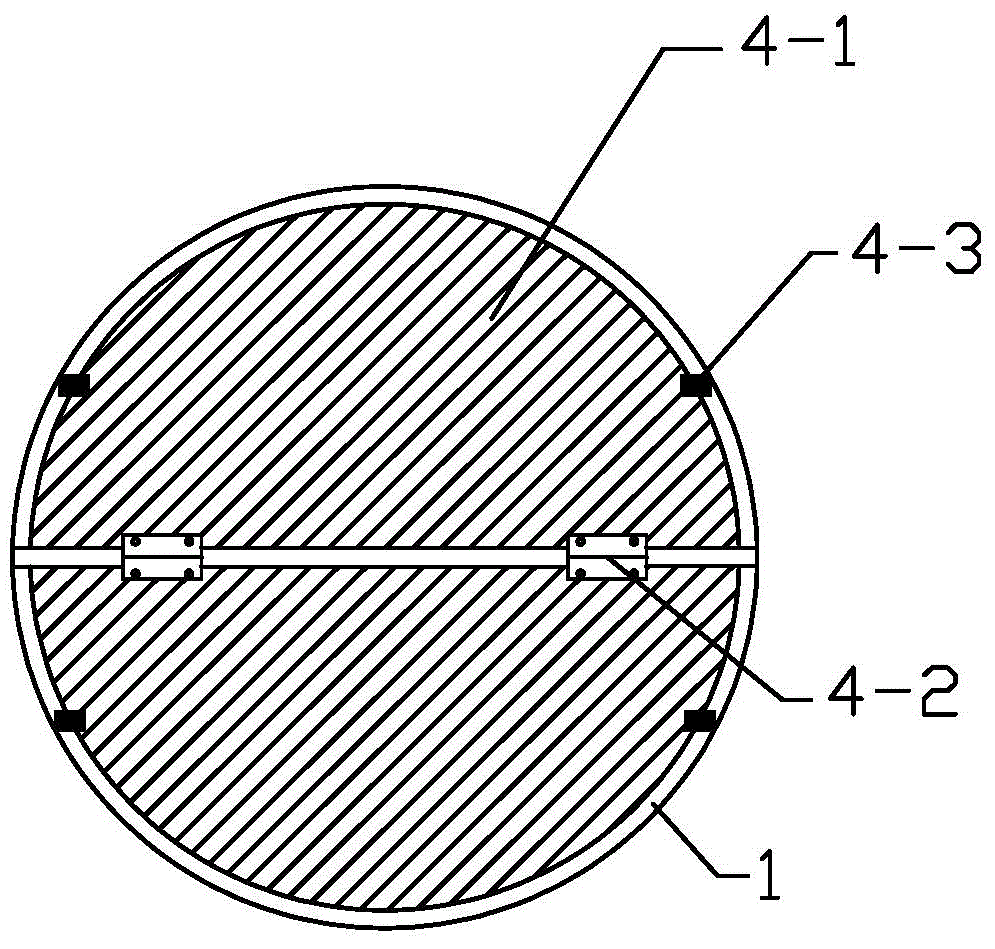

[0027] The present invention will be further described below in conjunction with accompanying drawing. Such as figure 1As shown, the control device for the elevation of the underwater concrete pouring pile includes a feeding barrel 1 and a telescopic rod 2, which is characterized in that: the telescopic rod 2 can adopt the structure of an existing telescopic sleeve rod, which is made of multi-section hollow It is formed by socketing the ruler rod, and its length can be adjusted by stretching. Each segment of the ruler can be fixed after stretching or shrinking (the fixing method can directly adopt the fixing method of the existing telescopic rod), ensuring that the adjustment Can not arbitrarily change its length after good length, the structure of telescopic ruler bar 2 can adopt the structure similar to fishing rod; All be provided with scale layer on the outer surface of every joint ruler, and the scale value of multi-section ruler is continuous, After being stretched out,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com