Omnibearing traveling type forepoling hydraulic support

A technology of hydraulic support and advanced support, which is applied in the direction of mine roof support, earth square drilling, mining equipment, etc., can solve problems such as roof damage, and achieve the effect of solving damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

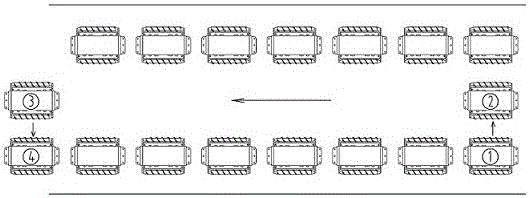

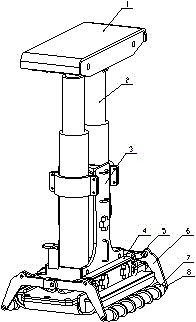

[0012] Such as figure 1 As shown in the figure, an all-round walking advance hydraulic support is mainly used for the advance support of the return air tunnel of the working face, including the hydraulic support top beam (1), column (2), stable support (3), base (4) , lifting jack (5), fixed frame (6), screw drum (7), power unit (8) and other components. The spiral drum (7) is arranged on both sides of the base (4). When the advanced hydraulic support needs to move, the column (2) shrinks, the top beam (1) leaves the roof of the roadway, the lifting jack (5) moves, and the fixing frame (6) Rotating downwards, the helical drum (7) touches the bottom plate.

[0013] A pair of right-handed helical rollers (7) rotate clockwise synchronously under the action of the power unit (8), and the leading bracket moves parallel to the left; the helical rollers (7) r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com