Easy-to-read scales

A technology of reading and weighing scales, applied in the field of easy-to-read weighing scales, which can solve the problems of exhaustion and labor of operators, and achieve the effect of convenient operation and convenient observation of readings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, this design is illustrated.

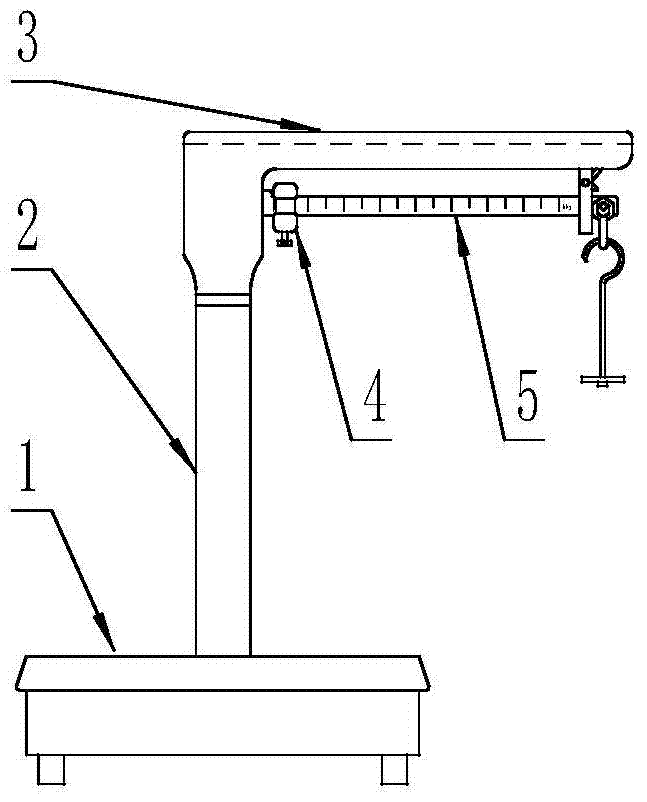

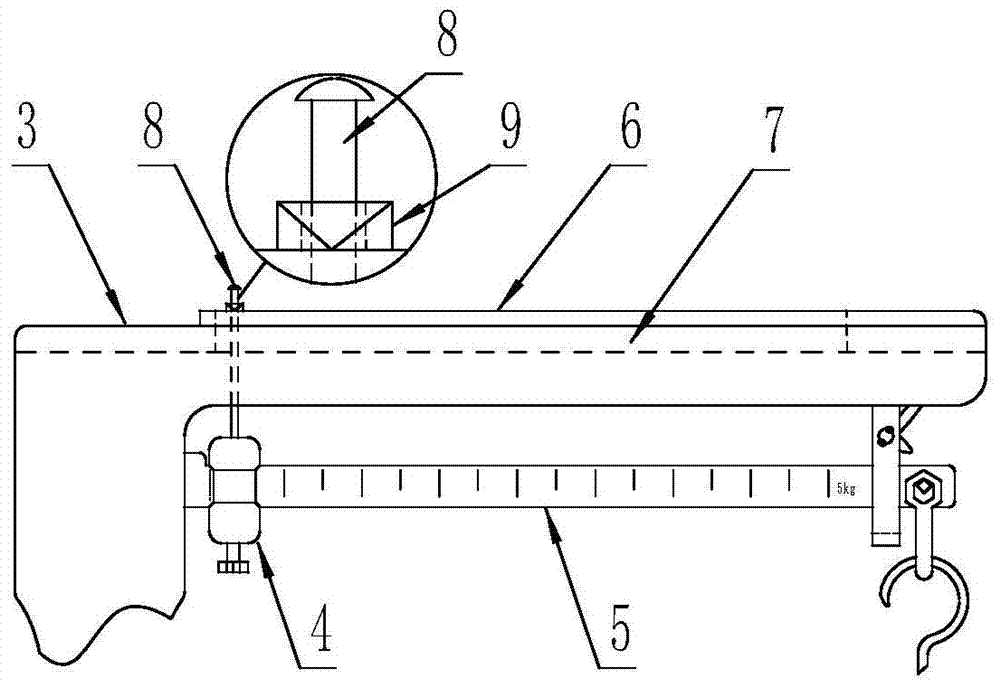

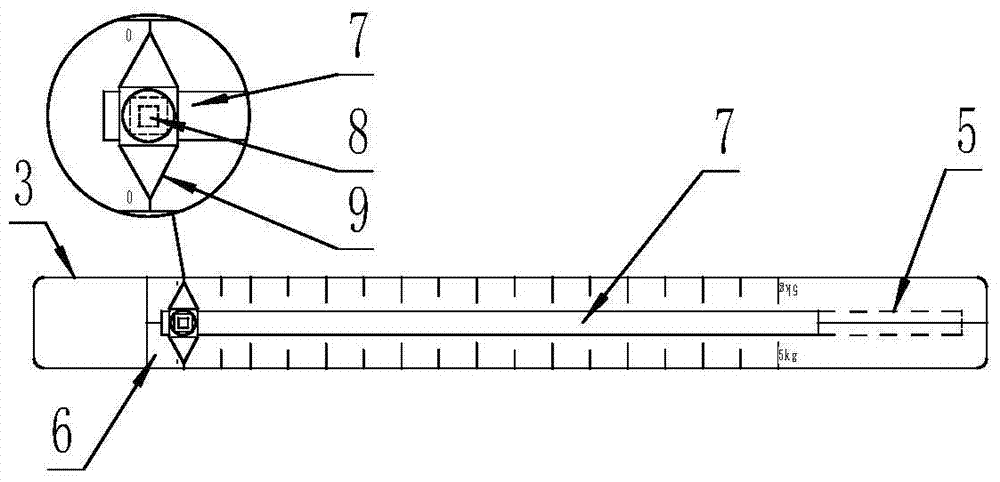

[0011] Such as figure 1 As shown, a common scale that uses the principle of lever balance to work is mainly composed of a chassis 1, a column 2, a panel 3, a beam 5, and a slider 4. A narrow strip is processed on the panel 3 facing the beam 5. Shaped notch 7, the width of notch 7 is the same as the front and back thickness of scale beam 5, and the length of notch is then slightly longer than the length that the numerical value part of the scale mark on the scale beam occupies length, and be positioned at the front and back position of notch on panel 3 toward Each device of the forward and backward directions is printed with the mark plate 6 that is identical with the scale identification value on the scale beam 5, such as figure 2 , image 3 As shown; a cross-section is fixed vertically upwards on the central part of the top surface of the slide weight 4 and is a square mark post 8, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com