Patents

Literature

44results about "Tribo-charging spraying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

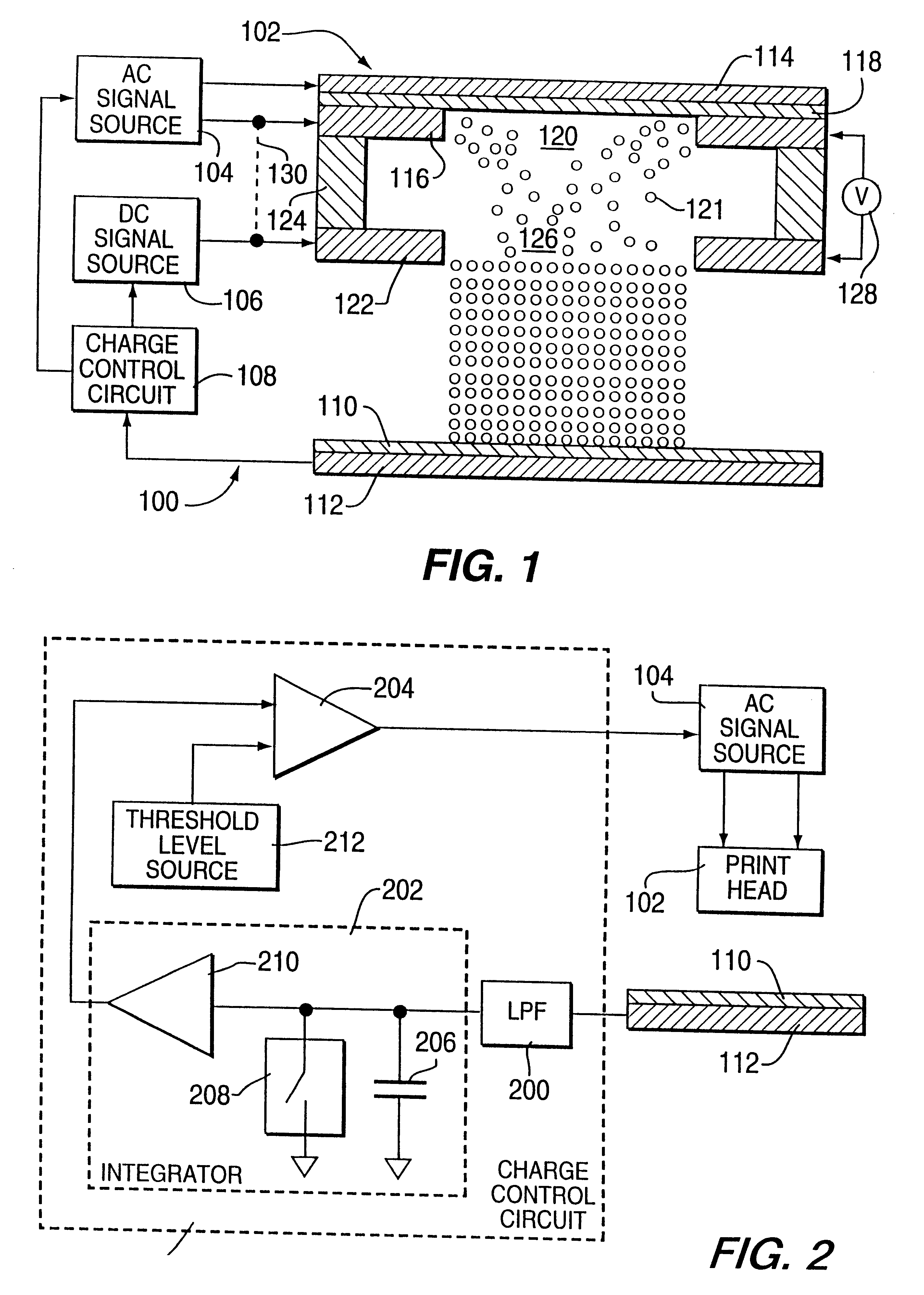

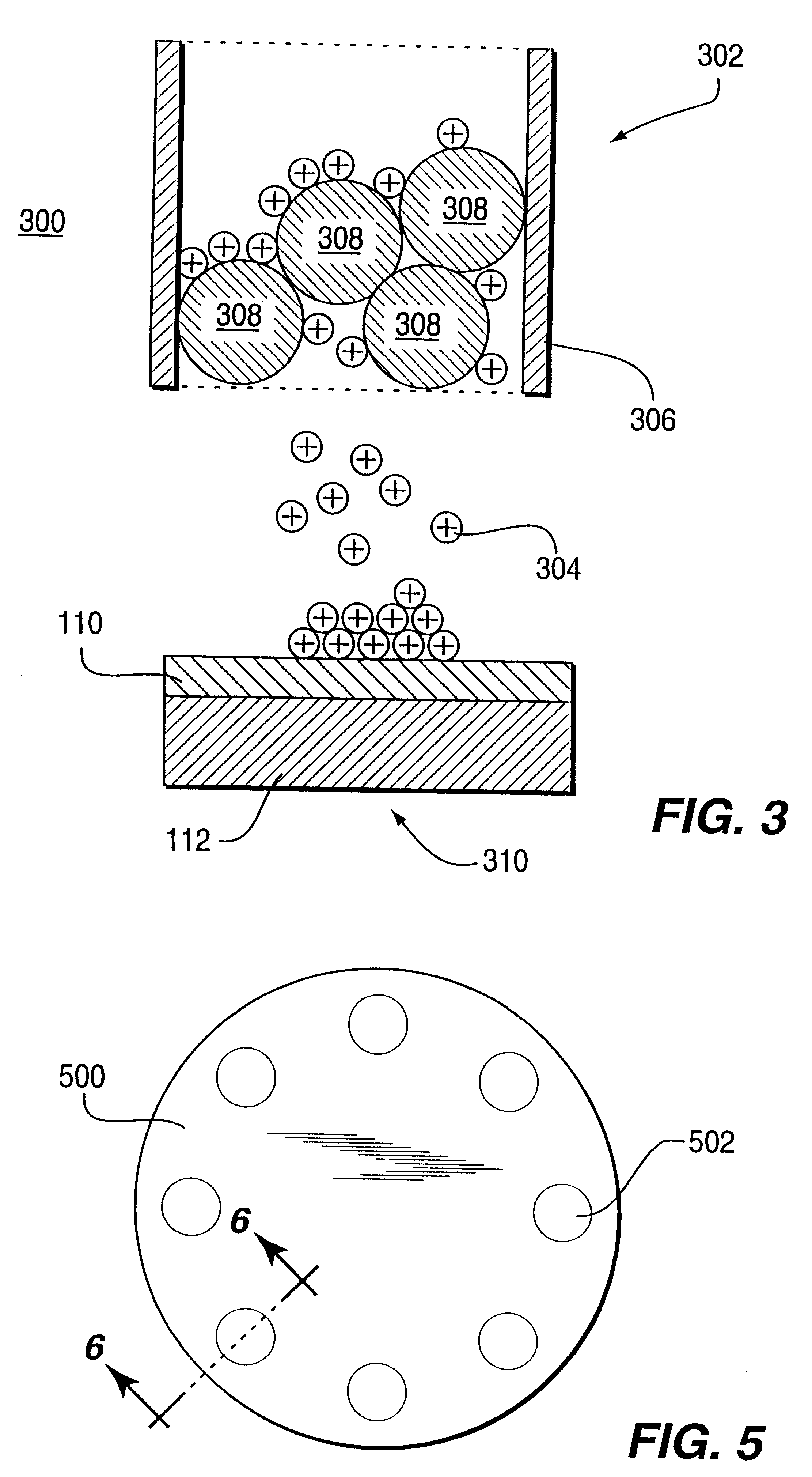

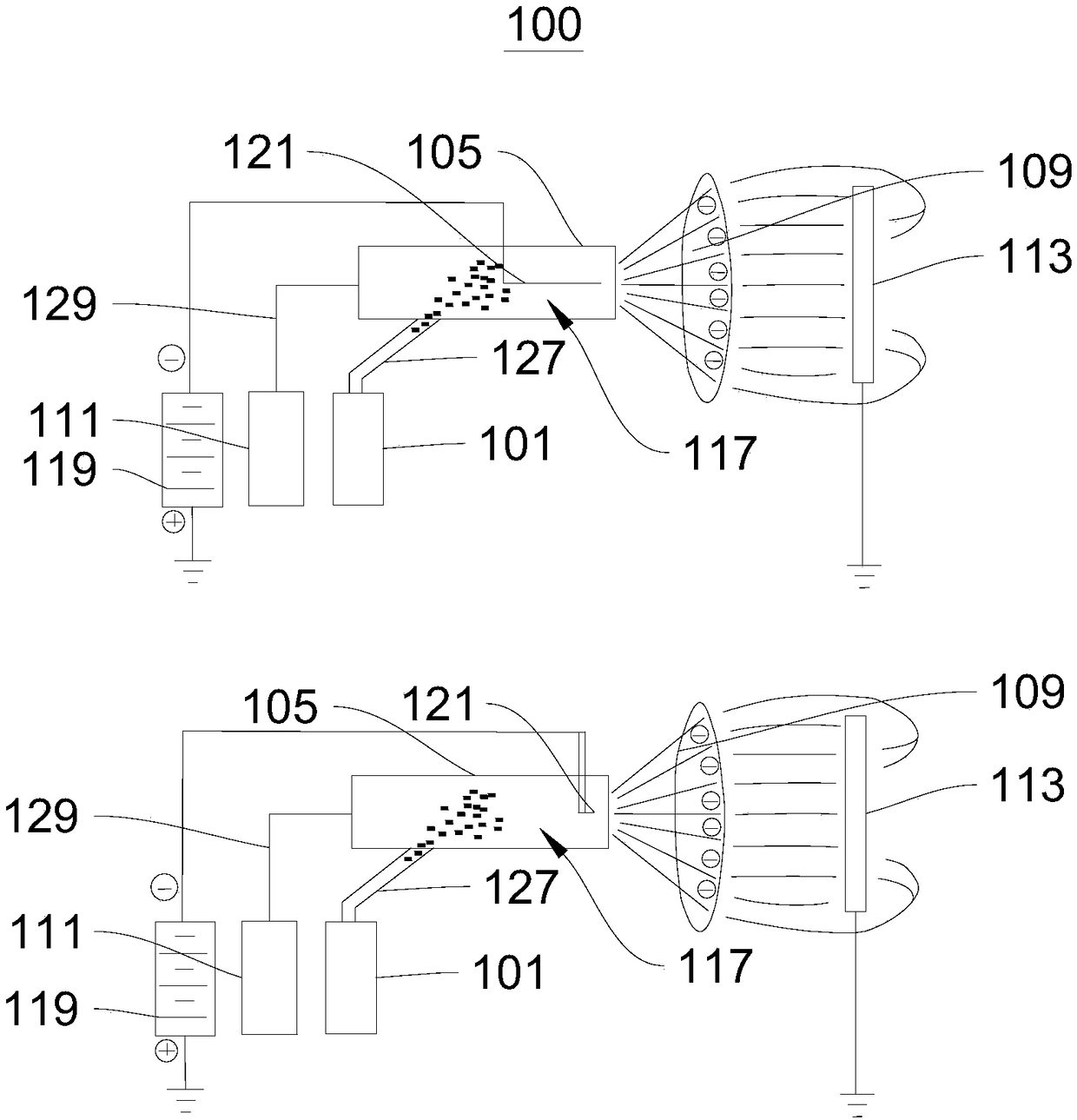

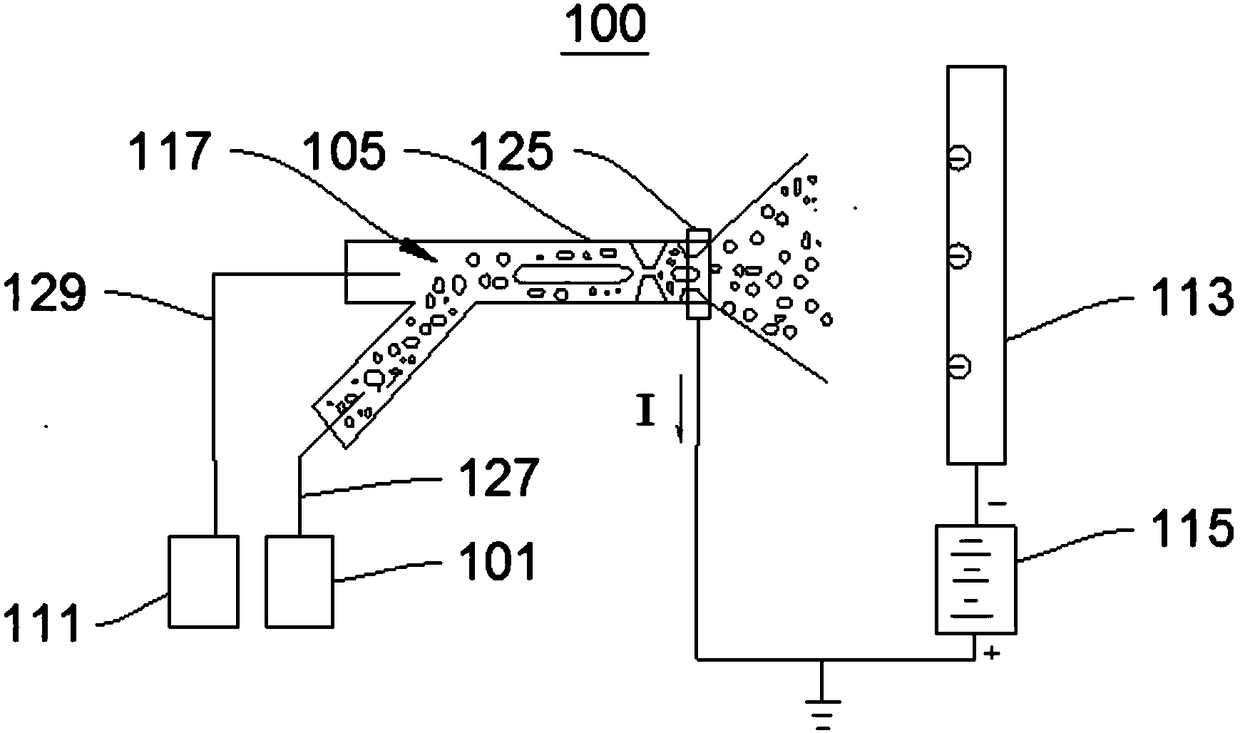

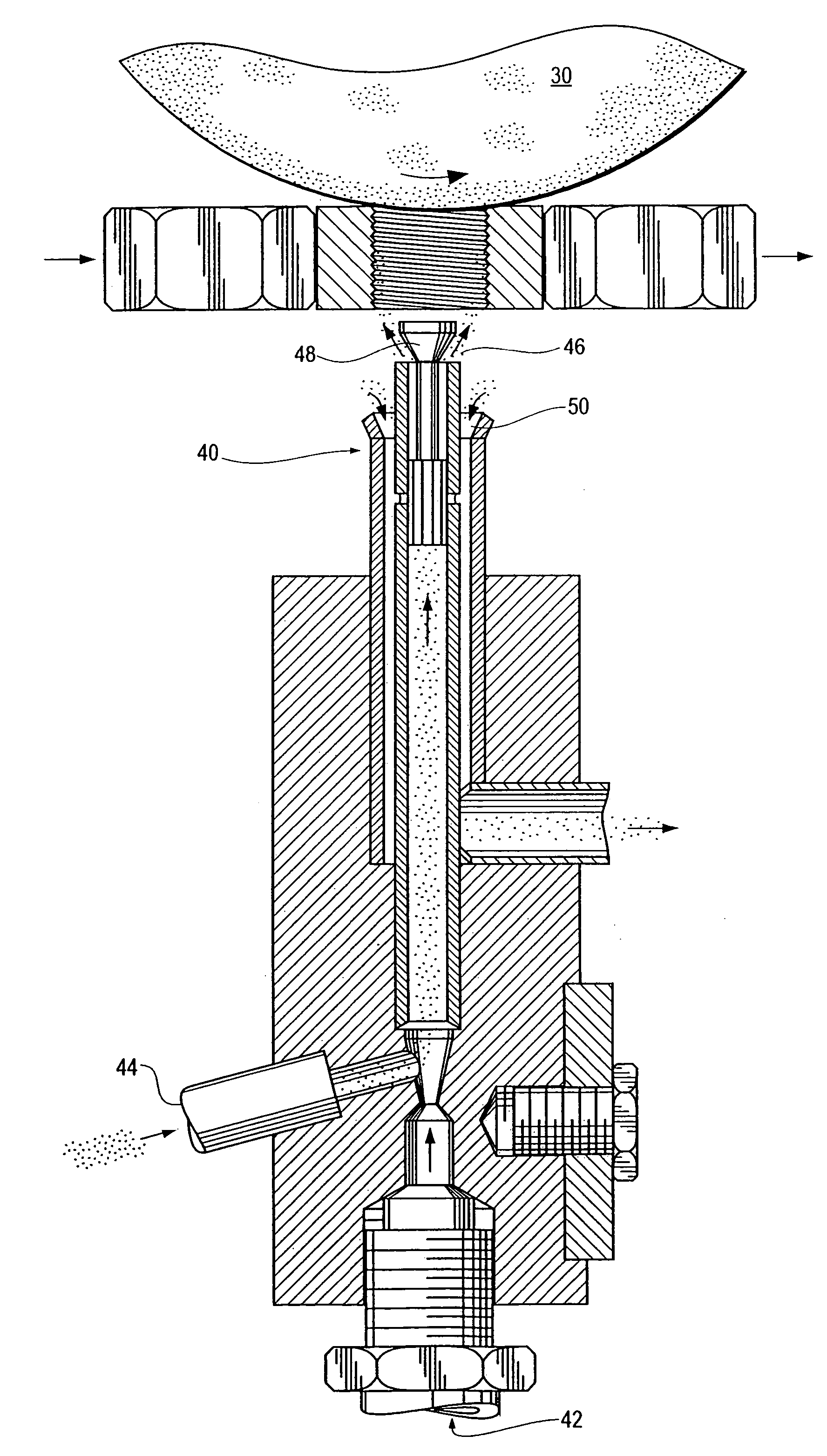

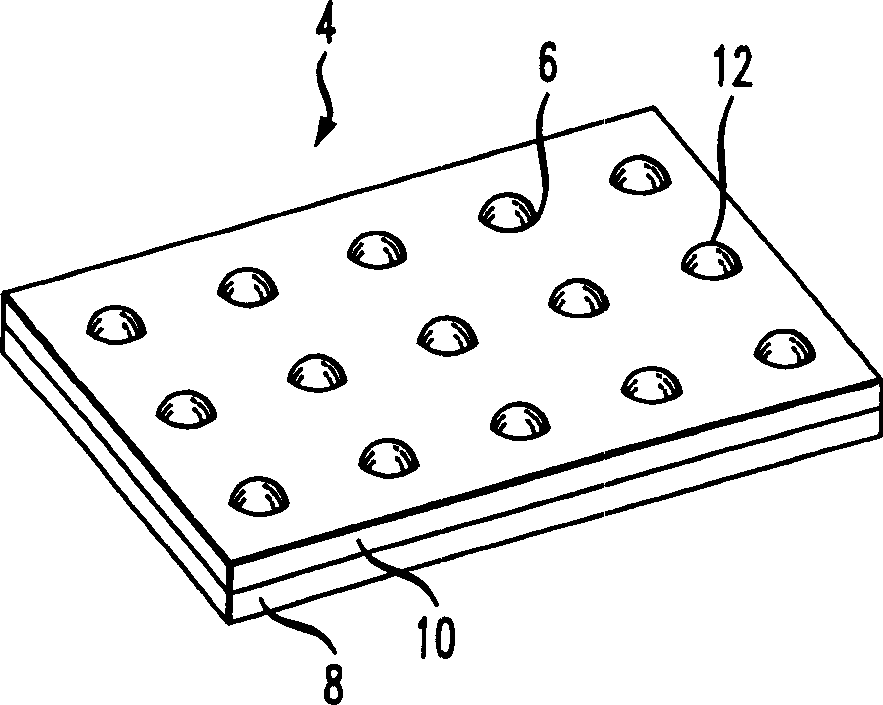

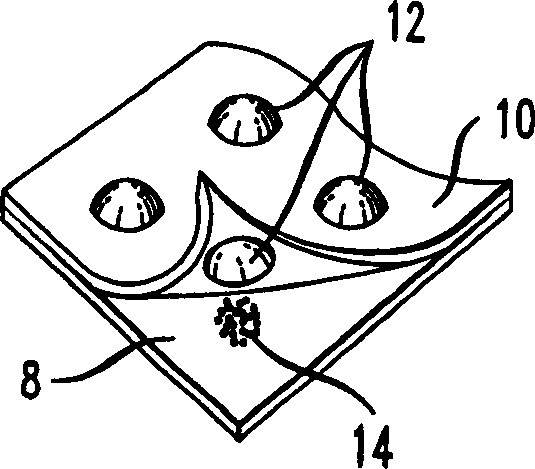

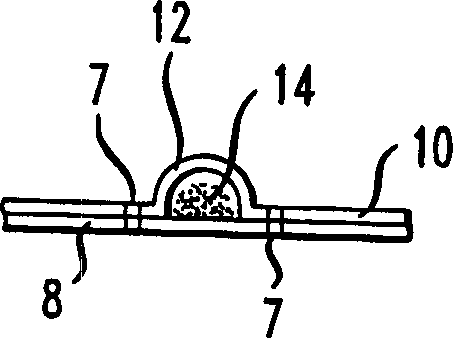

Method for electrostatically depositing a medicament powder upon predefined regions of a substrate

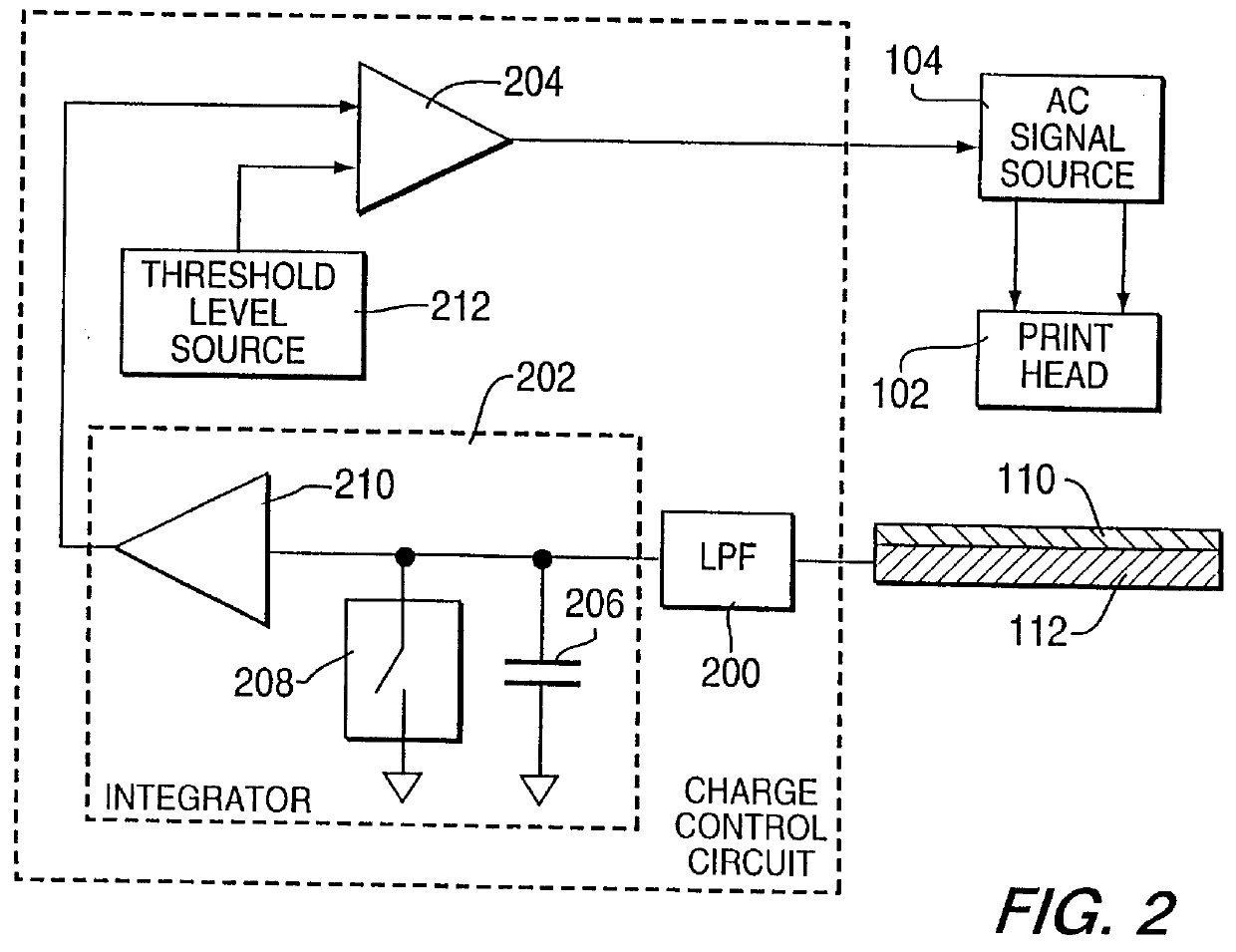

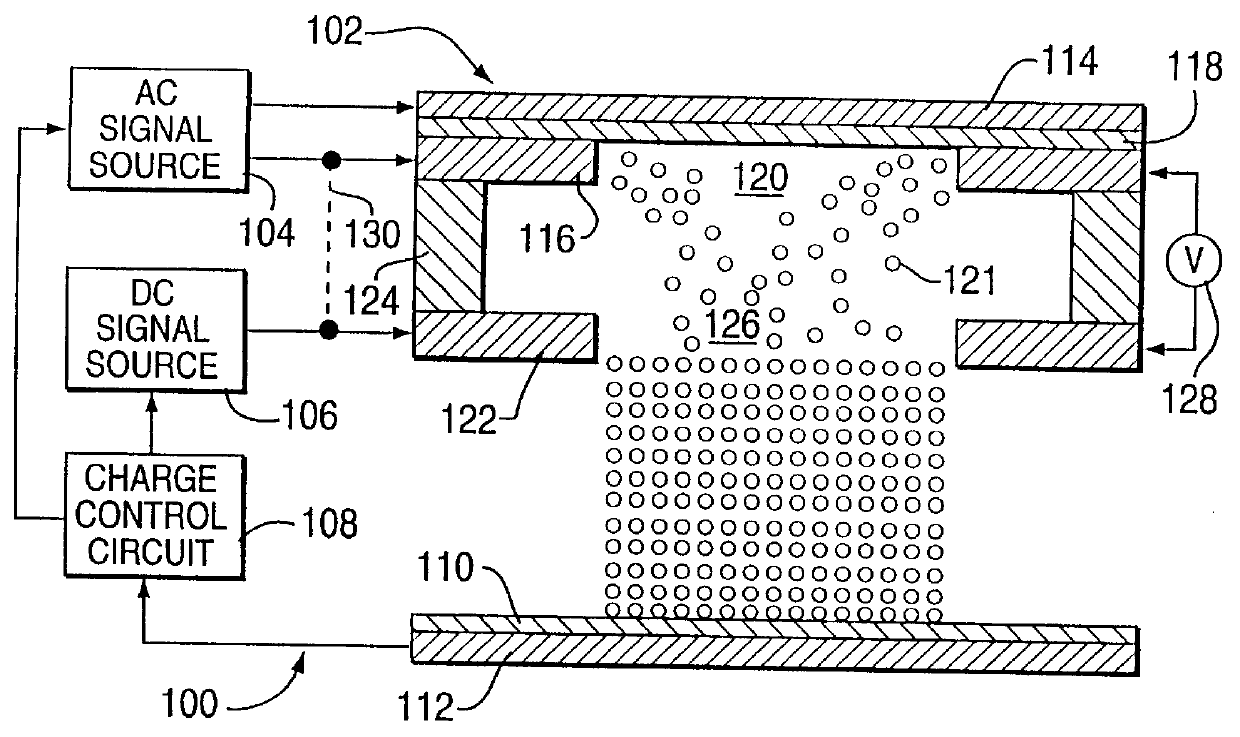

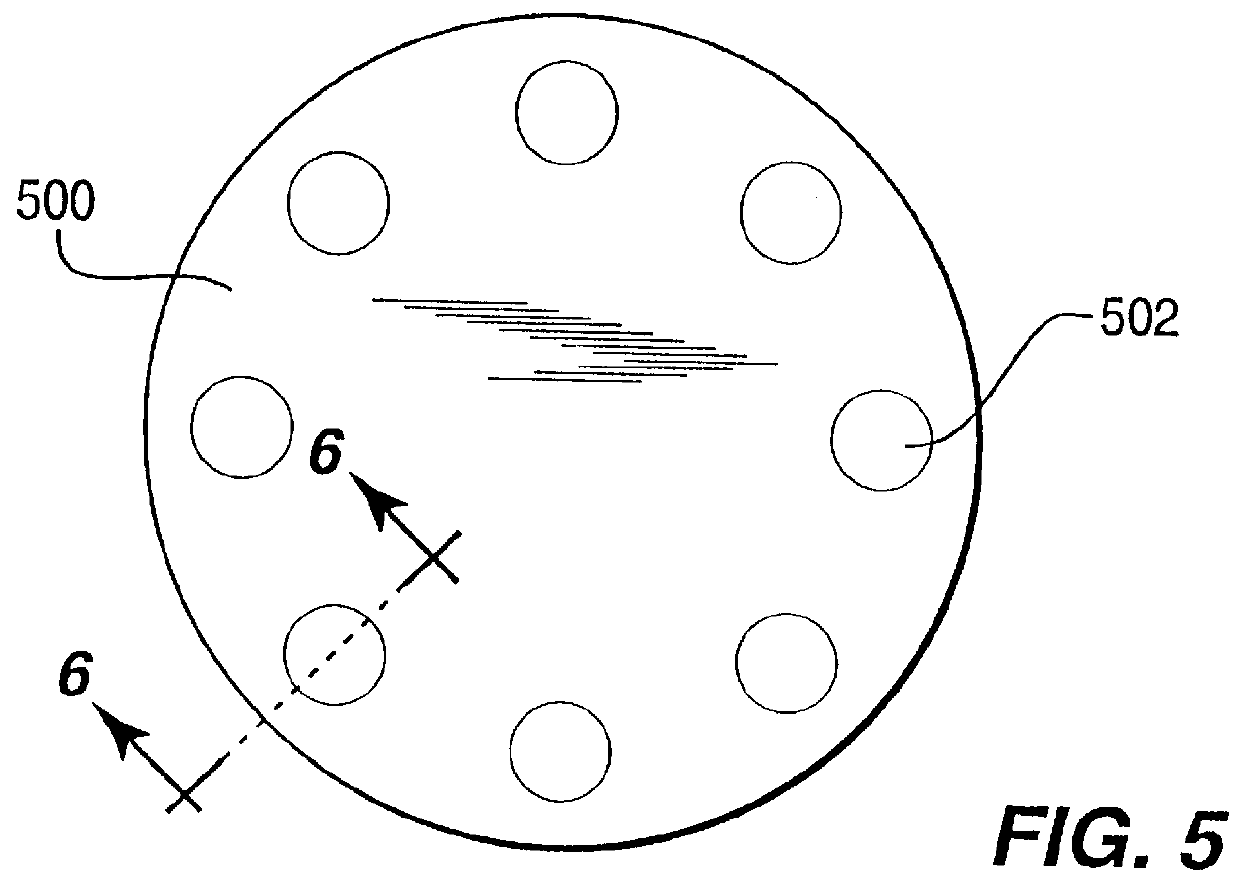

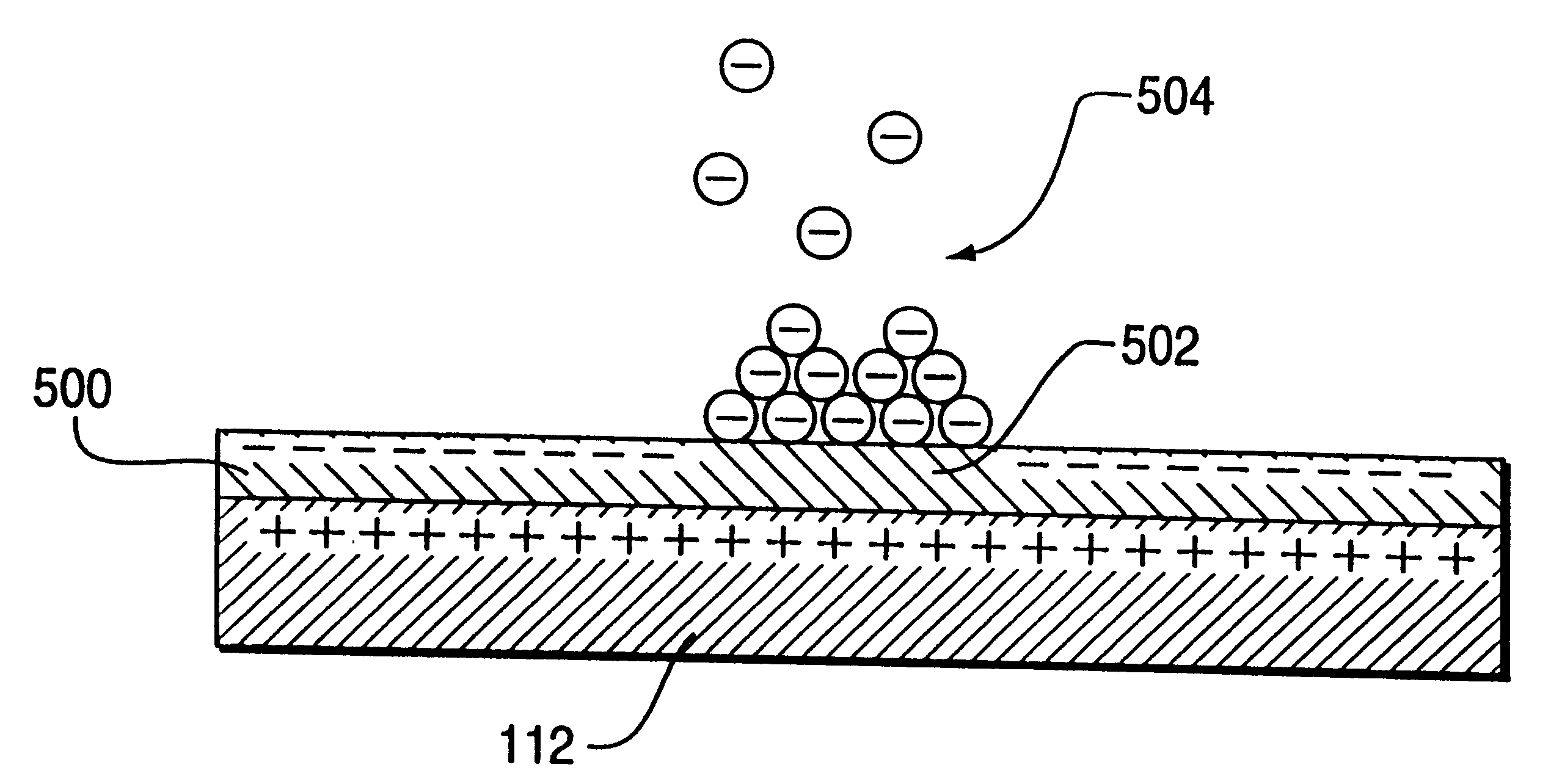

Method for electrostatically depositing select doses of medicament powder at select locations on a substrate. Specifically, the apparatus contains a charged particle emitter for generating charged particles that charge a predefined region of a substrate and a charge accumulation control circuit for computing the amount of charge accumulated upon the substrate and deactivating the emitter when a selected quantity of charge has accumulated. Additionally, a triboelectric charging apparatus charges the medicament powder and forms a charged medicament cloud proximate the charged region of the substrate. The medicament particles within the medicament cloud electrostatically adhere to the charged region. The quantity of charge accumulated on the substrate at the predefined region and the charge-to-mass ratio of the medicament powder in the cloud control the amount (dose) of medicament deposited and retained by the substrate. Consequently, this apparatus accurately controls both medicament dosage and deposition location. Furthermore, since the substrate can be of any dielectric material that retains an electrostatic charge, the apparatus can be used to deposit medicament on substrates that are presently used in oral medicament consumption, e.g., substrates that are used to fabricate suppositories, inhalants, tablets, capsules and the like.

