Aluminum-plastic hook buckle type composite door/window profile

A door and window profile, aluminum-plastic composite technology, applied to windows/doors, wing frames, building components, etc., can solve problems such as bad smell, corrosion of steel lining, poor air tightness, etc., to improve the effect of heat insulation and sound insulation, The effect of improving composite strength, strengthening strength and reliable usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

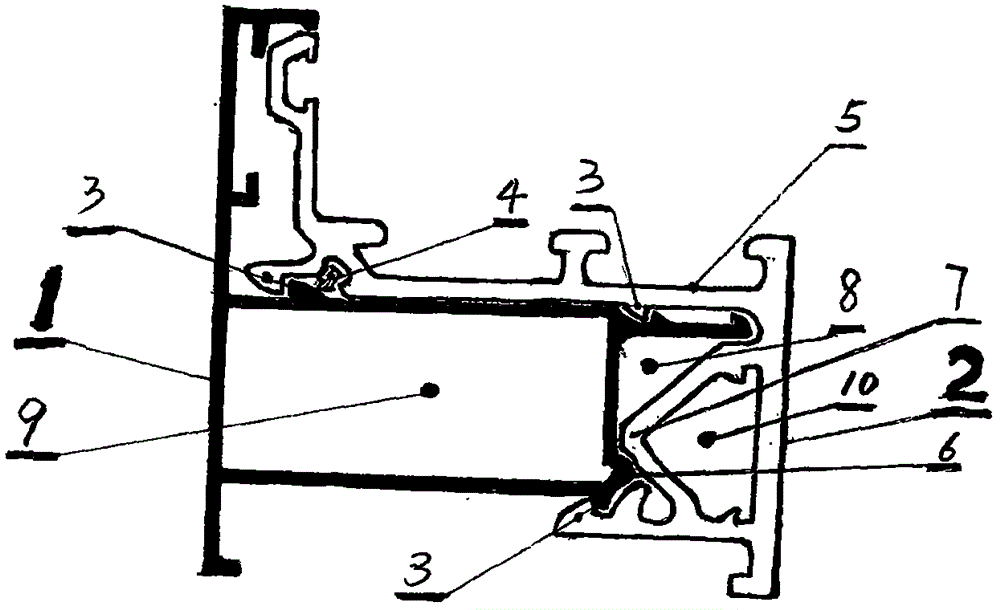

[0017] As shown in the figure, in the embodiment of the present invention, the outdoor aluminum alloy 1 occupies the main body and the chamber area is relatively large, which fully embodies the characteristics of aluminum alloy as the main body, and intuitively shows the firmness and reliability. The indoor attachment plastic material 2 occupies a small proportion in the figure and is wrapped and attached to the aluminum alloy surface. 3 in the figure is the hook and buckle connection point, which is the key to the combination and the key to realizing environmental protection recycling. 4 in the figure is the encryption point of the soft rubber strip, which is the encryption point of the composite assembly of aluminum alloy and plastic material, and has the functions of waterproof, dustproof and anti-drag sliding. 5 in the figure refers to the screw reinforcement point, which strengthens the composite tightness between the aluminum alloy and the plastic material; and restrains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com