Molding process of display components

A technology of display assembly and molding process, applied in the direction of rack/frame structure, etc., can solve the problems of incompatibility with ergonomics and complex visual effects of the appearance of display components, and achieve the effect of reducing visual layers and increasing visual effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

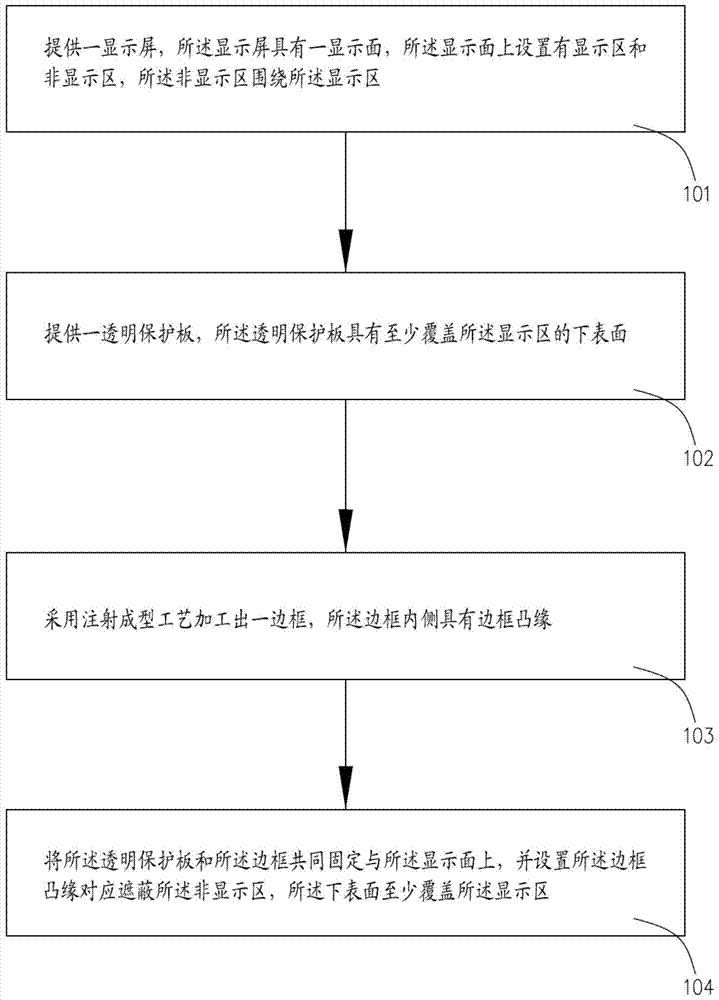

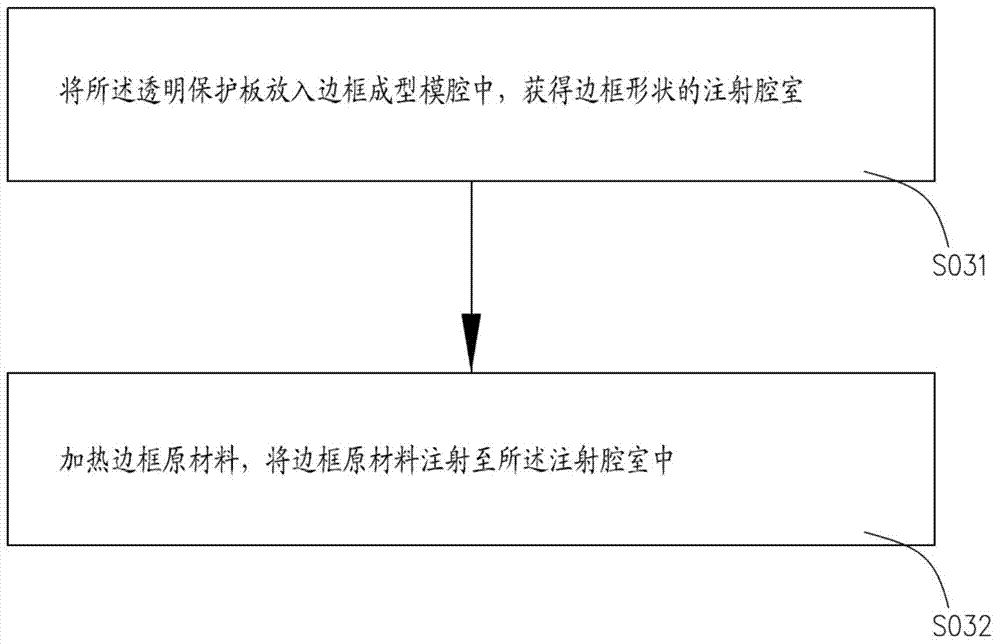

Method used

Image

Examples

no. 1 example

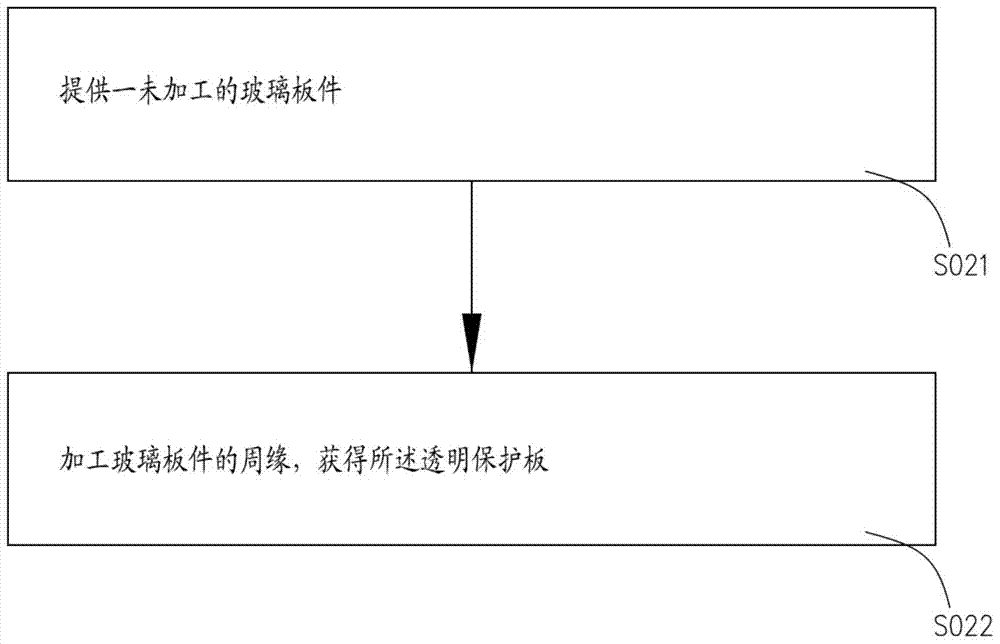

[0037] The first embodiment is provided, and the step of providing a transparent protective plate includes:

[0038] S021: Provide an unprocessed glass plate.

[0039] Unprocessed glass sheets can be obtained by roll forming process, cutting process, or casting and rolling process. The light transmittance of the unprocessed glass plate must reach more than 90%, so that the display effect of the display screen assembly is good; the flatness of the unprocessed glass plate is between 0.005mm and 0.01mm, specifically preferably 0.005mm, so that The appearance of the display assembly has a smooth surface and a good appearance. In other embodiments, the flatness of the raw glass sheet may also be 0.008.

[0040] S022: Process the periphery of the glass plate to obtain a transparent protective plate.

[0041] In this embodiment, a cutting process is adopted to cut the glass plate according to a preset size, which is the same as the size of the display area 11 . Specifically, such...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com