Owner:DELSYS PHARMA

Method and apparatus for electrostatically depositing a medicament powder upon predefined regions of a substrate

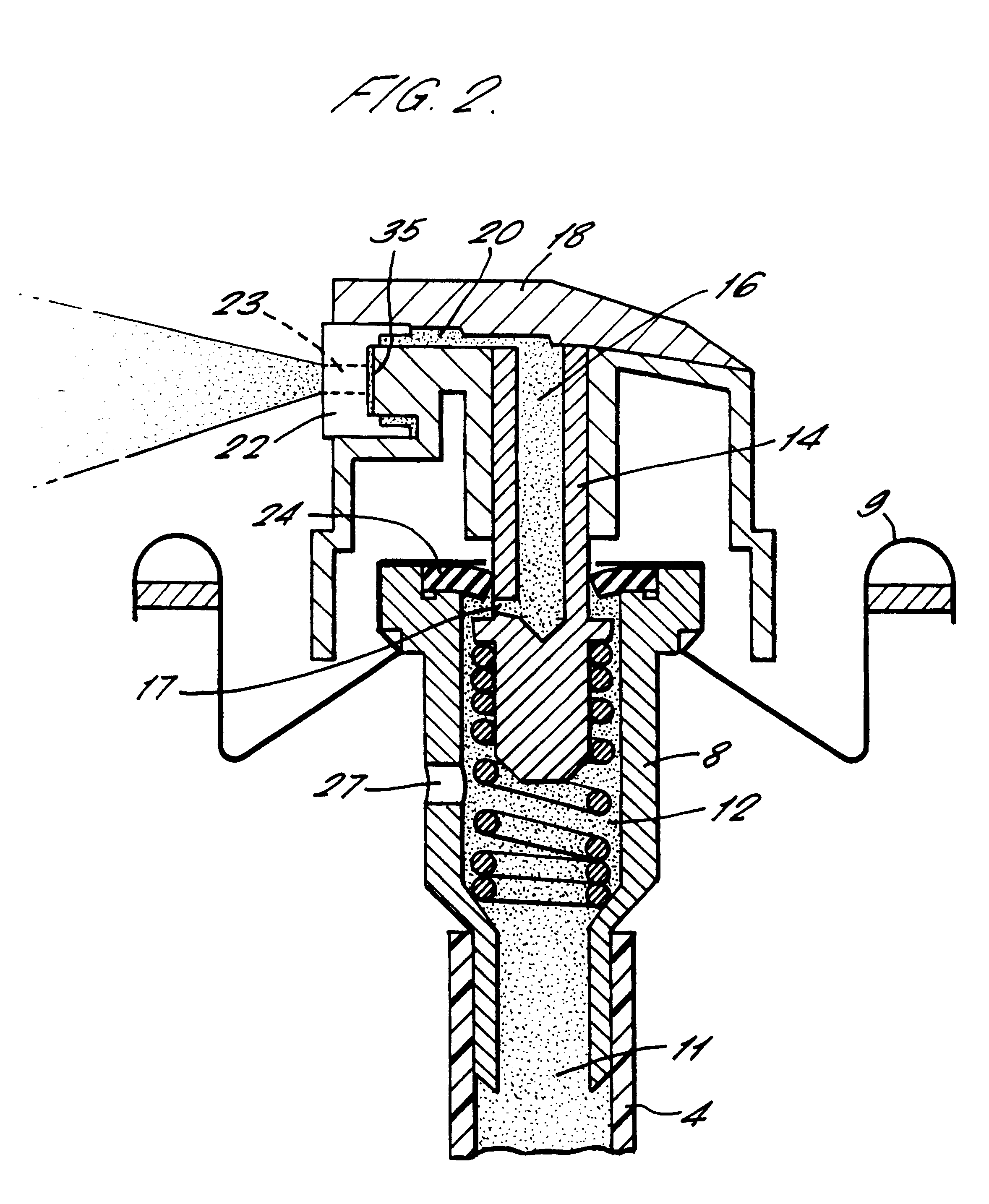

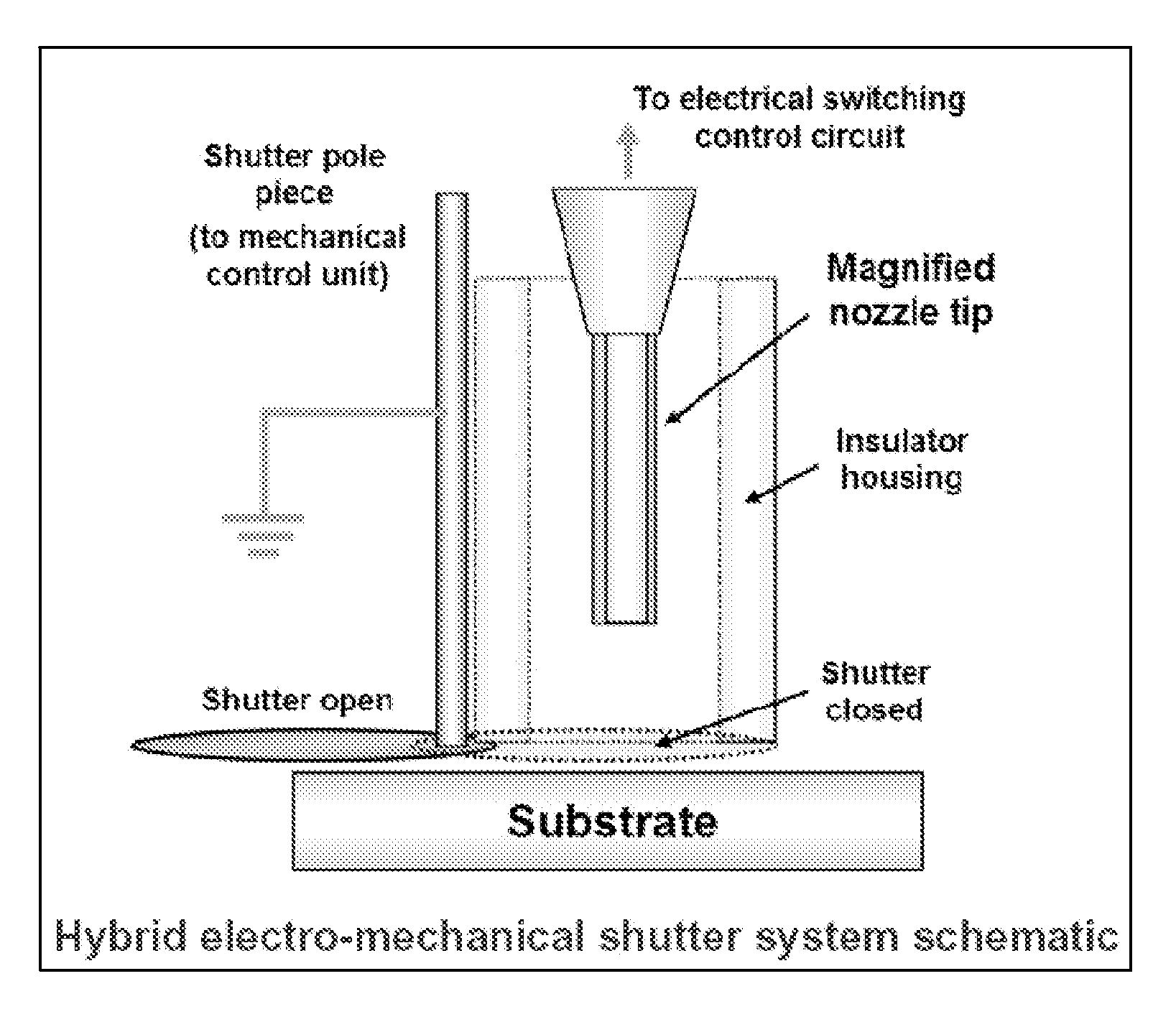

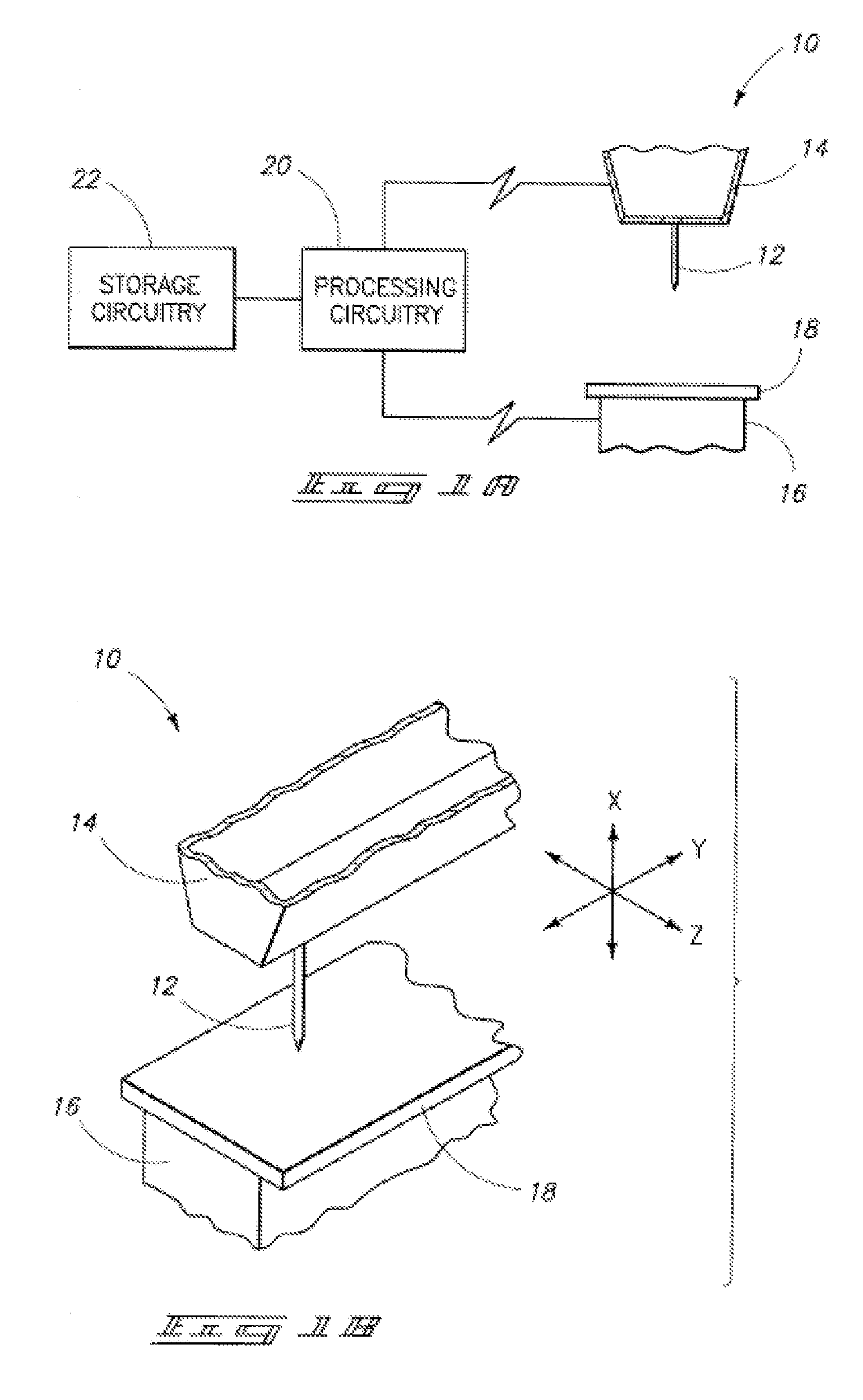

A method for electrostatically depositing select doses of medicament powder at select locations on a substrate. Specifically, an apparatus contains a charged particle emitter for generating charged particles that charge a predefined region of a substrate and a charge accumulation control circuit for computing the amount of charge accumulated upon the substrate and deactivating the emitter when a selected quantity of charge has accumulated. Additionally, a triboelectric charging apparatus charges the medicament powder and forms a charged medicament cloud proximate the charged region of the substrate. The medicament particles within the medicament cloud electrostatically adhere to the charged region. The quantity of charge accumulated on the substrate at the predefined region and the charge-to-mass ratio of the medicament powder in the cloud control the amount (dose) of medicament deposited and retained by the substrate. Consequently, this apparatus accurately controls both medicament dosage and deposition location. Furthermore, since the substrate can be of any dielectric material that retains an electrostatic charge, the apparatus can be used to deposit medicament on substrates that are presently used in oral medicament consumption, e.g., substrates that are used to fabricate suppositories, inhalants, tablets, capsules and the like.

Owner:DELSYS PHARMA

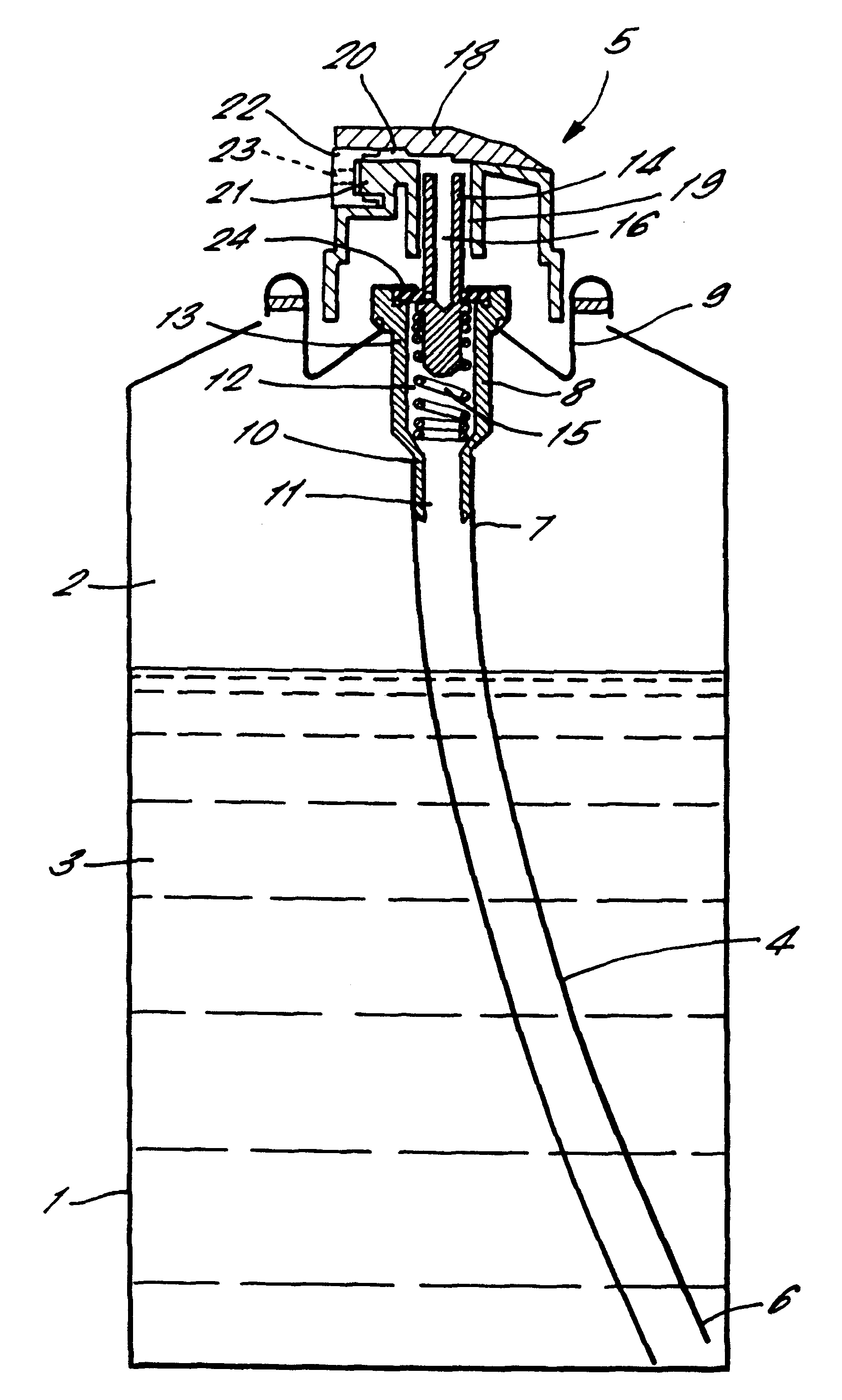

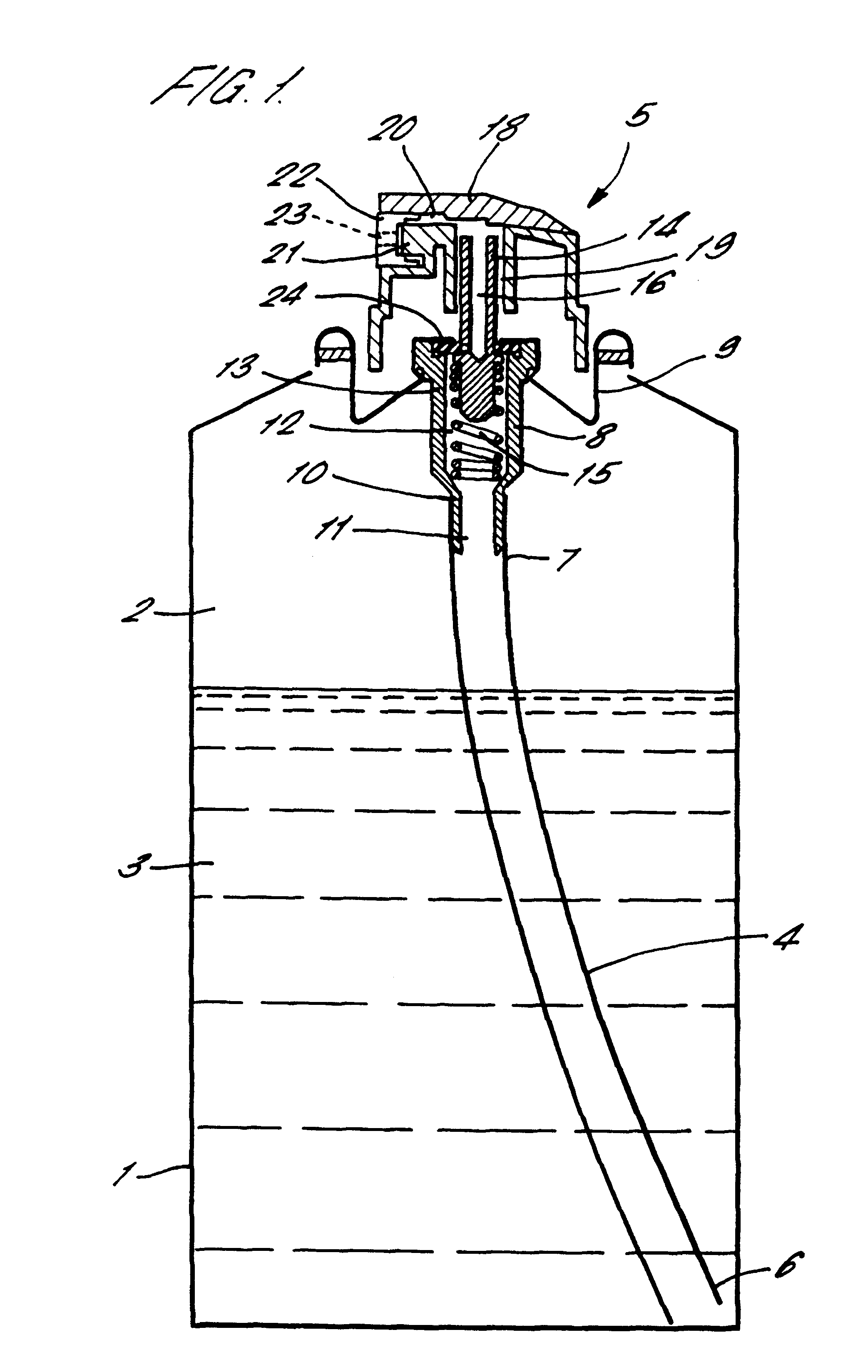

Targeting of flying insects with insecticides and apparatus for charging liquids

InactiveUS6199766B1Improve targetingIncrease ratingsLiquid supply arrangementsSpray nozzlesAerosol sprayGram

A method of killing flying insects which method comprises spraying into the air in which insects are flying liquid droplets of an insecticidal composition, a unipolar charge being imparted to the said liquid droplets by double layer charging and charge separation during spraying, the unipolar charge being at a level such that the said droplets have a charge to mass ratio of at least + / -1x10-4 C / kg. An aerosol spray device which is capable of imparting a unipolar charge by double layer charging and charge separation to liquid droplets of a composition sprayed therefrom has a spraying head in the form of an insert in an actuator, the spraying head having a bore through which liquid is expelled having an outlet, preferably with a tortuous periphery, having an L / a ratio of at least 8 (preferably at least 10) where L is the length of the periphery defining the bore outlet in mm and a is the cross-sectional area of the bore outlet in mm2 and the apparatus being constructed such that the droplets are expelled from the spraying head at a flow ratio of at least 0.4 (preferably at least 0.5) grams per second and have a charge to mass ratio of at least + / -1x10-4 C / kg.

Owner:UNIV OF SOUTHAMPTON +1

Apparatuses and methods for applying one or more materials on one or more substrates

A system that incorporates teachings of the present disclosure may include, for example, an apparatus having a tube with an ingress opening to receive a liquid, and an egress opening to release the liquid, a conductor positioned in a conduit of the tube, the conductor and the conduit having dimensions to cause a surface tension of the liquid to prevent a constant flow of the liquid from the egress opening, and a power supply coupled to the conductor to apply a charge to the liquid to overcome the surface tension and form at the egress opening a single jet stream of the liquid applicable on a substrate to create a pattern. The single jet stream can be controllable in part by a viscosity of the liquid. Additional embodiments are disclosed.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

