Catalytic regenerative combustion device

A regenerative combustion and catalytic technology, applied in the direction of combustion using catalytic materials, combustion methods, combustion types, etc., can solve problems such as increased operating costs, increased pressure loss, increased power consumption of blowers, etc., to achieve easy maintenance and operation , the effect of low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

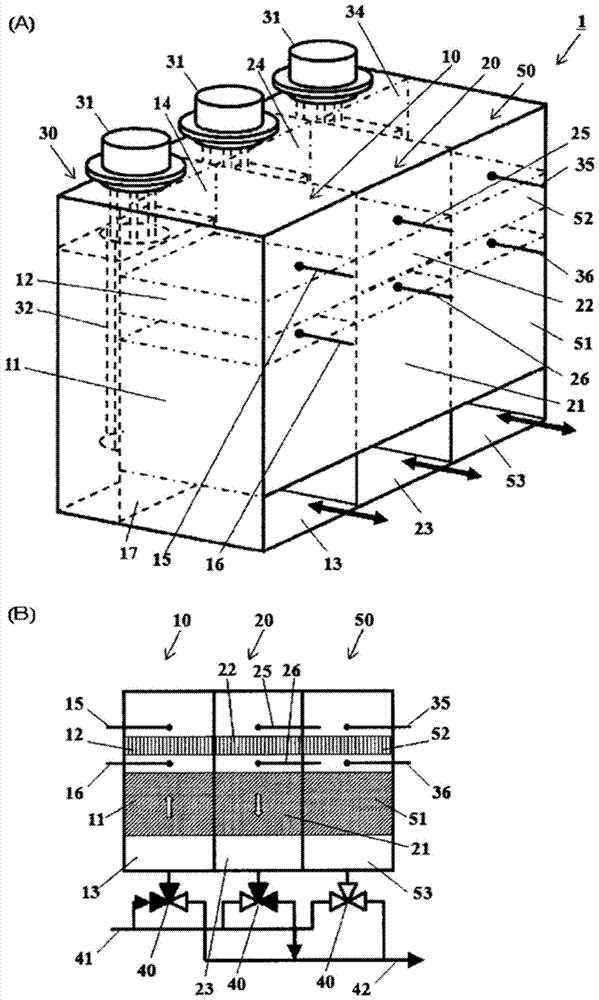

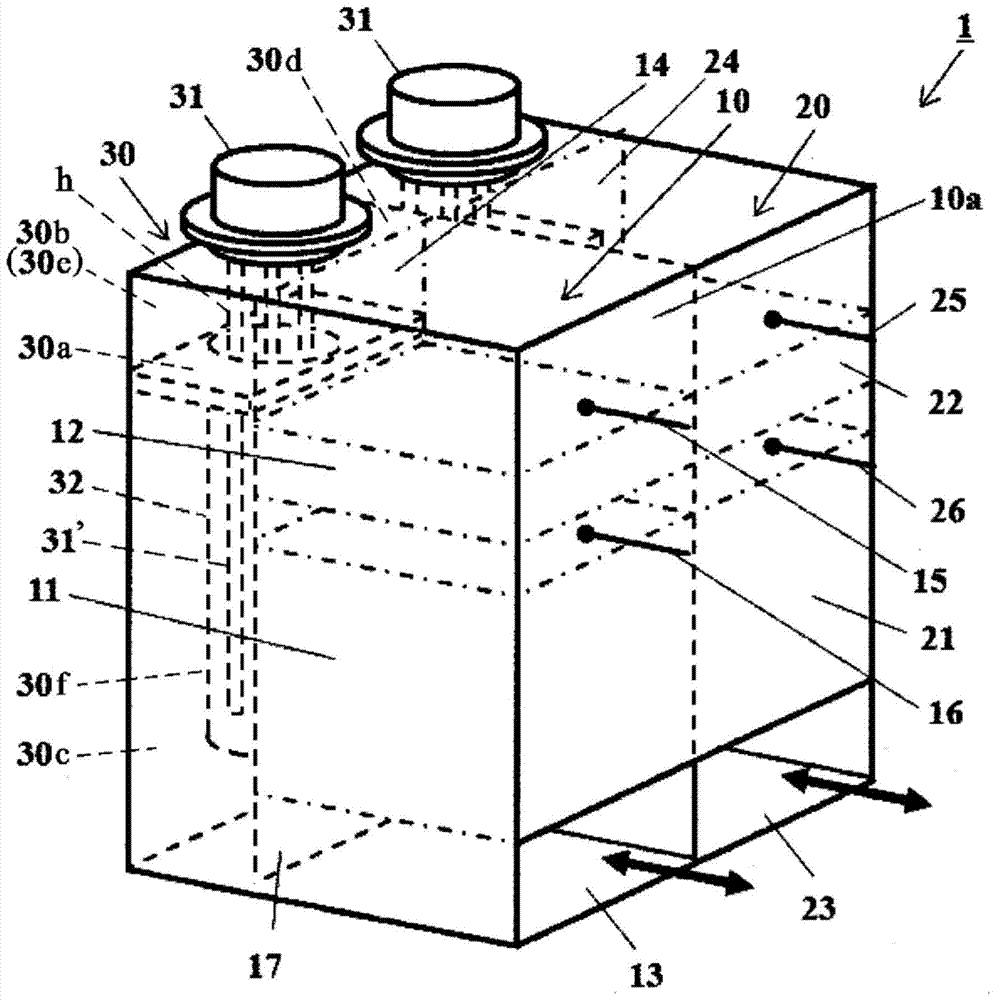

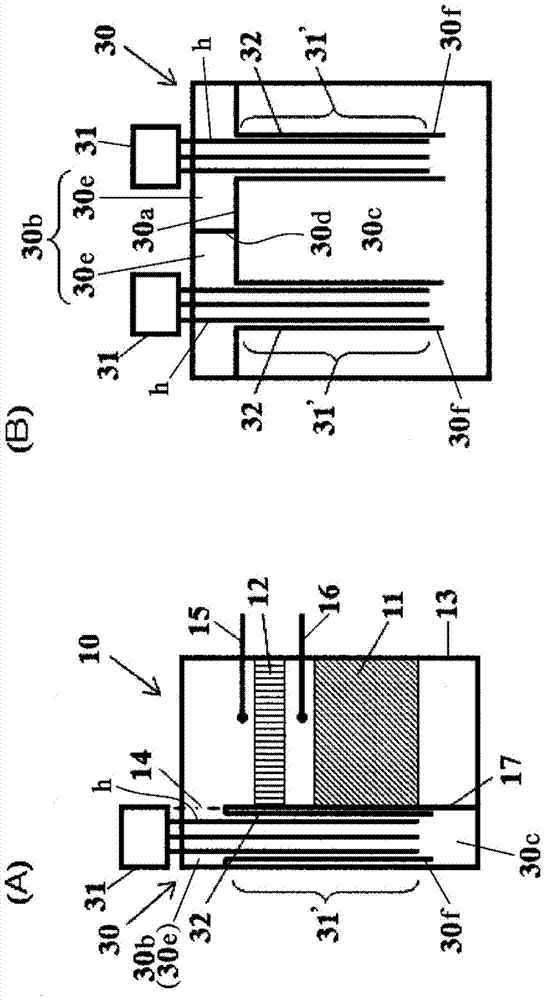

[0052] Hereinafter, a catalytic type regenerative combustion device 1 according to a preferred embodiment of the present invention will be described with reference to the drawings.

[0053] The catalytic thermal storage combustion device 1 is a so-called catalytic thermal storage combustion device for purifying the exhaust gas by burning combustible harmful components in the exhaust gas. In this specification, exhaust gas refers to gas containing combustible and harmful components such as harmful components and volatile organic compounds discharged from various production facilities and processing facilities. In addition, the flammable harmful components contained in the exhaust gas are flammable harmful components such as toluene and ethyl acetate, volatile organic compounds, and the like.

[0054] figure 1 It is a schematic perspective view of the catalytic type regenerative combustion apparatus 1 which concerns on the preferable embodiment of this invention. figure 2 It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com