Continuous mining technology of thin ore body subsection caving and retaining ore

A technology of segmental caving and thin ore bodies, which is applied in the field of mining and mining technology, and can solve problems such as inapplicability, high blasting clamping, and a large amount of engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

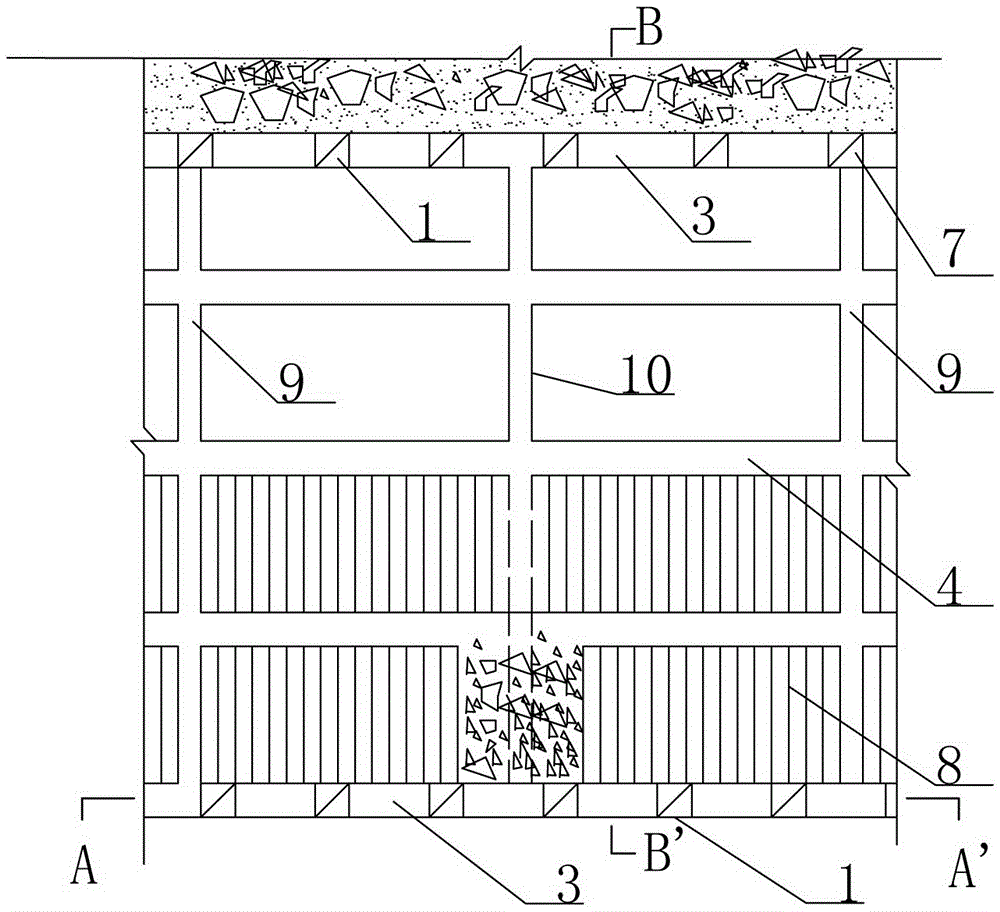

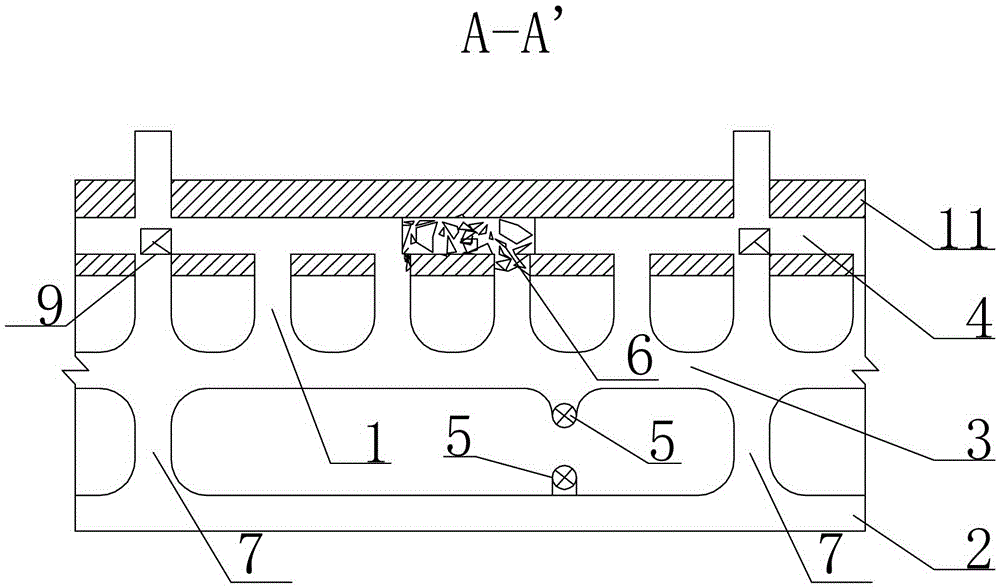

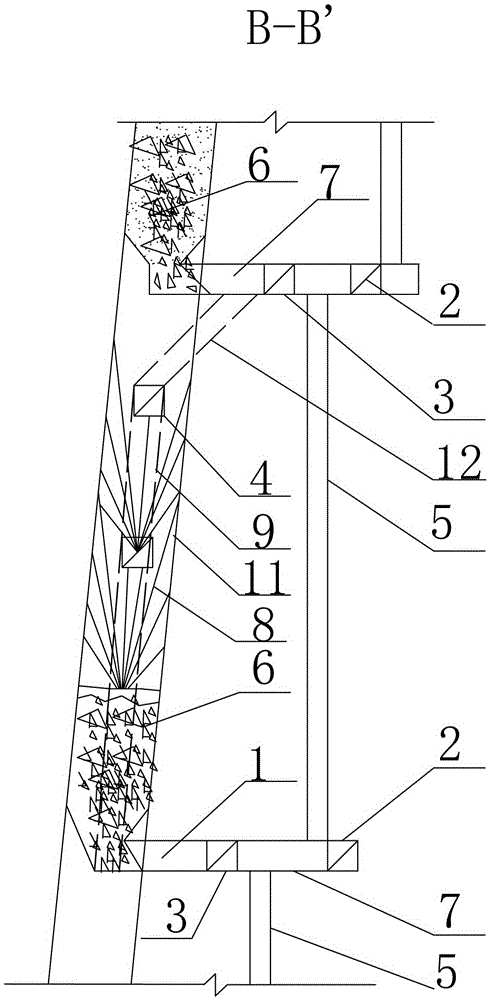

[0035] Such as Figure 1-Figure 5 As shown, the thin ore body segmental caving and ore retention continuous mining process of the present invention includes dividing the ore body 11 into stages, and the stages are further divided into segments, and the mining standard is carried out between the upper level and the lower level of each stage. , cutting, medium and deep hole mining and rock drilling, ore retention and mining, and ore extraction, characterized in that the specific steps are as follows:

[0036] 1) Acceptance:

[0037] In each stage, there are horizontal ore-exiting roadway 3 along the vein, horizontal vein-piercing ore-exiting roadway 1, connecting roadway 7, transportation roadway 2 along the vein, ore-discharging chute 5 and recovery roadway 4, and the horizontal ore-exiting roadway along the vein Roadway 3 is set at a dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com