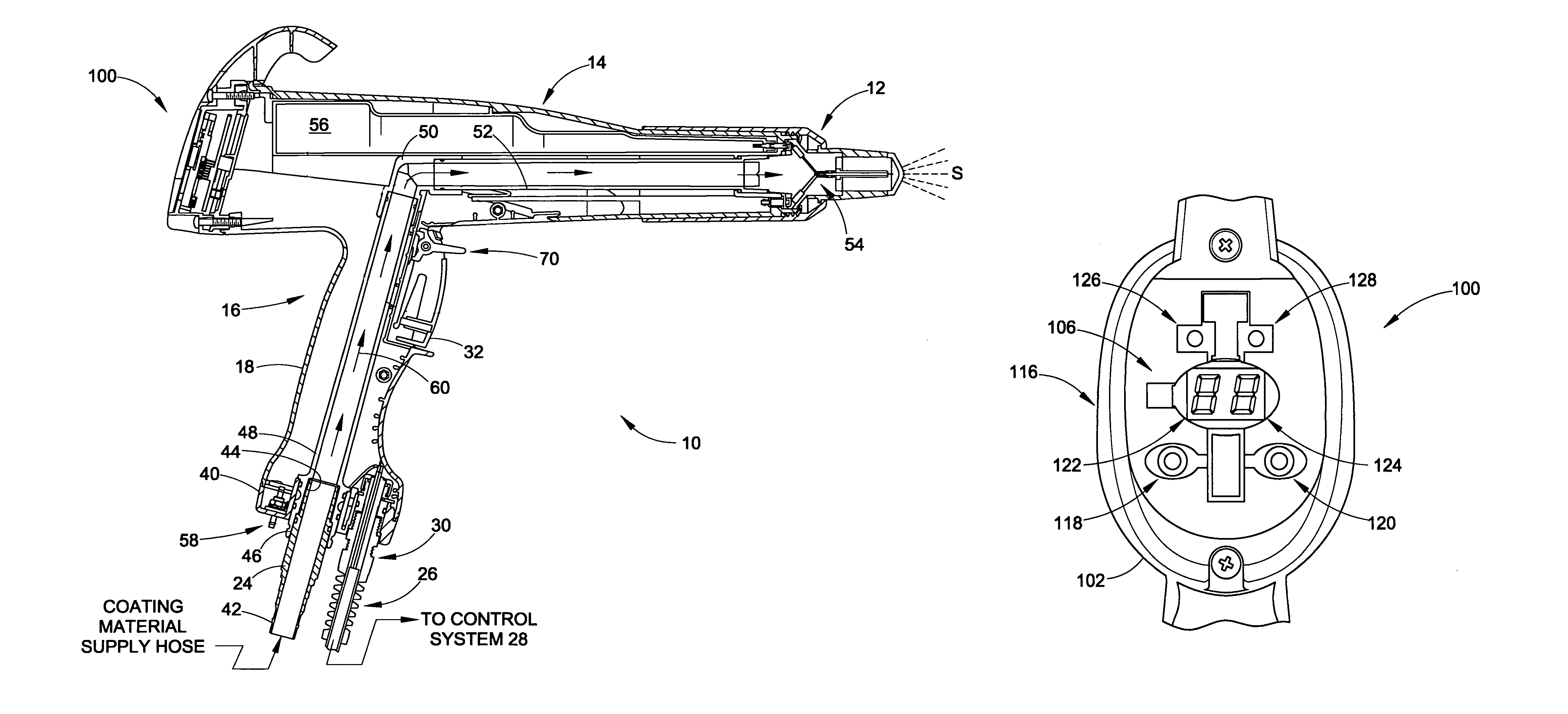

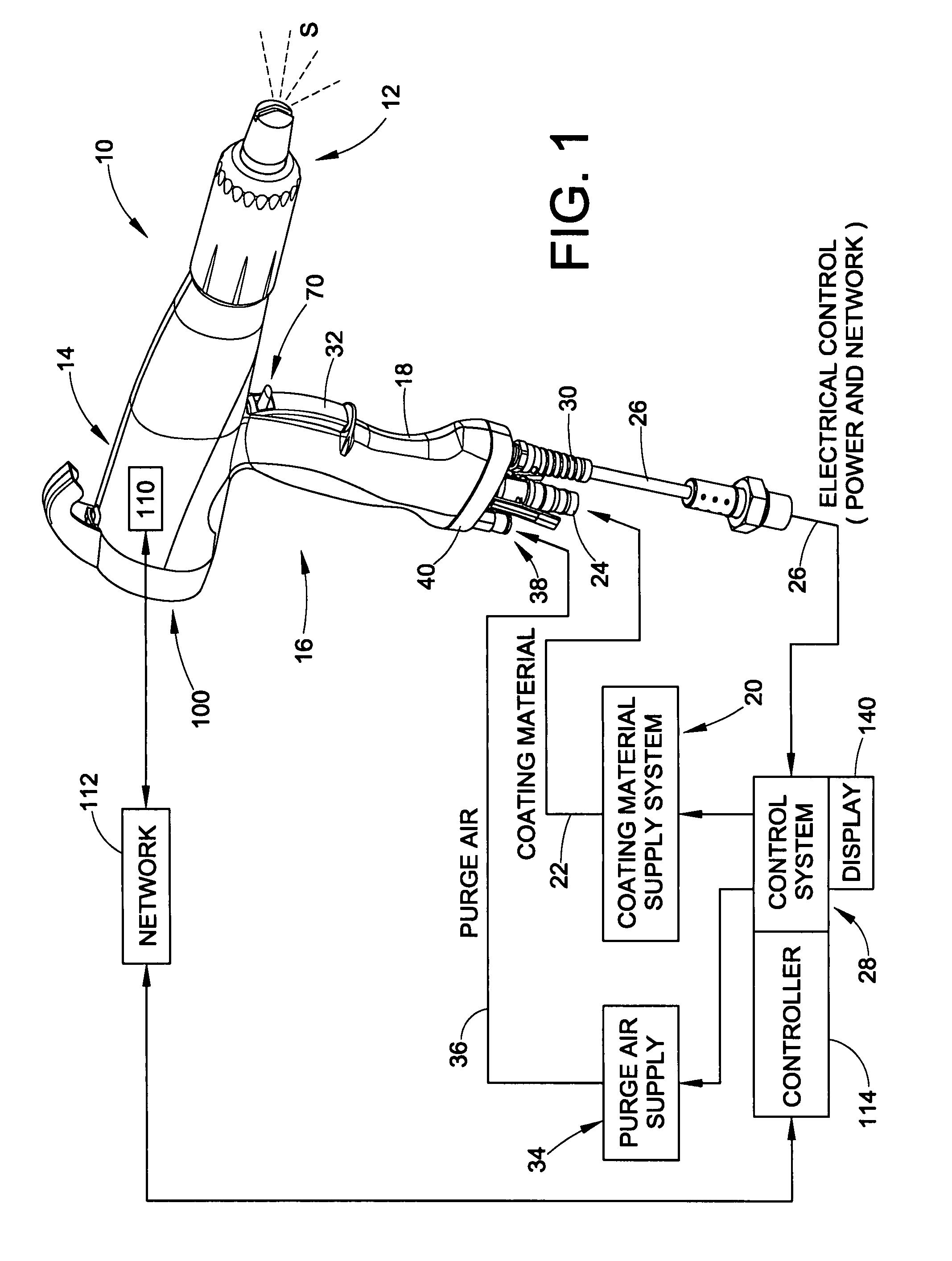

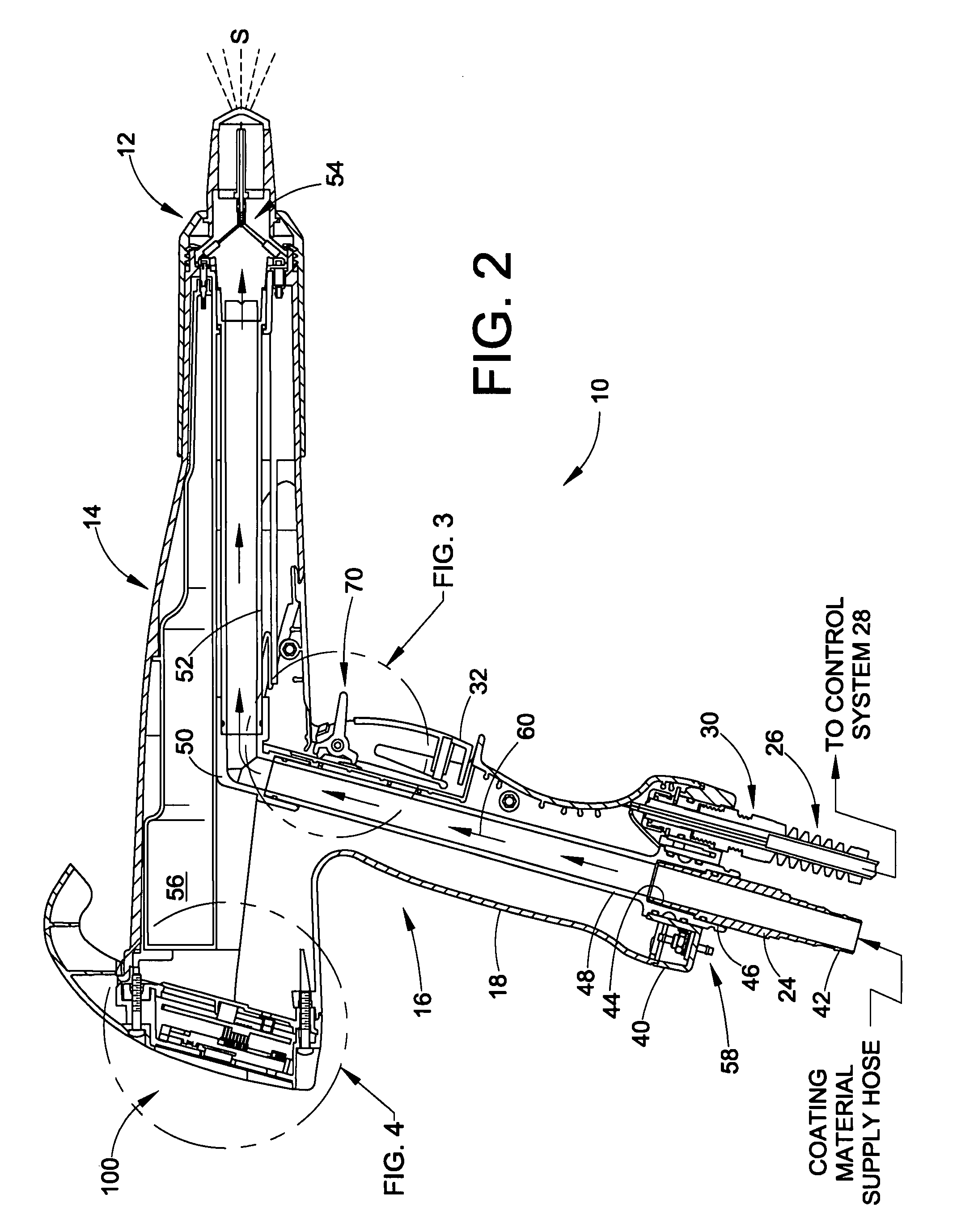

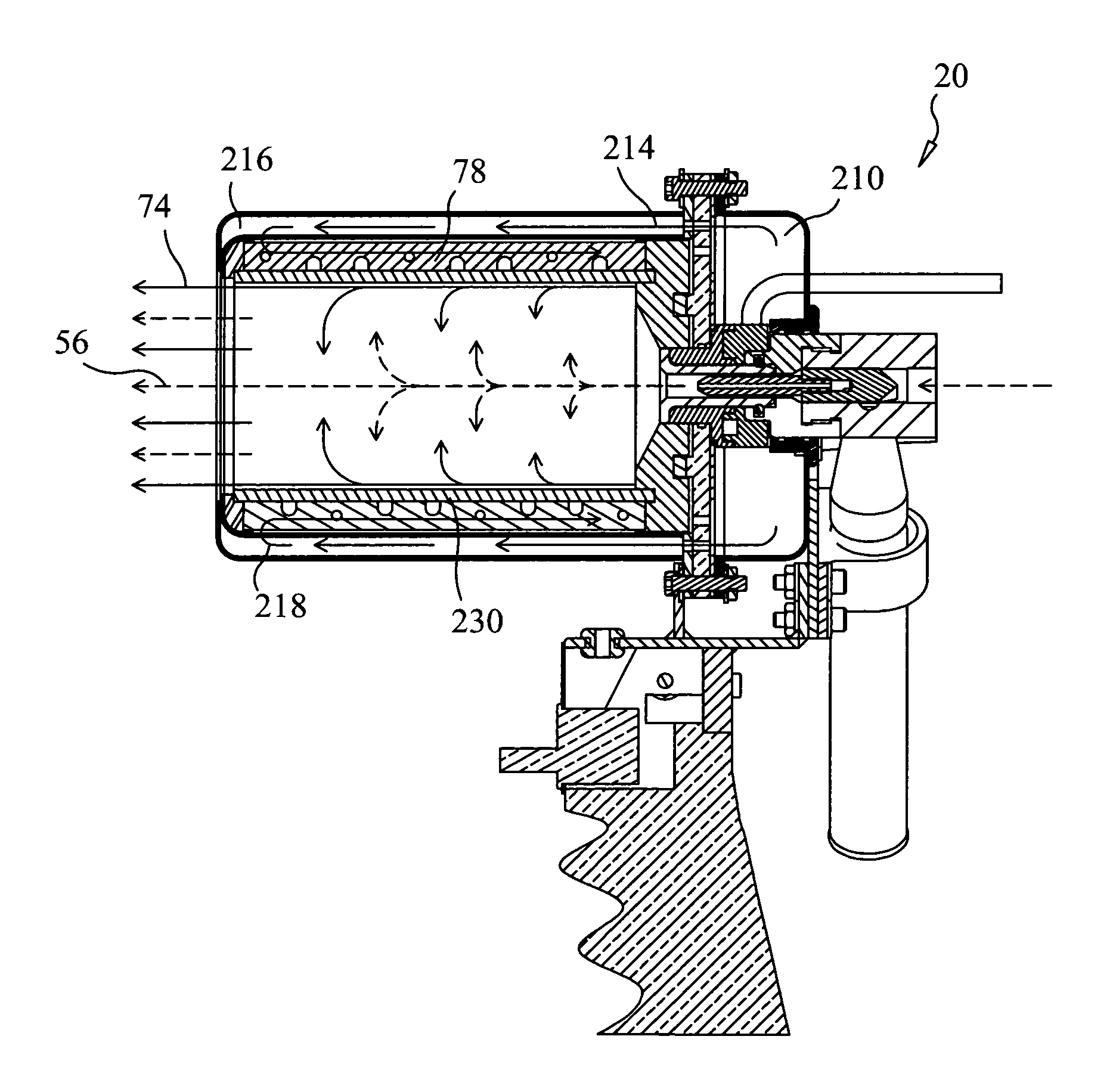

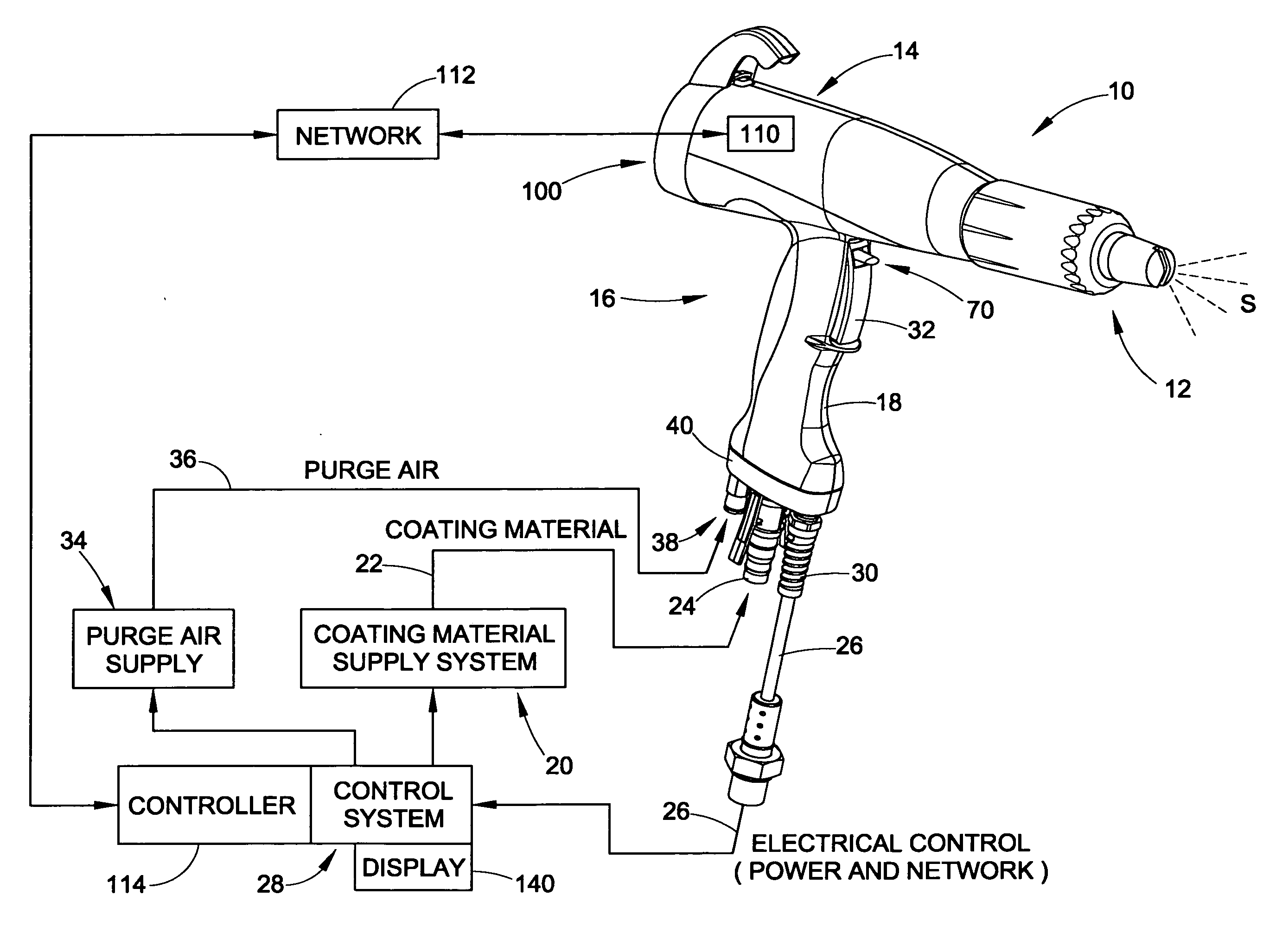

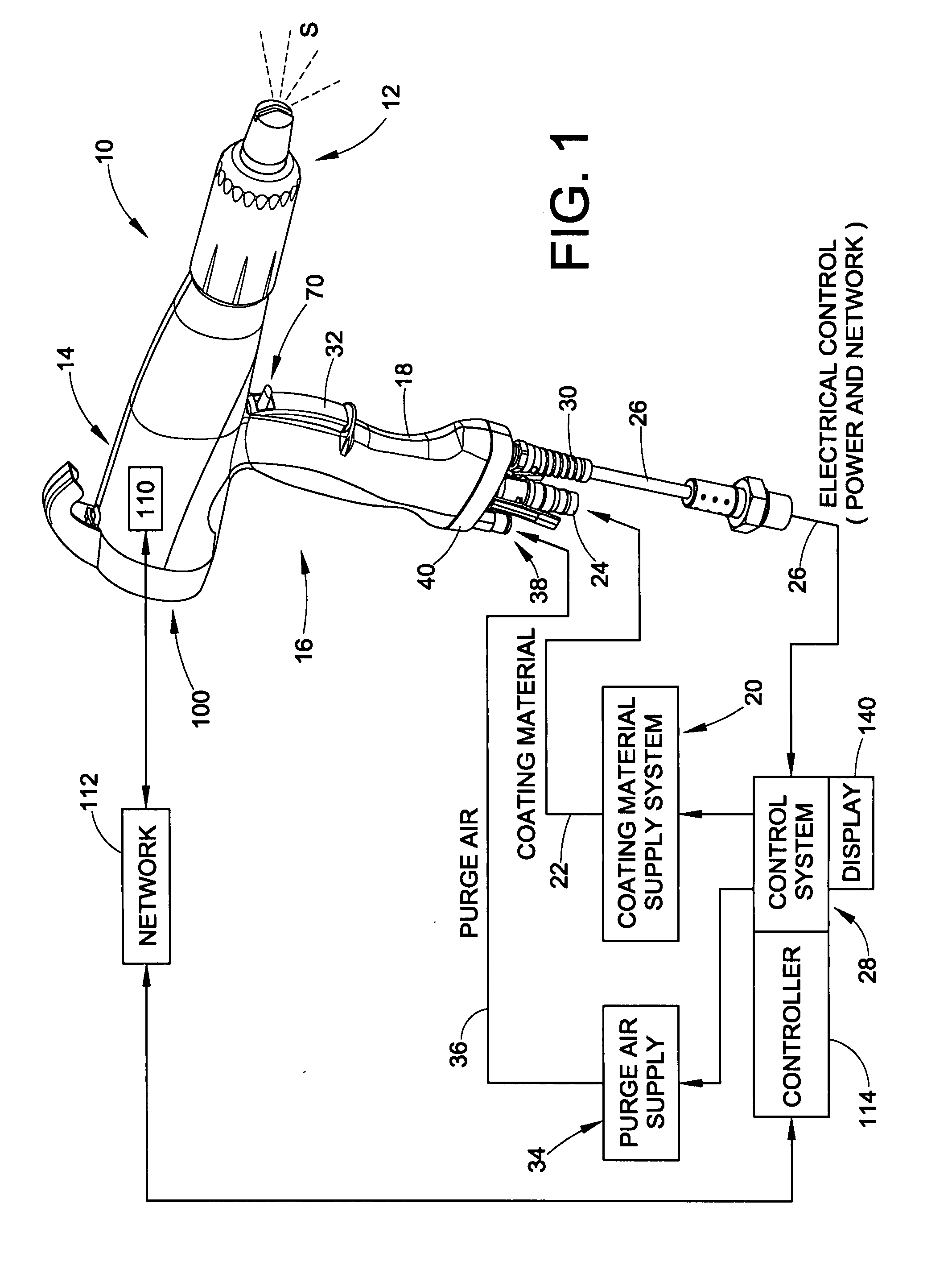

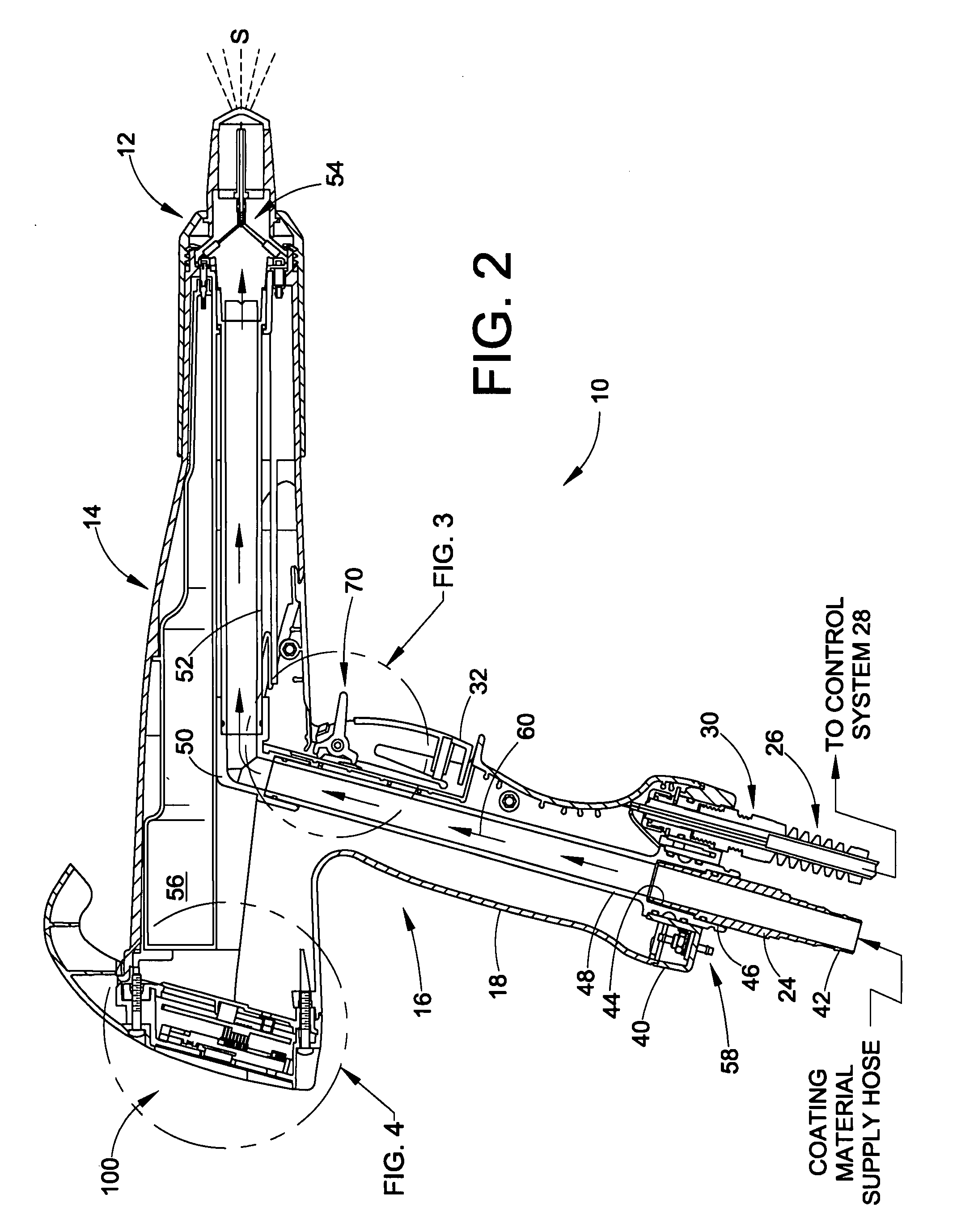

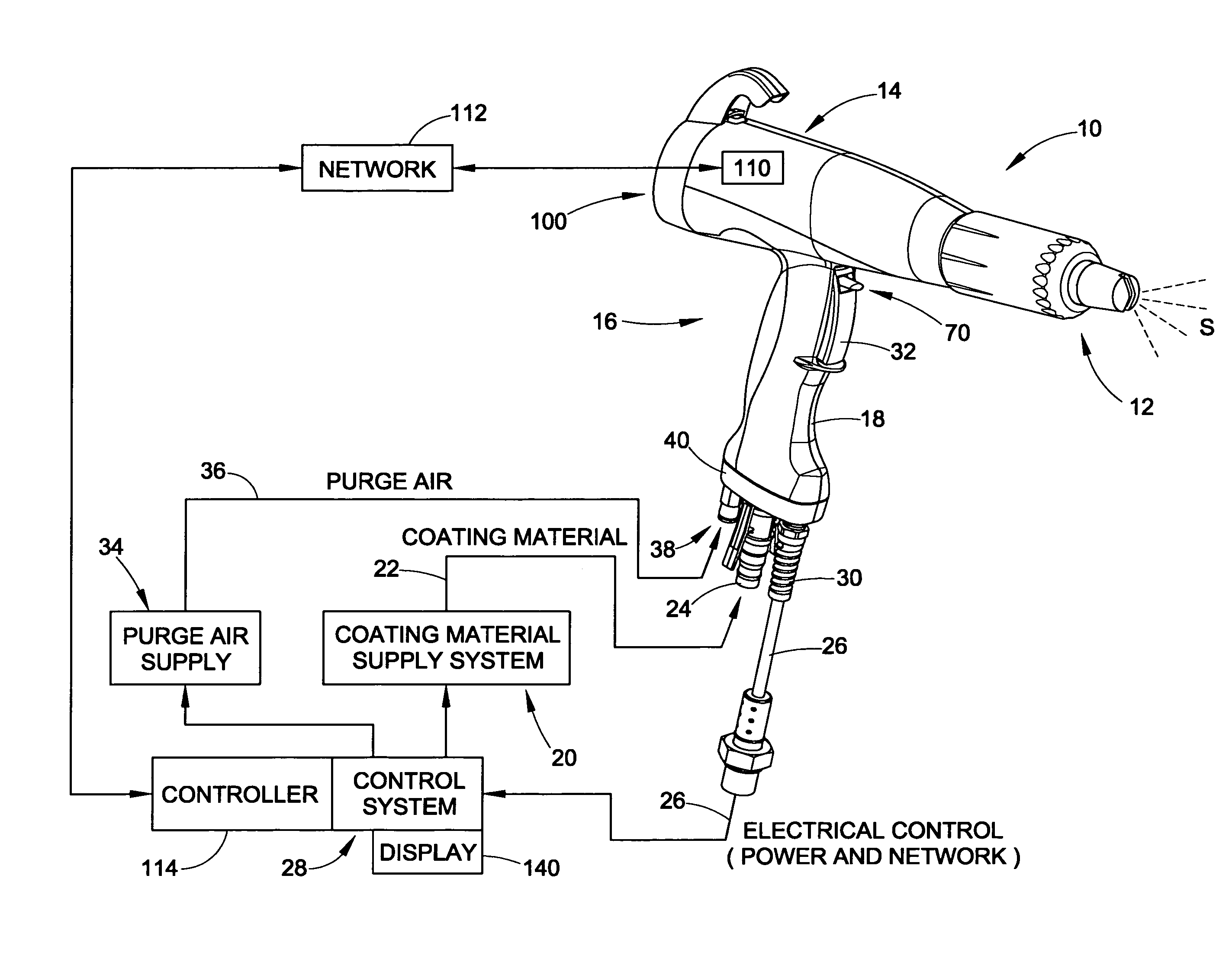

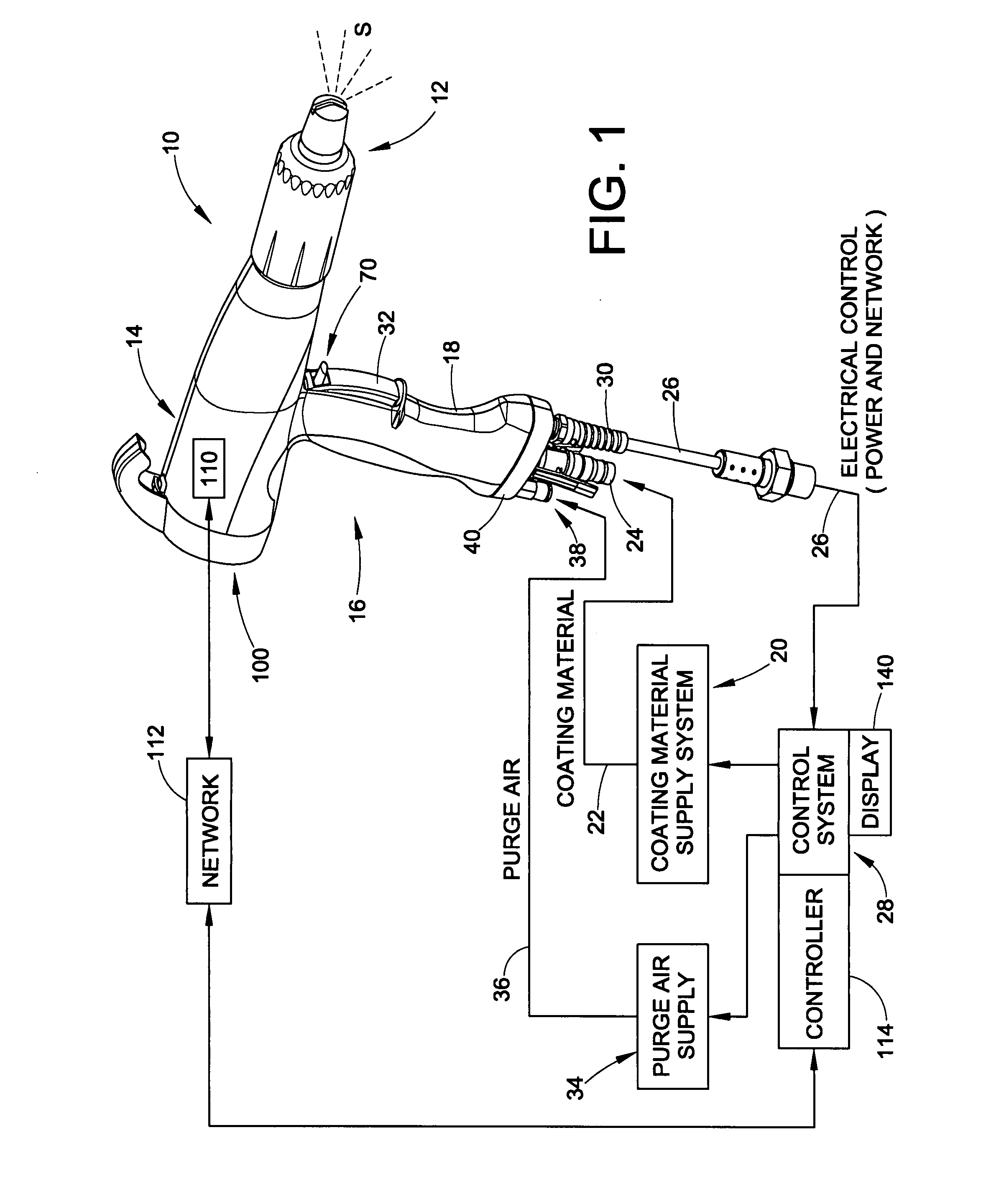

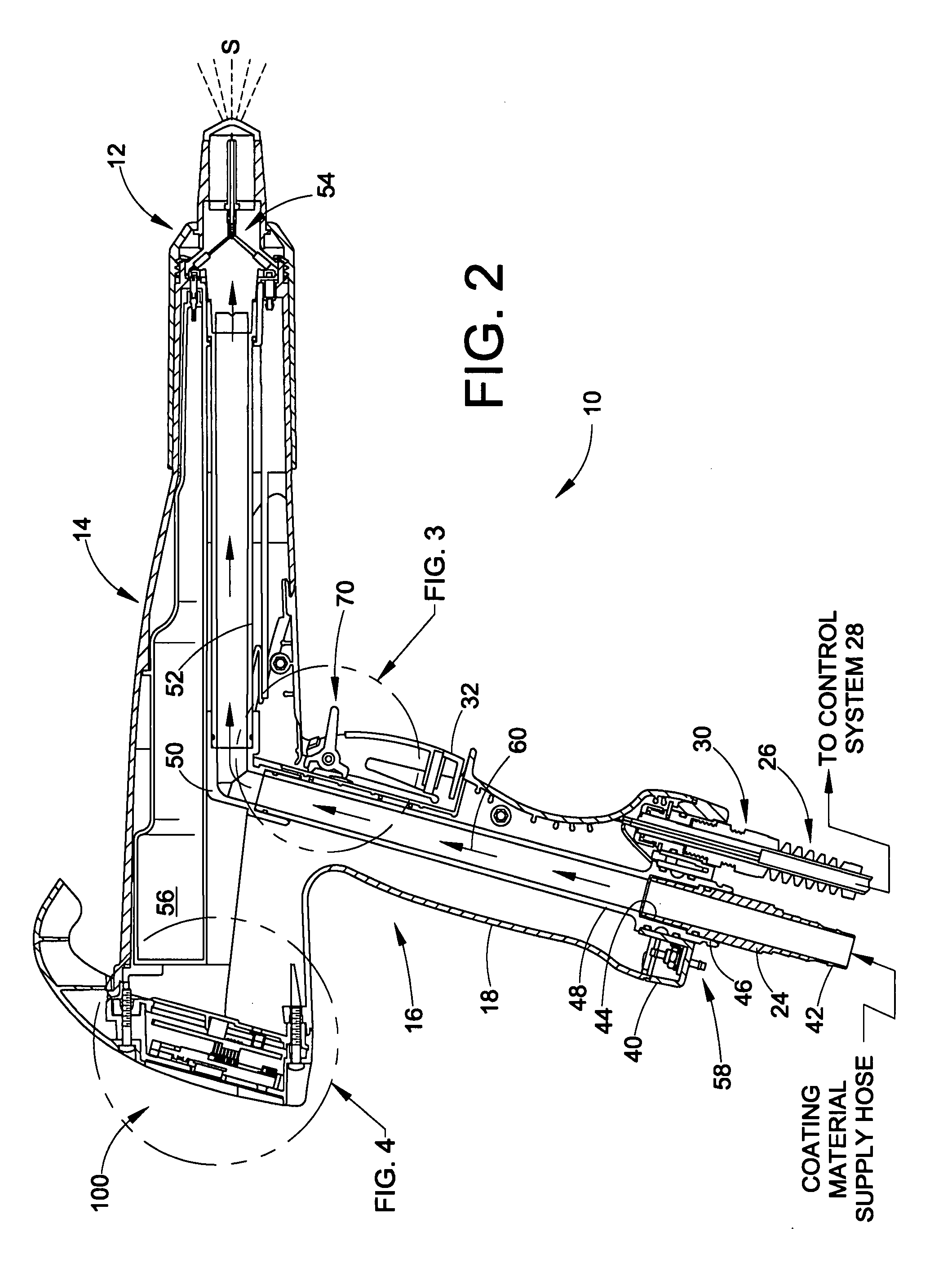

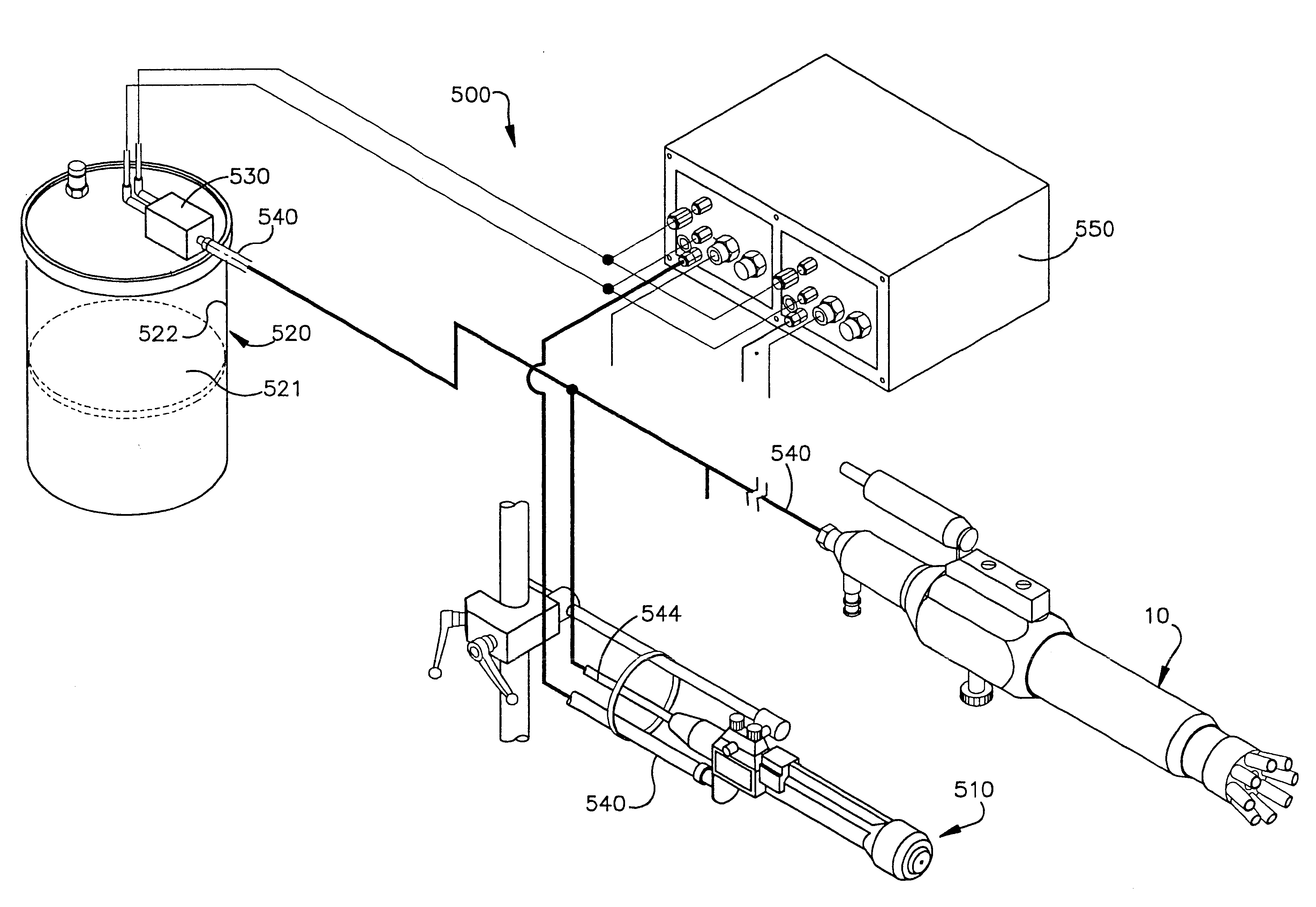

Spray gun having display and control members on gun

Control method and apparatus for a manual spray gun includes display that is disposed on the spray gun and that provides information to an operator about one or more coating operation parameters. An auxiliary trigger may be used that enables an operator to make selections or changes of one or more coating operation parameters. The display and auxiliary trigger together permit an operator to make selections or changes without having to divert attention or field of view away from the spray gun or the coating area, especially during a coating operation. The display may include numeric information, for example, data relating to a coating function being displayed.

Owner:NORDSON CORP

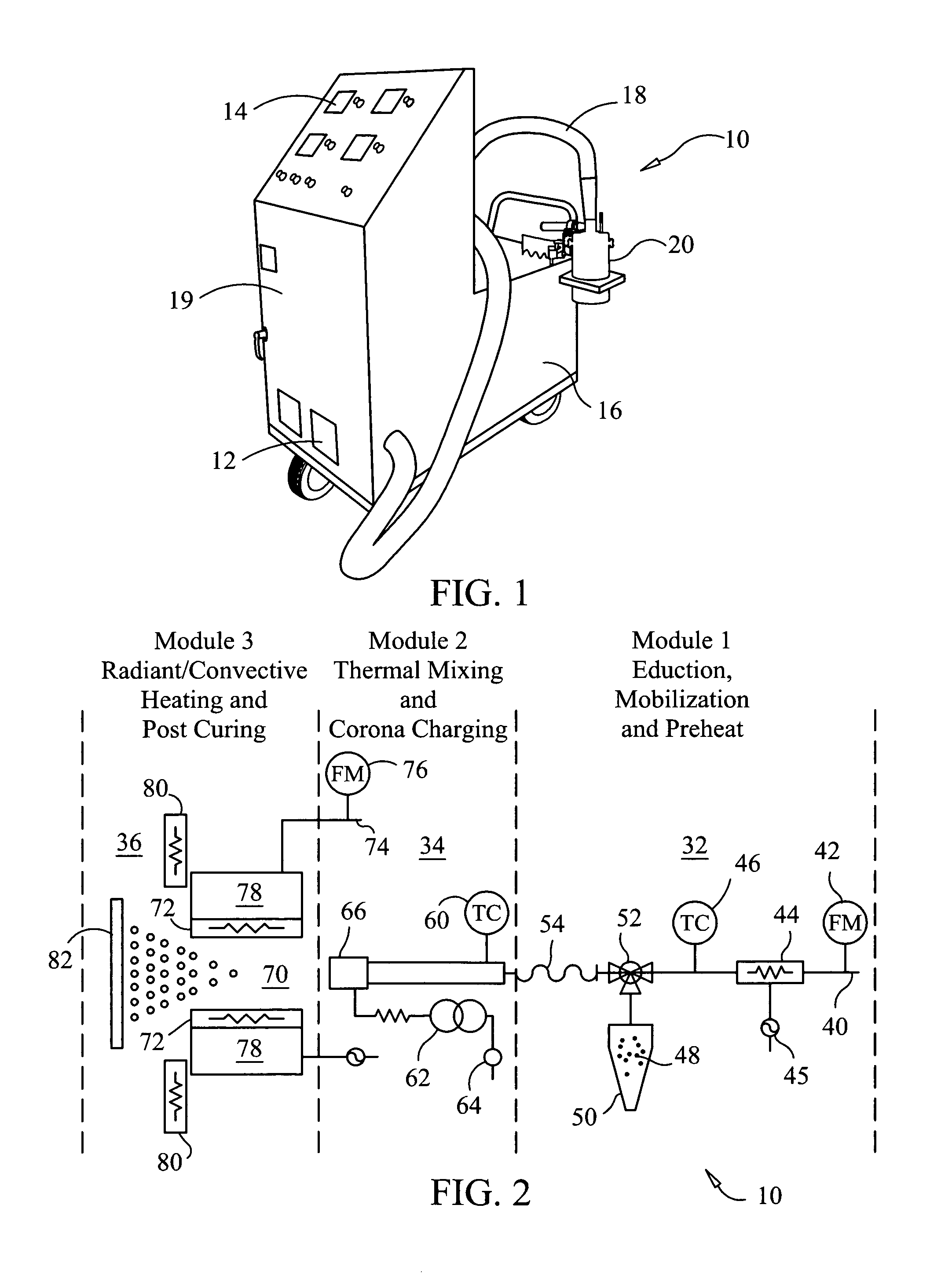

Thermal spray formation of polymer compositions

ActiveUS7959983B1Inexpensively appliedFacilitate thermal sprayingPretreated surfacesLiquid spraying apparatusEpoxyPolyester

A system and method for applying a material, such as a polymer composition, to a substrate, the method comprising mixing the material with a heated carrier gas stream, spraying the material through a nozzle, and radiant and convective heating of the material during transport. Preferred embodiments of the system and method can be used to spray polyetherimides, polyimides, polyamides, thermoset resins (e.g., and epoxies, polyesters and silicones), liquid crystal polymers, compositions comprising a blowing agent, compositions comprising a binder, compositions comprising a metallized material, compositions that produce an open cell foam, and compositions that produce a closed cell foam.

Owner:FARRAR LAWRENCE C +2

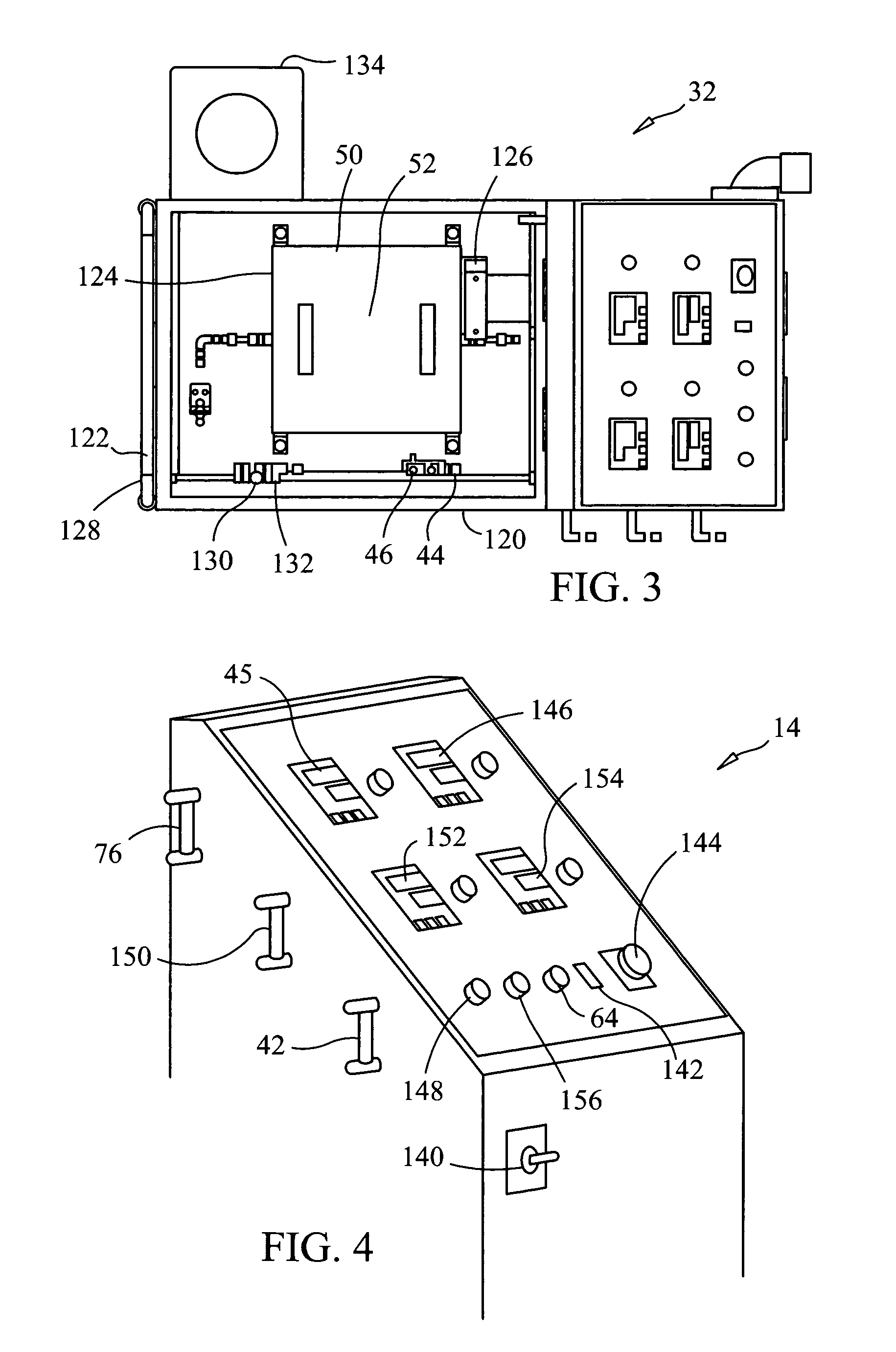

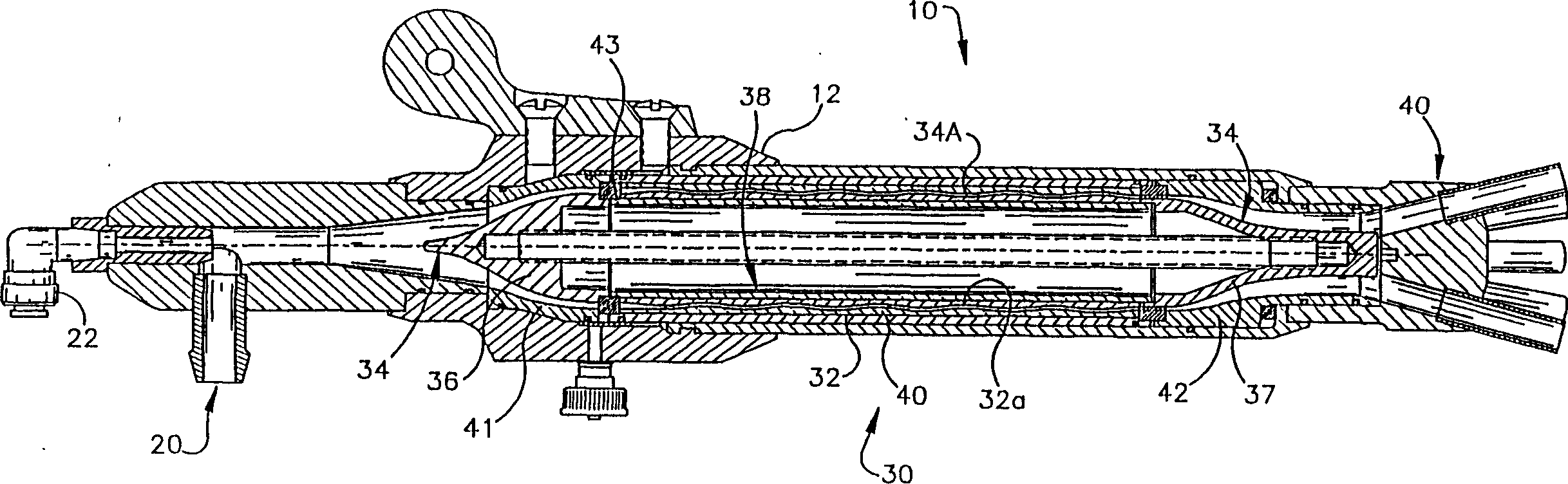

Modular powder application system

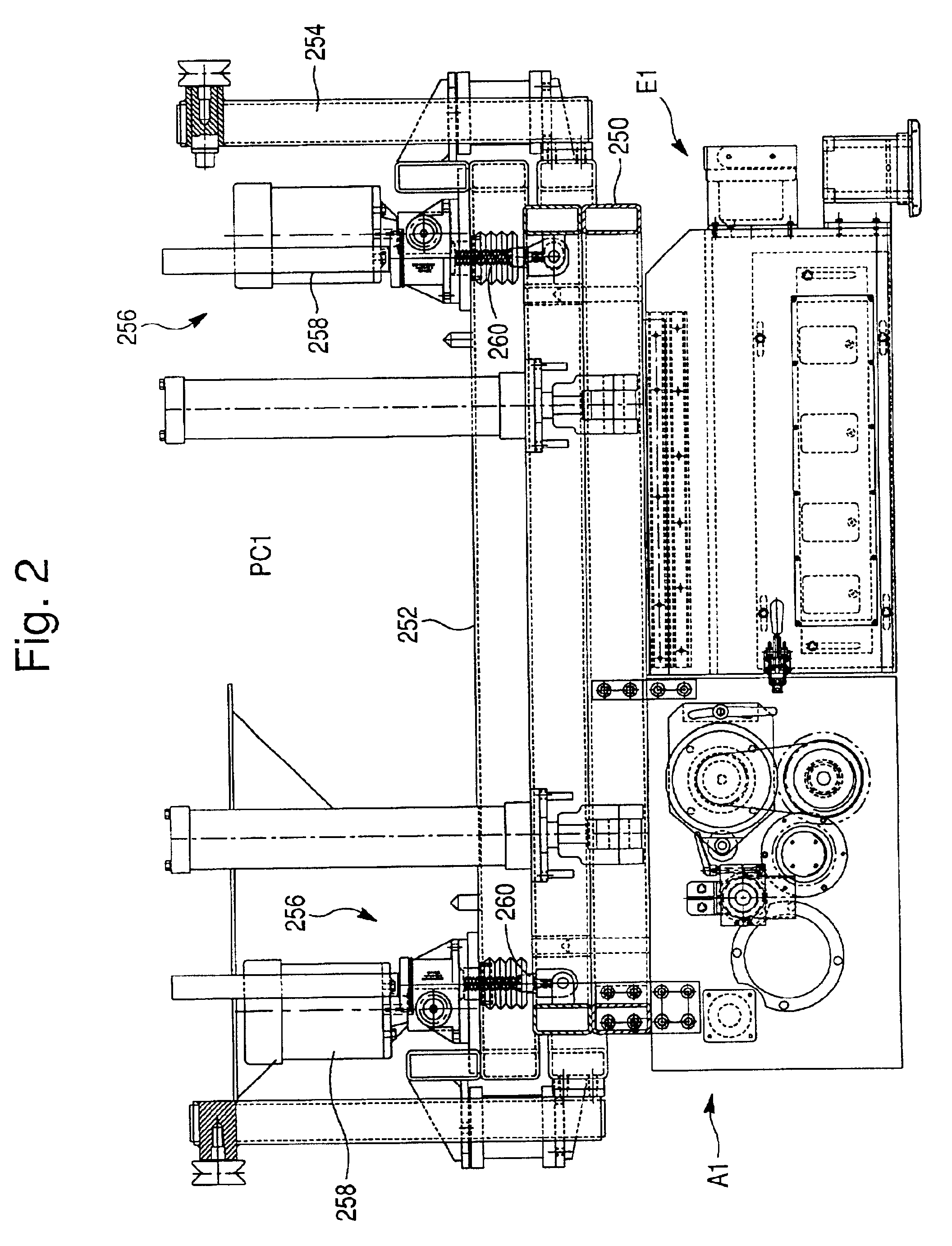

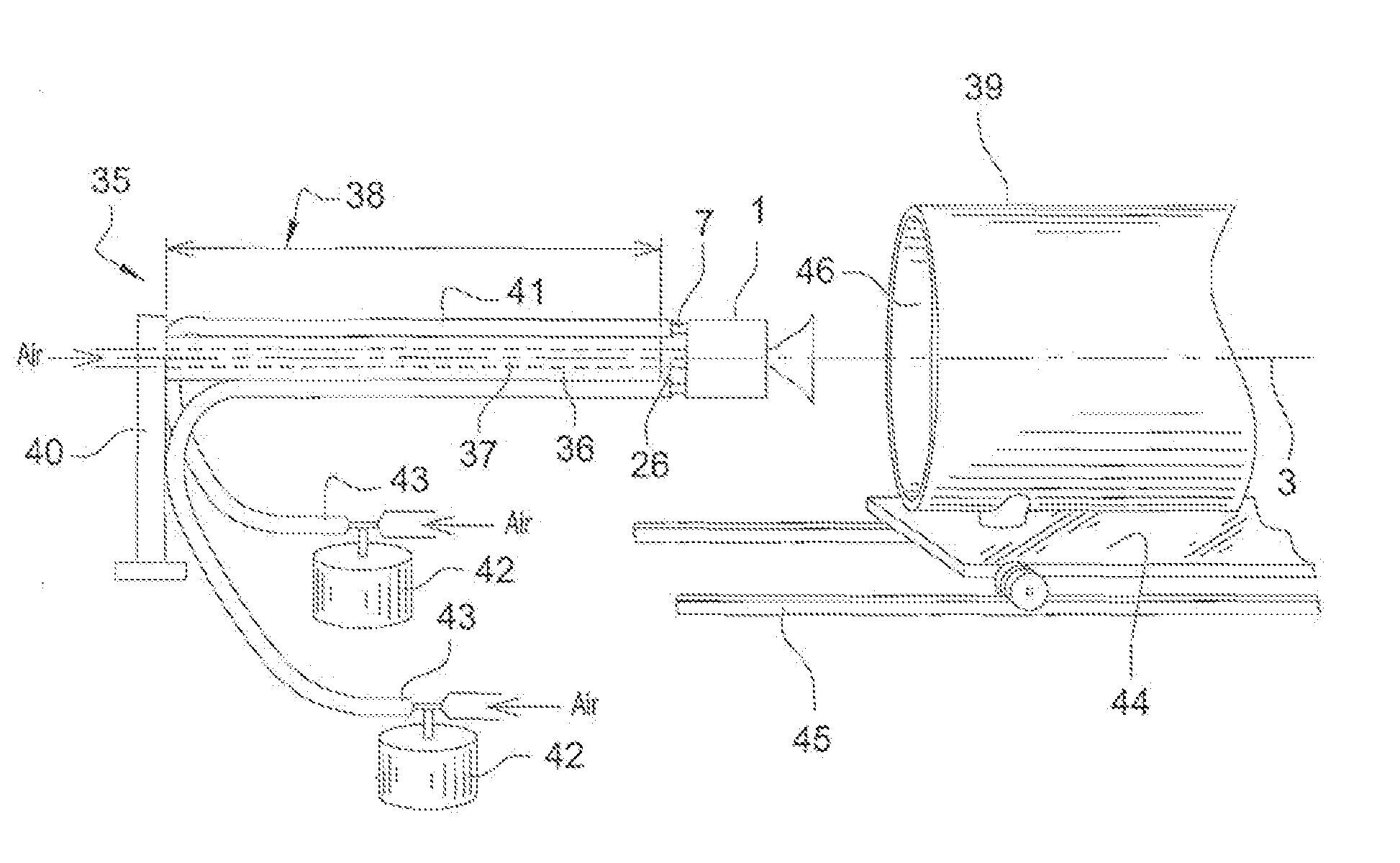

InactiveUS6875278B2Facilitates rotation of shaftReduce pollutionBurnersLiquid spraying plantsEngineeringMechanical engineering

A powder atomizer comprises a rotatable powder conveying brush operably associated with a powder supply. A powder receptacle has an inlet and an outlet. The powder conveying brush extends along the inlet and supplies powder to the receptacle. A rotatable powder metering brush is operatively associated with the outlet and withdraws powder from the receptacle. A rotatable powder atomizing brush is operatively associated with and receives powder from the metering brush and discharges the powder. A shoe is operatively associated with the atomizing brush, and is pivotable about a pivot axis between a first and a second position.

