A box bottom folding machine and its working method

A folding machine and folding device technology, applied in packaging and other fields, can solve the problems of heavy operator workload, waste of human resources, high labor intensity, etc., achieve the effects of reducing labor intensity, realizing full automation, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be further described below in conjunction with specific drawings:

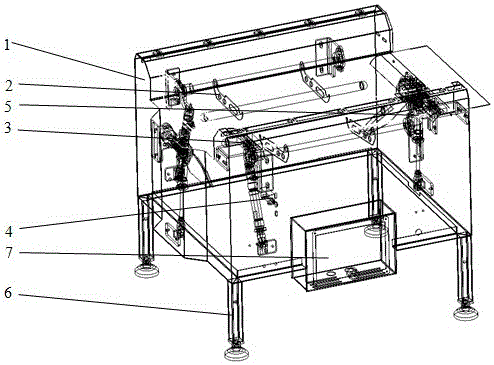

[0026] See figure 2 , is a structural schematic diagram of an embodiment of a box bottom folding machine of the present invention, including a box body 1, a folding device 2, a pushing cylinder 3, a photoelectric sensor 4, a photoelectric sensor 2 5 and a base 6, and the base 6 is provided with a box with an upper end opening Body 1, the box body 1 is provided with a folding device 2, and the box body is provided with a pushing cylinder 3 for positioning the carton and a photoelectric sensor 1 4 and a photoelectric sensor 2 5 for detecting the position of the carton.

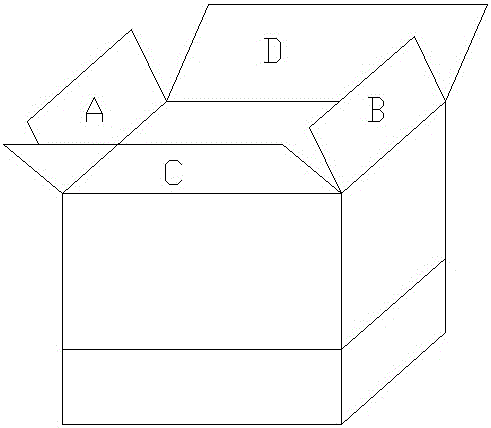

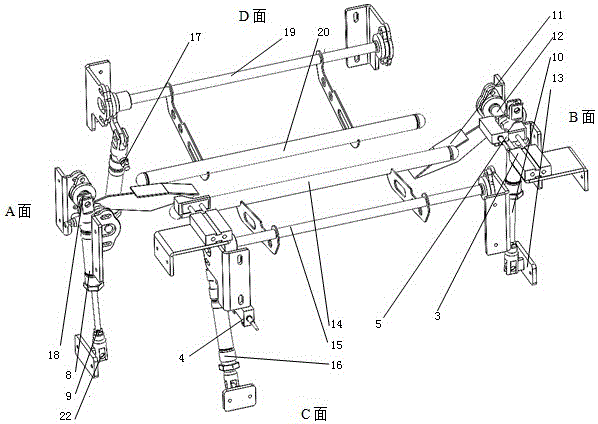

[0027] See image 3 , the folding device includes A surface mechanism, B surface mechanism, C surface mechanism and D surface mechanism, wherein the A surface mechanism includes A surface supporting plate 8, A shaft 18, cylinder one 9 and cylinder one fixed frame 22, A surface supporting plate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com