An impact type constant pressure coffee tamper

A constant-pressure, impact-type technology, applied in kitchen utensils, household utensils, beverage preparation devices, etc., can solve the problems of easy brewing of coffee, unguaranteed operation force of pressing powder, laborious operation, etc., and achieve the effect of rigid transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

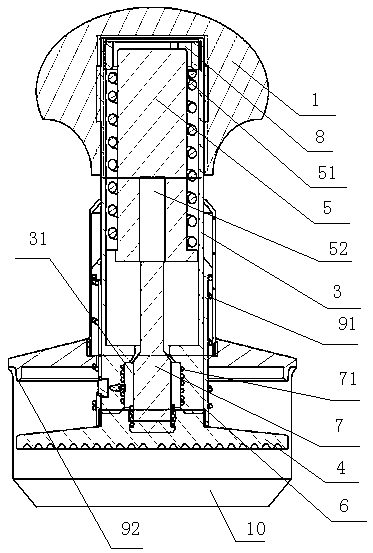

[0020] The specific composition, structure and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred solutions.

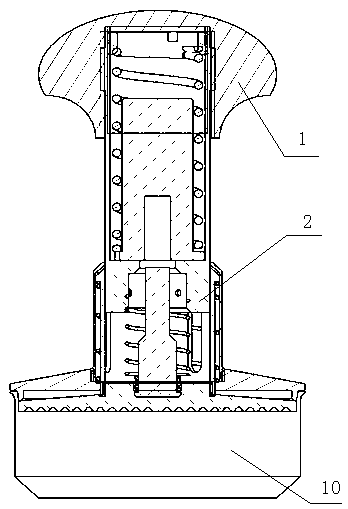

[0021] combined with Figure 1-3 As shown, to illustrate the structural composition of the present invention, the specific description is the structural composition of an impact-type constant pressure coffee powder tamper, which includes a handle 1 and an impact constant force mechanism 2, and the impact constant force mechanism 2 It includes a pressure cylinder 3, a pressure block 4, a slider 5, a sliding sleeve 6 and a thimble 7, the slider 5 is provided with a slider spring 51, and the thimble 7 is provided with a thimble spring 71; the pressure cylinder 3 One end is connected with the handle 1, and the other end of the pressure cylinder 3 is connected with the sliding sleeve 6; the sliding sleeve 6 is connected with the pressure block 4; the slider 5 is arranged in the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com