Owner:MATERIAL SCIENCES CORPORATION

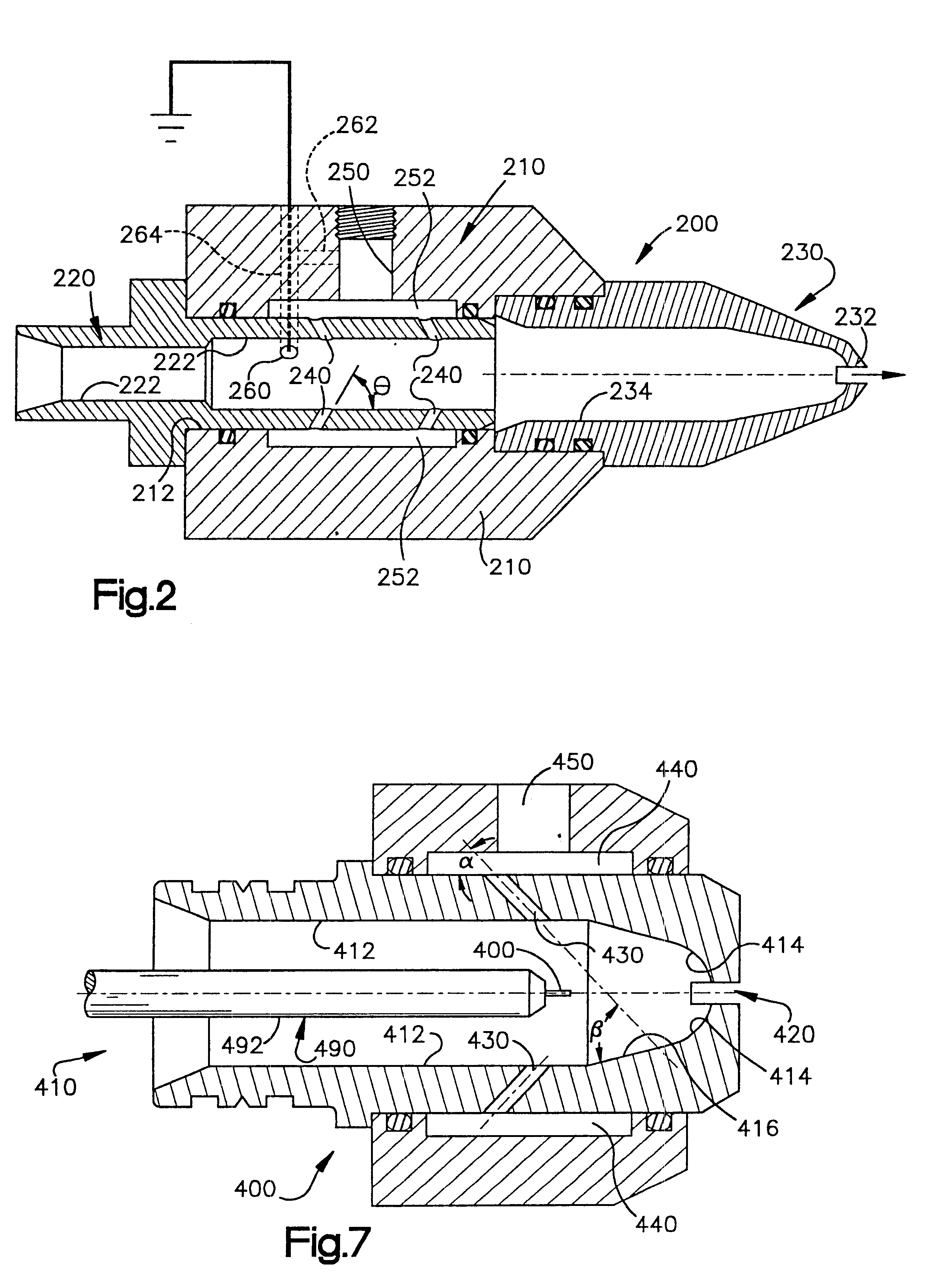

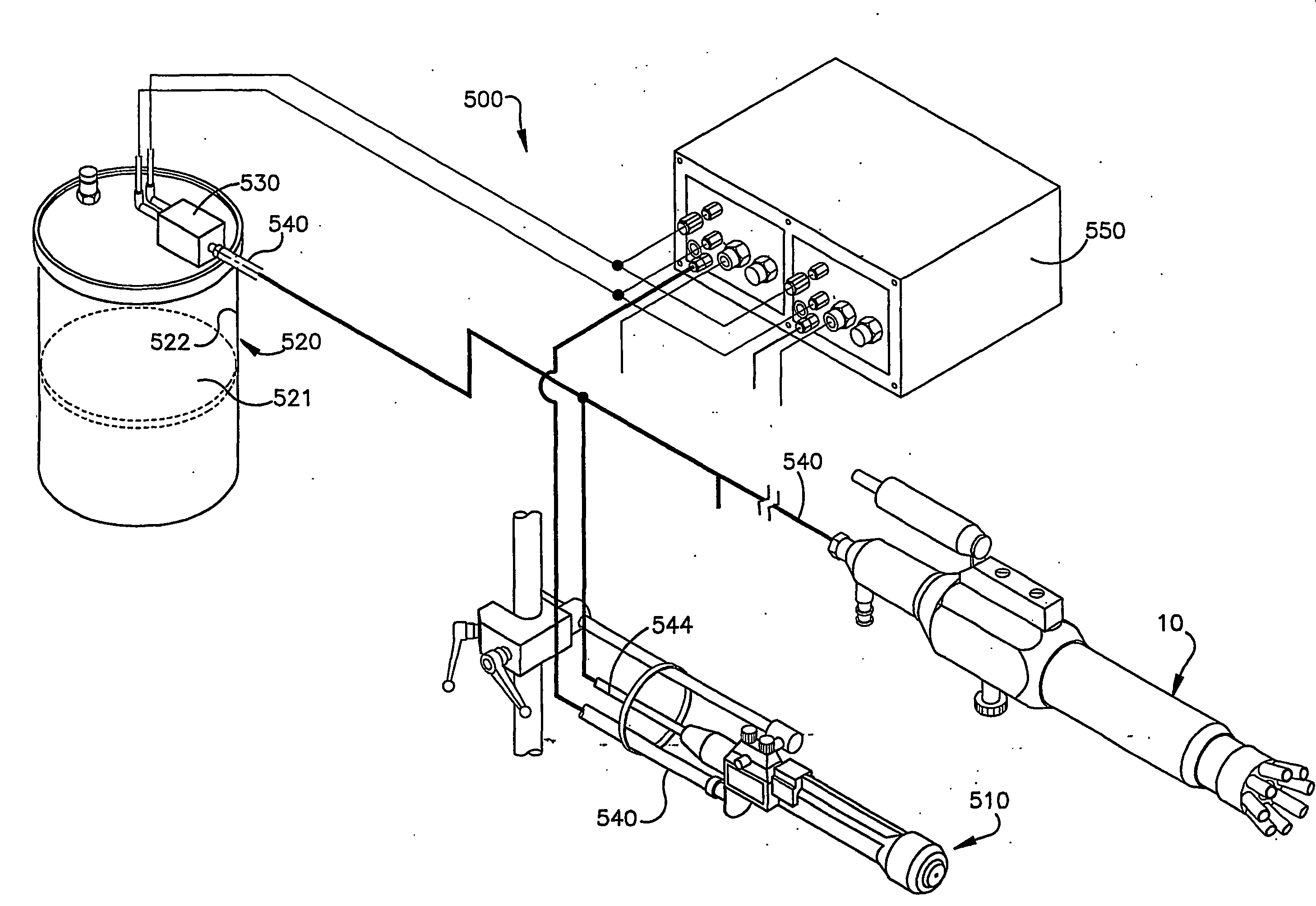

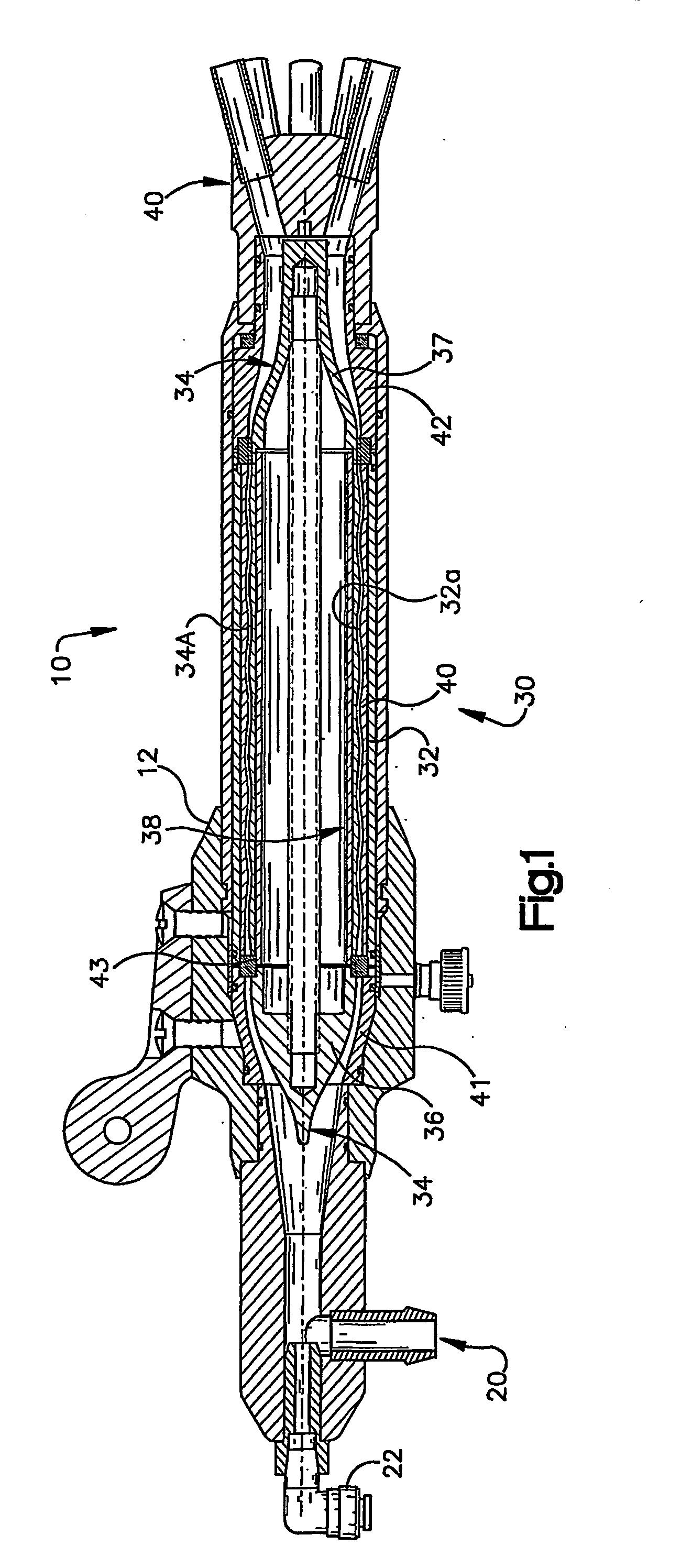

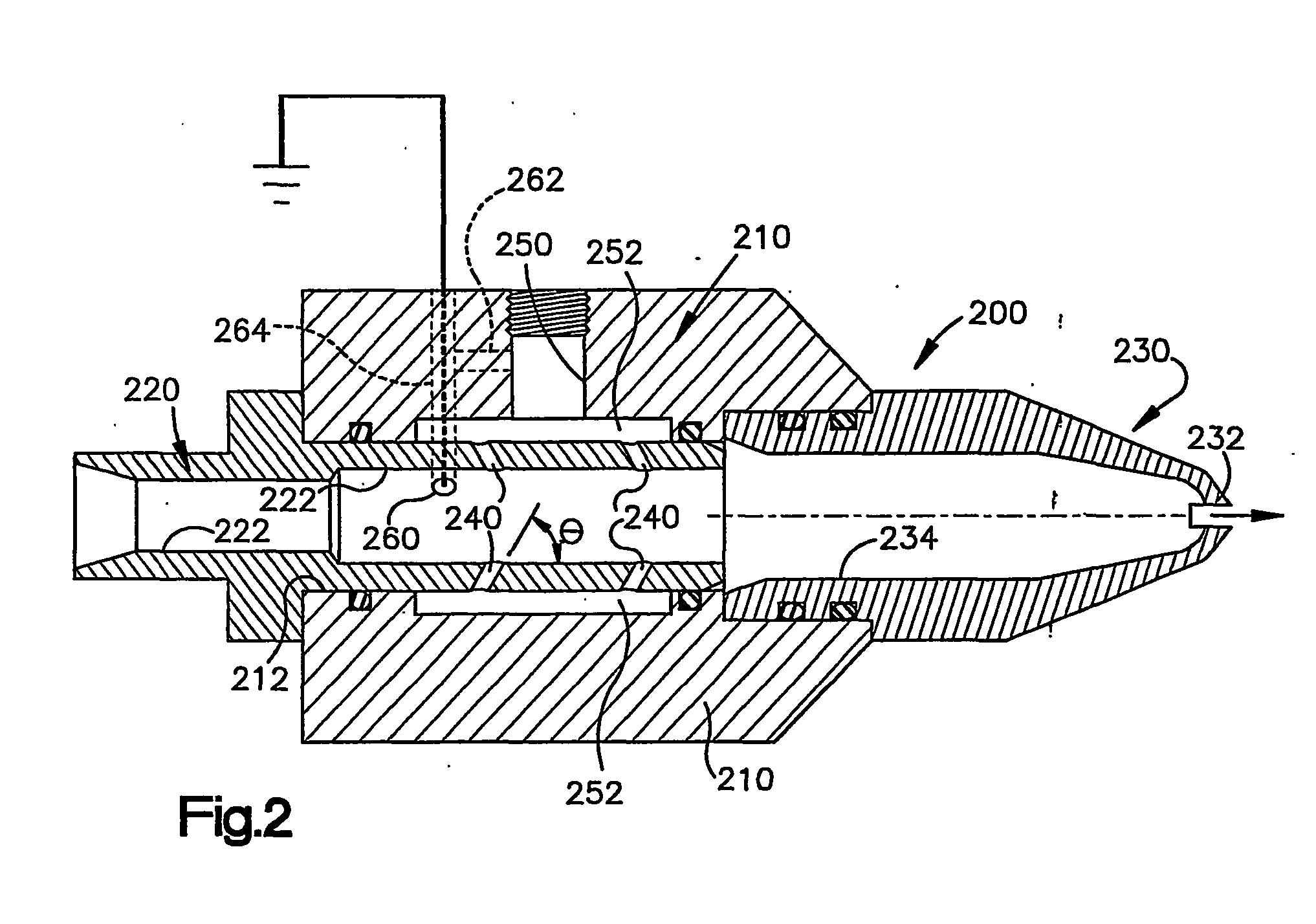

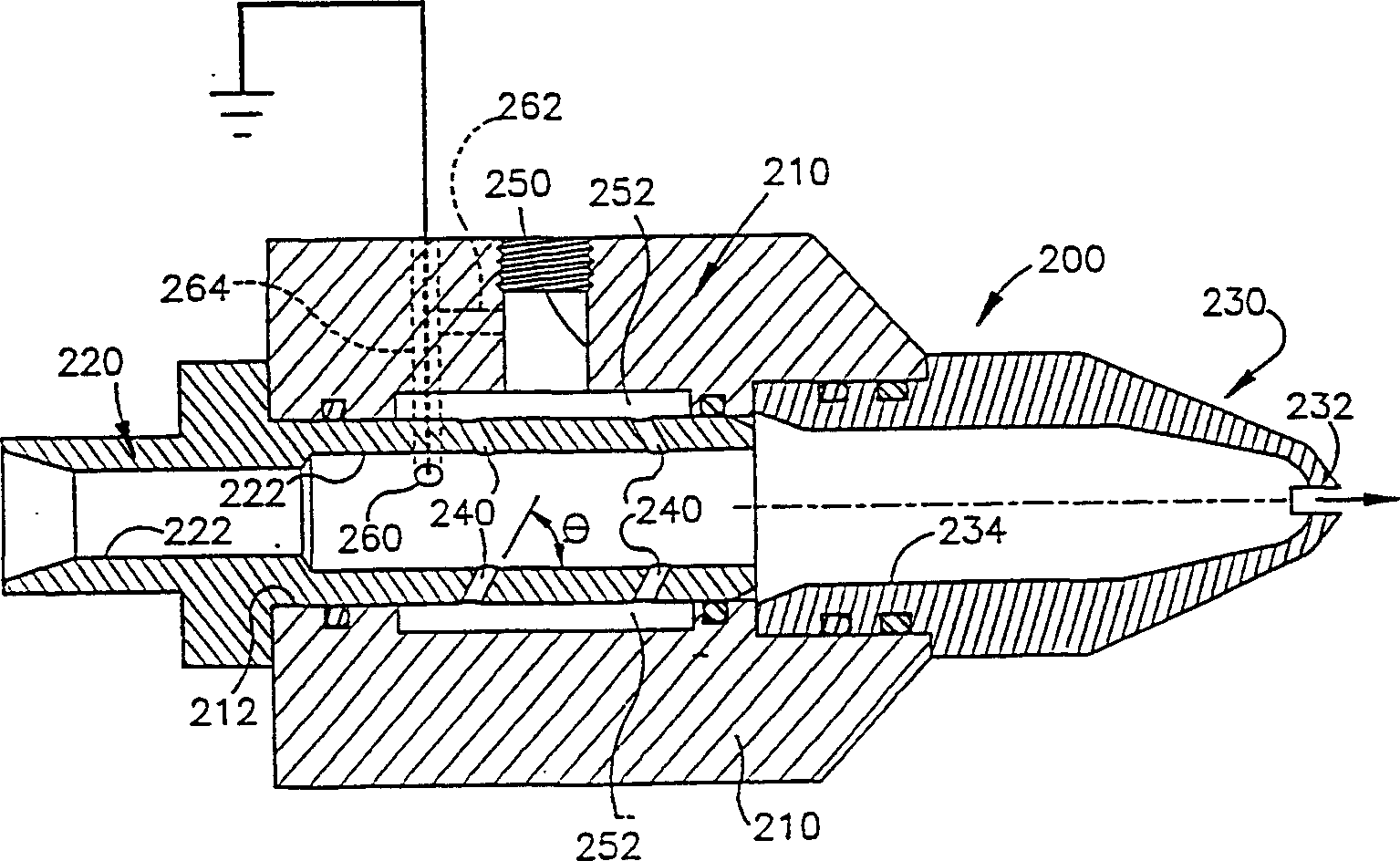

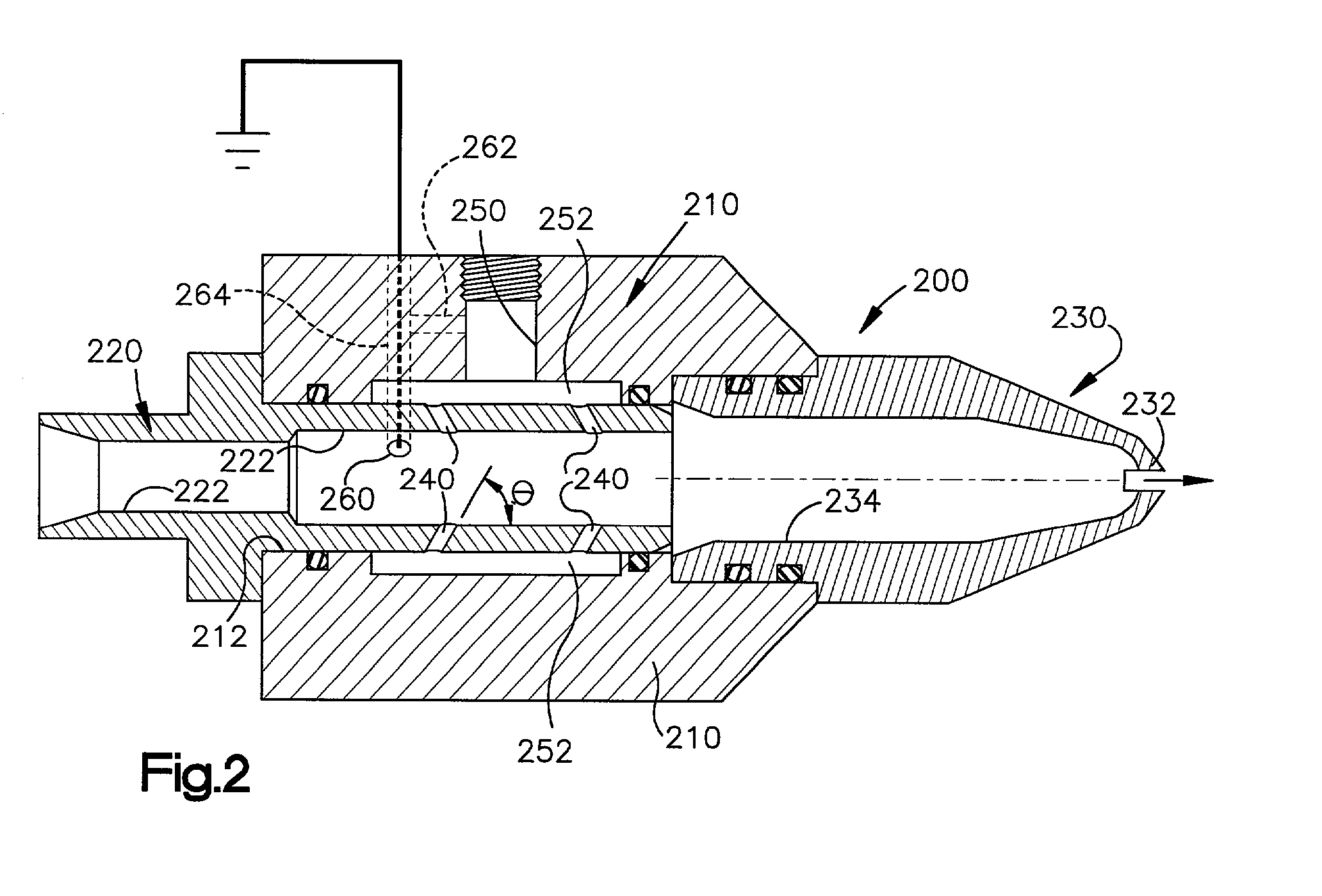

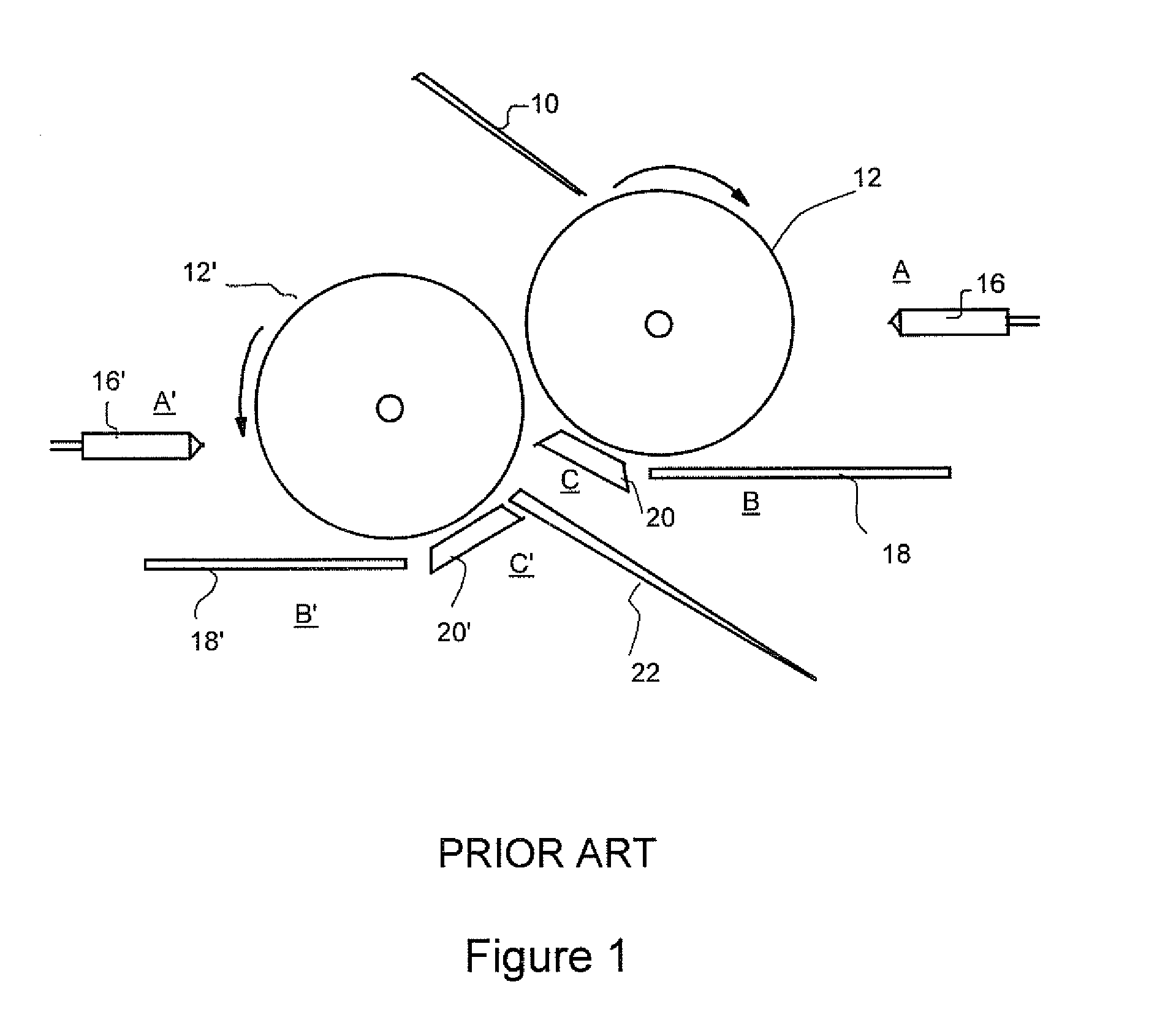

Unipolarity powder coating systems including tribocharging and corona gun combination

InactiveUS20040251327A1Reduce and minimize likelihoodEnhance tribochargingBurnersSpraying power supplyMetallurgyElectrical polarity

