A deep hole inner diameter measuring device

A measuring device and technology of inner diameter, applied in the direction of mechanical diameter measurement, etc., can solve the problems of low efficiency and small measurement range, and achieve the effect of accurate measurement, guaranteeing accuracy and avoiding intermediate transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

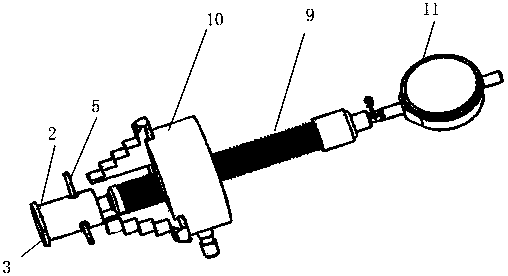

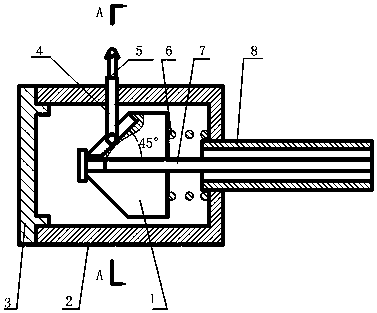

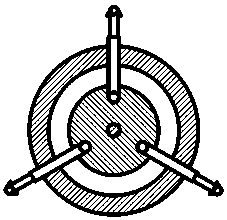

[0026] Such as Figure 1-3 As shown, a device for measuring the inner diameter of a deep hole includes a tapered block 1, a sleeve 2, three measuring rods, a spring 6, a push rod 7, a sleeve rod 8, a threaded sleeve rod 9, a three-jaw chuck 10 and an inner diameter hundred Sub-table 11. The tapered block 1 is located in the sleeve 2, and the ejector rod 7 is located on the axis of the tapered block 1. One end of the ejector rod 7 is fixedly connected with the tapered block 1, and the other end is connected with the inner diameter dial indicator 11; the sleeve rod 8 Sleeved on the push rod 7, one end of the sleeve rod 8 is threadedly connected with the end of the sleeve 2, and the other end of the sleeve rod 8 is connected with the push rod 7 through a sliding bearing; the spring 6 is arranged in the sleeve 2, and Set on the ejector rod 7, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com