Venturi pumps and equipment for applying paint

A Venturi pump, powder technology, applied to mechanical equipment, parts of pumping devices for elastic fluids, pumps, etc., can solve problems such as expensive maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

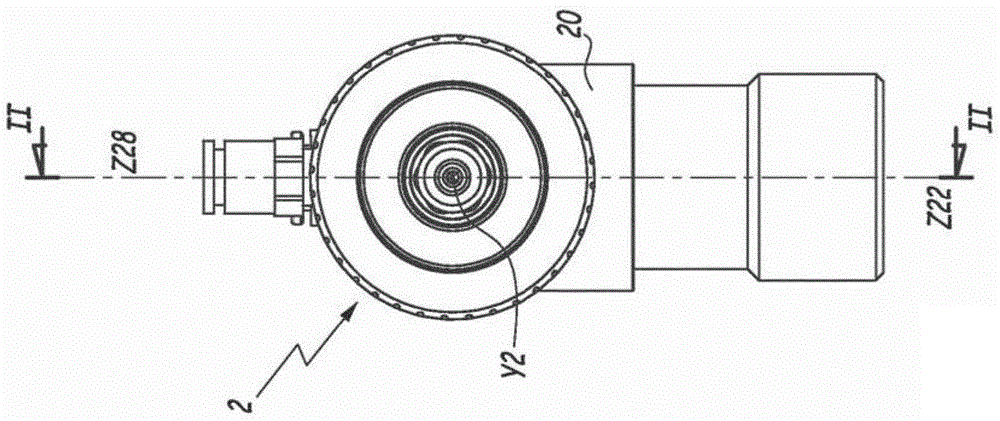

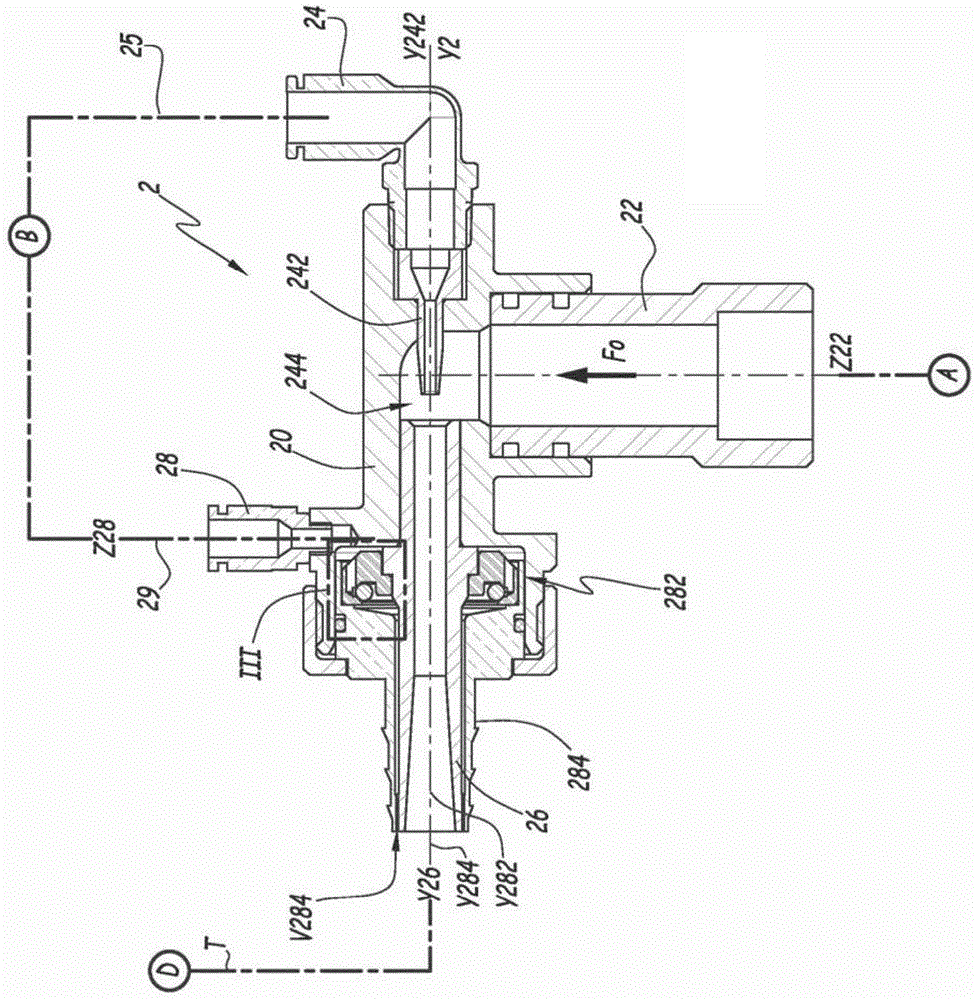

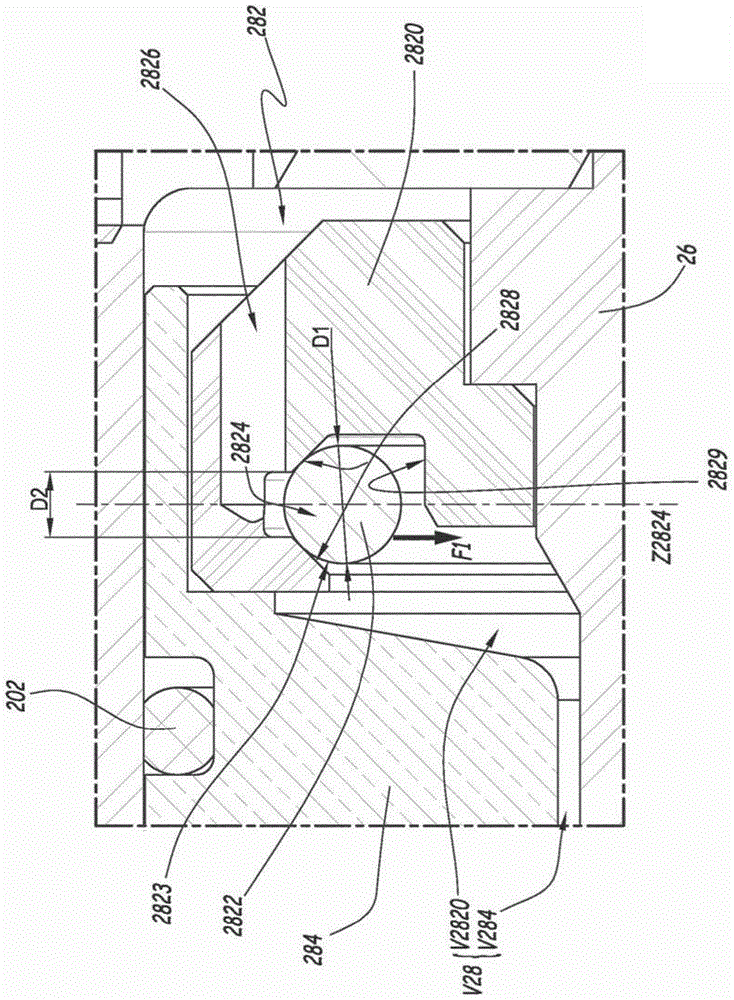

[0027] figure 1 and figure 2 A Venturi pump 2 is shown, which is designed to be used in a device for applying powdered paint products. The Venturi pump 2 extends along the main axis Y2 and comprises an outer body 20 . The outer body 20 includes a plurality of openings enabling the reception of different inlet and outlet conduits. The access duct comprises a first suction duct 22 having a generally cylindrical shape centered on the axis Z22. Upstream of the suction conduit 22 is connected to a reservoir A, which is not shown in the figure and contains a bed of fluidized powder.

[0028] Venturi pump 2 also comprises a first air injection connection 24 at its inlet. The connector 24 is connected to the pneumatic supply module B through a conduit 25 . On the end portion of the connector 24, a syringe 242 is arranged extending along an axis Y242, which coincides with the previously defined axis Y2. The syringe 242 is located on an extension of the connector 24 that is narro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap