A bridge with self-cleaning expansion joint device with dust-proof aprons

A technology for automatic cleaning and expansion joints, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of waste of manpower, damage of covering plates, long cycle time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

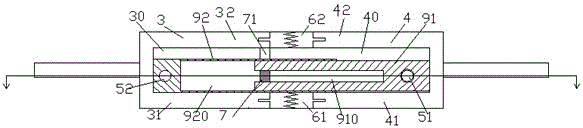

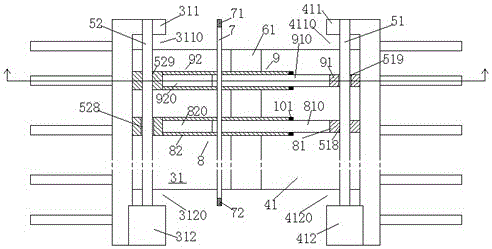

[0010] combined with Figure 1-2 , to explain the present invention in detail.

[0011] According to the bridge of the self-cleaning expansion joint device with dust-proof aprons, the self-cleaning expansion joint device includes a left half frame 3, a right half frame 4, and The upper elastic cover 62 and the lower elastic cover 61 are respectively used to cover the expansion joint between the left half frame 3 and the right half frame 4 on the road surface and under the road surface of the bridge between the half frame parts 4. The cavities 30, 40 surrounded by the left half frame 3, the right half frame 4, the upper elastic cover 62 and the lower elastic cover 61 are provided with the first moving cleaning plate assembly 9 and The second moving cleaning plate assembly 8, each of the first moving cleaning plate assembly 9 and the second moving cleaning plate assembly 8 includes left plate parts 92, 82 and right plate parts 91, 81, and the right plate parts 91, 81 extend in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com