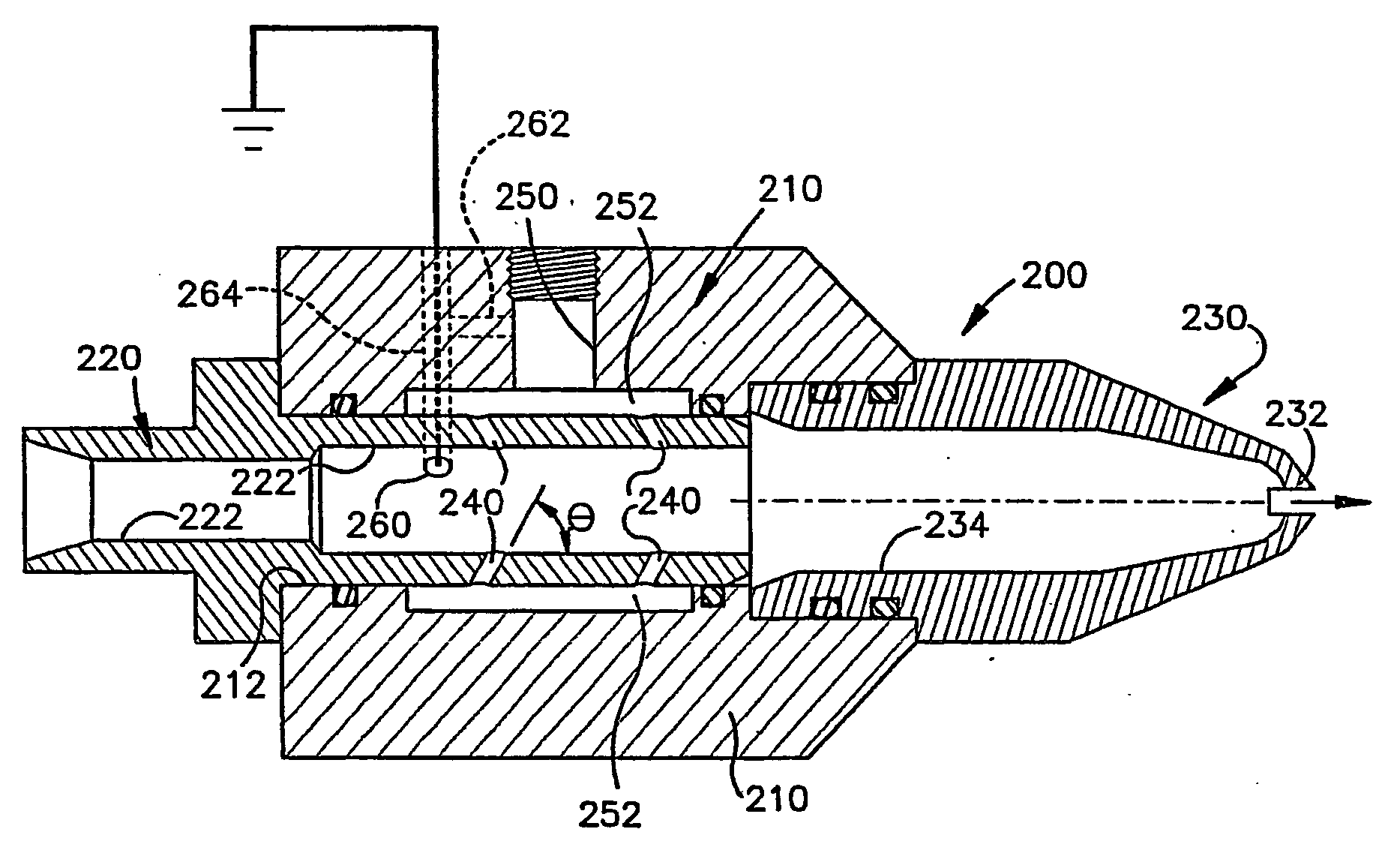

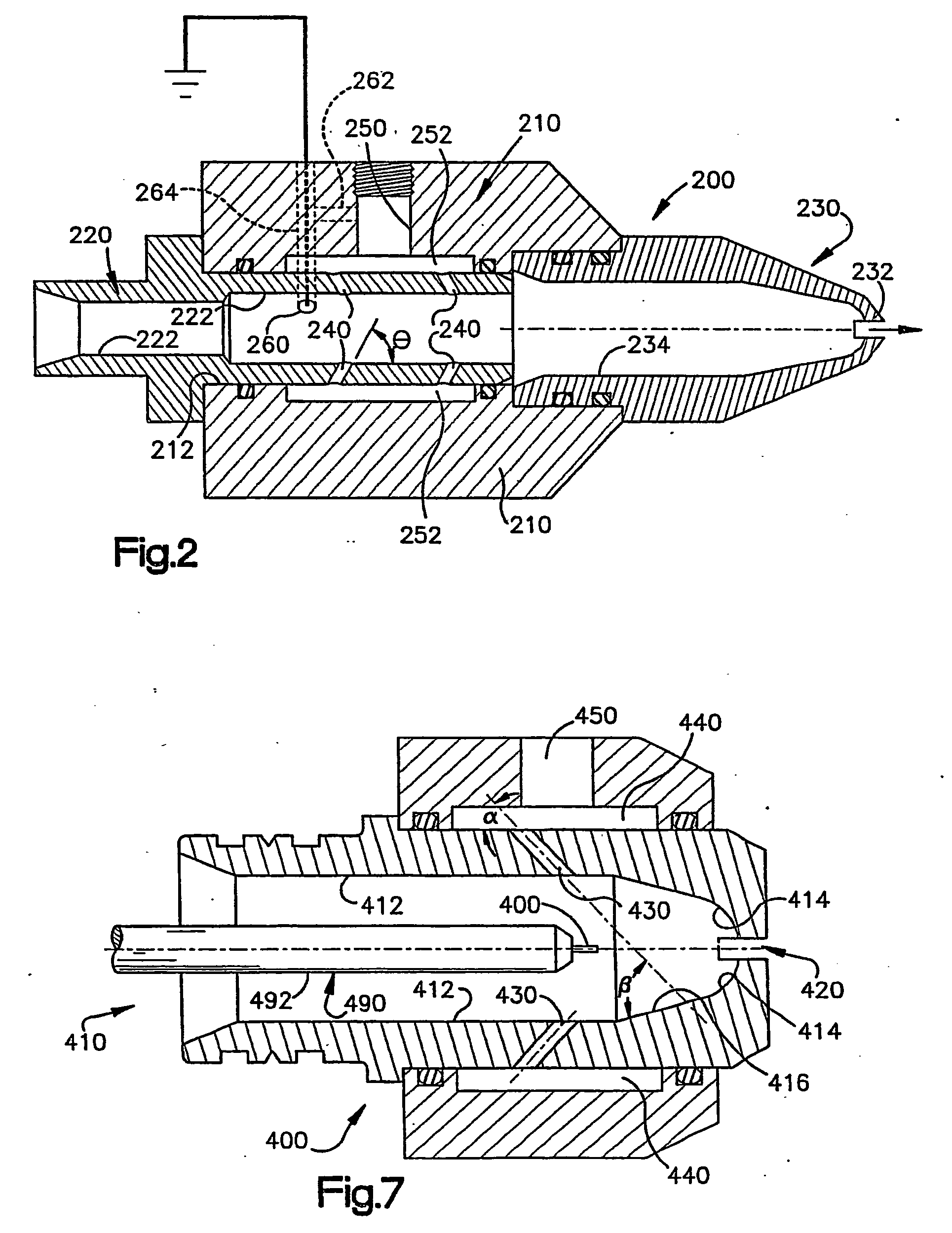

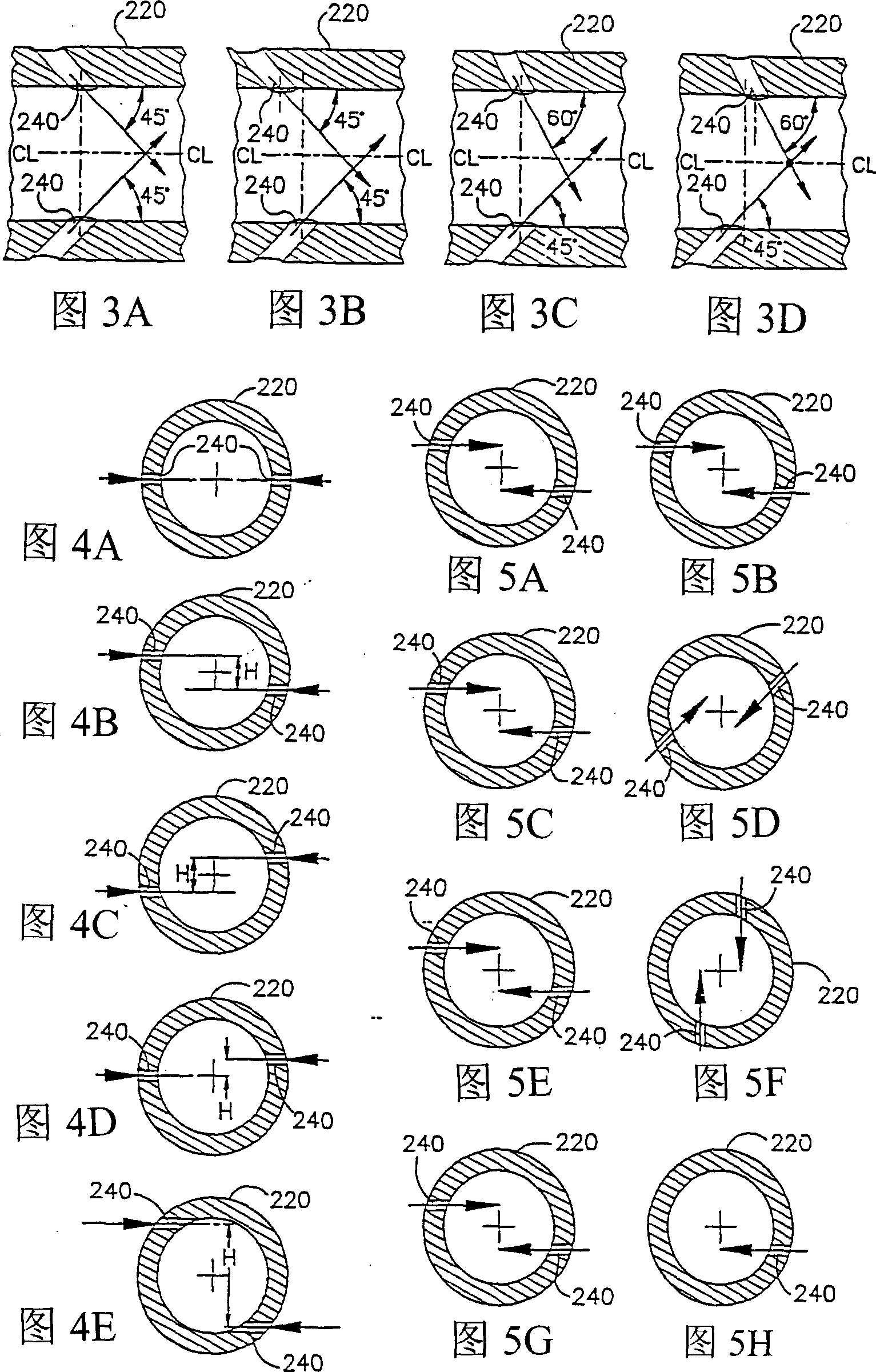

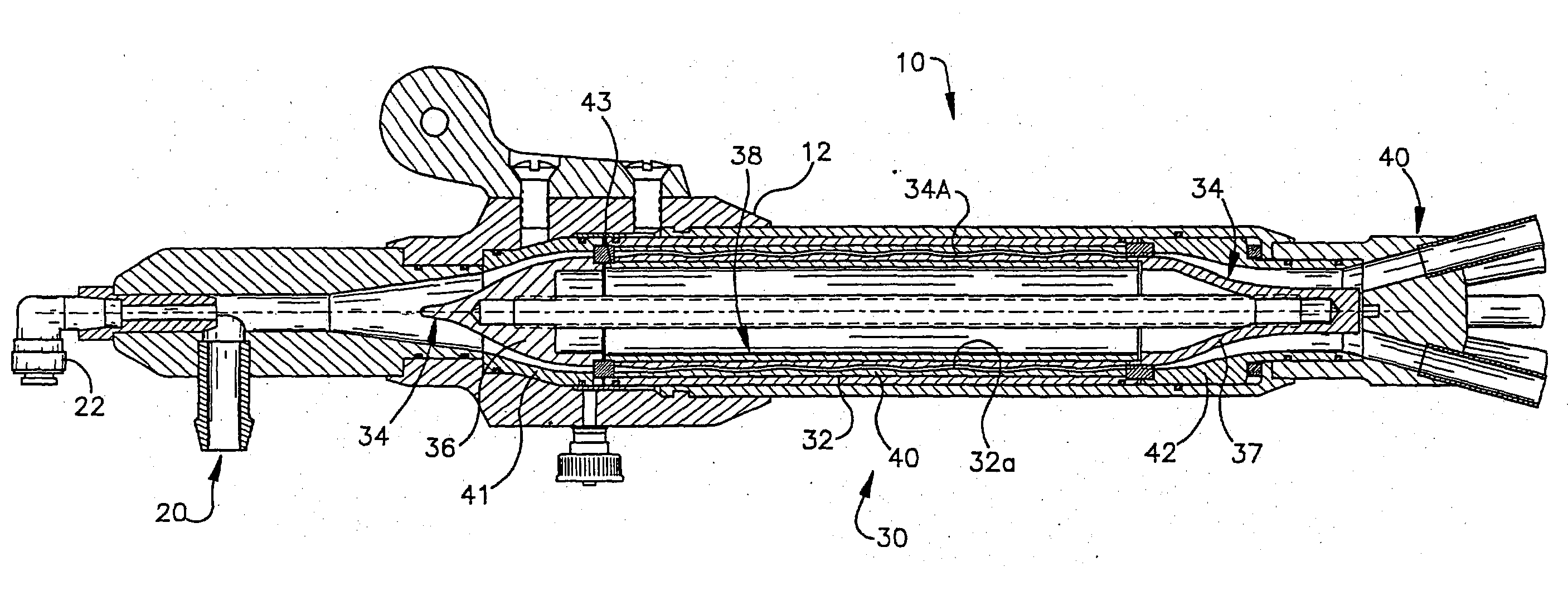

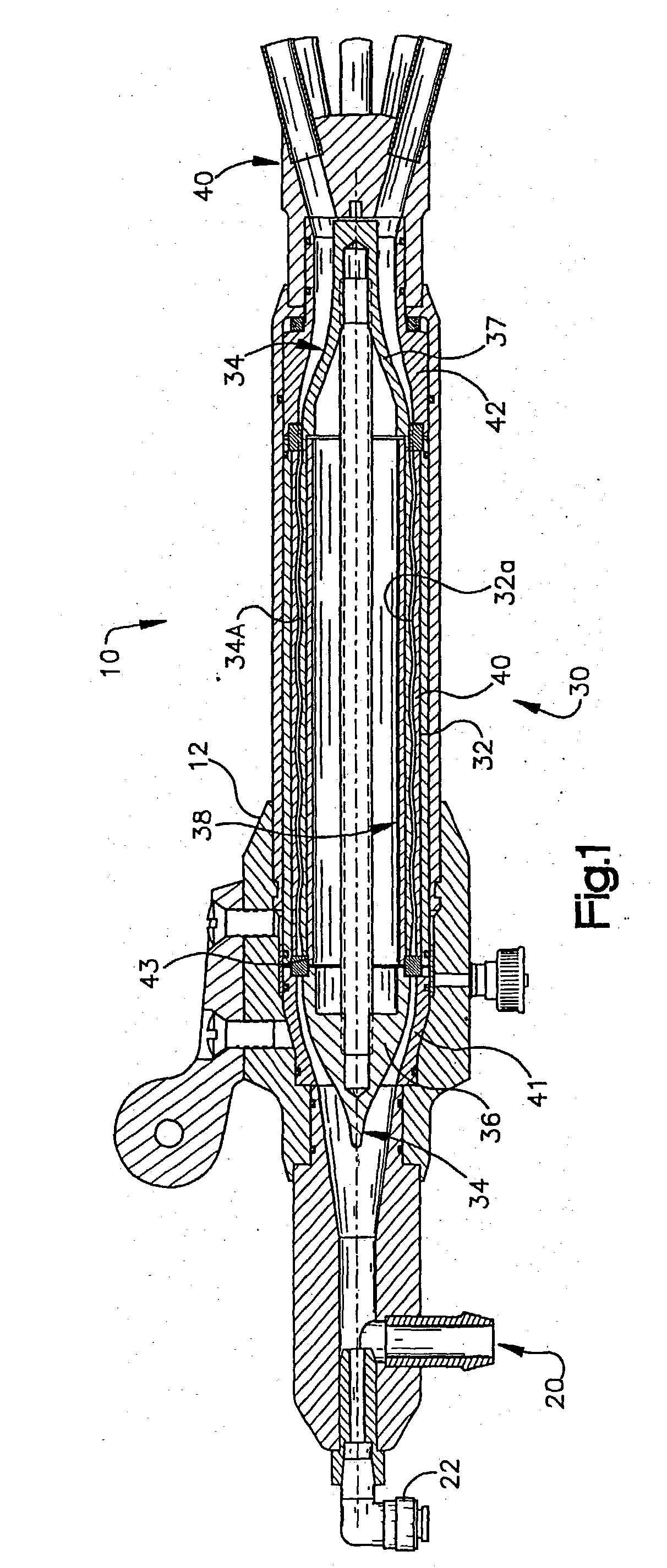

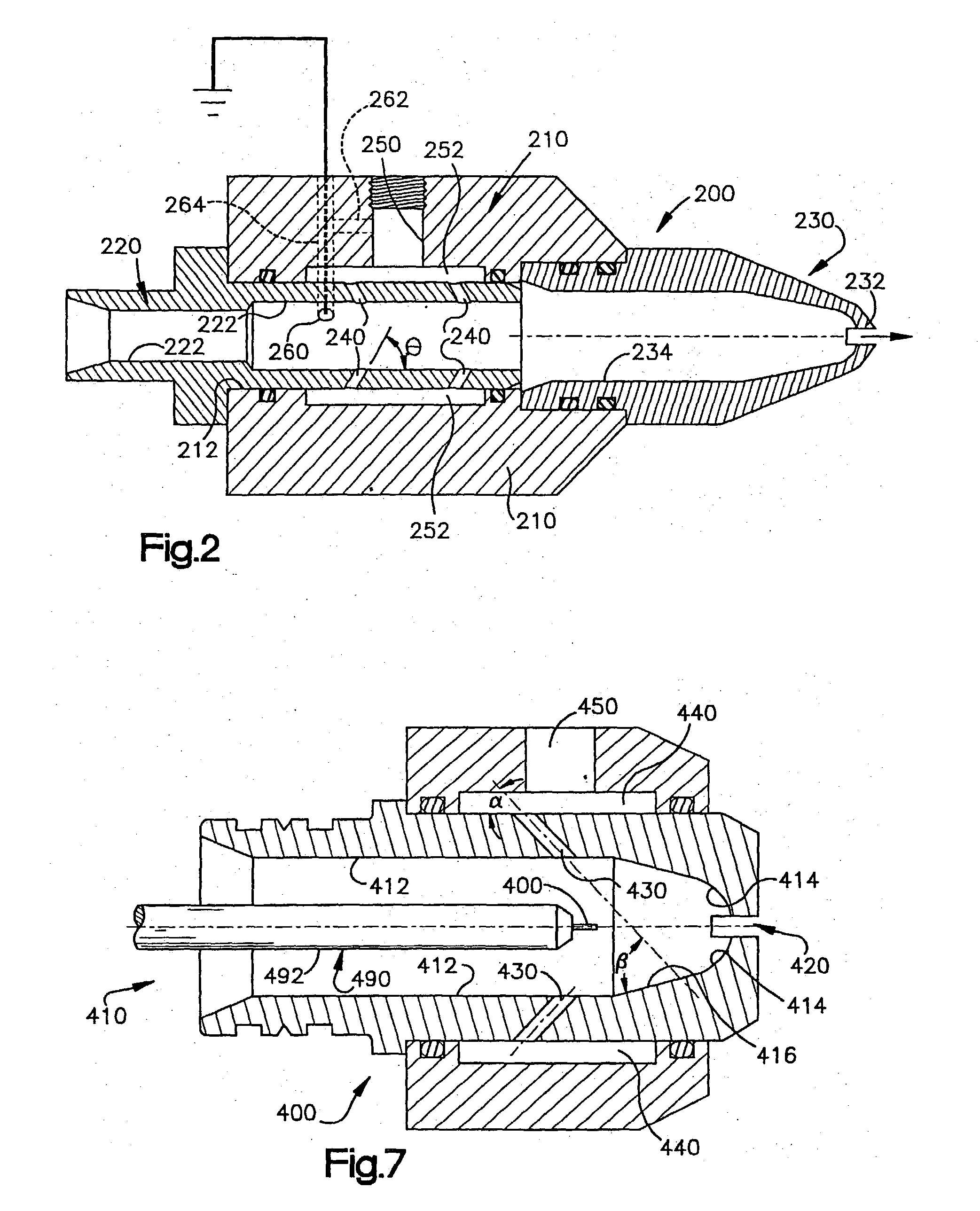

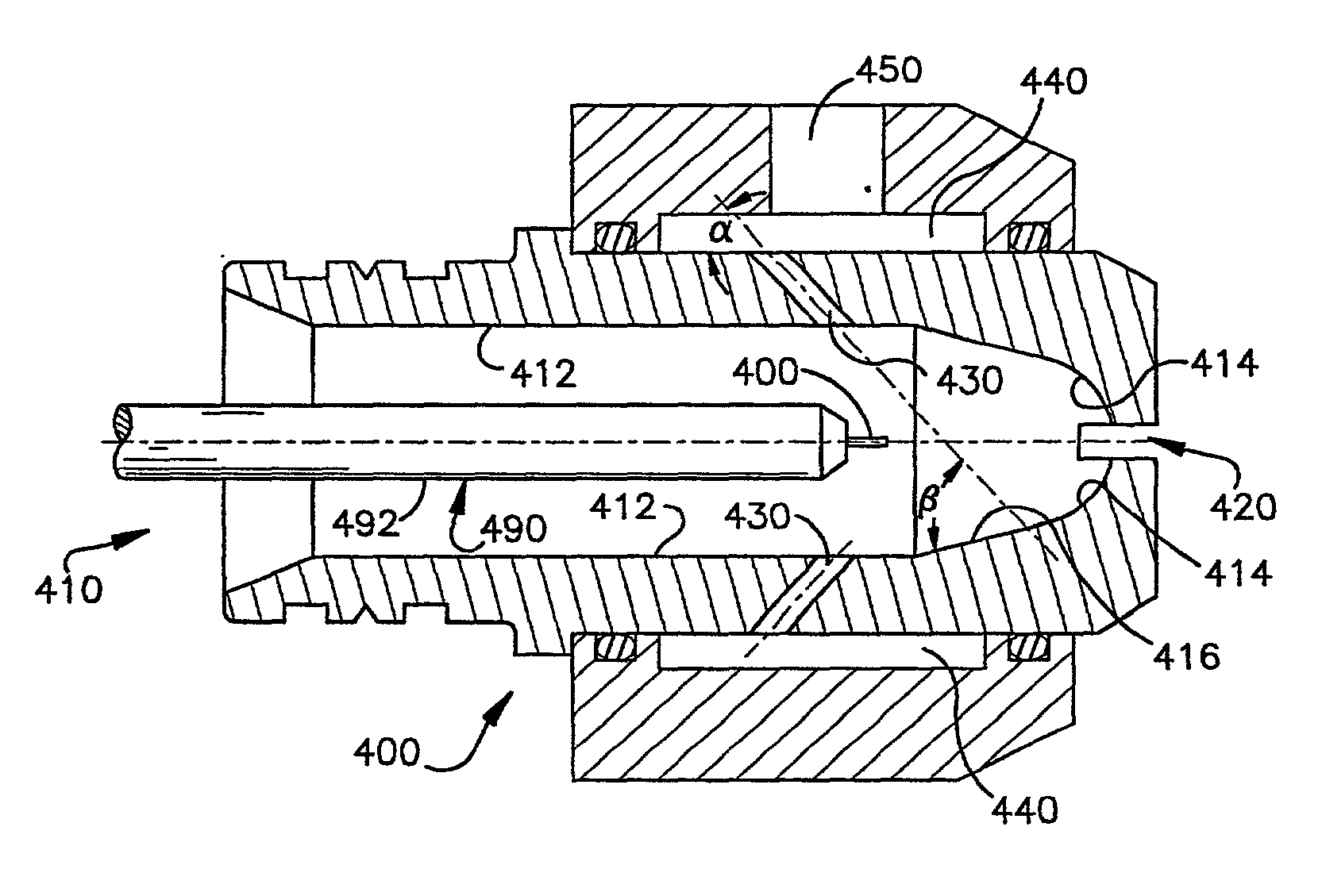

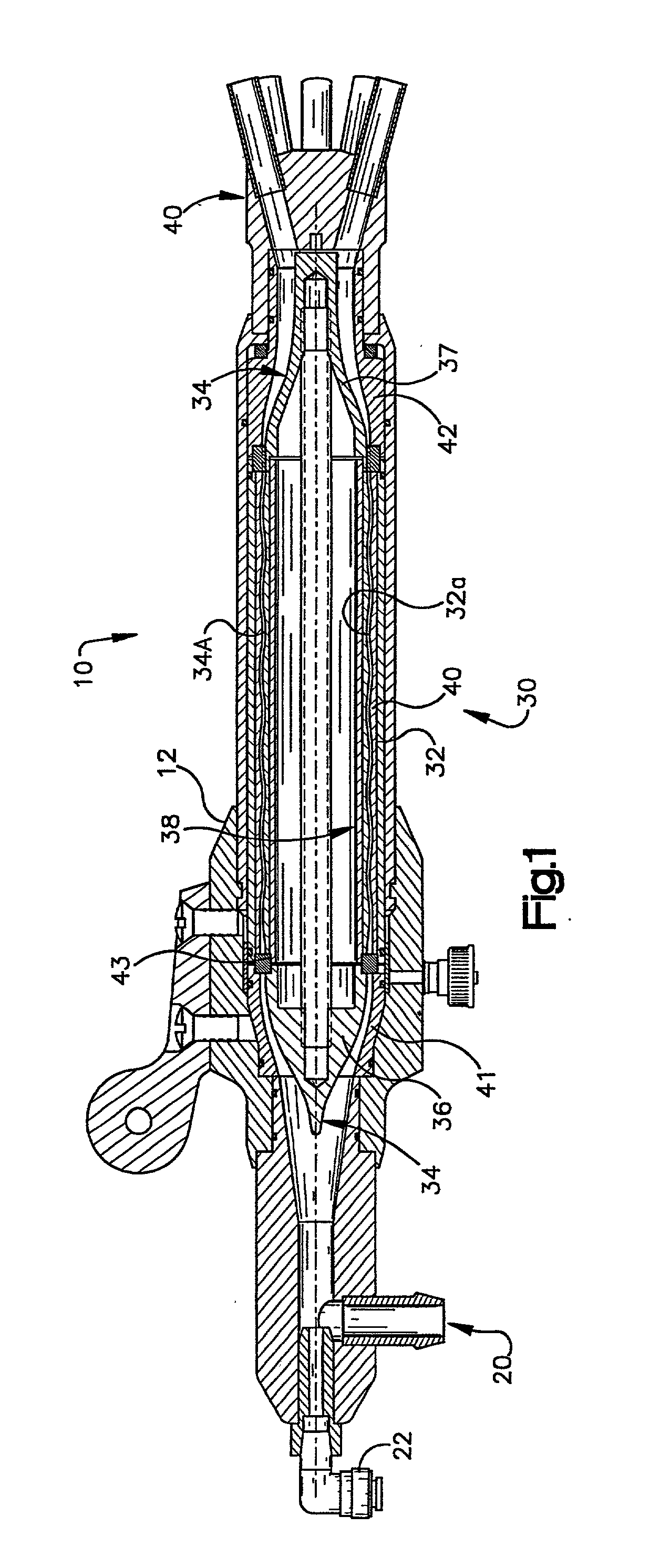

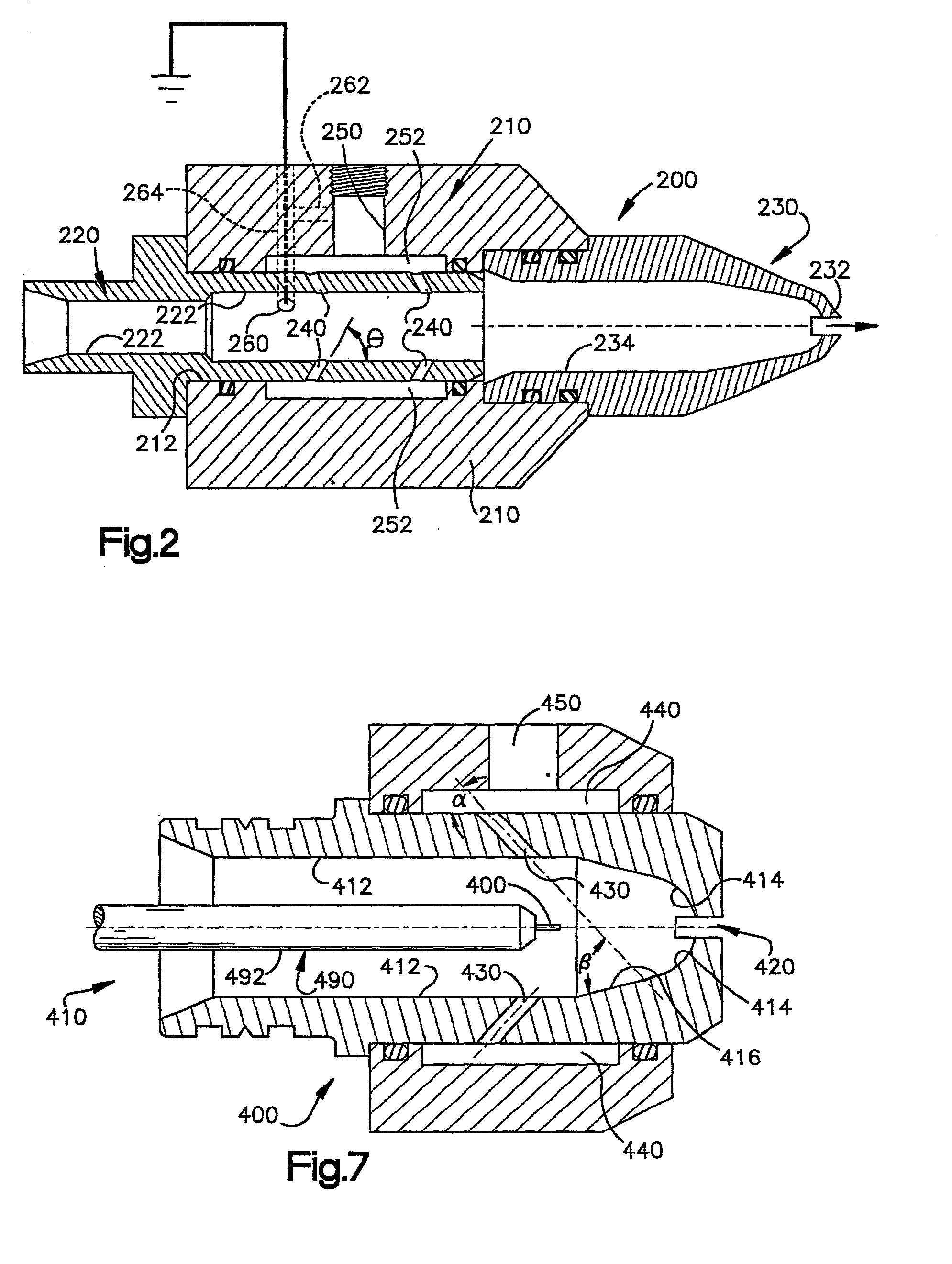

A plurality of unconventional negative tribo-charging materials are described for use as the powder contact surfaces in tribocharging and corona powder spray guns, gun components, and powder delivery system components. The invention also provides a short s barrel tribo-charging powder spray gun (200) having an interchangeable powder contact insert (220) and nozzle (230), with turbulence inducing air jets. The invention further provides novel tribocharging and corona gun designs. Improved powder coating systems are made possible wherein, for example, negative tribo guns can be utilized with negative corona guns to coat different parts of the same workpiece in a powder coating system Also provided is an inside-out configuration in which pressurized air directs powder coating material outward towards a charging surface. Additional configurations provide air jet (981) induced tribocharging and conventional tribocharging portions combined in a single gun. Also provided is a spraying apparatus that combines tribocharging and / or directed air tribocharging with corona charging. A switch arrangement (1000) is provided to select or change charging modes of the spraying apparatus.

Owner:MESSERLY JAMES W +1

Control function and display for controlling spray gun

Control method and apparatus for a manual spray gun includes display that is disposed on the spray gun and that provides information to an operator about one or more coating operation parameters. An auxiliary trigger may be used that enables an operator to make selections or changes of one or more coating operation parameters. The display and auxiliary trigger together permit an operator to make selections or changes without having to divert attention or field of view away from the spray gun or the coating area, especially during a coating operation. The display may include numeric information, for example, data relating to a coating function being displayed.

Owner:NORDSON CORP

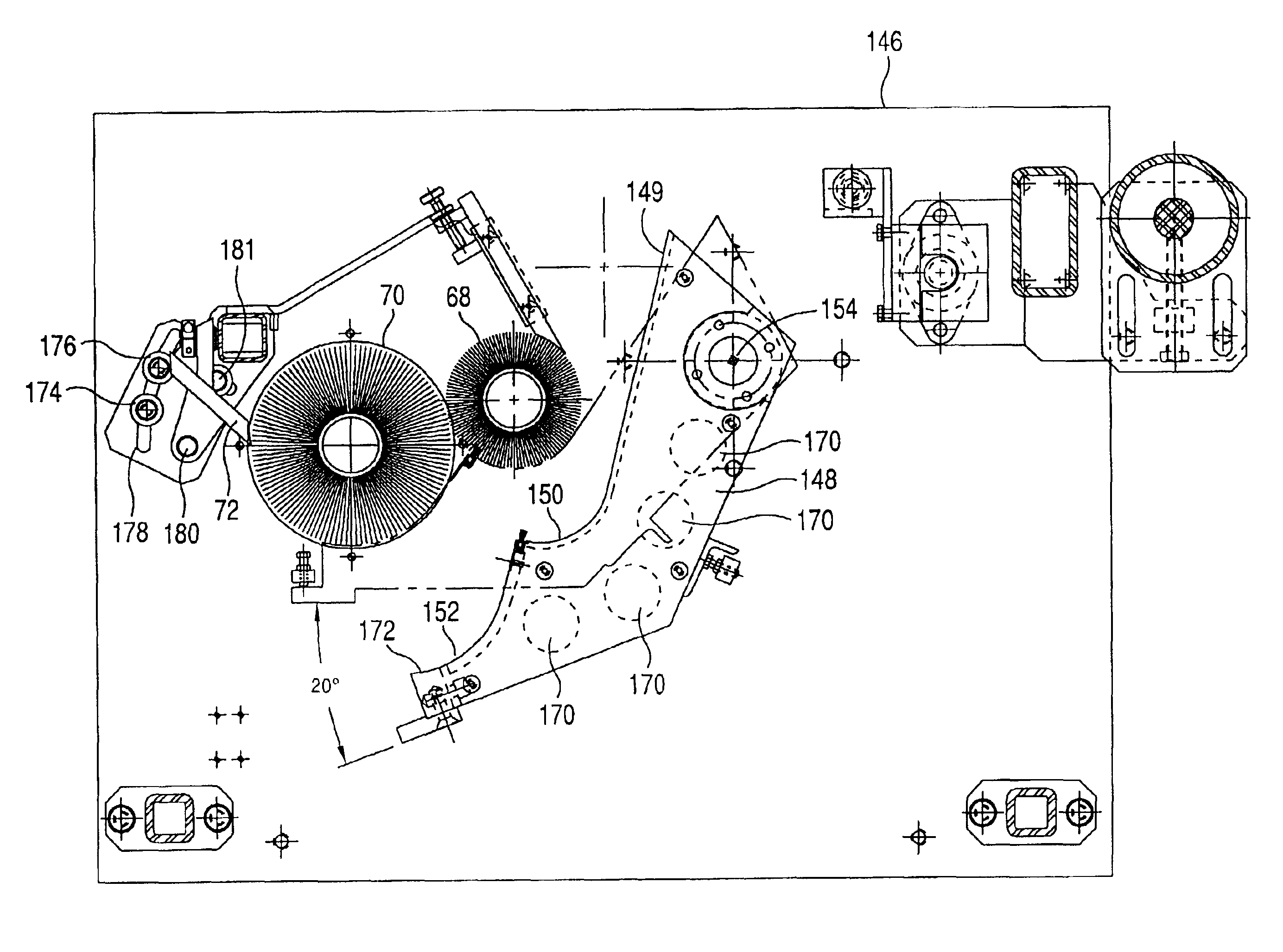

Unipolarity powder coating systems including improved tribocharging and corona guns

Owner:NORDSON CORP

Unipolarity powder coating systems including improved tribocharging and corona guns

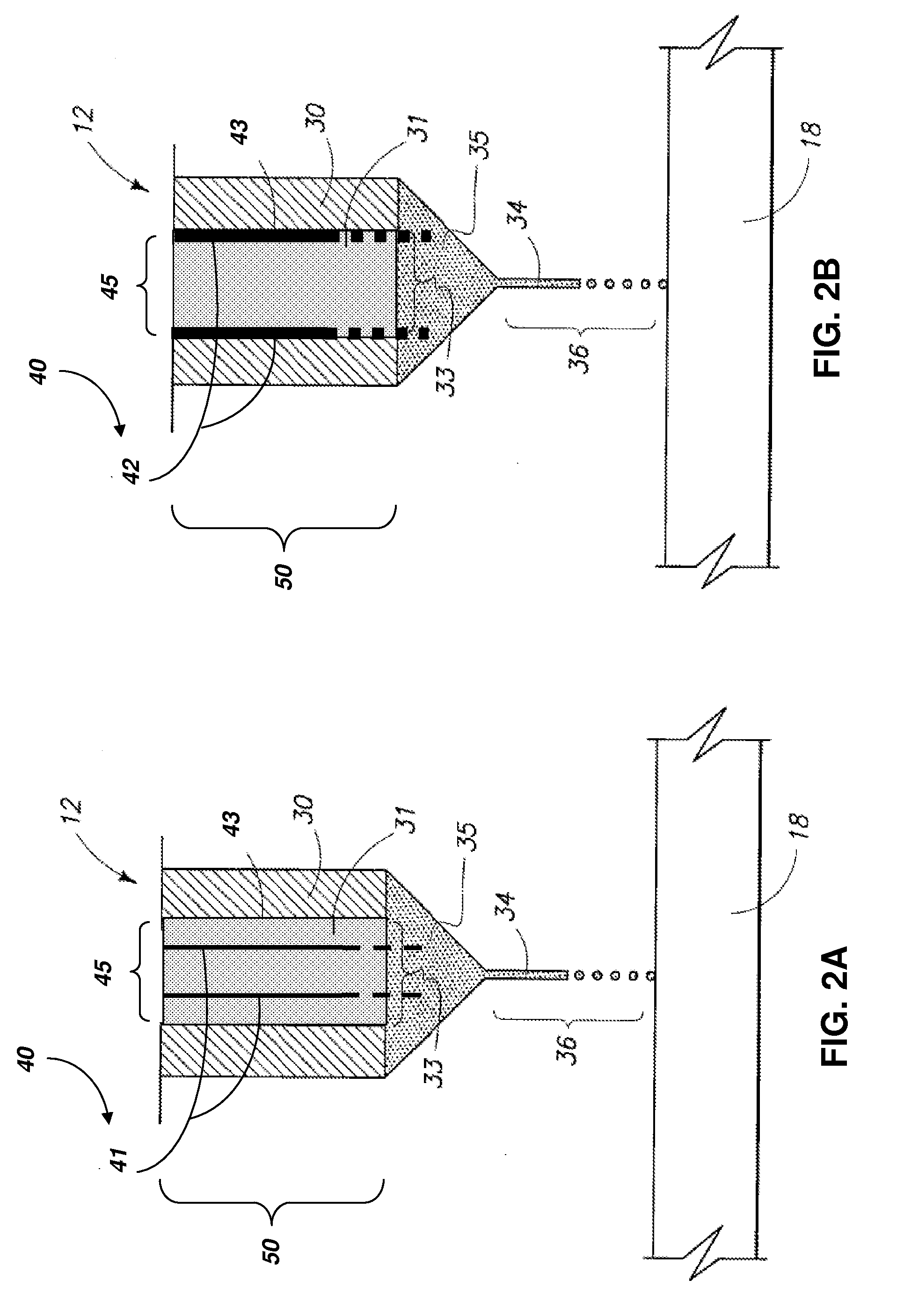

InactiveUS20040159282A1Increase and enhance applied chargeIncrease and enhance and transfer efficiencyBurnersSpray nozzlesMetallurgyCoating system

A plurality of unconventional negative tribo-charging materials are described for use as the powder contact surfaces in tribocharging and corona powder spray guns, gun compounds, and powder delivery system components. The invention also provides a short barrel tribo-charging powder spray gun having an interchangeable powder contact insert and nozzle, with turbulence inducing air jets. The invention further provides novel tribocharging and corona gun designs. Improved powder coating systems are made possible wherein, for example, negative tribo guns can be utilized with negative corona guns to coat different parts of the same workpiece in a powder coating system and to realize a repair coating process. Also proived is an inside-out configuration in which pressurized air directs powder coating material outward towards a charging surface. Additional configurations provide airjet induced tribocharging and conventional tribocharging portions combined in a single gun.

Owner:SANNER MICHAEL R +2

Spraying device and method

The present invention relates to a spraying nozzle, a spraying device including such a nozzle, and a spraying method implementing such a device. A nozzle for projecting powdery sold products for coating objects. The nozzle comprises a body having an essentially cylindrical shape and comprises at least two tunnels extending there through and insulated from each other. Each tunnel developing helically about a main axis of the nozzle. The tunnels are independently supplied with a fluid / powdery solid(s) mixture. The helical shape of the tunnels makes it possible to obtain a powerful jet with a conical shape capable of coating the inner surfaces of tubular objects.

Owner:ARKEMA FRANCE SA

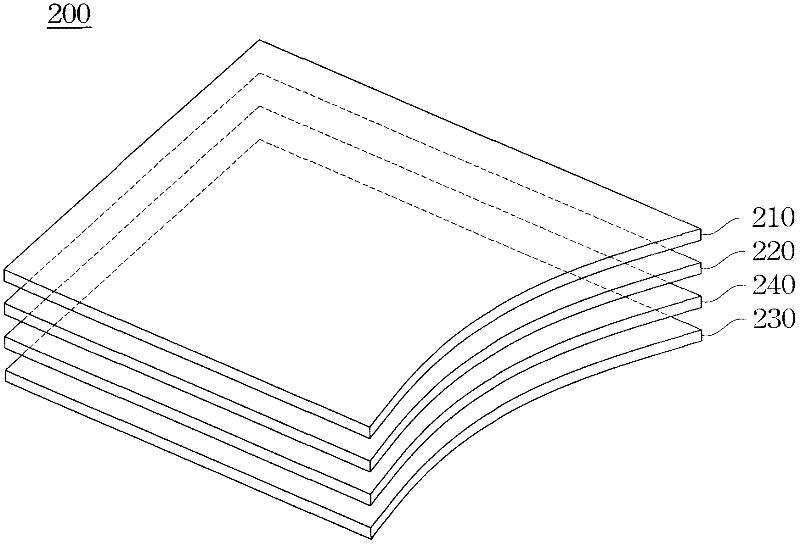

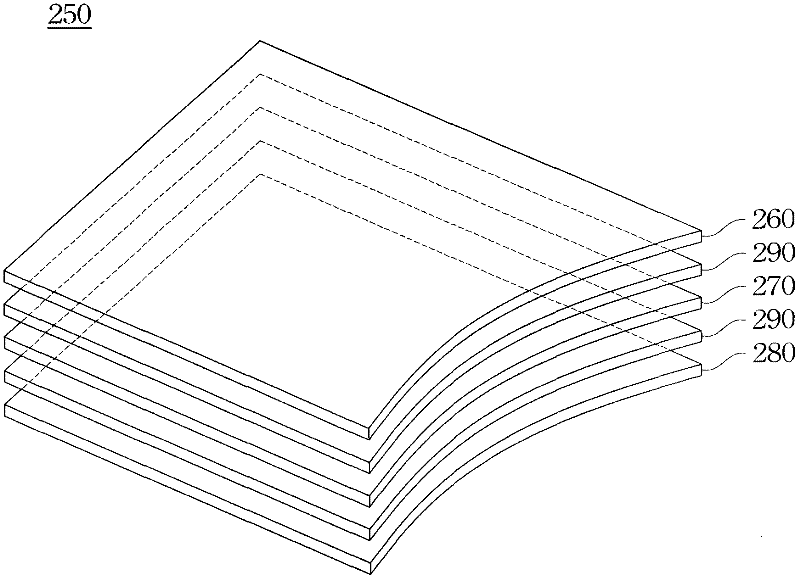

Powder coating for photovoltaic module

InactiveCN102456758AShorten the timeReduce manufacturing costLiquid surface applicatorsSpraying power supplyDielectric layerPowder coating

Disclosed herein is a backsheet for a photovoltaic module. The backsheet includes a dielectric layer, an adhesive layer disposed on the dielectric layer, a barrier layer disposed on the adhesive layer and bonded to the dielectric layer via the adhesive layer, and a weather resistant layer directly disposed on and bonded to the barrier layer by a powder coating method.

