Auto shop service equipment with means for determining the coefficient of rolling resistance of tires

A technology of rolling resistance coefficient and service equipment, applied in tire installation, measuring device, tire parts, etc., to achieve reliable and accurate rolling resistance coefficient, accurate rolling resistance coefficient, and eliminate parasitic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

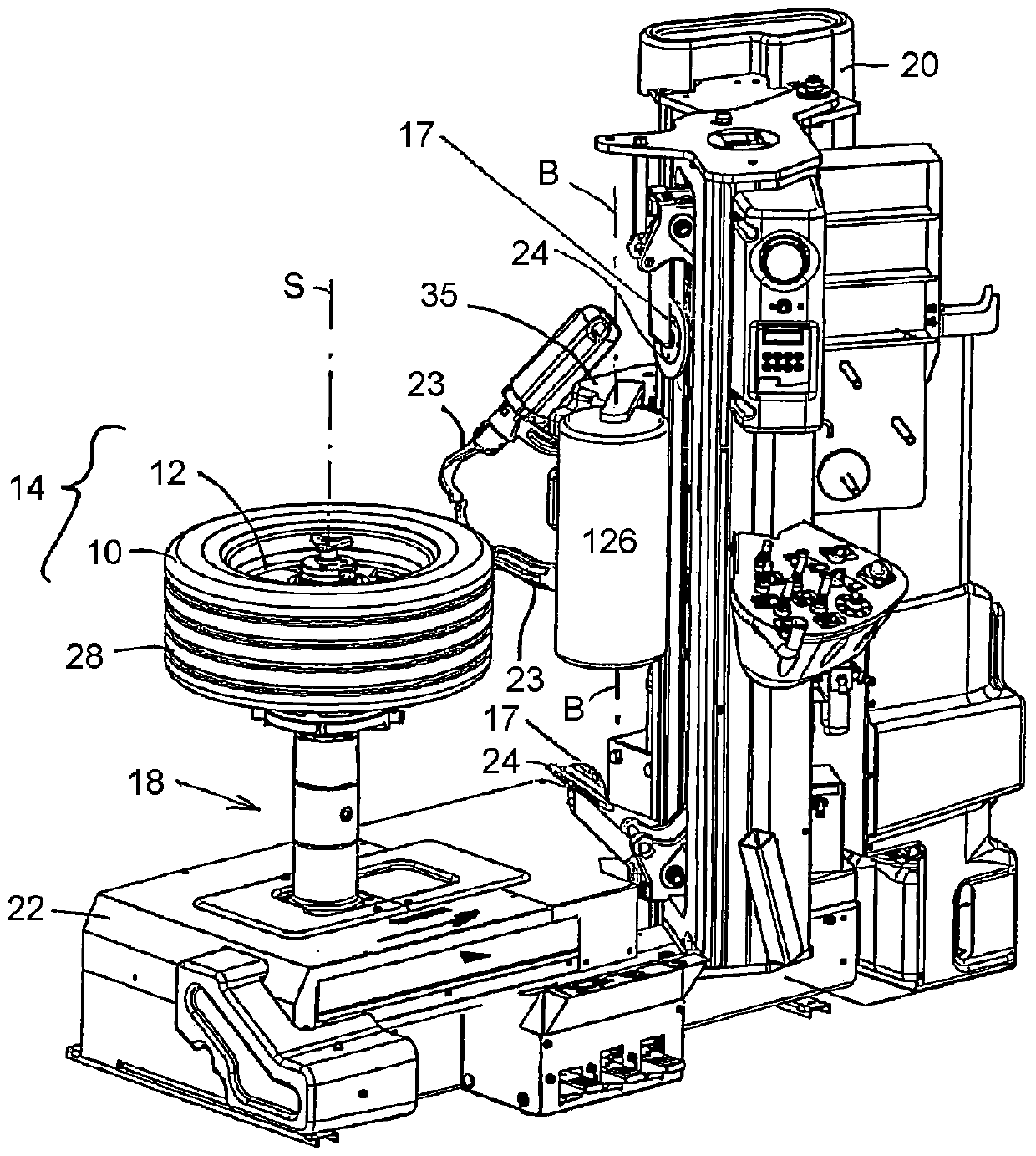

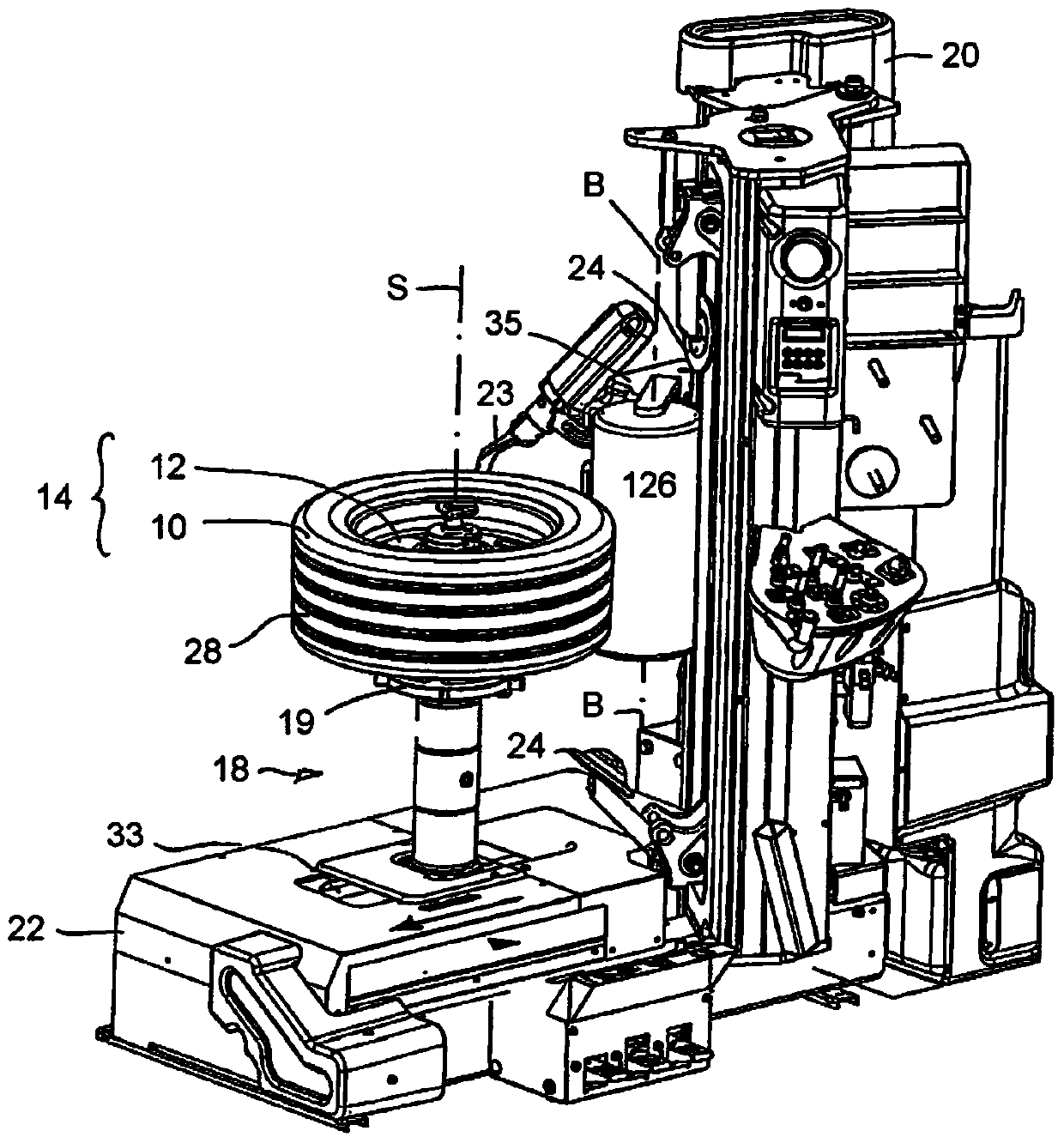

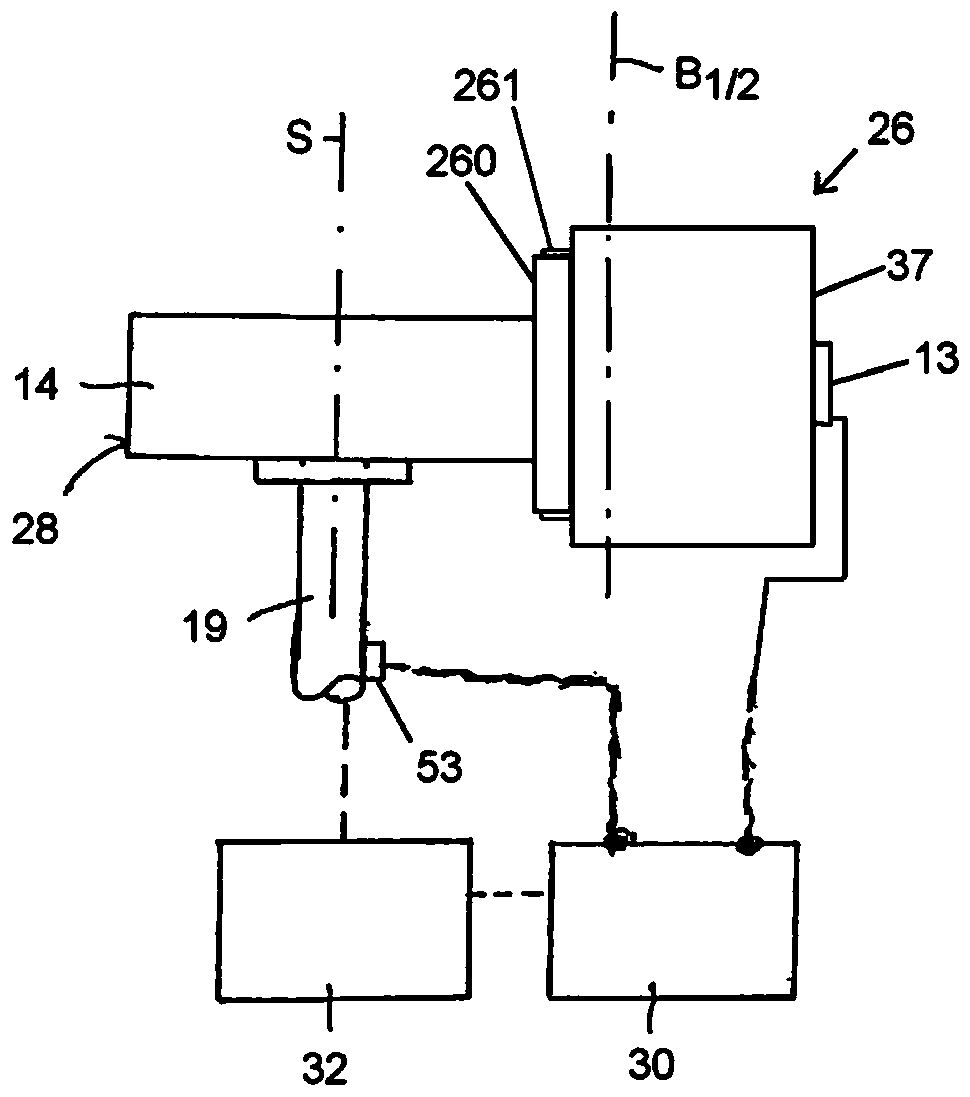

Embodiment Construction

[0038] It should be noted that the drawings are not truly to scale, but merely illustrate the principles of the invention. In other words, the distances, dimensions and ratios of the components depicted in the figures may vary within the spirit of the present invention. Furthermore, in the description of the following preferred embodiments of the present invention, the terms left, right, top, bottom, etc. in relation to the drawings should be interpreted as the directions in which the reference numerals in the drawings can be read. These terms should not be related to any position or orientation relative to the overall device in a limiting manner, but are merely provided to facilitate an understanding of the present invention.

[0039] First explain about Figure 10 The physics of how tires roll on flat surfaces such as road surfaces. When a normal tire rolls on a flat, hard surface such as a road, due to the deformation of the tire at the contact portion (tire / road interfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com