Wireless bridge with tool box

A technology of wireless network bridge and tool box, which is applied in wireless communication, network connection, electrical components, etc., can solve the problems of inconvenience of carrying a large number of tools, and the wireless network bridge does not have the function of storing maintenance tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

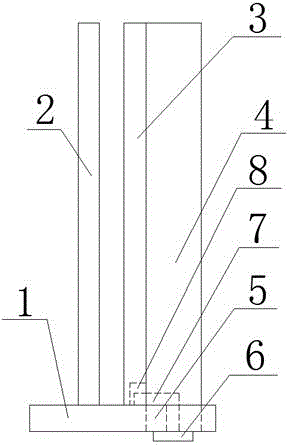

[0018] This embodiment provides a wireless network bridge with a tool box, including a base plate 1 and a circuit board 2, the right side of the circuit board 2 is provided with a tool box baffle 3, the tool box baffle 3 The right side is provided with tool box 4, and the lower end of described tool box 4 is provided with bottom surface baffle 5, and described bottom surface baffle 5 is nested in the base plate 1, and the lower surface of described bottom surface baffle 5 is provided with knob 6, so The knob 6 is connected with the catch 7 located on the upper surface of the bottom baffle 5 , the lower end of the tool box baffle 3 is fixed to the bottom plate 1 , and a groove 8 is provided within the rotation range of the catch 7 .

Embodiment 2

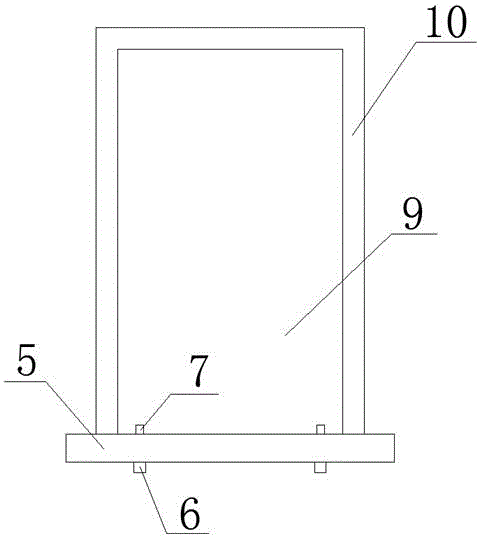

[0020] Such as figure 2 The side baffle 10 and the rear baffle 9 of the shown tool box 4 are fixed together, and are respectively provided with a plurality of small holes that can fix U-shaped cards, and the U-shaped cards are used to fix the tools placed in the tool box 4 , the maintenance personnel can choose the tool stored in the tool box 4 according to the actual needs. Since the tool box 4 is vertical, the U-shaped card can fix the tool without being messy. The position of the U-shaped card is set according to the different tools. Adjustable and flexible.

Embodiment 3

[0022] Such as figure 1 The shown knob 6 is connected to the blocking piece 7 through a threaded bolt, and the blocking piece 7 can be rotated synchronously by turning the knob 6. When a tool needs to be used for maintenance, the tool box can be opened to obtain the tool by turning the knob 6 .

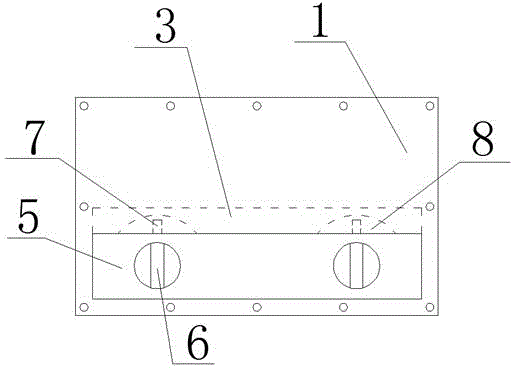

[0023] Such as figure 2 and image 3 There are two knobs 6 shown, which are respectively arranged at positions on the left and right sides of the bottom baffle 5 close to the bottom baffle 5, so that the tool box 4 is fixed firmly.

[0024] Such as figure 2 The shown groove 8 is arc-shaped, and fits the rotation range of the blocking plate 7 , so that the groove 8 will not affect the stability of the tool box blocking plate 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com