Device for cleaning and recycling loose sand in the working box of 3d printing equipment

A 3D printing and working box technology, applied in the field of 3D printing, can solve problems such as low cleaning efficiency and easily damaged sand cores, and achieve the effects of simplifying operations, prolonging service life, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

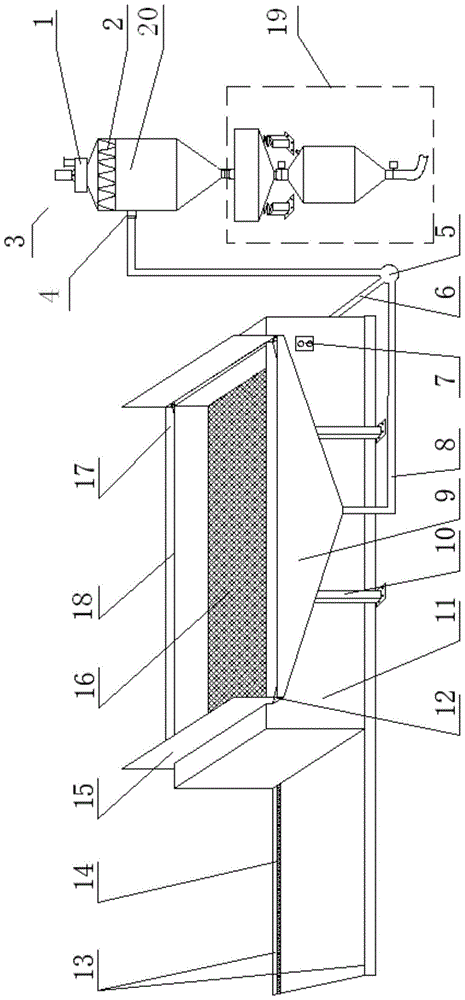

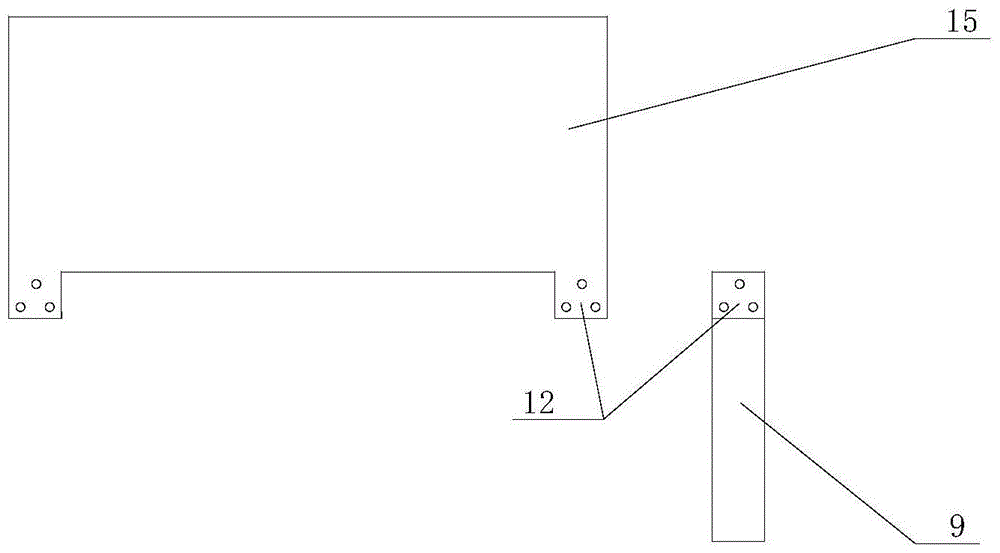

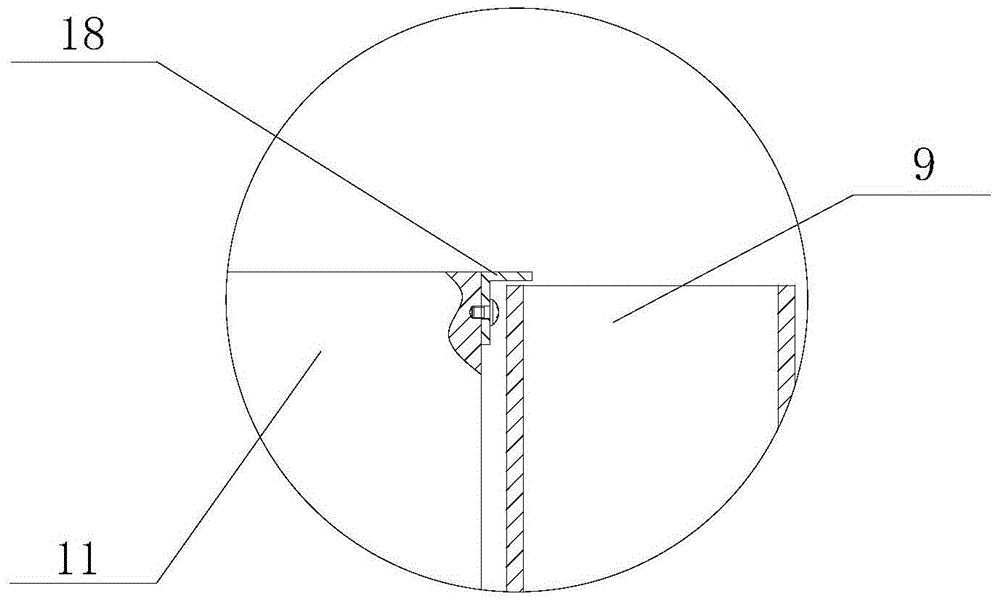

[0026] The device for cleaning and recovering loose sand in the working box of the 3D printing equipment of the present invention will now be described with reference to the accompanying drawings. figure 1 A schematic diagram of an embodiment of a device for cleaning and reclaiming loose sand in the working box of the 3D printing equipment, figure 2 A schematic diagram showing an embodiment of the connection between the sand retaining plate and the sand collection and suction bucket, image 3 It is a partially enlarged schematic diagram of the working position of an embodiment of the sand collecting and suction bucket.

[0027] Specifically, such as figure 1 As shown, the device for cleaning and reclaiming loose sand in the working box of the 3D printing equipment includes at least one sand collection and suction bucket 9 and a negative pressure sand suction device 3, wherein the negative pressure sand suction device 3 is configured to cooperate with the sand collection and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com