Owner:DU PONT APOLLO

Unipolarity powder coating systems including improved tribocharging and corona guns

The present invention describes a variety of unconventional tribo-negative materials for use as powder contact surfaces in tribo- and corona powder spray guns, in-gun components, and powder delivery system components. The present invention also provides a short barrel triboelectric powder spray gun having interchangeable powder contact inserts and nozzles. The present invention further provides a new type of friction electrification and corona gun structure. The improved powder coating system allows the use of a triboelectric negative gun with a negative corona gun to coat different parts of the same part in the powder coating system. The present invention also provides an inside-out structure in which pressurized air directs the powder coating to the charged surface. In other configurations of the present invention, the air nozzle-induced triboelectric charging and conventional triboelectric charging parts are also combined in a single gun.

Owner:NORDSON CORP

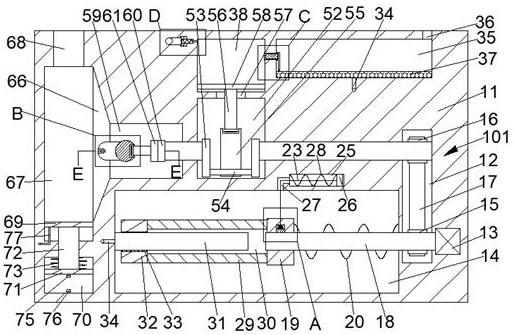

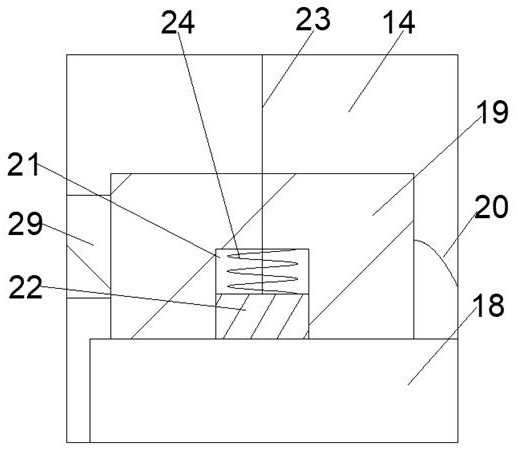

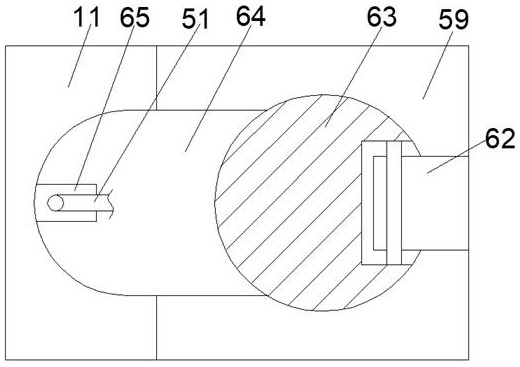

Molding device of thickening powder material

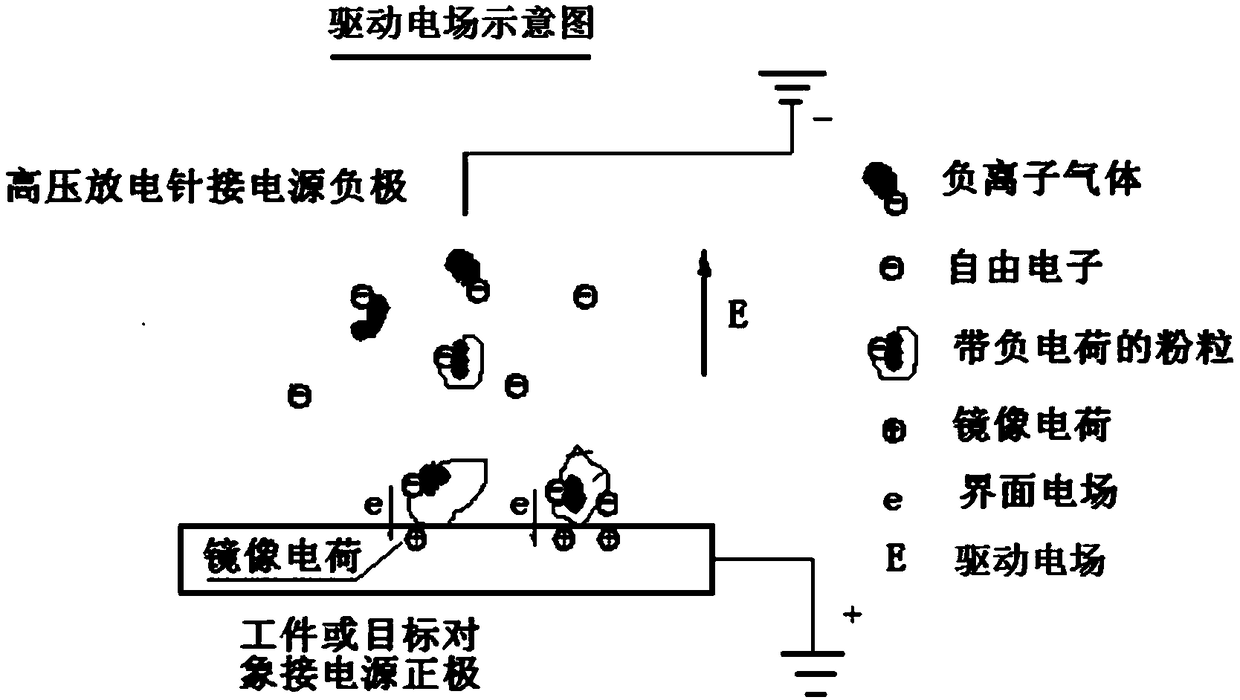

PendingCN108554663AIncreased rejectionReduce investmentLiquid spraying plantsLiquid supply arrangementsDepolymerizationHigh pressure

The invention provides a molding device of a thickening powder material, and relates to the technical field of powder depolymerization (homogenization) preparation and molding of blank bodies. According to the device, an action principle of polarized electrification of a high-voltage discharging needle or electrification by friction caused by air stream impact is utilized, the powder shows the same electric charge, rejection reaction is increased so as to control aggregation of the powder, and a conventional powder depolymerization (homogenization) preparation process is replaced, so that thequality and the efficiency of the depolymerization operation can be improved, the corresponding equipment input and workload are reduced, and the working cost is reduced. Meanwhile, in a static fieldof a blank body molding process, an alternating current electromagnetic field sensing device is additionally arranged, so that gas (air and negative ion gas) filled between powder materials is once ionized, directional vortex motion is carried out under an effect of an induced electric field, the phenomena that ions are escaped from a powder coating and then electric charge carried in the powder is neutralized are effectively terminated, the self-limitation property is eliminated, and the thickness dimension of the powder coating can be effectively increased and controlled; meanwhile, production procedures can be simplified, so that the production efficiency is improved, and energy consumption is reduced.

Owner:湖北金稽山机械科技有限公司

Composition for powder coating material, powder coating material, and coated article

ActiveUS20160362559A1Improve adhesionGood weather resistanceMolten spray coatingSpraying power supplyVitrificationWeather resistance

To provide a composition for powder coating material which can be sufficiently pulverized, and with which a powder coating material capable of forming a coating film excellent in weather resistance and adhesion to the substrate can be obtained; a powder coating material capable of forming a coating film excellent in weather resistance and adhesion to the substrate; and a coated article having a coating film excellent in weather resistance and adhesion to the substrate, on its surface. A composition for powder coating material comprising a polyvinylidene fluoride (A) having a melting point of from 151 to 200° C., and an acrylic resin (B) having a glass transition temperature of from 40 to 90° C. A powder coating material comprising the composition for powder coating material, and a coated article having a coating film formed of the powder coating material.

Owner:ASAHI GLASS CO LTD

Modular powder application system

InactiveUS20050160978A1Maximum regulationMore constructionLiquid spraying plantsLiquid surface applicatorsEngineeringMechanical engineering

A powder atomizer comprises a rotatable powder conveying brush operably associated with a powder supply. A powder receptacle has an inlet and an outlet. The powder conveying brush extends along the inlet and supplies powder to the receptacle. A rotatable powder metering brush is operatively associated with the outlet and withdraws powder from the receptacle. A rotatable powder atomizing brush is operatively associated with and receives powder from the metering brush and discharges the powder. A shoe is operatively associated with the atomizing brush, and is pivotable about a pivot axis between a first and a second position.

Owner:MATERIALS SCI CORP

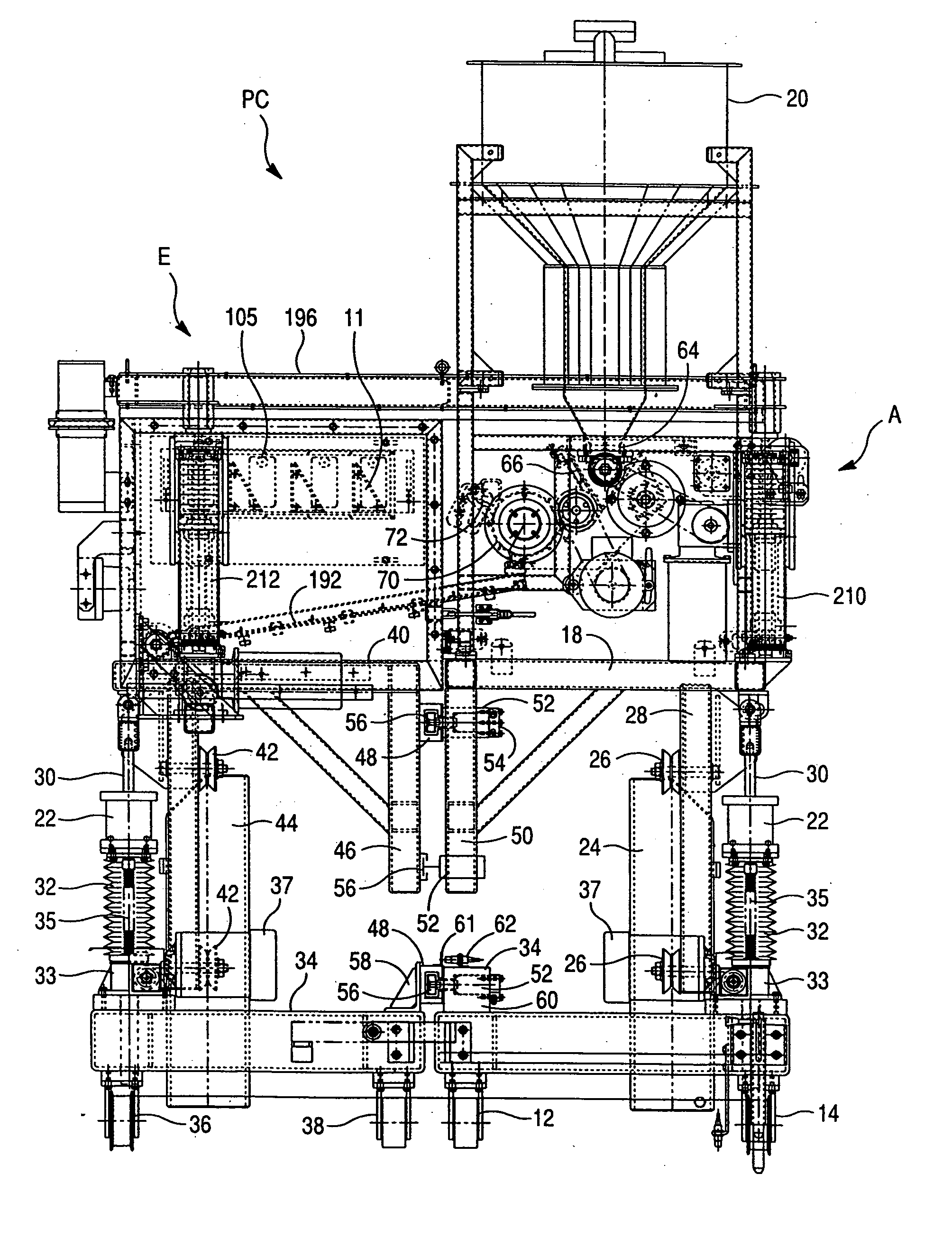

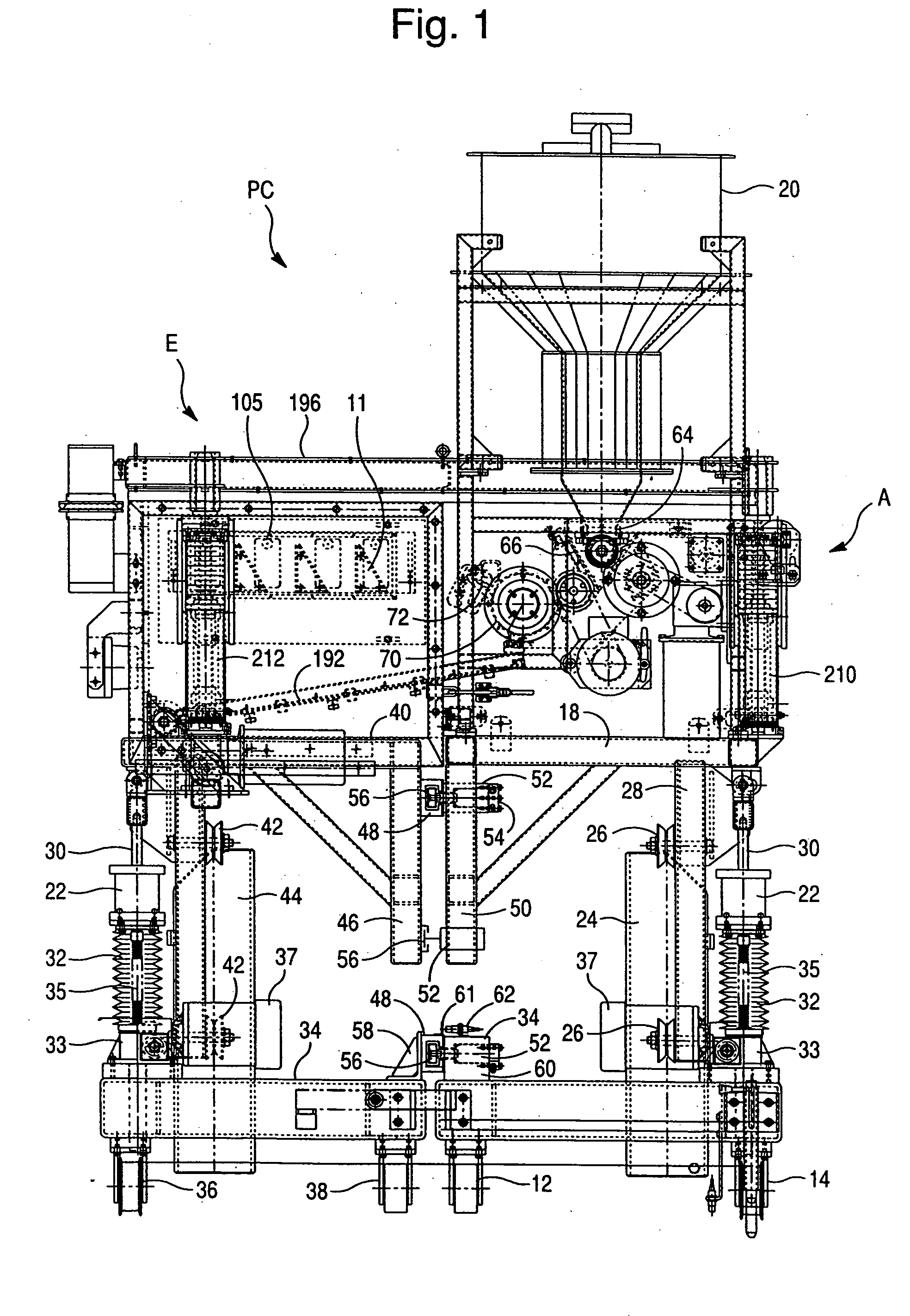

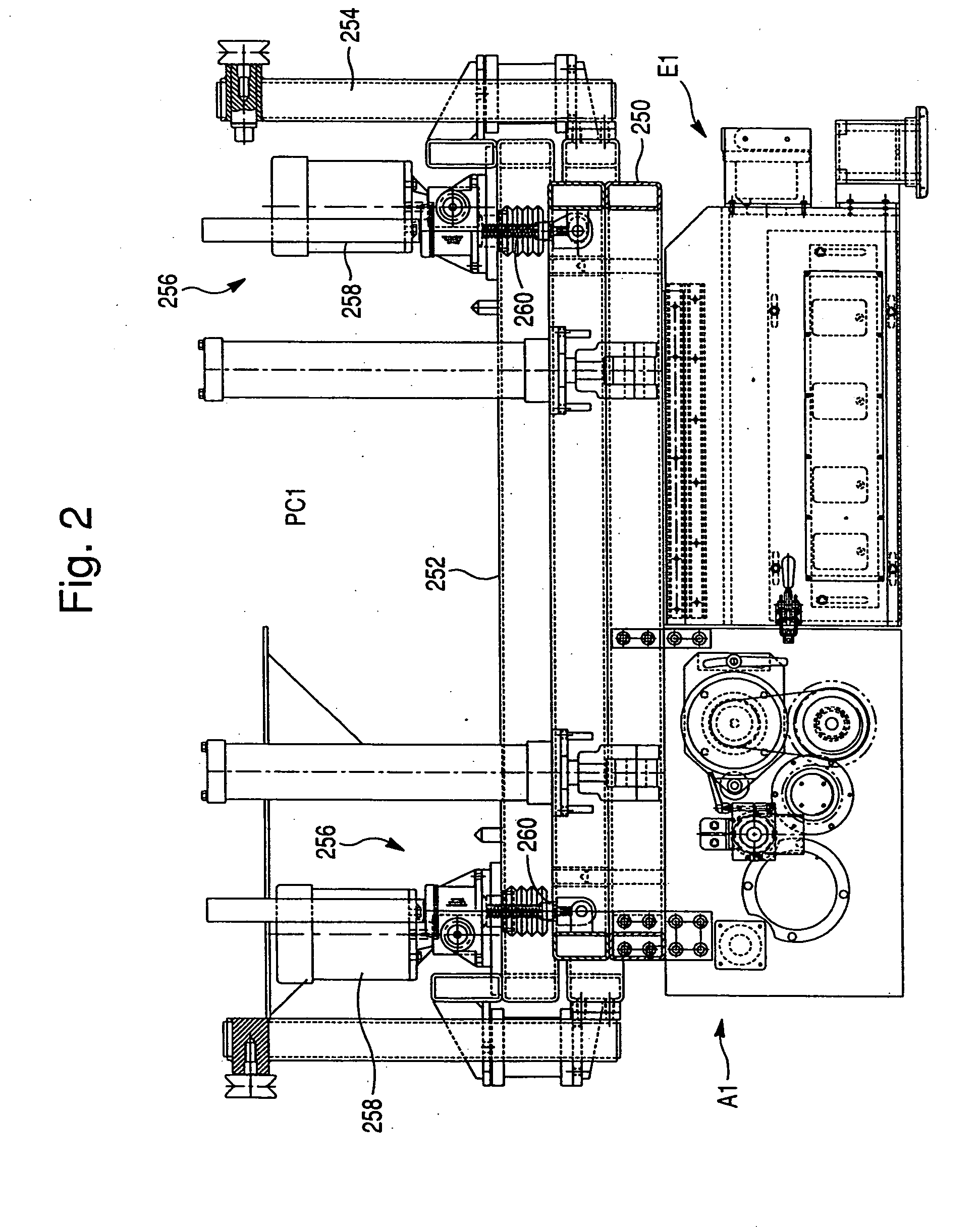

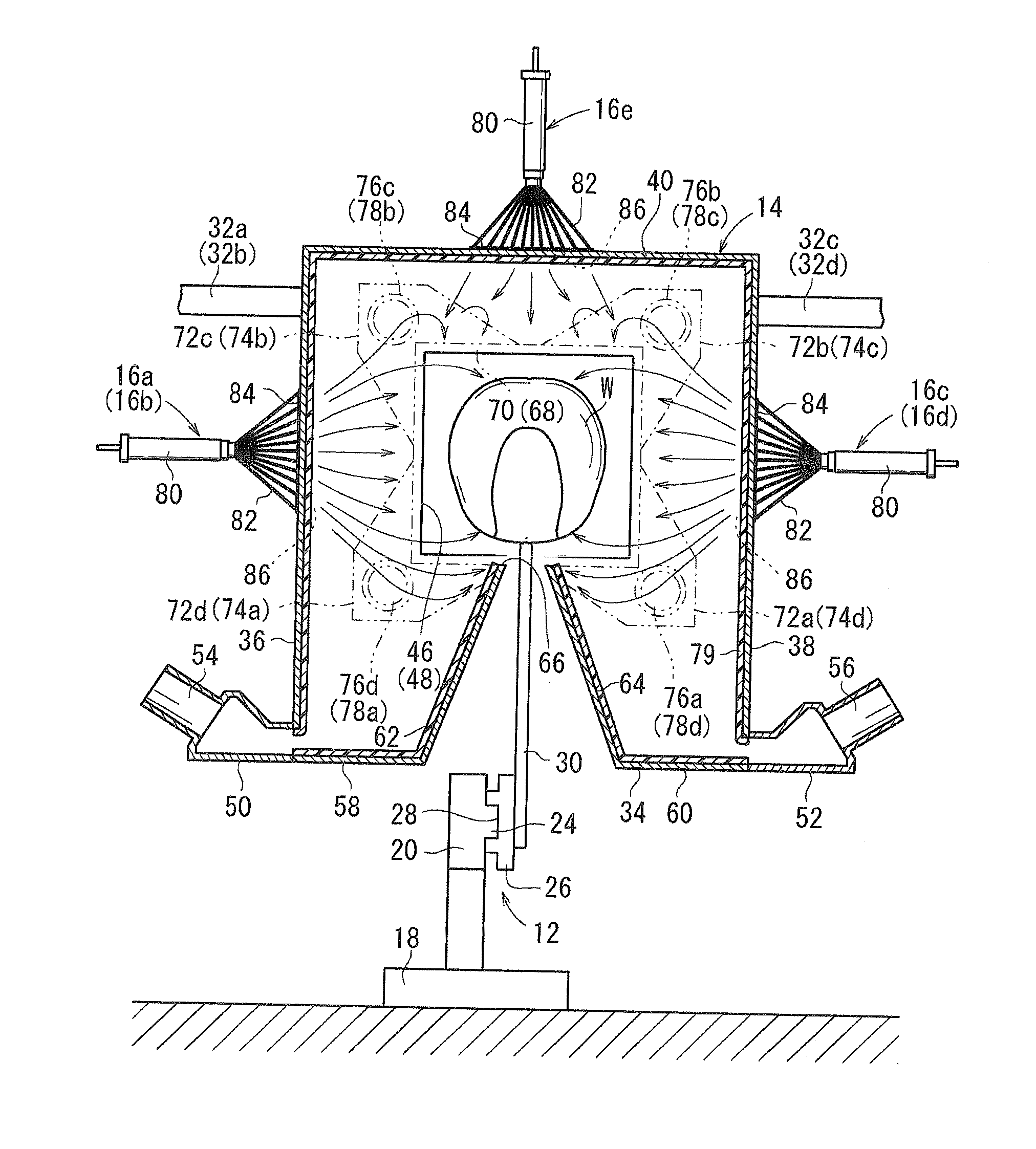

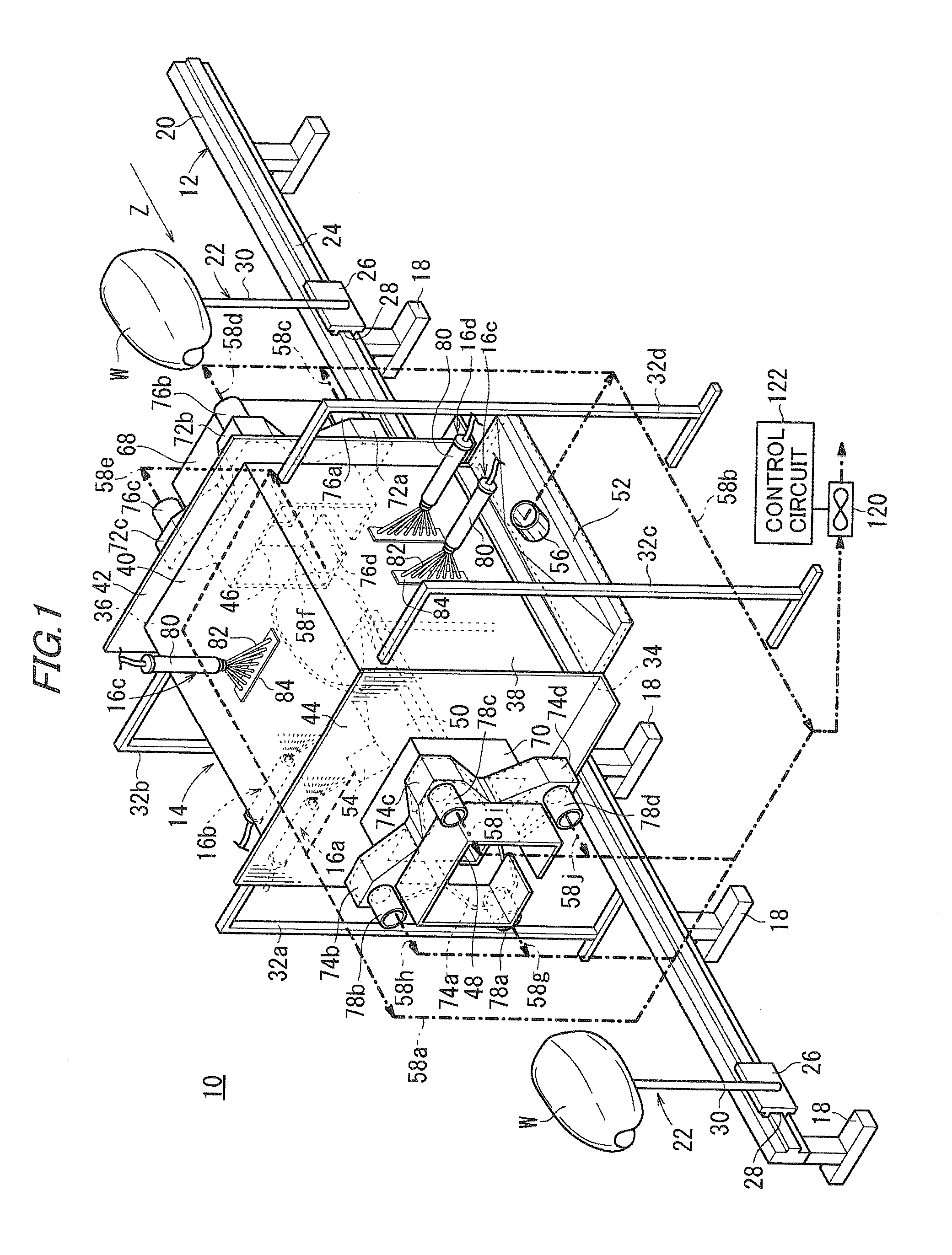

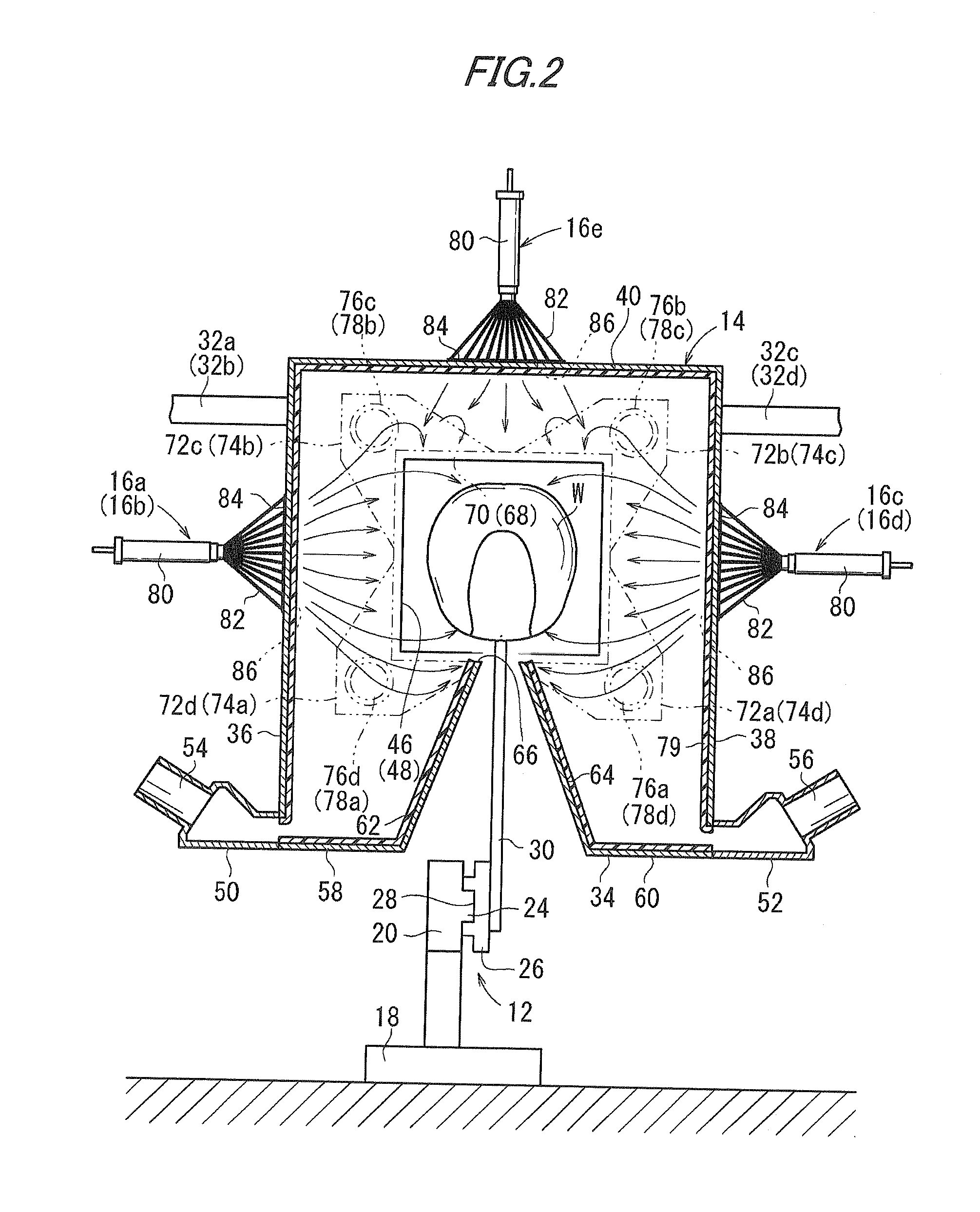

Powder coating apparatus and powder coating method

InactiveUS20110250364A1Efficient coatingReduce maintenance frequencyLiquid surface applicatorsSpray nozzlesMetallurgyPowder coating

The powder coating apparatus is provided with a coating booth into which a ground-connected object to be coated can be delivered and a plurality of coating tools respectively provided on the coating booth and adapted to discharge electrically charged powder coating materials onto the object to be coated. At least two of the coating tools are disposed on walls of the coating booth such that discharge openings thereof for discharging the powder coating materials are opposed to each other. The respective opposed discharge openings simultaneously discharge the powder coating materials onto the object to be coated. The powder coating materials, which are discharged from one of the at least two coating tools and are diffusing in the interior portion of the coating booth, are moved up to the object to be coated by a delivering air discharged together with the powder coating materials from the other of the two coating tools.

Owner:HONDA MOTOR CO LTD

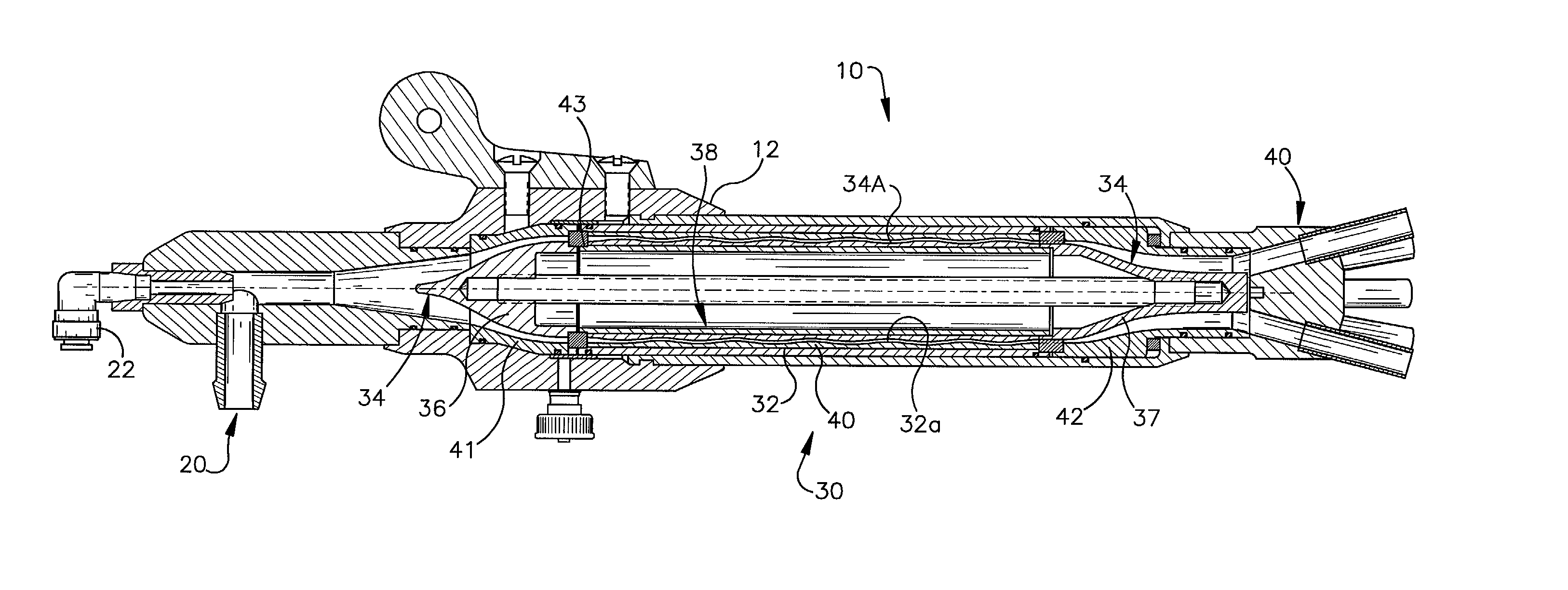

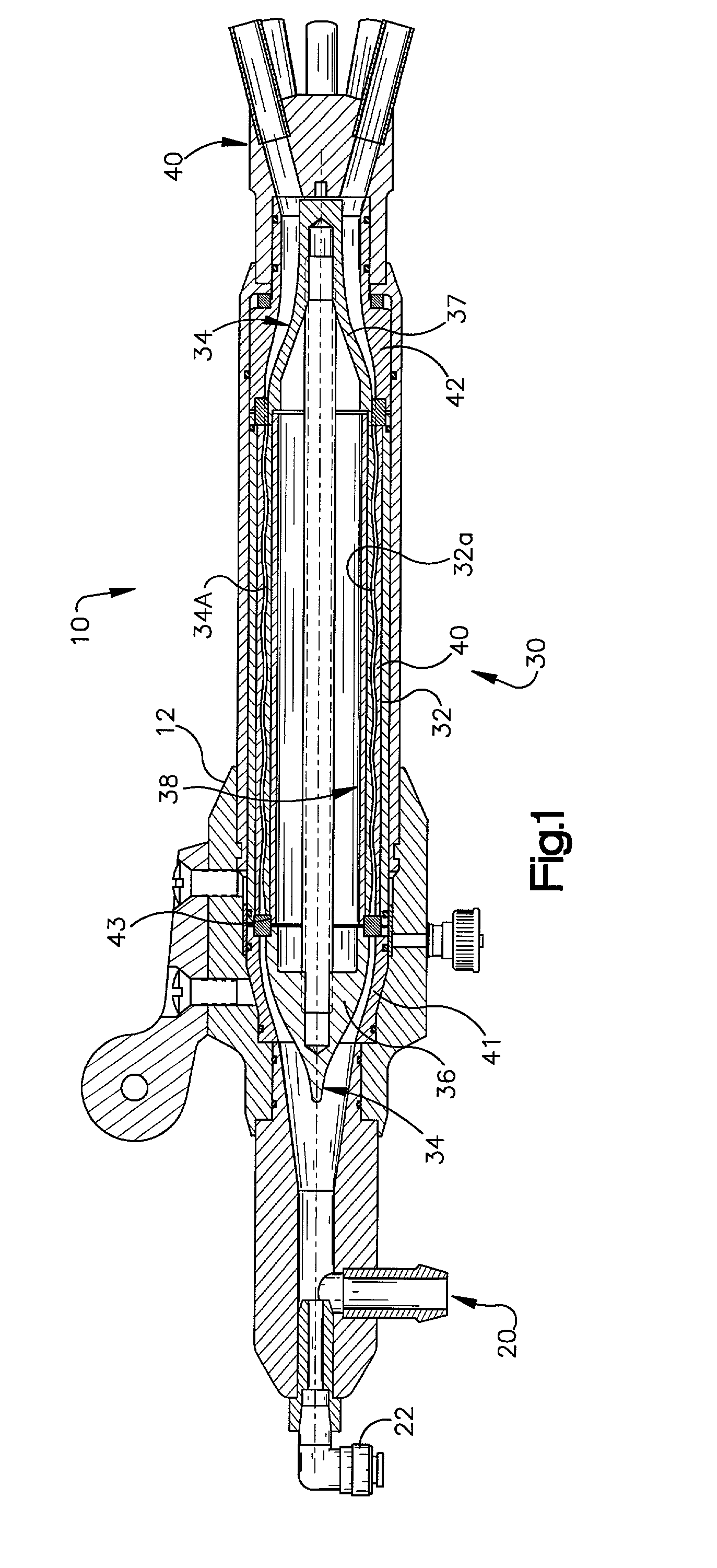

Unipolarity powder coating systems including improved tribocharging and corona guns

InactiveUS20030038193A1Increase and enhance applied chargeIncrease and enhance and transfer efficiencyBurnersSpraying power supplyMetallurgyElectrical polarity

A plurality of unconventional negative tribo-charging materials are described for use as the powder contact surfaces in tribocharging and corona powder spray guns, gun components, and powder delivery system components. The invention also provides a short barrel tribo-charging powder spray gun having an interchangeable powder contact insert and nozzle, with turbulence inducing air jets. The invention further provides novel tribocharging and corona gun designs. Improved powder coating systems are made possible wherein, for example, negative tribo guns can be utilized with negative corona guns to coat different parts of the same workpiece in a powder coating system. Also provided is an inside-out configuration in which pressurized air directs powder coating material outward towards a charging surface. Additional configurations provide air jet induced tribocharging and conventional tribocharging portions combined in a single gun.

