Defrosting sensor, refrigerator and defrosting method

A technology of frost sensor and temperature sensor, which is applied in defrosting sensor, refrigerator and defrosting field, which can solve the problems of increasing energy consumption, delaying the timing of defrosting, and early timing of defrosting, etc., and achieves the effect of reliable defrosting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

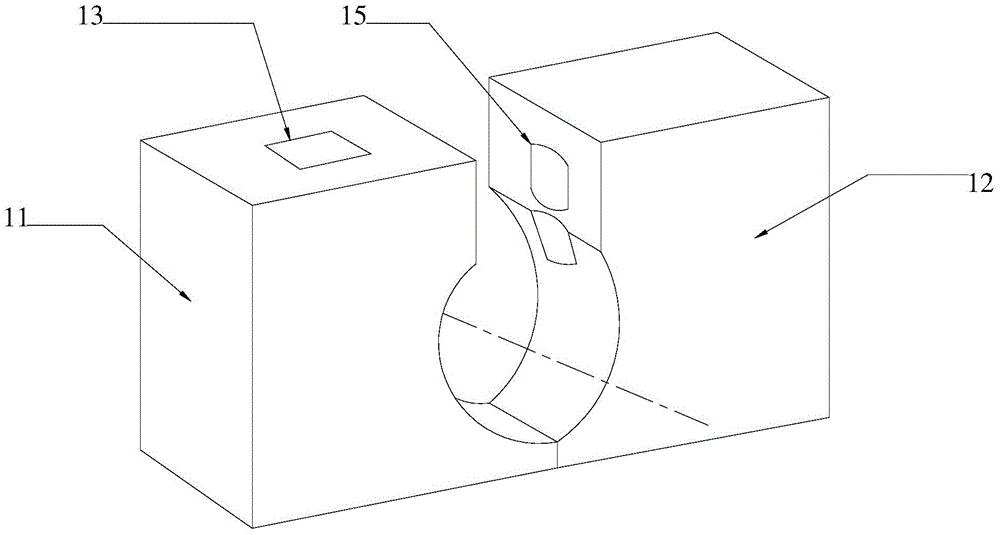

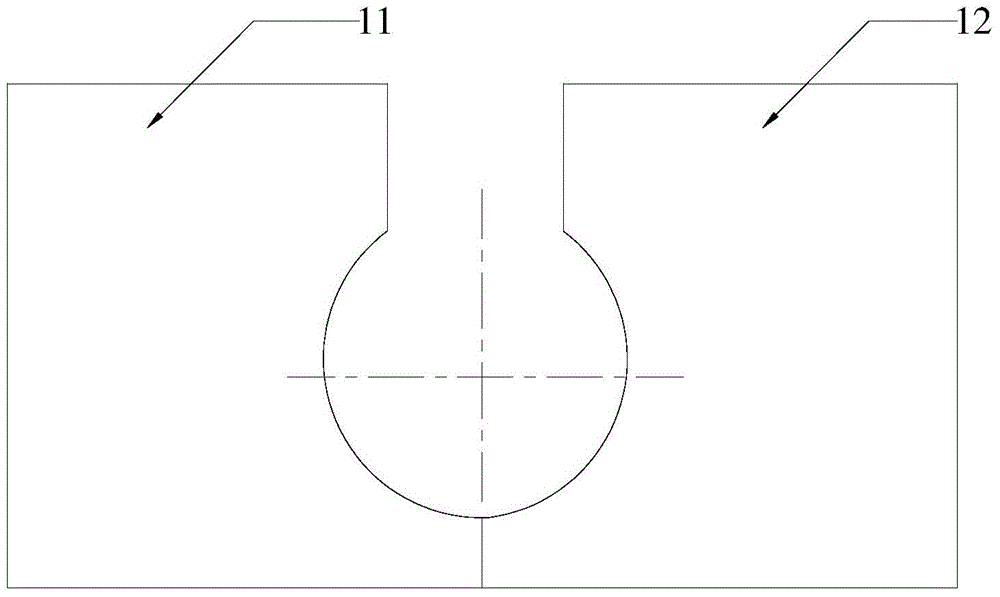

[0034] figure 1 An overall diagram of a defrosting sensor provided by an embodiment of the present invention, figure 2 for its front view, image 3 for its left view, Figure 4 for its top view, Figure 5 its section view.

[0035] see Figure 6 , in the embodiment of the present invention, the defrosting sensor is installed on the evaporating pipe 20 of the refrigerator.

[0036] see Figure 5 , the defrost sensor includes:

[0037] The first support seat 11 and the second support seat 12 that are arranged oppositely, the first temperature sensor 13 that is arranged on the outer surface of the first support seat 11 / second support seat 12, and the first temperature sensor 13 that is arranged on the first support seat 11 and the second support seat 12 respectively The light emitting end 14 and the light receiving end 15 on the two opposite surfaces of 12, and the second temperature sensor 16 arranged on one of the two opposite surfaces of the first supporting base 11 an...

Embodiment 2

[0049] An embodiment of the present invention provides a refrigerator, including: an evaporation tube, a main control chip, and the defrosting sensor provided in Embodiment 1. Wherein, the evaporation tube is close to the second temperature sensor of the defrosting sensor, and the light emitting end, the first temperature sensor, the second temperature sensor, and the light receiving end are all connected with the main control chip of the refrigerator.

[0050] Specifically, for the defrosting method using the refrigerator provided in the embodiment of the present invention, reference may be made to the description in Embodiment 4, which will not be specifically introduced in the embodiment of the present invention.

[0051] Based on the refrigerator provided by the embodiment of the present invention, the defrosting sensor can detect whether the thickness of the frost layer in the evaporating tube reaches a preset defrosting thickness value, and then defrosting is performed af...

Embodiment 3

[0053] An embodiment of the present invention provides a refrigerator, including: an evaporation tube, a main control chip, and the defrosting sensor provided in Embodiment 1. Wherein, the evaporation tube is close to the second temperature sensor of the defrosting sensor, and the processing chip of the defrosting sensor is connected with the main control chip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com