header connector

A technology of joint connectors and connecting parts, which is applied in the direction of connection, parts of connecting devices, coupling devices, etc., can solve the problems of increasing the size, cost and weight of joint connectors, and increasing assembly process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Exemplary embodiments of the present disclosure will be described in detail with reference to the accompanying drawings.

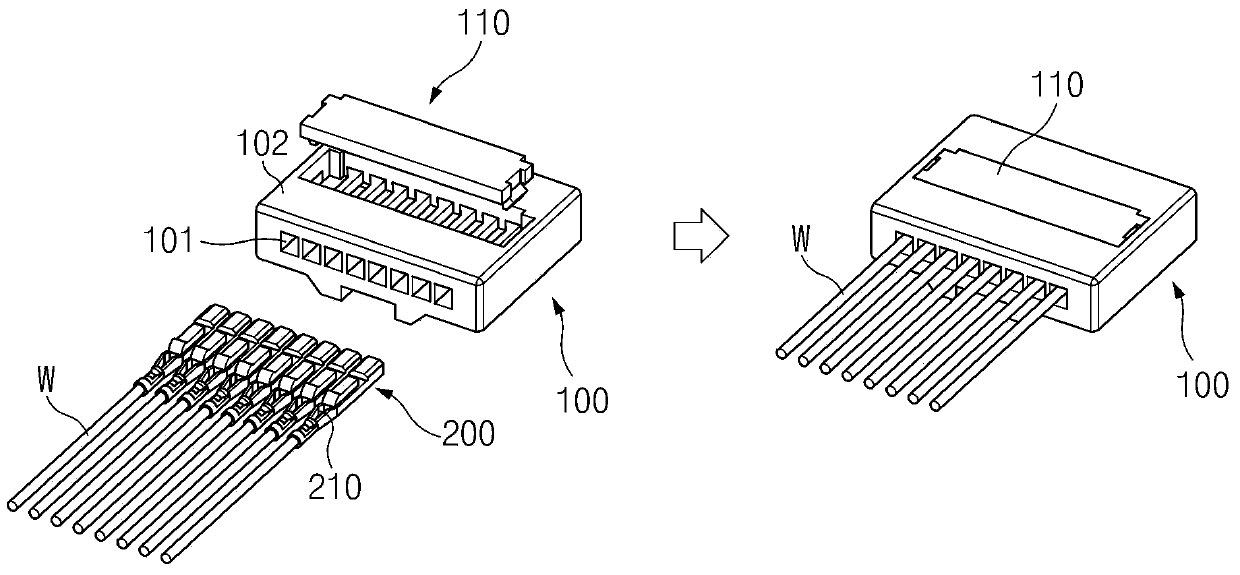

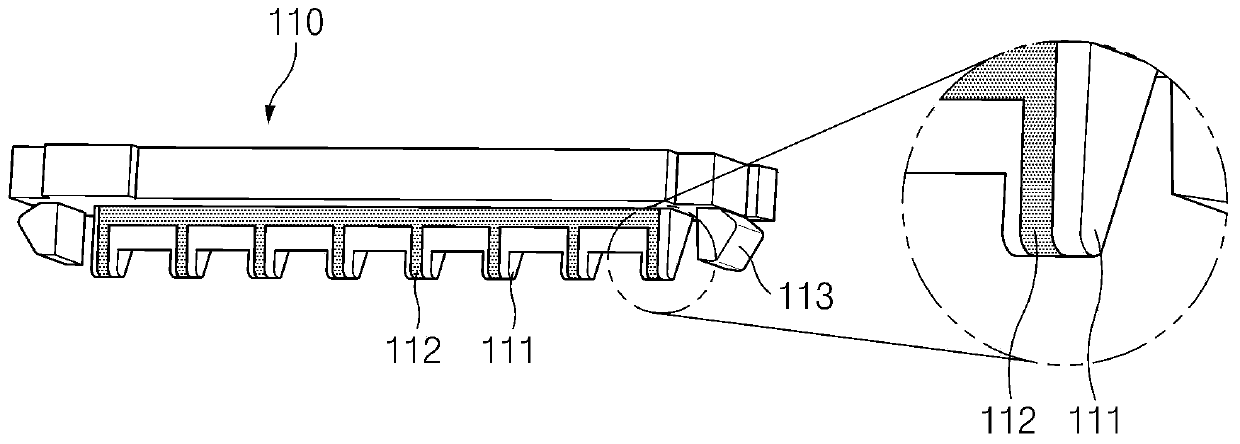

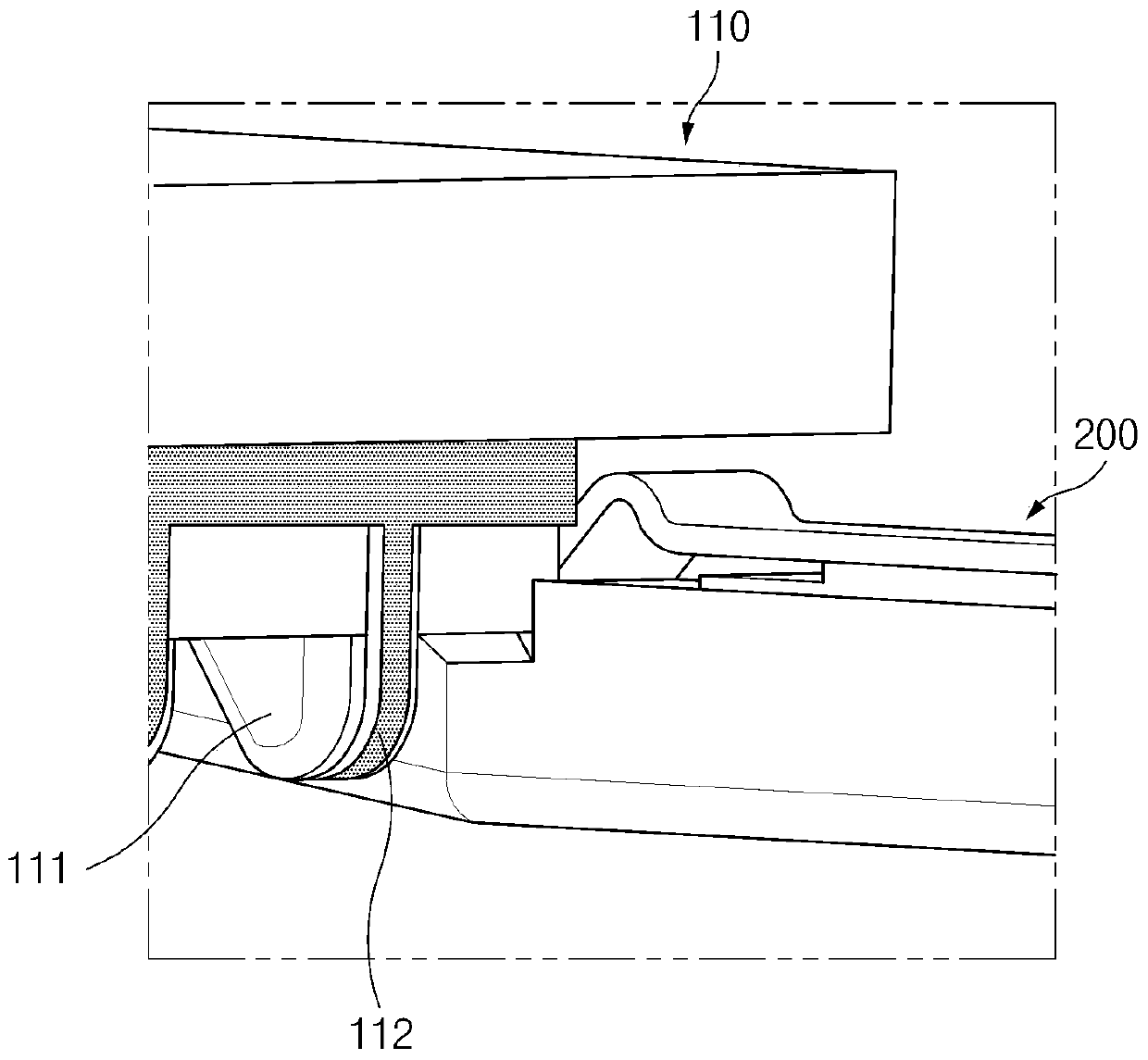

[0032] like Figure 1 to Figure 4 As shown, the joint connector according to the present disclosure may include: a housing 100 in which a mounting channel 101 and a fastening hole 102 are formed; a terminal 200 inserted into the mounting channel 101 of the housing 100 and connected to a lead wire W; and holding The member 110 is inserted into the fastening hole 102 of the housing 100 and fastens the terminal 200 to the housing 100 .

[0033] like figure 1 As shown, the housing 100 may be formed in a general connector shell shape, wherein a plurality of installation passages 101 into which the lead wires W may be horizontally inserted from the outside to the inside are formed in one surface of the housing 100 and communicate with the installation passages 101 Fastening holes 102 may be formed in the upper surface of the case 100 .

[0034] The ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com