Owner:NORDSON CORP

Device for detecting a flow of powder particles

A method and device is provided for detecting a flow of particles, particularly paint particles, in a powder transportation line connected to a powder spray gun. The powder transportation line of the device includes a portion having an interior face provided with an electrostatically friction charging material. The portion of the transportation line may be located upstream or downstream of the pump or within the pump itself. The transportation line portion is in electrical communication with a unit for sensing electrical signals. When the powder particles flow through the transportation line portion, an electrical charge is generated in the portion as a result of the friction between the particles and the friction-charging material. This electrical charge is detected by the sensing unit.

Owner:NORDSON CORP

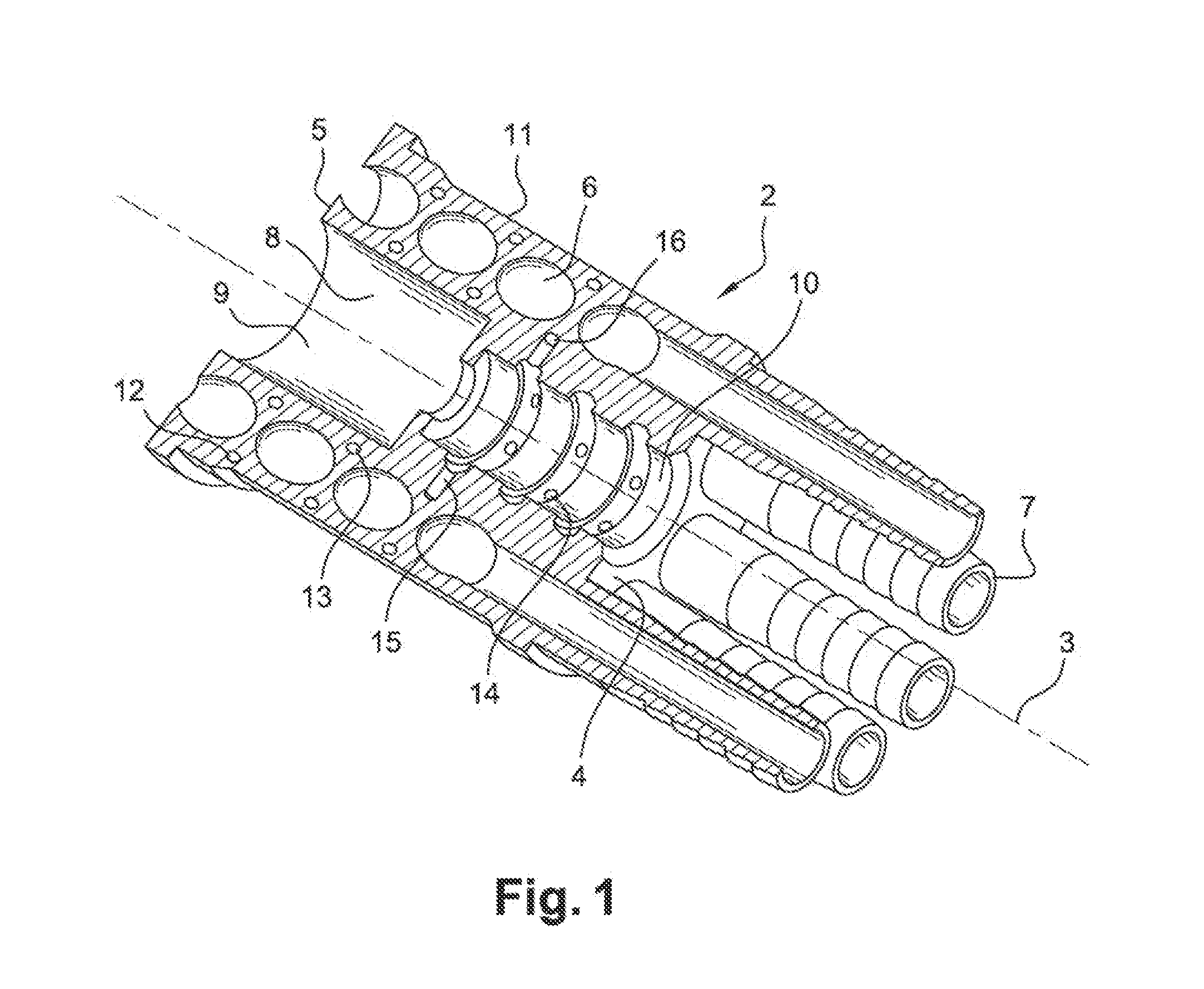

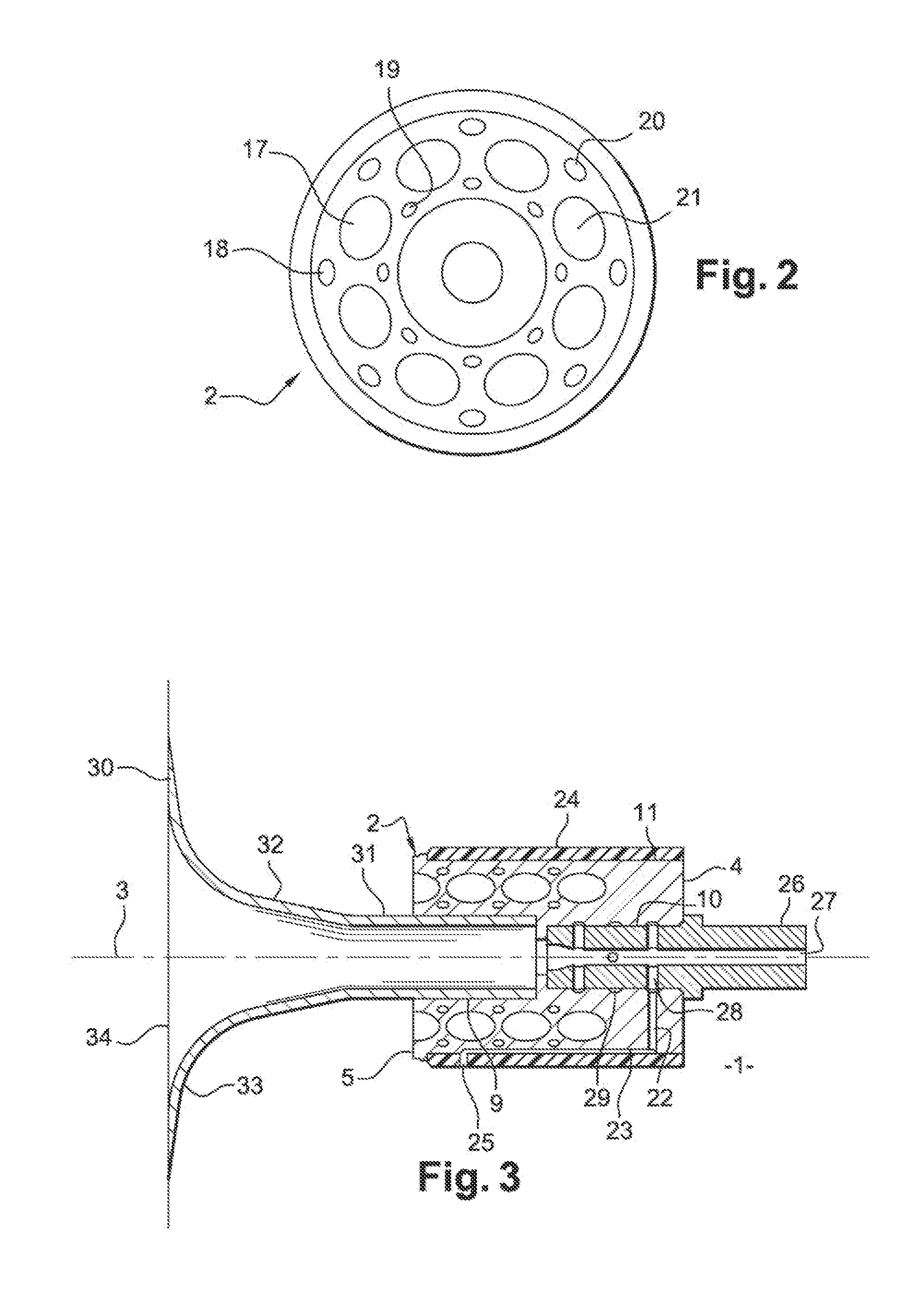

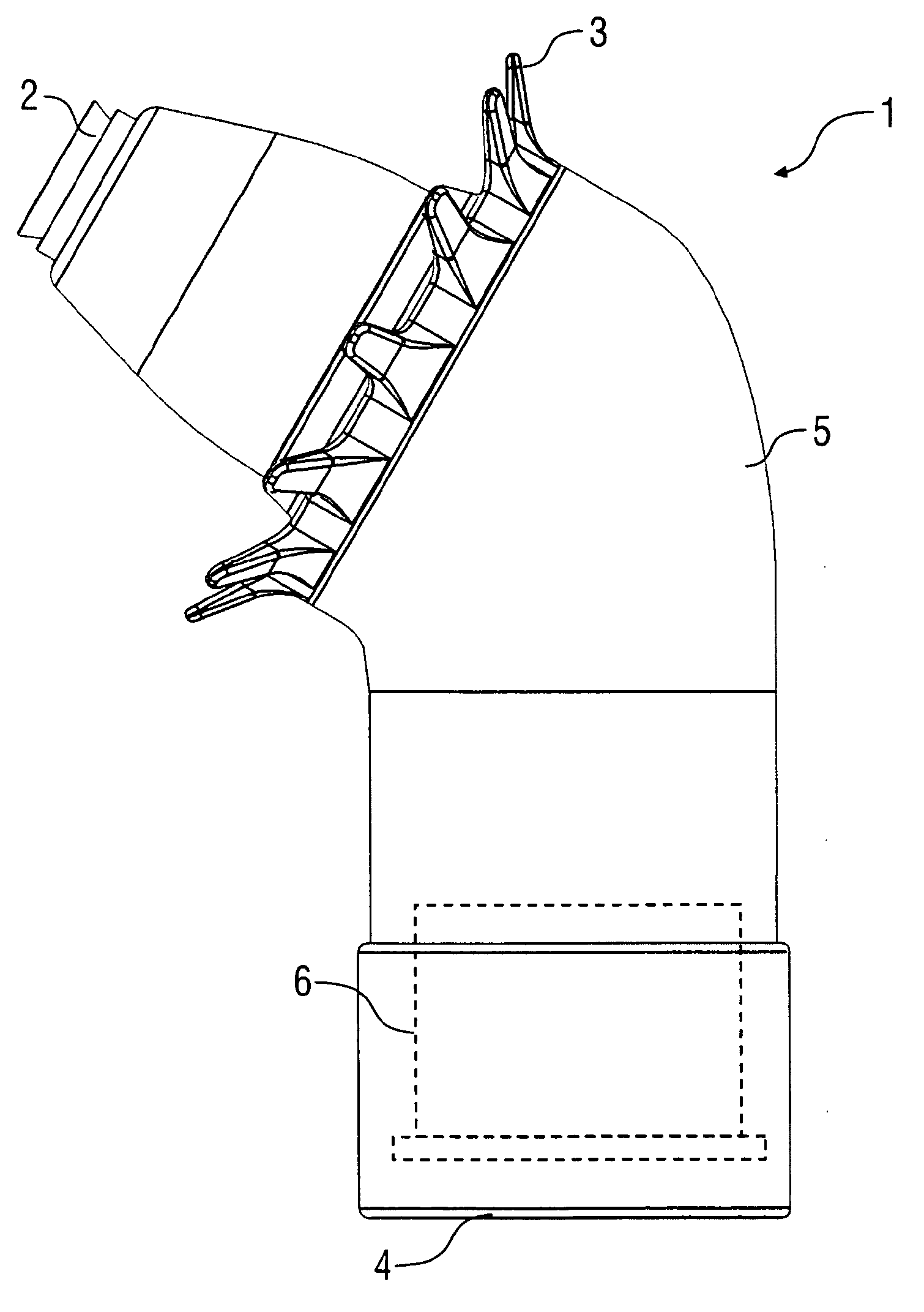

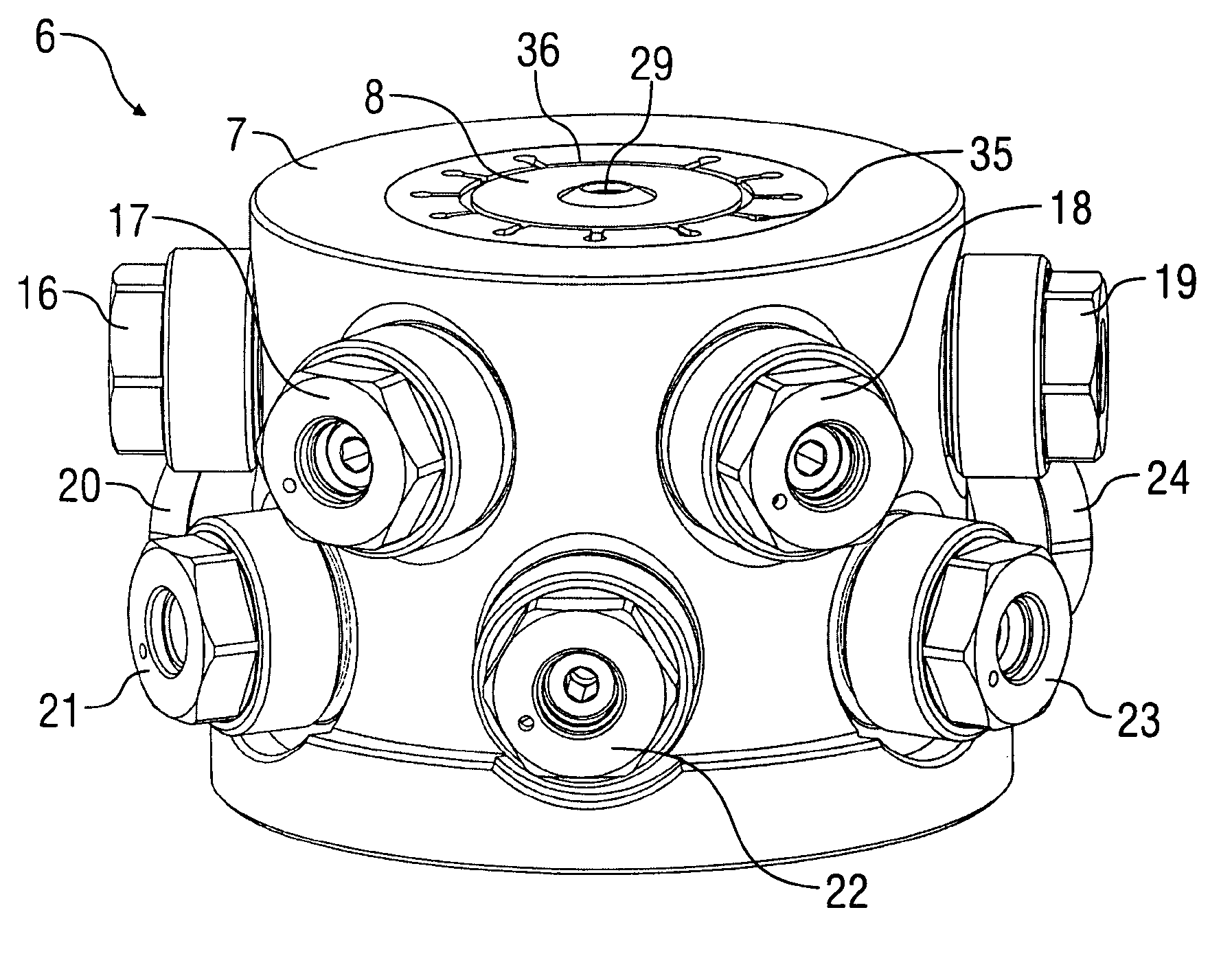

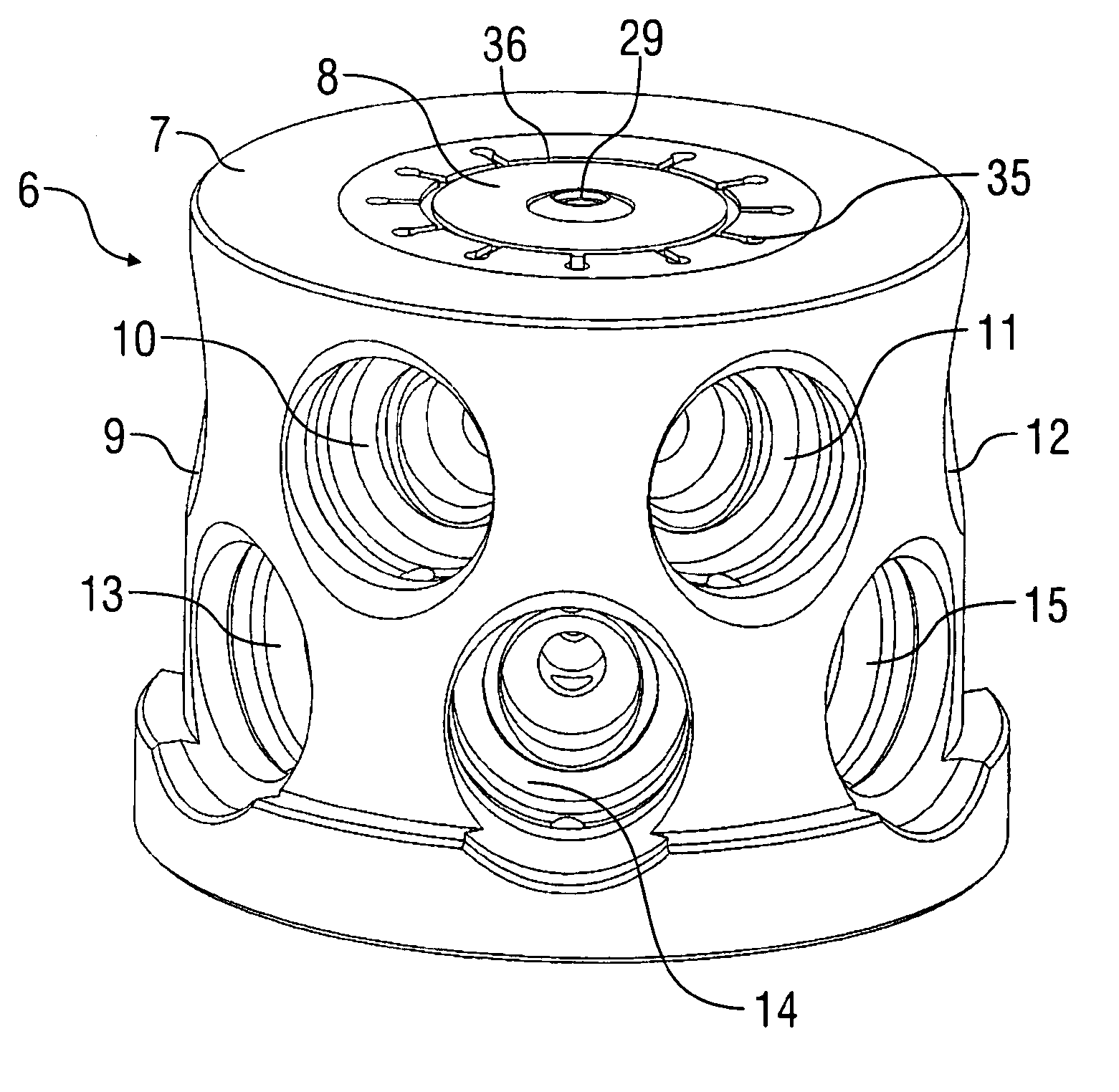

Valve unit for a coating system

ActiveCN102883819AHigh feasibilityThin material handlingTribo-charging sprayingCoating systemSprayer

The invention relates to a valve unit (6) for a coating system, in particular as an integrated colour changer or two-component mixer in a rotary sprayer (1), having a housing (7, 8) and at least one valve receptacle (15) which is arranged in the housing (7, 8) and serves to receive a valve (21). It is proposed that the housing (7, 8) has at least one first housing part (8) and one second housing part (7), wherein the first housing part (8) is composed of a different material than the second housing part (7).

Owner:DUERR SYST GMBH

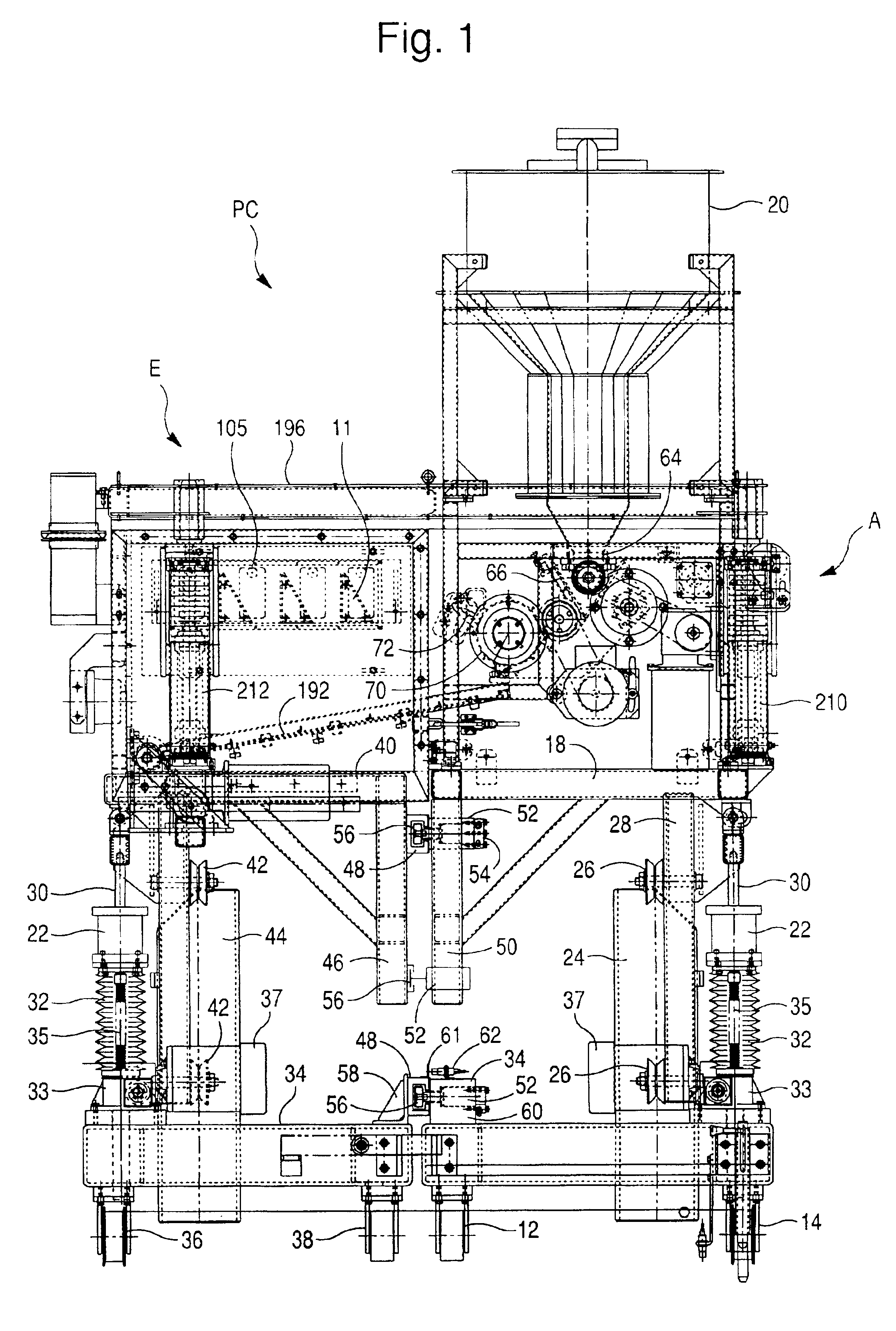

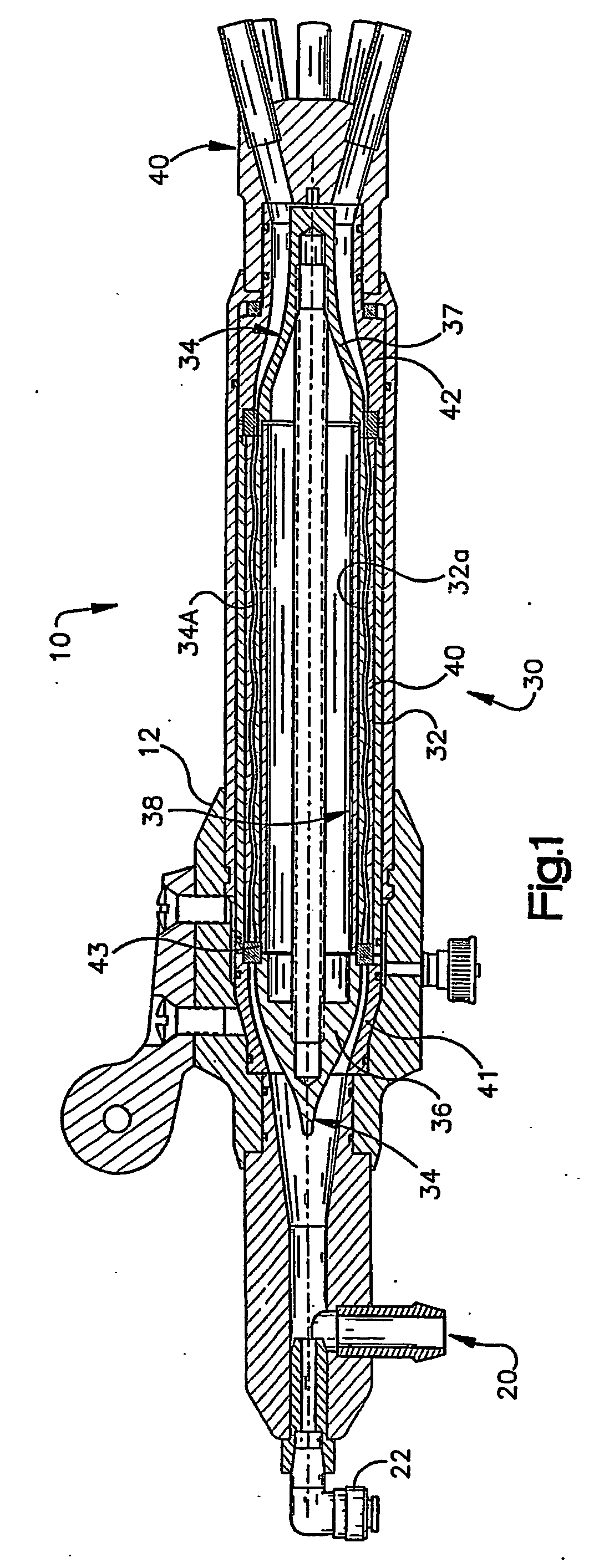

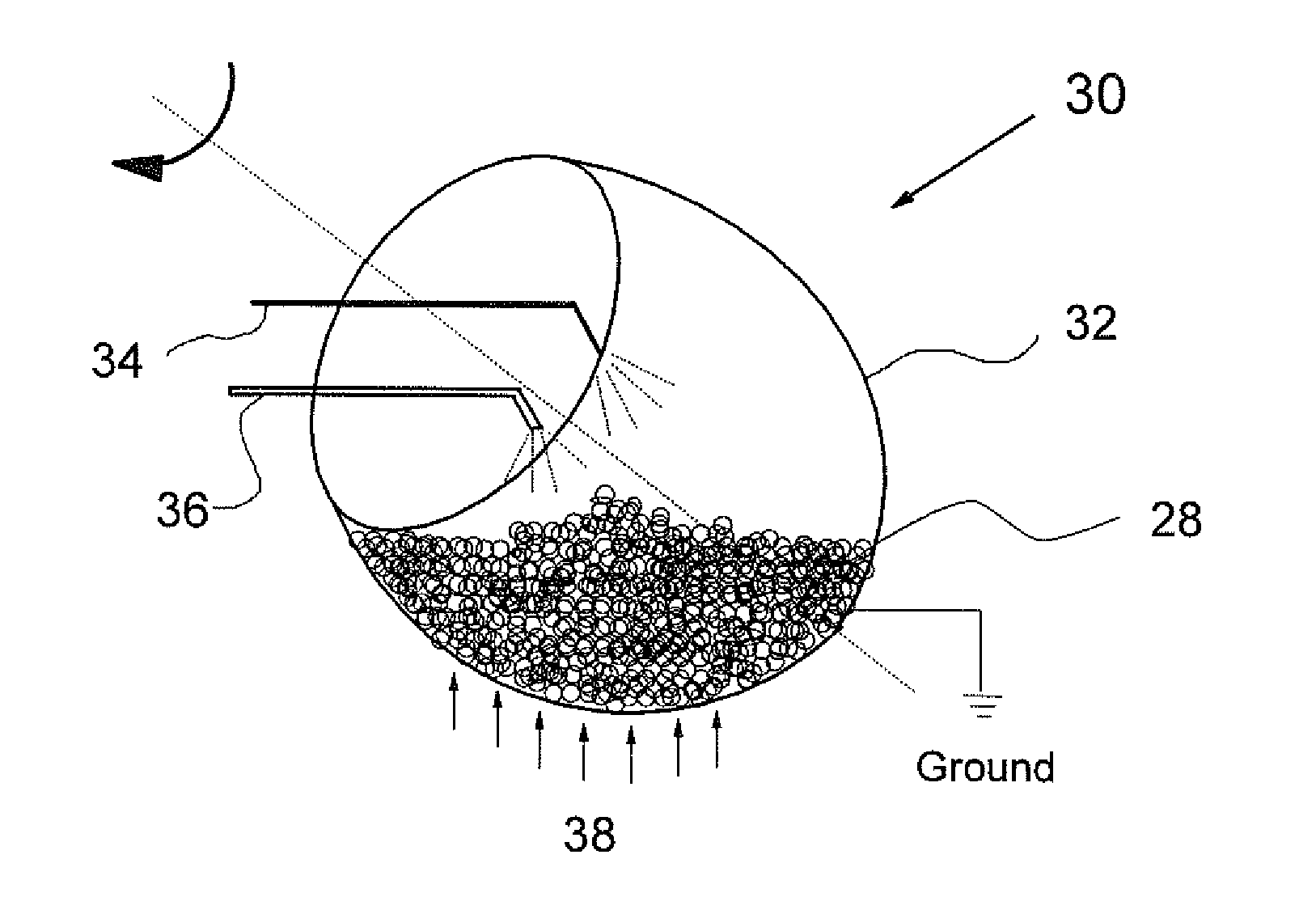

Direct coating solid dosage forms using powdered materials

The present invention provides a method and apparatus for dry coating solid dosage forms. The method includes the steps of placing solid dosage forms in a rotatable, electrically grounded housing, and spraying a film forming polymer powder composition into the housing during rotation thereof to form a polymer coating on the solid dosage forms, the polymer powder composition being sprayed using an electrostatic spray gun, and curing the coated solid dosage forms.

Owner:NINGBO WESDON POWDER PHARMA COATINGS CO LTD +2

Unipolarity powder coating systems including improved tribocharging and corona guns

A plurality of unconventional negative tribo-charging materials are described for use as the powder contact surfaces in tribocharging and corona powder spray guns, gun components, and powder delivery system components. The invention also provides a short barrel tribo-charging powder spray gun having an interchangeable powder contact insert and nozzle, with turbulence inducing air jets. The invention further provides novel tribocharging and corona gun designs. Improved powder coating systems are made possible wherein, for example, negative tribo guns can be utilized with negative corona guns to coat different parts of the same workpiece in a powder coating system.

Owner:REHMAN WILLIAM R +6

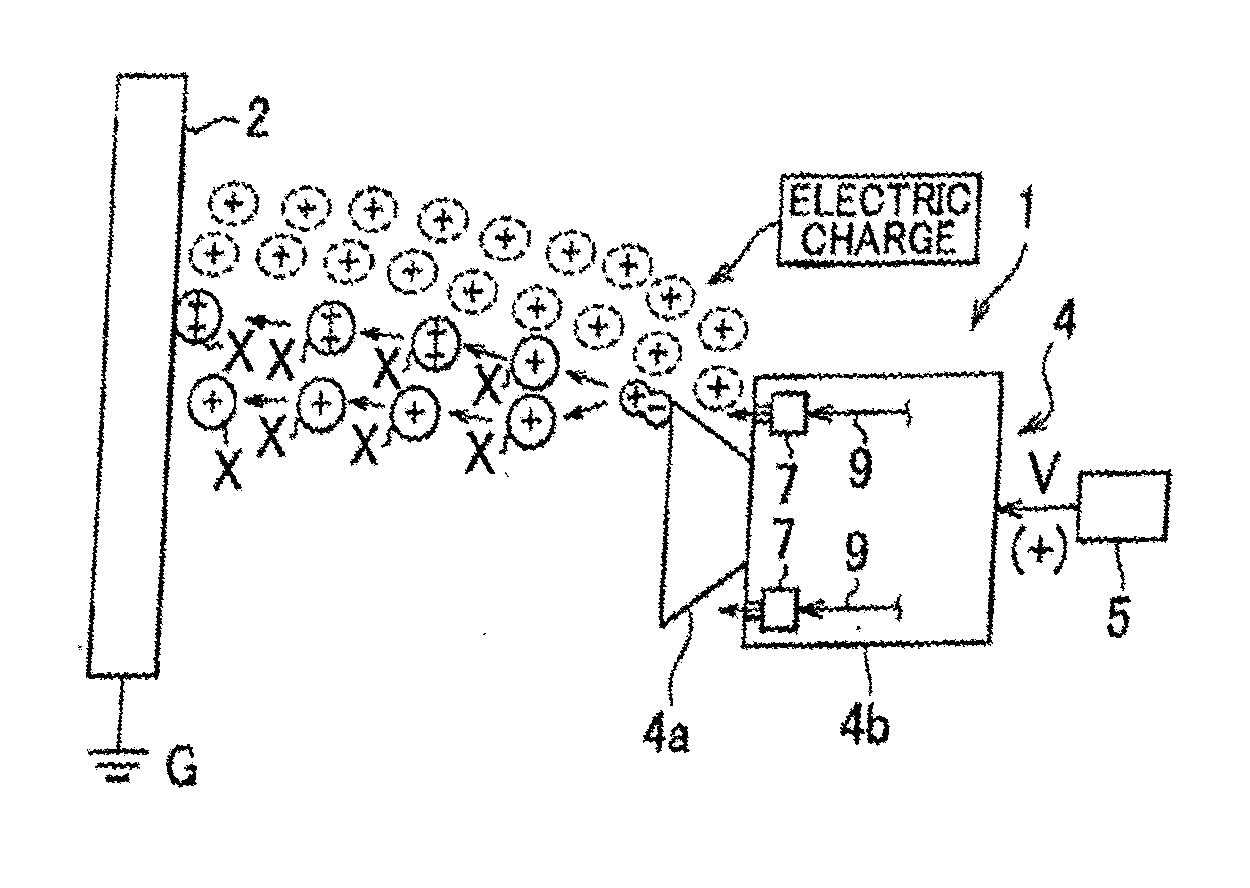

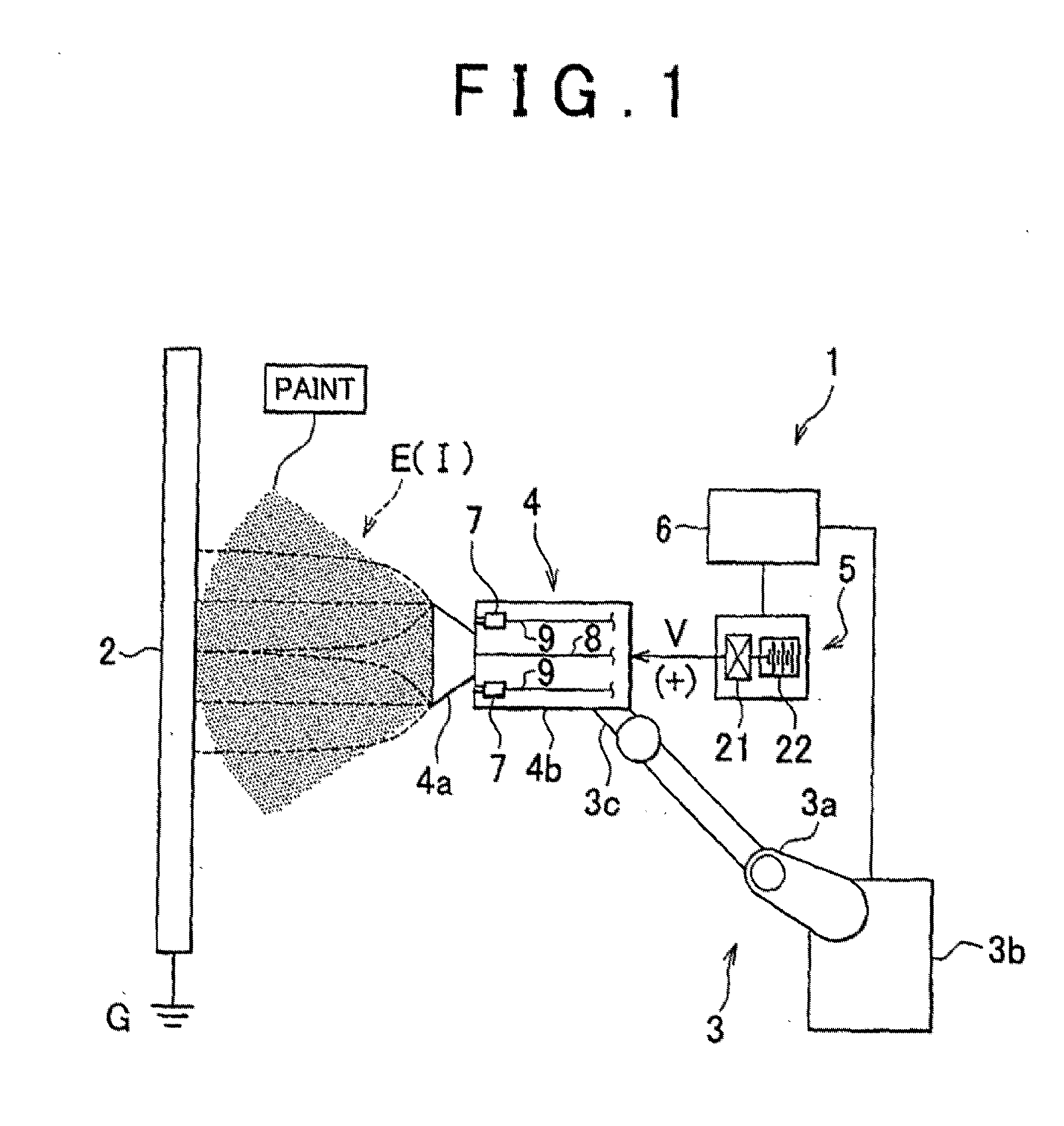

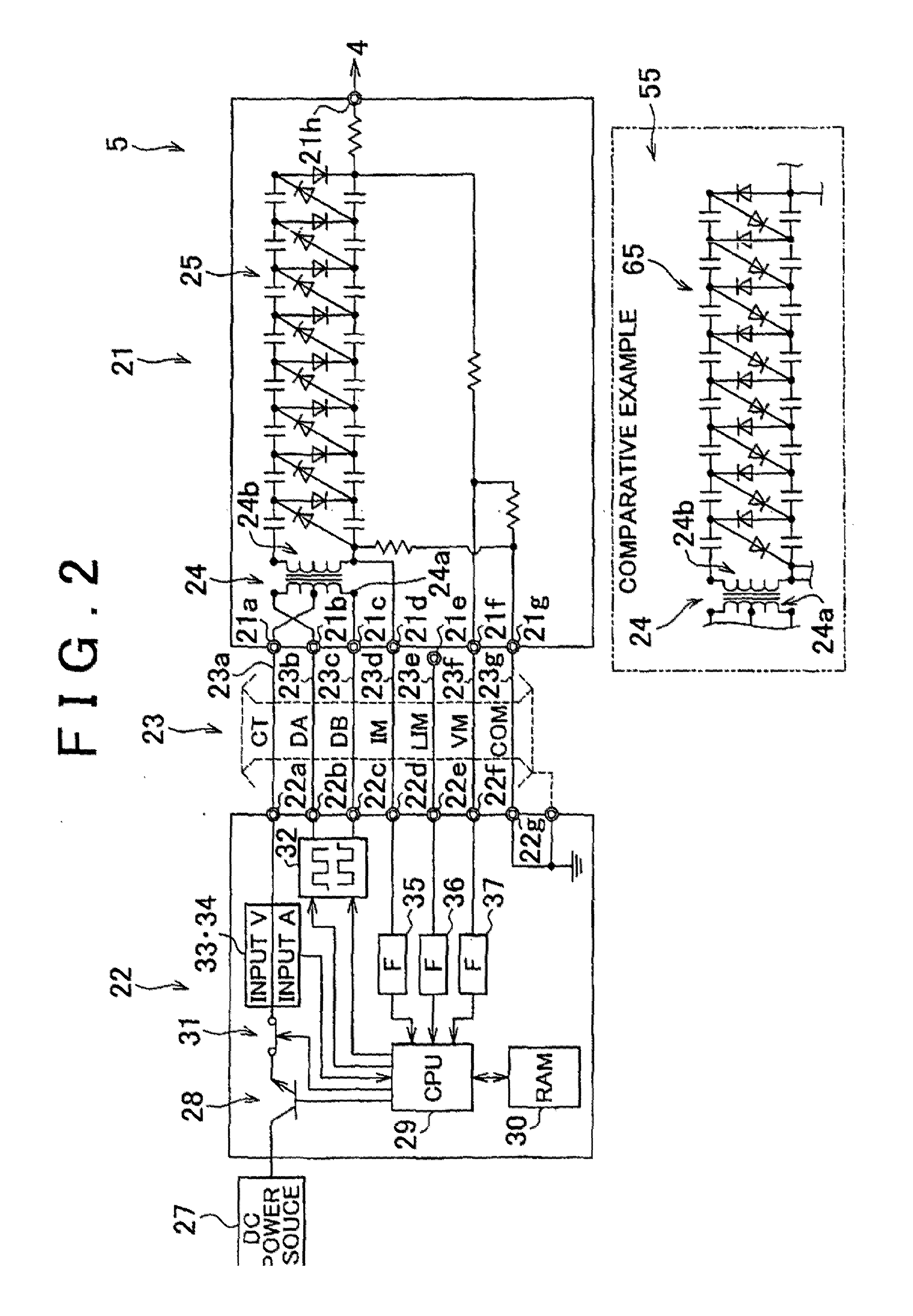

Electrostatic painting apparatus and electrostatic method

InactiveUS20130084402A1Improving paint adhesion efficiencyHigh strengthBurnersLiquid surface applicatorsHigh pressureControl theory

An electrostatic painting apparatus (1) includes: a paint gun (4) that has a bell cup (4a) serving as an atomization portion that atomizes a paint, and an air nozzle (7) serving as an air discharge portion that discharges shaping air for controlling a diffusion pattern of the atomized paint; a high-voltage generator (5) that applies a high voltage to the paint gun (4); and a controller (6) that controls the high voltage to be applied from the high-voltage generator (5), wherein the high-voltage generator (5) generates a high positive voltage.

Owner:TOYOTA JIDOSHA KK

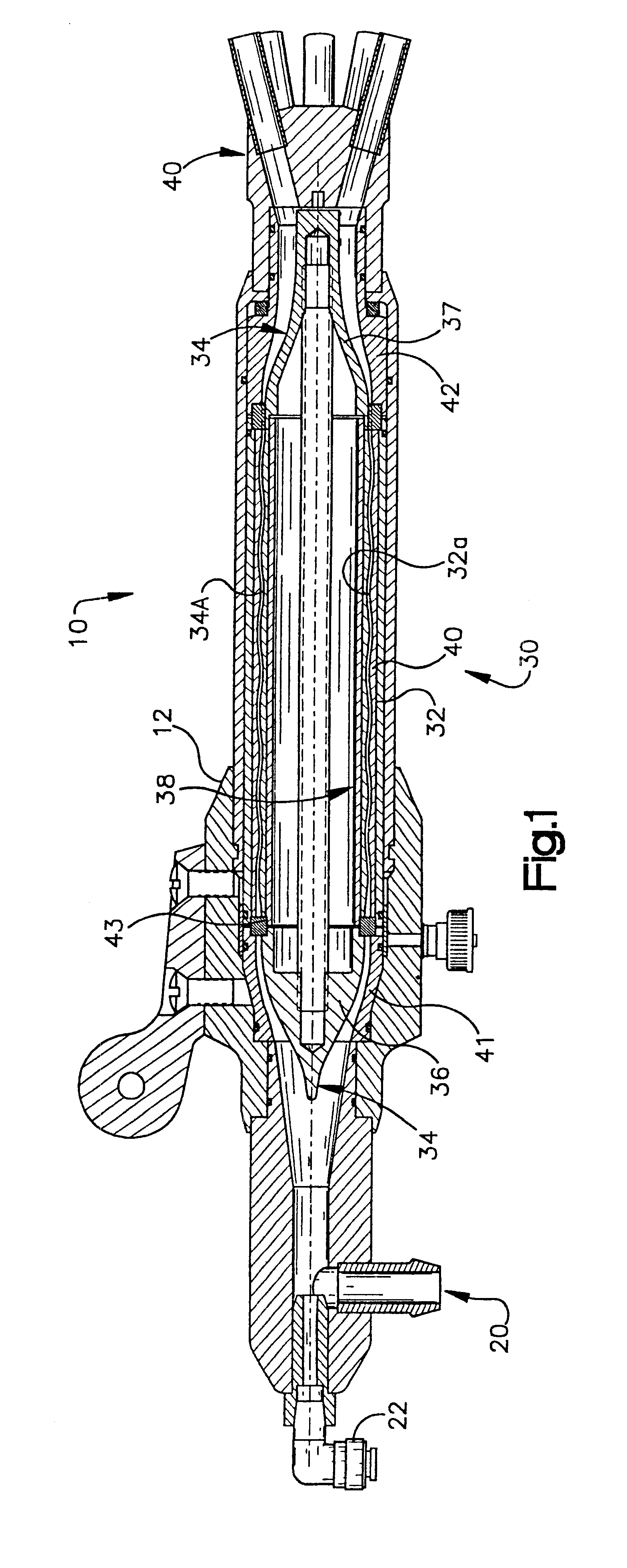

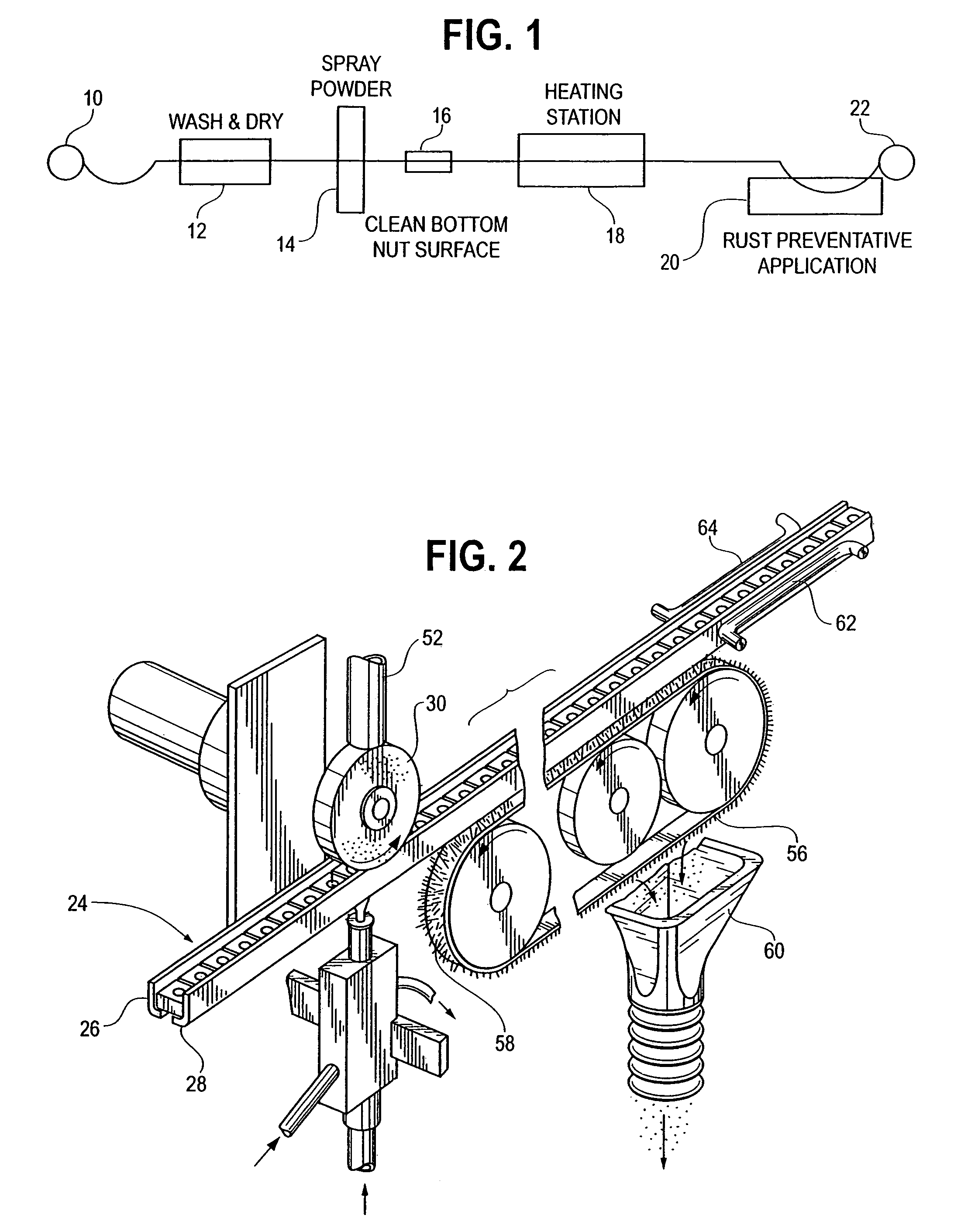

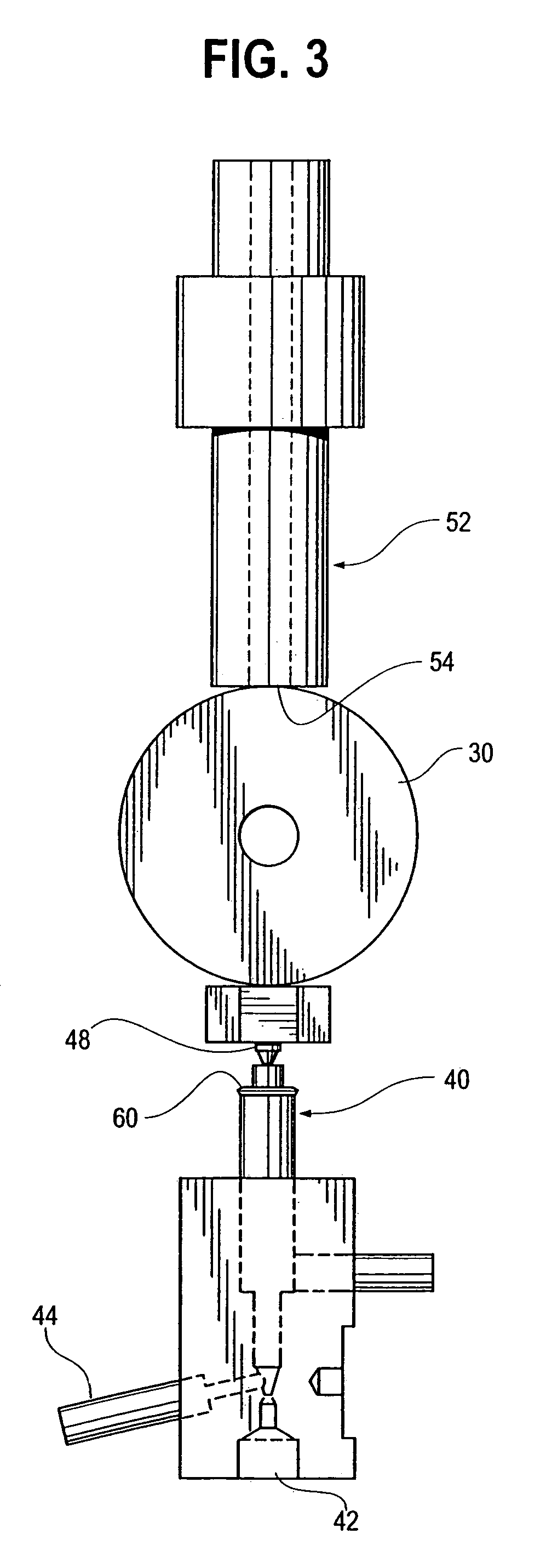

Apparatus for the application of fluoropolymer coating to internally threaded fasteners

An apparatus for the application of a fluoropolymer coating to the threads of an internally threaded fastener. The fastener has a body and a threaded bore extending to opposing ends of the body to define opposing first and second openings in the fastener. A conveyor moves the fastener along a path of travel with its threaded bore in a predetermined orientation. An obstruction member closes, the first opening, while a nozzle directs an air stream carrying entrained fluoropolymer powder through the second opening and into the threaded bore. The nozzle is stationary and is located at an axially displaced position relative to the second opening of the fastener and immediately adjacent the conveyor. A heating station heats the fluoropolymer powder to its melting temperature causing it to melt and fuse into a generally continuous film covering the fastener's threads.

Owner:NYLOK

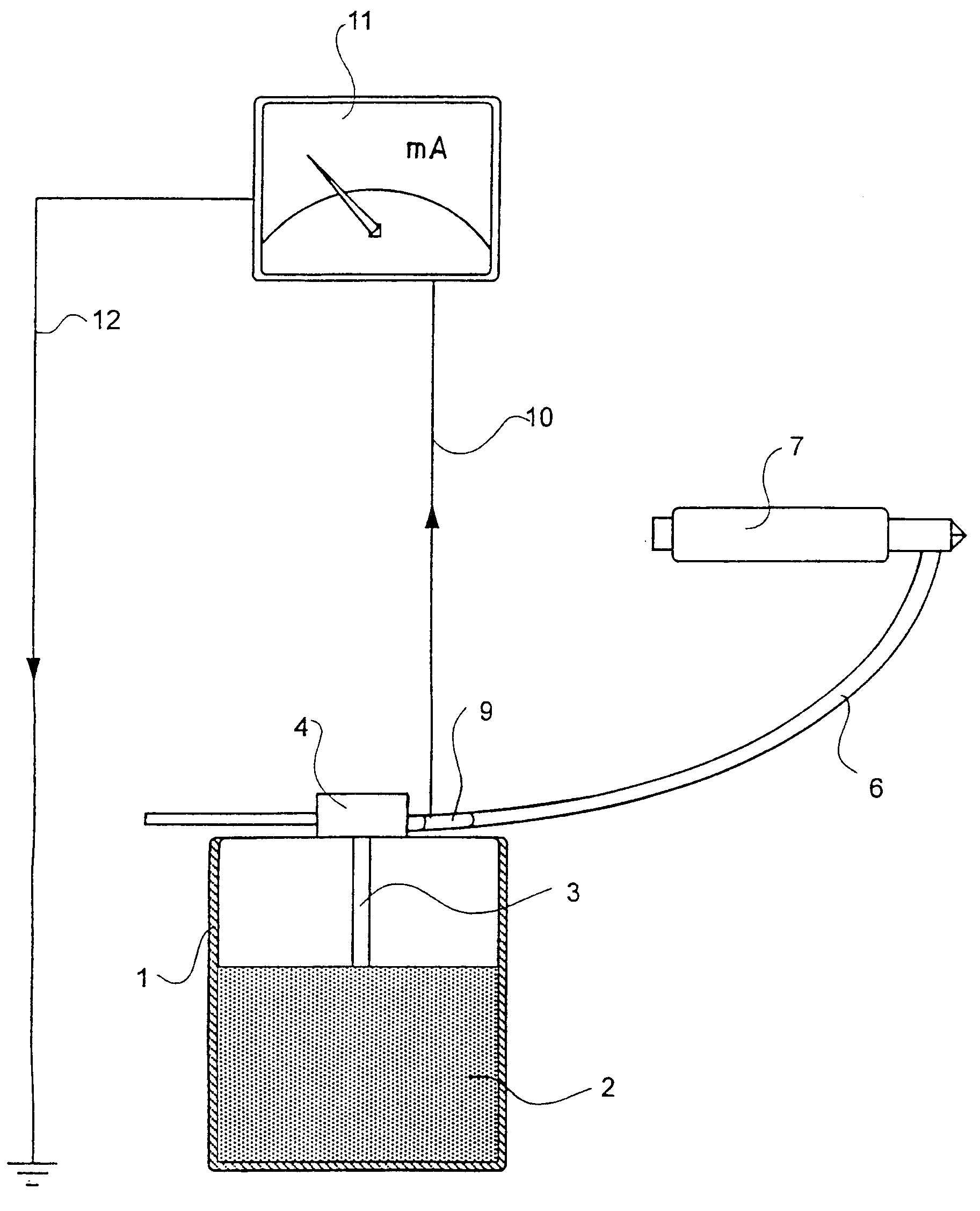

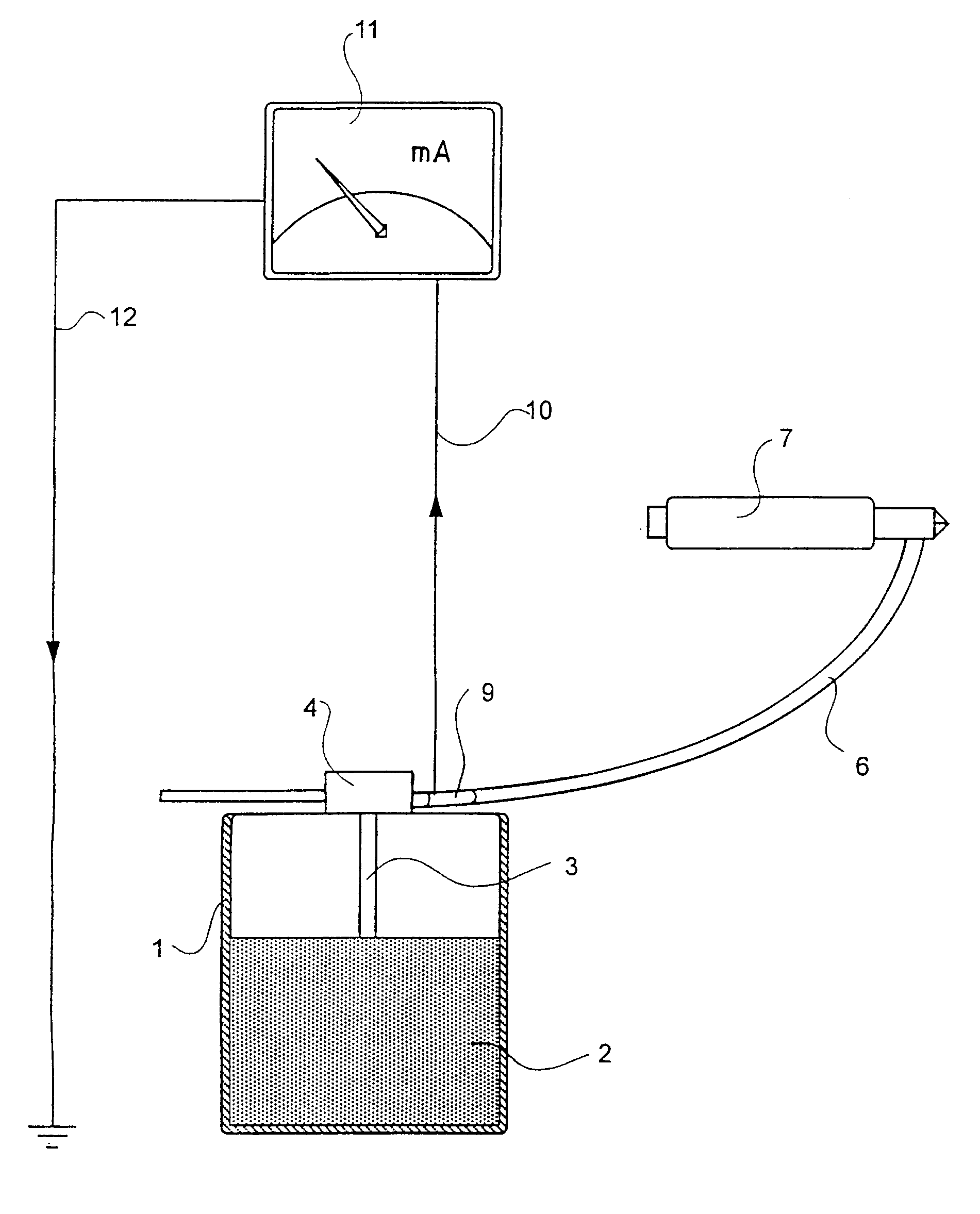

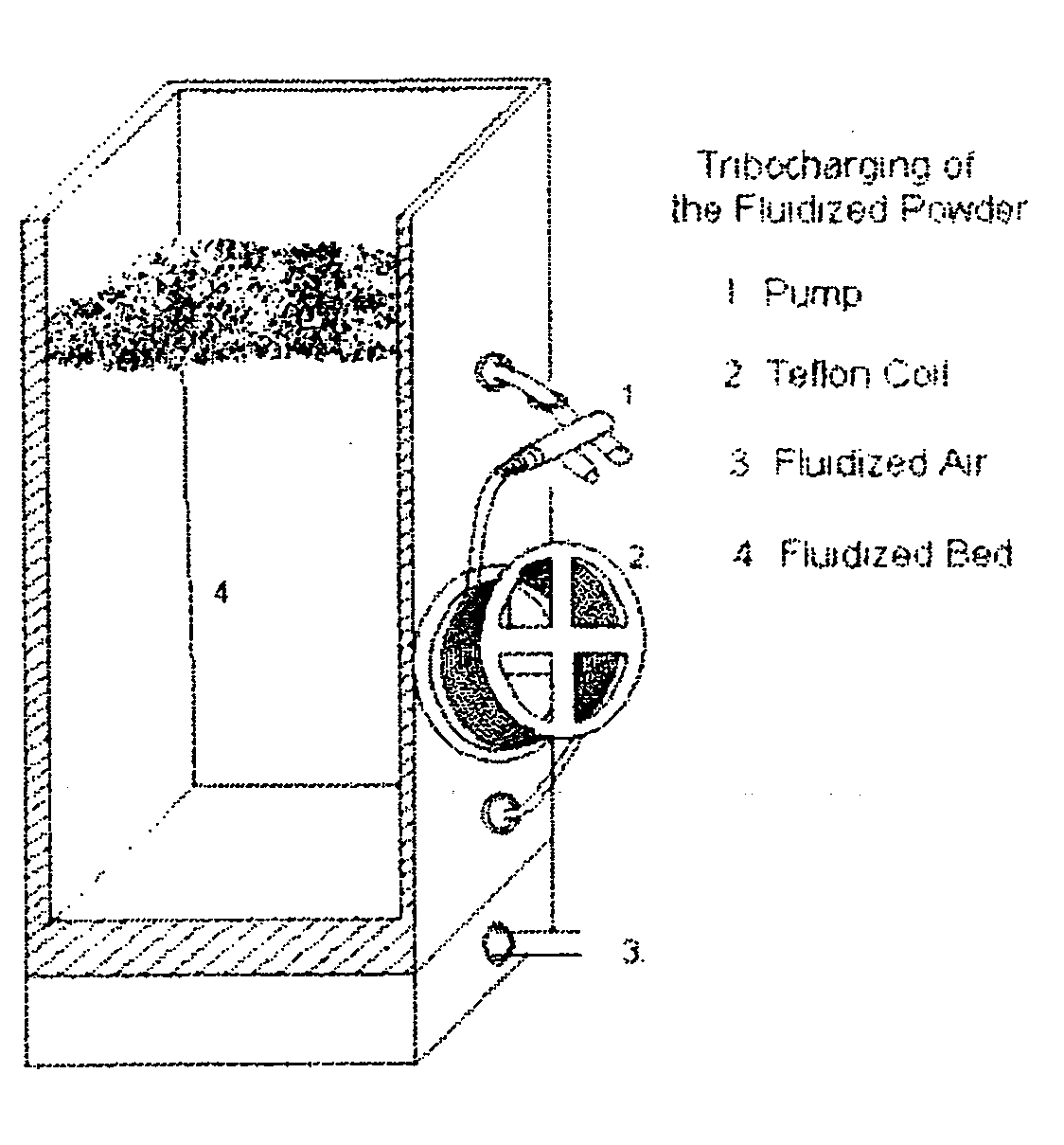

Method for coating an object with a film and equipment therefor

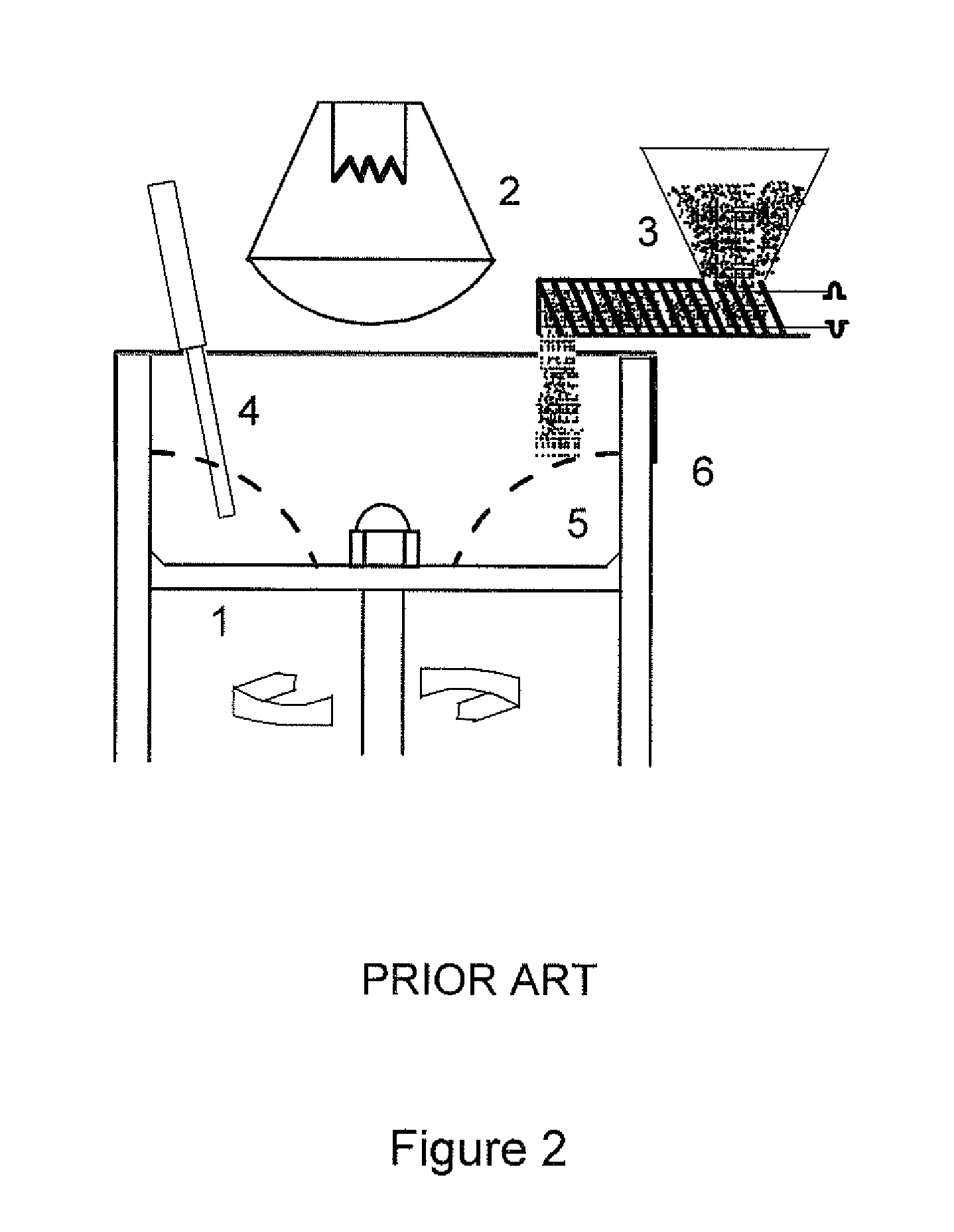

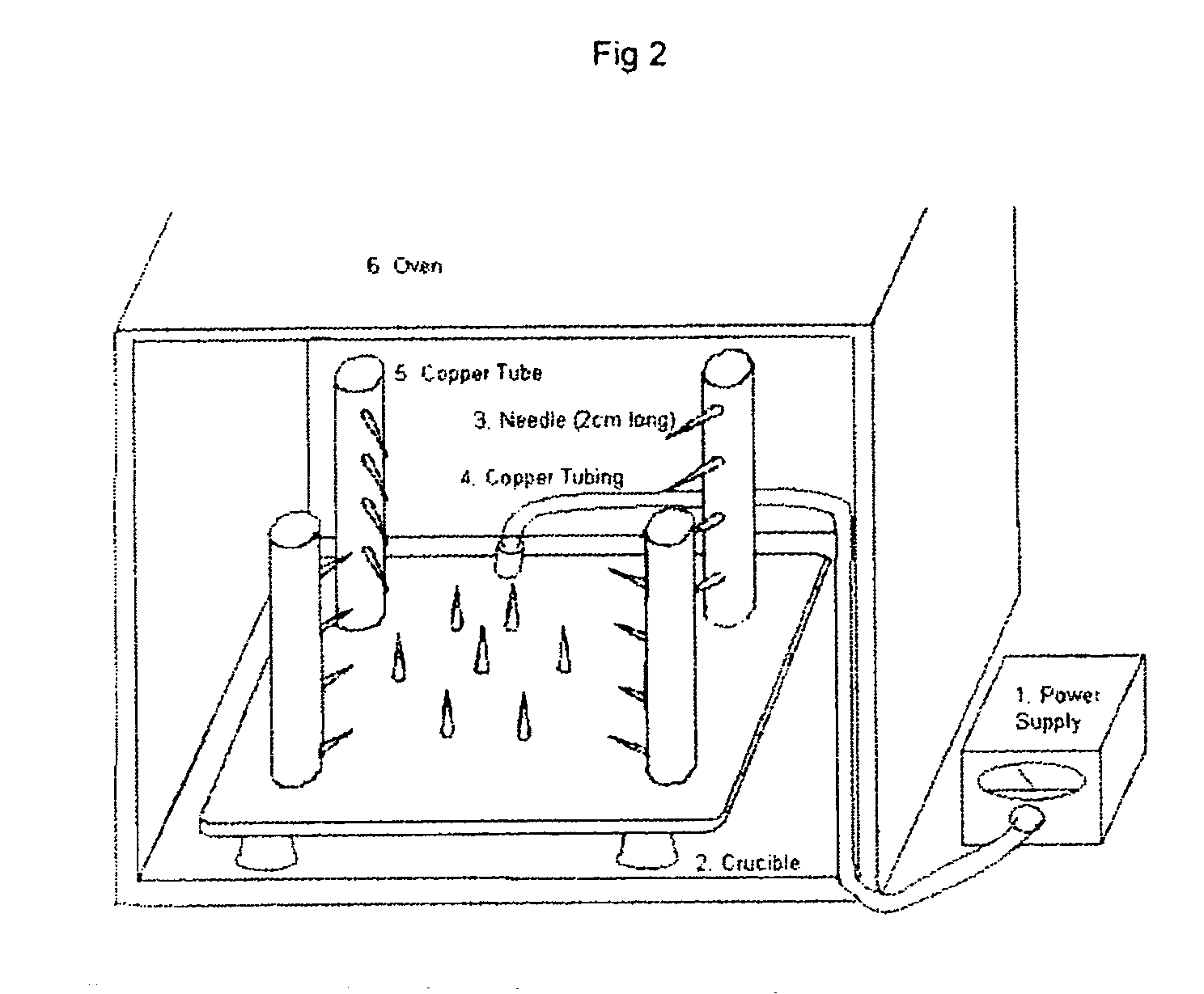

The present invention is a method for covering an object with a film resulting from the melting of a thin layer of powder, in which method comprises: (a) having a bed of electrified fluidized powder in a tank, this powder being charged by a forced-circulation tribocharging device; (b) dipping the object, connected to zero or sufficient potential, into the tank in order to cover it with powder; (c) placing the object, covered with the powder, in an oven at a temperature high enough to obtain the coating film by melting the powder. According to one advantageous embodiment of the invention, the oven includes electrodes raised to a high electrical potential so as to cause a corona effect which compensates for the relaxation of the charge on the powder particles while they are being heated. The charge on the particles is maintained and therefore they remain on the object and thus can form the film by melting. The present invention also relates to the apparatus for implementing the method.

Owner:ARKEMA FRANCE SA

Unipolarity powder coating systems including improved tribocharging and corona guns

A plurality of unconventional negative tribo-charging materials are described for use as the powder contact surfaces in tribocharging and corona powder spray guns, gun components, and powder delivery system components. The invention also provides a short barrel tribo-charging powder spray gun having an interchangeable powder contact insert and nozzle, with turbulence inducing air jets. The invention further provides novel tribocharging and corona gun designs. Improved powder coating systems are made possible wherein, for example, negative tribo guns can be utilized with negative corona guns to coat different parts of the same workpiece in a powder coating system.

Owner:REHMAN WILLIAM R +2

Steel plate spraying machine capable of utilizing static electricity and achieving automatic spraying

InactiveCN112238009ASpray until effectiveReduce wasteMovable spraying apparatusTribo-charging sprayingElectric machineEngineering

The invention discloses a steel plate spraying machine capable of utilizing static electricity and achieving automatic spraying. The machine comprises a spraying machine body, wherein a belt cavity isformed in the spraying machine body, a linkage device is arranged in the belt cavity, a power motor is fixedly arranged in the left wall of the belt cavity, and power of the linkage device comes fromthe power motor. A friction cavity is formed in the left side of the belt cavity, the left end face of the power motor is in power connection with a lead screw, the left end face of the lead screw penetrates through the belt cavity and extends into the friction cavity, and a transversely-moving sliding block capable of sliding left and right is arranged in the friction cavity. The manner that furrubs with a rubber rod, and then the rubber rod carries negative electricity is utilized, firstly, electrons carried by the rubber rod are transmitted to paint, then the paint carrying the electronsis sprayed to a grounded steel plate through a spray head, due to the fact that the steel plate is grounded, the electric potential energy of the steel plate is zero, then the paint can be effectivelysprayed to the surface of the steel plate, waste is reduced, meanwhile, the spray head can swing, and the spraying effect is improved.

Owner:温州根旭电子科技有限公司

Article comprising a diffuser with flow control features

InactiveCN1423581AReduce excess spaceShorten the timePowder deliveryLiquid spraying plantsMomentumEngineering

A diffuser comprises a conduit having a cross-sectional area that increases in a direction fluid flow. In one embodiment, the diffuser is used to reduce the incidence and severity of flow fluctuations that occur in an electrostatic deposition apparatus. In some embodiments, the diffuser includes one or more flow control features. A first flow-control feature comprises one or more appropriately-shaped annular slits through which fluid having a greater momentum than a primary fluid moving through the diffuser is injected into the "boundary layer" near the wall of the diffuser. A second flow control feature comprises one or more annular slits or, alternatively, slots or holes that are disposed at appropriate locations around the circumference of the diffuser through which a portion of fluid flowing in the boundary layer is removed. Boundary-layer flow removal is effected, in one embodiment, by creating a pressure differential across such annular slit or slots. Among other benefits, such flow control features reduce any tendencies for flow separation of the primary fluid in the diffuser.

Owner:DELSYS PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com